-

Posts

2,882 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by AON

-

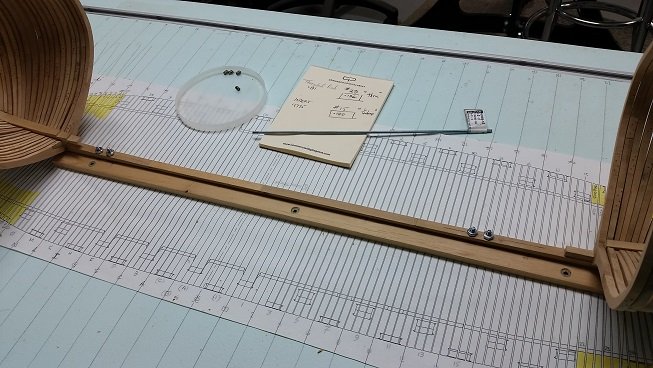

Mounted the model on the travelling base. Used a heavier clamp at one end as a counter balance as I made adjustments to align the drill bit with the mark then clamped it to the drill press base. Drilled the holes. #29 thru, #15 1/4" deep. Set it on the build table and drilled thru the table. Made up lengths of threaded rod, chased the threads after cutting the lengths (borrowed my son's tap and die set for this). Installed the helicoil inserts as described earlier. Now it sets up and cures. I left one of the original wooden clamping bars on the table as I can set the keel to it/align to it, and it holds the plan in place on the table.

-

-

-

Life is like that, eventually you either are no longer needed or worse, outlast your usefulness (1802)

-

-

-

As a picture is worth a thousand words I thought I'd try to explain it another way. In the photo below I show the Helicoil thread insert (in a stepped hole) versus a hex nut (set in a customized pocket). I have also drawn in the rising wood (top), keel, and false keel (below) at the end of the block of wood. The hex nut and helicoil are buried in the rising wood. The hex nut is as thick as the rising wood so it necessitates the removal of a great deal more wood than the helicoil. In my mind it is cleaner and simpler. More rising wood is left in place. The frames glue to the rising wood... so it would be nice if some wood were there. The hex nut is entrapped and so cannot spin. With the tang removed from the helicoil it does not move. So both are equal in that sense. The hex nut has 3.6 threads and the helicoil has 7.

-

-

This one was mis-labelled as 7 July 1801 but when opened it was realized to be 24 Sept 1795 It has a special meaning for me, as I had spent 5 summers on Vancouver Island, and earned my sailing and pulling cox'n papers in my third summer out their.

-

Thank you Mike. I had looked at these and thought they were quite large a barrel diameter and then also to the OD of the cutting thread, and in some cases the length. I was hoping to minimize the material (wood) removal. My test worked, but I will need to remove the "tang" as if you continue to turn the rod after it contacts the tang the insert threads out of the hole. Of course there will eventually be a frame covering the hole so the rod will only thread in so far and have to stop. In my application, I used a somewhat backwards installation as I cannot cut the proper size thread in the wood (as I am a cheap ol' coote). Normally they feed in the same side as the screw or rod, but mine in in the opposite side to create the retaining shelf for clamping.

-

a substitution for HEMP cordage is discovered..... and the list of officers gets even more inflated. (1801)

-

Above is a threaded insert (aka helicoil threaded insert) Below is a blind nut. I think you are referring to the blind nut with the flange and spikes that have a much larger diameter cylinder (with the threads inside) than the OD of the threaded insert, requiring a larger hole and length removing more wood than I prefer. The flange on the #6-32 blind nut is too large for the width of my keel and would require filing. The thickness of the flange requires a spotface in the keel to get the top flush or buried. The spikes are just a pain in the behind. I was looking for something cleaner than the flanged/spiked blind nut, and cleaner than a standard hex nut that would need to be filed across flats to fit in a pocket that would need to be chiselled out of the top of the keel. I am attempting something different. If this does not work I will resort to the hex nut, that is quite functional, but ugly (and, yes, I know it will be hidden). And you, sir, are anything but thick.

-

TESTING the stainless steel #6-32 helicoil thread insert for mounting my build to the table and eventually the display mounting board. FYI: #6 refers to the screw thread diameter; 32 means 32 threads per inch. I learnt long ago that the full strength of a thread is developed in the first fully engaged 5 threads, everything after that is safety factor. When I ordered mine I made sure it was long enough to have at least 5 full threads... mine has 7. I decided to drill and thread a hole in an attempt to assist the insert into feeding into the wood. First I drilled a 9/64 inch (0.1406 inch) hole for a #8-32 tap. Now a #8-32 thread is a slightly smaller diameter than the outside diameter (OD) of the insert but I thought as it was going into wood I might be able to ease it in so it followed the 8-32 and cut it's own threads a wee bit deeper. That did not happen as the "wire" is very slim and so it deformed. I then tried feeding it in with it on the threaded rod and that did not work. If I had spent an extra $40 for the correct tap and proper holder for the insert I likely would have been successful, but I didn't think the extra expense was worth it for 4 holes. Luckily I purchased 10 inserts and only need 4 for the job. So next I decided to try by drilling a stepped hole. First I used a #29 drill bit which is slightly larger than the rod OD at 0.136 versus 0.132 inches and drilled through the wood. So the rod slips thru easily. Second I used a #15 drill bit and drilled down 1/4". The #15 bit is 0.180 inch diameter and the insert is 0.1785 inch OD. The next smaller bit would be too small (#16 at 0.177 inch). This created a step or shelf that the insert rests on when placed in the hole. Although advertised as 0.276 inches tall the insert is actually 0.232 inches tall so a 1/4" (0.25 inch) deep hole puts it just below the surface. My keel assembly is almost 1/2" tall. I then inserted the threaded rod and rub some good old petroleum jelly (Vaseline) on the OD of the rod threads. Then I screwed the insert onto the end of the rod. Then I cleaned up a bit of the petroleum jelly that got pushed out of the threads by the insert. I applied a thick two part epoxy onto the OD of the insert. The petroleum jelly is supposed to keep the epoxy from migrating through the coil of the wire and gluing the threaded rod to the insert. I then pulled the rod back into the wood block to draw the insert in and up to the shelf or step. I let that set for a while and eventually removed the threaded rod. Now it is curing. Later today or more likely tomorrow morning I will test that it is holding, does not spin. I will apply reasonable torque (a wee bit over snug) for the small thread. The end of the stainless steel threaded insert has a tang blocking the hole. This is used with the proper insertion tool to help thread the coil into a threaded hole. It is meant to be broken off after the item is installed. If what I just did works, I think I will leave it on as a stopper for the threaded rod. Below are some photos.

-

Prior to e-mail was snail mail before that was the proverbial message in a bottle (AND NOW THE SONG IS STUCK IN MY HEAD)

-

What is interesting about this article is the figure carved was said to be the last prior to the cut backs that resulted in less ornamental, and more importantly, less costly carvings. 23 June 1800

-

-

The destruction of the Queen Charlotte (1800) caused by a single match, a breeze, and a stack of hay. I've also read in another paper that although rated as 110 guns she actually had 120.

-

I read an excellent article by Peter E Demarest in NRG Vol 56, Spring issue 1 (2011) pgs 57-58 regarding CA glue attacking white metal, copper and cotton/linen fibres (scale rope). There was a followup letter by the same fellow in the next issue pg 117. Concerns for off gases over time in a confined space (display case) ? I've also read online (https://en.wikipedia.org/wiki/Cyanoacrylate) that it can have an exothermic reaction with wood and leather! But then it is sold to be used on wood (?). Any search I've done list the pH of CA glue as "not applicable". I've always thought yellow and white wood glue to have a pH of about 4 to 5.5 I've also seen and read about the white glue being diluted and used in rigging (i.e. making faux splices). Your comments are food for thought. I am now looking into book binders glue. Thank you Allen Ed for the additional info on Bees wax.

-

I took advantage of some recovery time (pinched nerve in my lower back) to go through a bunch of the newspaper articles. (I am much better today) Over this time (my last push) I concentrated on the 1700's and (just now) completed that era. Only 497 more pages to complete 1800's (originally almost 1000 pages). Attached is a PDF of the index of my transcriptions at this time for those interested. This is far more info than any book I've read on this ship and her travels. HMS Bellerophon - Part 2 - Newspaper Articles and Letters - INDEX.pdf

-

-

-

Apparently Nelson's report on the victory of the Battle of the Nile almost didn't get delivered.... (1798)

-

Thank you.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.jpg.f3dde6ab67609995f6a224321669739a.jpg)

.jpg.70cd553384d425074d42c086918e7fbb.jpg)