-

Posts

2,580 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by AON

-

Dowmer Thank you for the links. It seems simply enough although I am not familiar with the spray... worth Googling. Just had a review and they both look wonderful. However I just had a look at my flag and she seems much better now that she is thoroughly dried. I simply need to touch up two tiny spots. Held it up to the light and the flag is translucent (can see through it) except for the hoist edge which was the effect I was after. I will also need to add the grommet dots and drill holes through so it can be fixed to the staff. Then it needs to be shaped. Hope to post these later today. Druxey: As this is day four after my eye needle I am now allowed back in my workshop so I'll be getting back to my forward cant frames. Slow and steady....

-

So it started off looking like crap but finished not so awful. Got all my gear out. A Number 2 brush seemed narrow enough. Mixed the Cobalt Blue Hue with tiny touch of Naples Yellow Hue to mute the blue. Thinned out the Red Oxide with water alone and applied light coats. Possibly I should have added a touch of green to mute the red but I thought it looked okay.... and I didn't have any green! Used water thinned Unbleached Titanium White in between. All blue and red hues of paint was thinned with water and applied as a wash so as not to be opaque. The white was applied similarly, but less so on the hoist edge so this edge would be opaque. Both sides of the material were painted, allowing one colour to dry before switching to another. I had the red and blue colours bleed into the white area before the white was applied.. At first I found the mounting board was so thin that when the Silkspan got too wet it sagged and touched the paper below that was on my table top and started the bleeding... but then it happened when I set it on top of a plywood board I had used in the sail-making workshop. Possibly my hand wasn't steady enough... or I can blame it on my bad eye After applying the titanium white wash the blue and red bleeding seemed to disappear. I'll have another look in the morning and do some touch ups... wait a bit and then decide if I'll call this the trial run and take another stab at it or decide that this is a keeper.

-

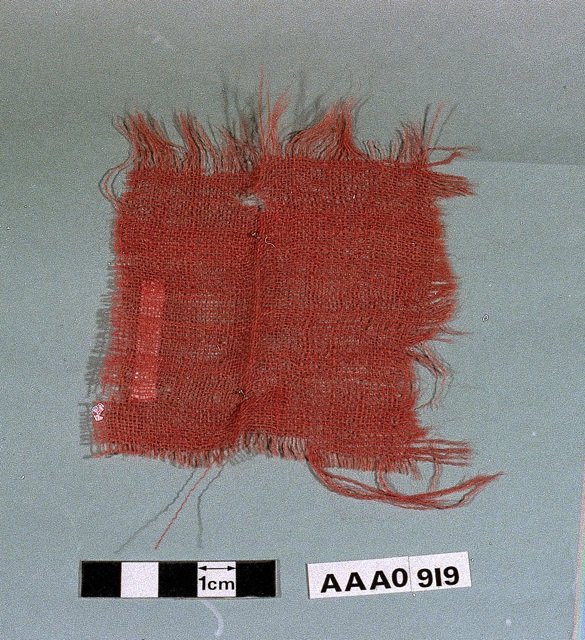

The following post is with permission from Admiralty Models, specifically David Antscherl. This technique was learnt at both the Admiralty Model Sail-making and the Flag Making Workshops I had attended years past. They are also presented in David's Books: The Fully Framed Model, Volume IV (referred to as TFFM) and in The Greenwich Hospital Barge. I must explain that although I had decided to go with the 1:2 ratio for the size of my flag, after printing it and the 2:3 ratio version, and having noted that the actual flag I found online at the NMM, RMG website was more square than rectangular, I've changed my mind and decided to go with the more box looking version. First you need a mounting board. My mounting board is made from stiff illustration board and has a rectangular hole cut out of it. The plug from the hole is saved and reinserted when tracing the image to the cloth. It is light and easily handled. Second you need brown gummed tape, the type used by artist. It looks like butchers tape to me. I purchased mine online through DeSerres of Longeuil, Quebec. They refer to it as "gummed brown paper". The tape is cut into four lengths to hold the Silkspan down to the mounting board. You dampen a sponge and wipe the gummed side lightly and it is ready to use. I cut my Silkspan oversized, larger than the mounting board hole. Silkspan is the cloth used by airplane modellers and looks like the material used for tea bags. I dampened it with water and let the excess drain away. Then I placed it on the mounting board over the hole while the cloth was still wet. Note that the plug was removed from the mounting board! I did my very best to lay it flat but had to ask for help with an extra set of hands to get the job done. The damp Silkspan was taped to the mounting board with the brown gummed tape. This was put aside and allowed to dry. As the cloth dried it stretched tight... no wrinkles. Once dry I re-installed the plug in the mounting board, then I traced the image of the flag onto the Silkspan using carbon paper, a sharp soft pencil and a short straight edge. I did not use too much pressure as the cloth, to me, is quite delicate (thin and open weave). The image was taped to the board with green painter's tape so it would not shift. With that job done now comes the fun part.... this involves mixing muted blue and red colours which will be applied (with a steady hand and fine brush) as a wash (thin

-

Funny enough, after reducing them 74% they scale 7-6" x 15'-0" I could easily re-scale in one direction (horizontally) to match The 2:3 ratio of TFFM versus the 1:2 ratio of The Anatomy of Nelson's Ships using MS Paint program. Found all my supplies from my Admiralty Models Sail-making Workshop (2014) and Flag workshop (2015), Plus the suppliment in TFFM Vol IV. Time to do some reading.

-

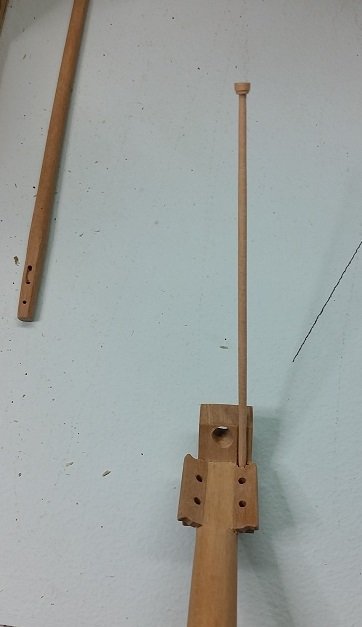

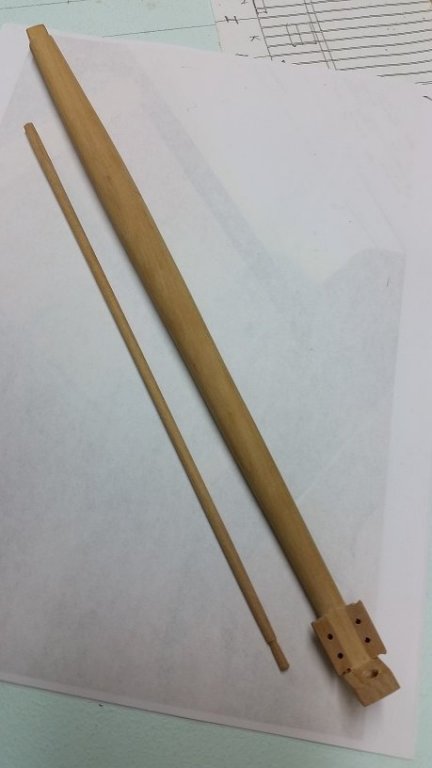

I took my second bowsprit (scrap) and turned it down as small as I dare. Then I used course sand paper wrapped partially around from behind so it also acted as a support and worked it lightly back and forth until that section was within dimension. Then I moved over to the next section and eventually finished off with finer sand paper. All this while I sang along to the tunes coming from the radio on the shelf just above.... it helped pass the time and it took a considerable amount of it. But my singing still needs considerable work. 😆😎

-

Thank you very much Lawrence for the kind words. There is a long story explaining my workshop and tools. One envolves a career mentor. It took as long as the telling of the story to aquire them both. I am presently recuperating from yesterdays needle in my eye. Pain killers and ice allow me to see your post. 8 am this morning was a whole other story. 8 pm last night was hell. As I cannot work in my shop for the next few days I think I might make my Union Jack tomorrow or Monday. Wish me luck painting.

-

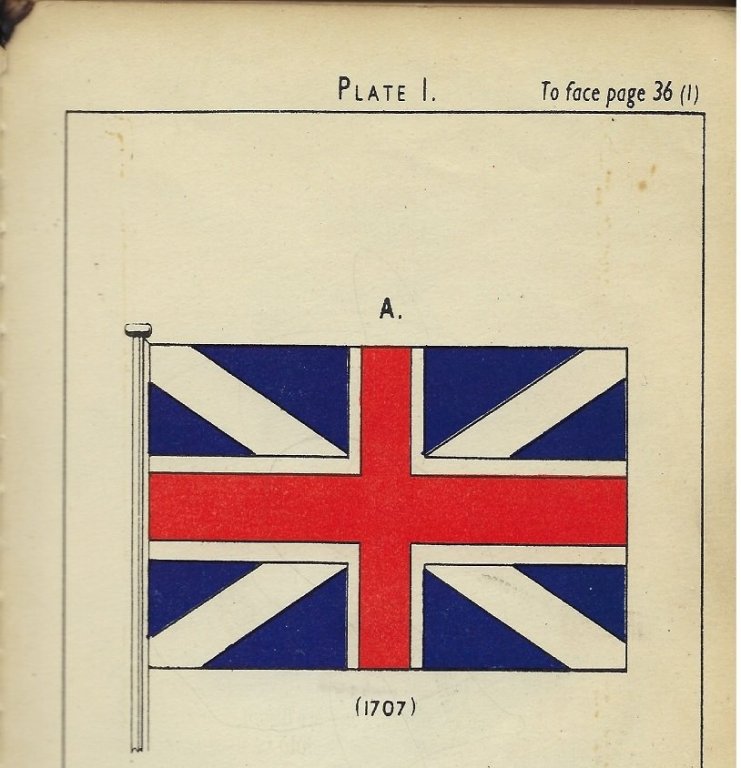

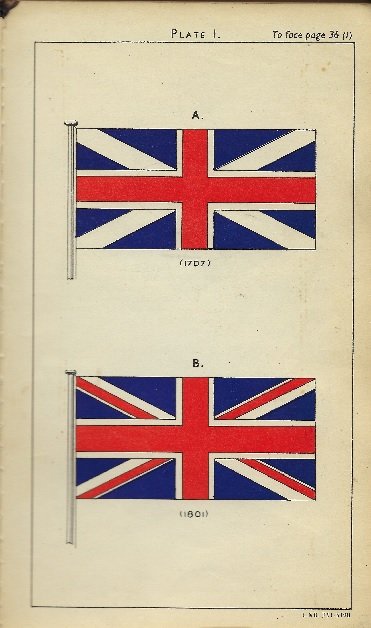

While I am still working on the forward cant frames I went ahead and made the Jack Staff for the Bowsprit Cap. Full disclosure... I had to make it three times. From Steels Rigging Tables I find the Jack Staff of the 74 Gun ship was 4-1/2" diameter x 18 feet tall. From The Anatomy of Nelsons Ship's I find they were tapered (smaller at the top) with a Cap or Truck. Visiting one of our club members on Wednesday I discovered the cap or truck had two small sheaves in it, one to port and one to starboard, one was a spare. The halyard had to be secured somehow so he figures they must have been something like a cleat near the bottom facing aft. Looking at TFFM Vol IV I see the cleat on the Jack Shaft. So My Jack Shaft is 4-1/2" diameter (0.07 inch) at the base or heel and 3-1/2" diameter (0.05 inch) at the head or top with an 7-1/2" diameter (0.12 inch) cap or truck. I used 1/8" diameter dowelling, secured it in my drill press chuck and carefully sanded it down to the tapered shape. When I had the shaft shaped proper I used a tiny saw blade to shape the truck to blend into it. I will not be cutting in the tiny sheaves as they are just too small. I have yet to make the cleat. The Flag (the jack or small version of the full size flag) will be 7'-6" hoist x 15'-0" fly as The Anatomy of Nelson's ships described them as 10 breadths (or 9 inches x 10 = 90 inches or 7'-6") and the size was a ratio 1:2. The Fully Framed Model, Vol IV reads they were sometimes 2:3 or 11:18 with one surviving Jack from Trafalgar measuring 7'-4" x 11'-7". As mine is dated prior to 1801 (when they added Ireland to the Union) there will be one saltire missing from what we recognize today. Following are pics of my Jack Staff, a union Flag dated prior to 1801 and a scrap from Bellerophon's ensign at Trafalgar. The last shows closeup the open weave of the material. Also one very short video of how I shaped the staff. I am going to make the Union Jack for this staff next. shaping jack staff.wlmp

-

it is akin to putting tinsel on a christmas tree... without it is is just a tree you dragged indoors.

-

Last weekend I went to Lee Valley Tools to pick up some clamps for the dust collection hoses. They had this drill press that caught my eye. I went over and grabbed the chuck and gave it a wiggle. The damn thing didn't move! After talking to the floor guy I brought it home. See my cheap Canadian Tire drill press wandered all over the place. The store clerk at Art's Tools (where I normally shop) told me you cannot get a decent drill press that doesn't wander anymore for a reasonable price. Only industrial grade ($$$$) have that. Well my new drill press does it. As a bonus it handles small number drills. The chuck sizes reads 0.8 to 16 mm (0.03 to 0.63 inch). Well I have had a #76 drill bit (0.02 inch or 0.53 mm) in it and no wiggle! Below is the heel of my Jib boom being drilled.

-

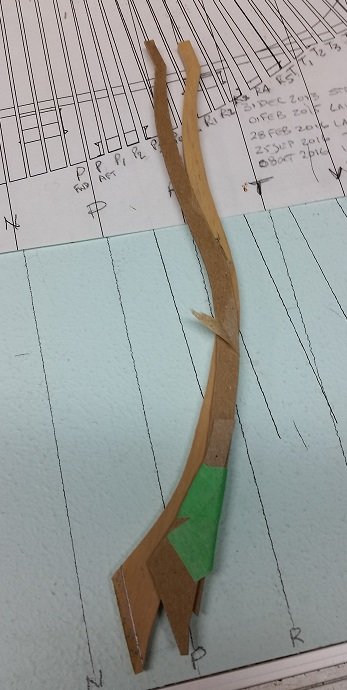

Also I was having a problem with my forward cant frame installation. I had to remove everything I hand done forward of the hawse pieces. As I wasn't happy with how this was going (dragging my butt on this) the amount of work required was minimal. The frames installed well to the forward deadwood but protruded far beyond the plan laid out below it on the table. After considerable head scratching I made a cardboard template of the frame, cut it in two pieces and overlapping the pieces to fit the plan properly I taped them together. This revealed how much they were too long. I then had to figure out why! Went back to my 3D model and after some time discovered I had not allowed enough opening between the frames for the deadwood. So I am presently sanding the frames shorter and reinstalling them. In the photo below you can see the template and the mark on the frame indicating what needs to be removed.

-

Having been busy with a number of things I think it is time for an update. First: an addition to my shop. I've added a dust collection system. The new more powerful vacuum is outside the shop to reduce the noise level inside (I can slide the barn style door closed). The hoses drop to a number of work stations and it picks up more than 90% of the mess I make! I just have to remember to turn it on and open the proper valve!

-

Good morning Mark, I had a quick review and find it to be bit difficult to read the fractions in the table of image 033 but I think it reads that the Fore-Top-Mast-Stay is 8-1/2 inch circumference ( = 2.7 inch diameter) and the Preventer Stay is 6-1/2 inch circumference ( = 2.07 inch diameter). I see I made an error. The Top Mast Stay is Half the size of the lower stay which makes it 8.33 inch circumference or 2.65 inch diameter). The topmast preventer stay is 3/4 of this which is the 6.25 inch circumference or 1.988 or 2 inch diameter. Thank you.

-

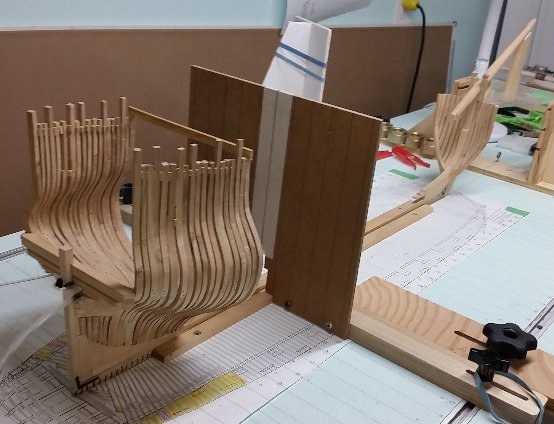

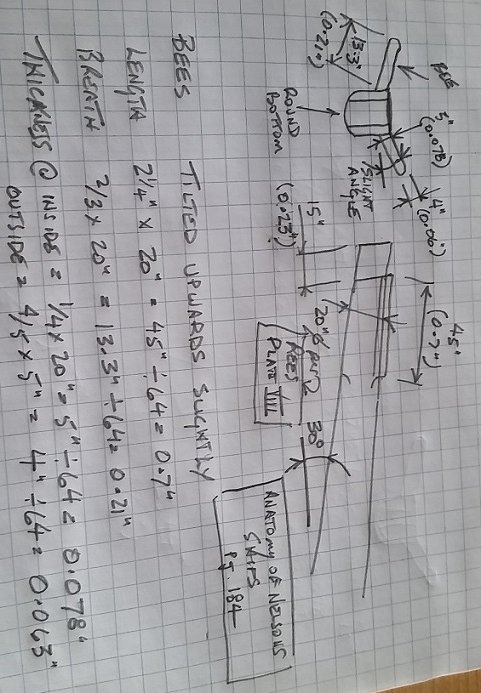

While I move ahead with my forward cant frames and the tree nailing of my aft cant frames to the deadwood, I want to complete my bowsprit. As I had made a number of rookie errors I thought I'd best get both my sketching and math down clearly on paper. I've made two bowsprits to date. The first was a quickly turned cigar shape on the lathe at proper dimensions to simply see the fit in the bollard clearance hole and determine my satisfaction with the diameter (posted earlier). The second was properly shaped on an Ed Tosti style board as he'd shown on his Young American build. This last one is not quite right so I will do it again. Practise makes perfect... or nearly so! To start with I must say I snagged a copy of an excel document entitled Masts and Rigging from somewhere. I believe it was this forum. I checked the properties and the author was Danny Vadas. I've found it to be a very helpful tool to cross check with. As I cannot see the formulae controlling the results in the cells I need to verify the numbers as best I can. The following explains the process. I am new to this so it also serves as my reference for later on as I will do more of this. I also snagged a copy of another excel document entitled Steels Dimensions by Y. Miroshnikov which is equally as useful. I must say that I found The Fully Framed Model Vol. IV by David Antscherl to have been very helpful because of the photos, plans and descriptions. The same can be said for Rigging Period Ship Models by Lennarth Petersson. They helped me understand what I was looking at or searching for. The following detailed explanation is quite long. I hope you do not mind, but I find the process fascinating. BOWSPRIT with CAPS, BEES and BEE BLOCKS As mentioned earlier I used REES's Naval Architecture (1819-1820), page 106, plate VIII for the dimensions, however he does not give much information regarding the Bee's and the Cap. I had looked at The Anatomy of Nelson's Ships (figure 116, page 185) but something wasn't quite right between this and some Vanguard kit builds I've been following. I needed to look deeper. Key dates: HMS Bellerophon was ordered in 1782, launched in 1786 and completed in 1787. This immediately suggests Rees might be a poor choice due to its date of 1819-20. I went to The Masting and Rigging of English Ships of War 1625-1860 by James Lee. All the information required is in Section 1. Mr. Lee agrees with Mr. Rees with regards to the ratio of the tapers of the bowsprit, but length and diameter differ in Appendix I ( Length = 0.6 x the length of the main mast = 104.25 x 0.6 = = 62.55 feet versus 64 feet; diameter = 62.55/3 x 1.555 = 32.3 inches versus 36 inches). Appendix II of Lee's reads HMS Valiant 74 gun 3rd rate Bowsprit was 36" diameter x 69'-5" long. Due to the scale of my build (1:64) a difference of 3.7 inches (at scale = 0.06") diameter is not at all noticeable, and 1.45 feet (at scale = 0.27") difference in length is arguable. As REES shows details I will follow his plate VIII as best I can. Mr. Lee suggests that looking down at the Bees they were somewhat scalloped fore and aft for the time period of my build. The Bees were 2-1/4 times the diameter of the bowsprit at this location (2.25 x 20 = 45 inches long); their breadth would be 2/3rds the diameter (2/3 x 20 = 13.3 inches wide); their thickness inside was 1/4 the diameter (1/4 x 20 = 5 inches thick at the bowsprit) and tapered to 4/5ths the thickness to the outside (4/5 x 5 = 4" thick outboard). The outboard edge tilted upwards by the thickness of the inner edge plus 1 inch. This would be 6 inches. This is all different than what was shown in The Anatomy of Nelson's Ships. I will be following Mr. Lee for the Bee's and Bee Blocks. Below the Bees are the Bee Blocks. They were 7/9 times the length of the Bees (45 x 7/9 = 35 inches long). They were half the width (13.3 / 2 = 6.65" wide) and 2 inches per foot of length in depth ( [35 / 12] x 2 = 5.83 inches deep). There were two holes in each Bee at one for each of the the foretop stay and the foretop preventer stay and one spare per side. These holes were elongated slightly fore and aft to better receive the stays as they passed through the Bees and Blocks. There were no sheaves at this time. What size hole do I need in the Bee for the Stay to pass through? If I know the size of the rope I can determine the hole size needed to clear. I went back to The Masting and Rigging of English Ships of War 1625-1860. In Appendix I it explains that the sizes of fore topmast stay and the fore topmast preventer stay are calculated to be a proportion of other considerations.... The topmast stay is 1/2 the size of the lower stay. The lower stay is 1/2 the diameter of the lower mast. The fore topmast preventer stay was 3/4 the size of the topmast stay. The foremast was the same proportions as the main mast. The main mast diameter from 1773 to 1794 was 9/10 inch per 3 feet of length. How long was it? In my time period the main mast length was 2.23 times the ships beam. The ships beam per the contract was to be 46 feet 9 inches (561 inches). 561 x 2.23 = 1251.03 inches (104.25 feet). The main mast diameter would be 104.25/3 = 34.75 x 9/10 = 31.3 inches diameter. The foremast would have been the same diameter. Now things start to not make sense to this novice. If the lower stay (rope) is half the diameter of the lower mast it would be 15.65 inches diameter! I think he meant size of rope which was the circumference not the diameter! The diameter is the circumference divided by Pi (3.1416). 15.65/3.1416 = 5.3" diameter rope. The top mast stay is half this 5.3 x 1/2 = 2.65 inch diameter (or 8.33 inch rope by circumference = 2.65 inch diameter) The topmast preventer stay is three quarters this or 2.65 x 3/4 = 1.98 or simply 2 inch diameter. I will make the holes 3" diameter (at 1:64 scale is 0.05" diameter = #55 drill bit). Since I'm all warmed up I may as well carry on with the Jib Boom details and get it over with. JIB BOOM I took the dimensions for my Jib Boom directly from REES's Plate VIII. The major diameter is 11" and the overall length is 51'-0". Only the heel end is octagonal in shape for a distance of 4'-4". The length differs from what is described in The Masting and Rigging of English Ships of War 1625-1860. Mr. Lee directs the length of the hex shape at the heel to be 3.5 times the diameter (3.5 x 11 = 38.5 inches). Mr. Lee also directs the length of the Jib Boom to be 0.41 x the length of the main mast (0.41 x 104.25 = 42.7 feet). This is a difference of 8.3 feet (1.5" at 1:64 scale). The diameter is to be 7/8 inch per 3 feet of length or 12.5 inches. Mr. Lee also gives some drawing details for the Heel Lashing Hole and Heel Rope Sheave. The slot in the Jib Boom for the Heel Lashing Rope Sleeve (sheave) is horizontal and the length of the slot is 1-1/16 x the diameter of the Jib Boom (1.0625 x 11 = 11.7 inches). The slot is located a distance of 1.5 times the diameter from the heel of the Jib Boom (1.5 x 11 = 16.5 inches whereas Mr. Rees locates this at 2 feet). The Heel Lashing Hole runs horizontally and is halfway between the Jib Boom heel and the slot for the sheave (8.25 inches). There is another sheave located at the head of the Jib Boom for the Jib Outhauler. This sheave runs up and down (vertically). Mr. Lee directs it to be located "a few inches abaft the rigging stop". For my time period the rigging stop was tapered back to a shoulder. Mr. Rees shows the horizontal heel sheave slot to be 18" long x 4 or 5" wide. The outhaul couldn't possibly be the same size as the head of the jib boom is so much smaller in diameter than the heel (7.3" versus 11"). In my novice opinion there seems not enough "meat" left either side in the boom to support it. To double check this I need to know the size of the Heel Lashing and Jib Outhauler ropes which will determine the sheave sizes. Mr. Lee directs that the Heel Lashing is the same size as the Bowsprit Shroud Lanyard which were the same size as the Gammoning which were 0.44 of the Forestay. The Lower Stays are 1/2 the diameter of the lower mast. The lower mast was the same proportions as the main mast... 9/10ths inch per 3 feet of length of the fore mast, which was 0.93 x the length of the main mast which I'd already determined to be 104.25 feet. 104.25 x 0.93 / 3 x 9/10 x 0.5 x 0.44 = 6.4 inches circumference / 3.1416 = 2 inches diameter rope. From Steels I find the sheave diameter is 5x the thickness of the sheave but in Lee's it is 4x; the sheave thickness is 1/10th more than the rope diameter; the breadth of the sheave hole is 1/16 inch greater than the sheave thickness; the length of the sheave hole is the sheave diameter plus one rope diameter in Steels whereas in Lee's it is 1-1/3 x the sheave diameter. A sheave for a 2 inch diameter rope would be 2.1 inches thick x 10.5 (Steels) or 8.4" (Lee's) inches diameter. The sheave slot would be 2.163 inches x 12.5 or 11 inches. For the Jib Heel Lashing on my drawing I find a 10.5 inch diameter sheave does not suit my 9.5" across flats hex shaped heel of the jib boom. I made my Heel Lashing Sheave 8.4" diameter and the hole 2.2" x 11". Search as I might I cannot seem to identify the rope size ratio for the Jib Outhauler. The Mast and Rigging spread sheet (which has proven to be reasonably accurate up to now) suggests the Spritsail Yard Halliard and Running Lifts and the Fore Trisail Outhauler are all 1" diameter. As these are all in the same general area it seems reasonable for the Jib Sail to be similar. The sheave for a 1" diameter rope would be 1.1 inches thick x 5.5 or 4.4 inches diameter. The hole would be 1.163 inches wide x 6.5 or 5.7 inches long. Again the differences are those between Messrs. Lee and Rees. I will use the 5.5 inch diameter sheave and the 1.1 inch wide x 6.5 inch long slot for the Jib Outhauler. This fits nicely in my drawing. PDF attached! Also a couple pictures from my second Bowsprit. **** This exercise took a number hours over just as many days. I needed to walk away and shake my head clear a few times, review a number of books and re-read passages many times. This is the kind of stuff that cranks me up and gets me jumping for more! Yes I really enjoyed it that much. Bowsprit + Jib Boom.pdf

-

Also, I made a quick bowsprit at about 37+ inches diameter (Ree's says it is 36" diameter) to see how it would look. I am not happy with the gap and so will make it a little larger. No one will be taking a caliper to it! Then I researched the finished shape of the cap end of the bowsprit to accept the BEES and made notes. I'll be making a good bowsprit soon enough to have a change of pace... after all they say a change is as good as a raise!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.