-

Posts

2,587 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by AON

-

-

found the following at: http://www.animatedknots.com/rope1.php?LogoImage=L..&Website=

Z Twist (Right Hand Lay) & S twist (Left Hand Lay)

Rope Lay

Most three-strand rope has a "Z" twist or a "Right Hand" lay (as the strands progress away from a viewer, they rotate clockwise). What is rarely known is that this is inherited from early recognition that Right Hand laid Hemp was stronger than Left Hand laid Hemp. A Left Hand lay or an "S" twist is normal for steel cables and used to be more commonly found in cotton rope where the Right Hand lay offered no benefit.

-

coils of line (rope) have a natural lay to them... when you hand coil a line it will naturally fall into a coil if you assist in taking the twist out as you coil the line otherwise it tangles. Understanding this I've used left and right hand steel wire rope wrapped around drums for overhead hoisting cranes.

possibly the differentiation in fibre rope lay might have made a difference in being wrapped around components... I will have to check some seaman's handbooks tonight when I get home from work

-

I have two magnifying glass/lights on spring loaded locking arms

One on my scroll saw and one on my work bench

Just push them back for illumination and pull them forward to highlight (enlarge) my mistakes

-

Why thank you Shiptek!.

I use to tell all the young'uns " just do it" long before those "shoe people" started saying it.

They should pay me a royalty.

I will be enlarging my play area starting tomorrow, doubling the length of the room so possibly my next project will stay contained inside of it.

I just love building things, including walls!

-

-

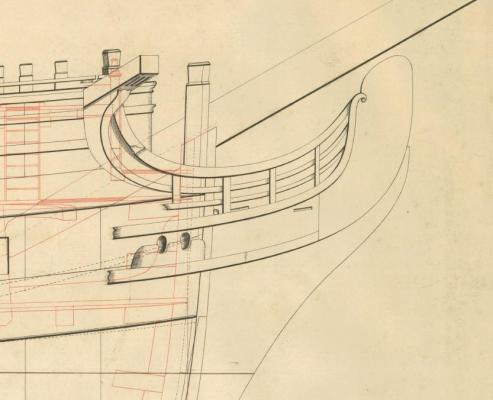

I began sketching in the deck elevations at the bow and stern and noticed the round house deck is slightly elevated (above) the upper deck.

Having studied the Vanguard models built and in progress on the forum I note they are at the same elevation on them.

I also have thumbnail images of the Edgar and my plans of the Goliath locate them at the same elevation.

Ree's plates show it as being on the same elevation.

Would anyone have an explanation why the Elephant's as built plans are so different?

- daHeld73, Elmer Cornish and mtaylor

-

3

3

-

-

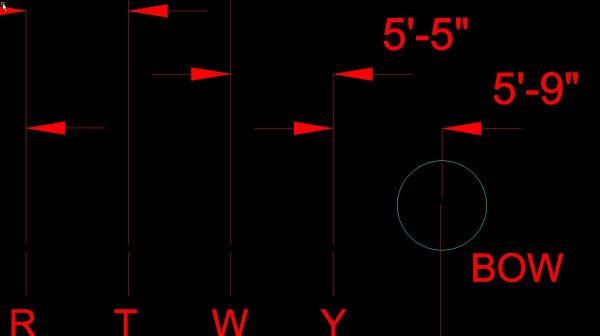

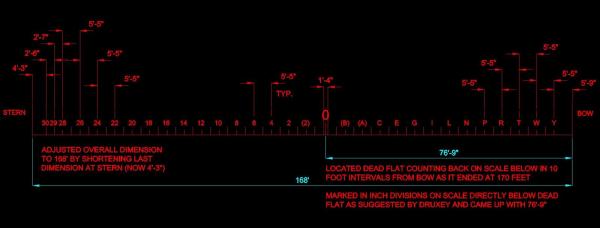

While making my corrections I found an error.

I had an extra inch in the overall length and it took me days to realize the error.

One dimension at the bow perpendicular was off.

The node on the dimension leader is not connected to the line

I had to zoom in to find it.

Once corrected all the stars aligned perfectly

-

Regarding the additional annotations... I post the following with written permission of the author:

I have taken a look at the contract in questions (ADT0009) and my conclusions are thus:a) The original contract was written for Bellerophon (1786).The amendments date from 1805 and are irrelevant to the above vessel.c) The amendments relate to building ships of the Fame class (1799) that had been ordered in 1805 - of which there were 4, possibly 5 (date of the latter is uncertain). The additional dimensions match the Fame class.I do not know why the Navy Office decided to reuse the contract as a specification for the Fame class, except that it may imply the Arrogant class and Fame class are more closely related than either David Lyon or Rif Winfield realised: the Arrogant class was designed by Slade and the Fame class by Henslow.For the purposes of the Bellerophon project the 1805 additions can be ignored.I hope that this makes sense. I have updated the Museum catalogue so it should go 'live' sometime.Yours sincerely,Jeremy Michell, MAHistoric Photographs and Ships Plans Manager, National Maritime Museum -

Bob

What an invaluable piece of common sense info!!!

I've been following this discussion as I have a hankering to pick up a lathe down the road but, like so many, it seems I don't have a clue.

Thank you

Alan

-

-

very good looking!

(you know I am taking notes, right)

-

-

-

Close? ...............I can almost smell the wood!

For some reason completing the hull has got me a little anxious but, like everything else, I'll eventually plough through it

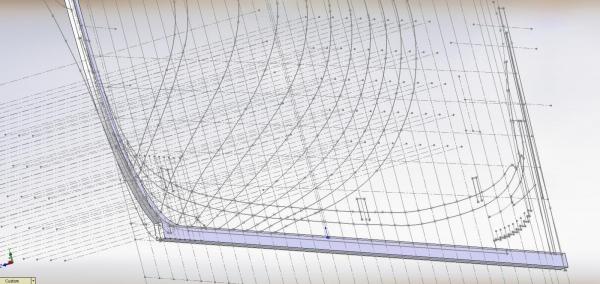

Not sure if I mentioned this before but I've always had to envision the part or assembly in my mind before I could draw it. The exciting part is I can now see all the timbers sitting on the keel and the cant frames curling into the posts. That is what excites me.

Thank you and everyone else for following, the helpful comments and the words of encouragement

(thank God for this forum, otherwise I'd likely be building a raft... and I'd get part of that wrong

)

)After having moved my stations I've noticed the sketch points for the stem and stern post and the keel need to be realigned as I had not yet anchored them. As I move them many seem to be falling into a more proper place now. Only half a zillion more to go.

Alan

-

Got an extremely quick response from Chris Watton suggesting all the penned annotations may have been a suggestion to lengthen the ship during a refit in 1805 but the idea was not implemented.

Considering it all history now.

I've moved my stations in my model and presently little seems to have been affected.

I will have to take some time to be sure, then clean up my keel, stem and stern post sketch, complete the hull and slice my timbers to make the templates.

There is a light at the end of the tunnel

-

Thank you Alan for the suggestion

I sent a PM to this gentleman and now get to practice the fine art of patience... something else I struggle with!

On another note...

I spent yesterday clearing out half the dungeon in preparation of expanding my play (work) room. Going to be more than doubling the size.

Lumber, nails, drywall, screws, second door, hardware jamb kit, electrical plugs and boxes to be delivered this coming Saturday

-

Yesterday was a rather rainy day in Niagara and so far I’m not sure today will be much better.... the flowers, grass and trees love it.

Decided I needed to get going on this project as I could not get any yard work done.

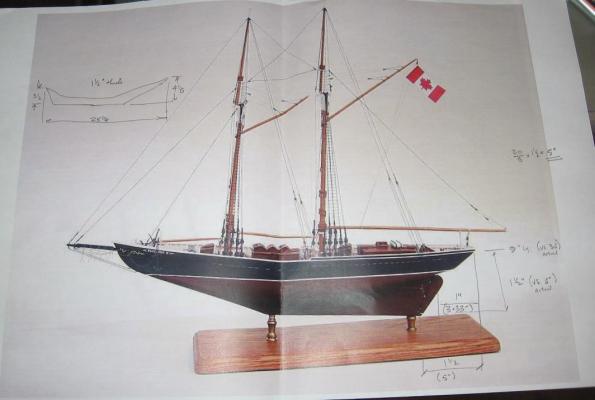

Earlier (see above) I took my tracing paper hull template and taped it to some stiff cardboard

Now I traced the shape onto the cardboard with a soft (HB) pencil.

I printed out a picture of the Bluenose from the forum for reference, measured the overall length, compared it to Charlie’s O/All Length and had my ratio to estimate dimensions

After working out the dimensions of the skeg to be added to the underside I drew the shape onto the cardboard. Then cut out the template.

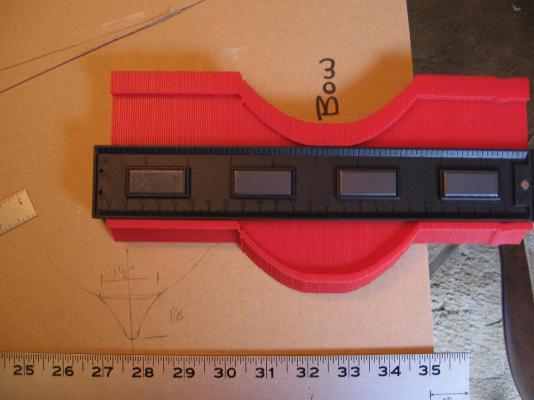

I transferred the hull cross sectional shape to paper using my new (larger and brighter!) profile gauge and estimated the width of the skeg or piece of wood I would need to use (looks like 1-1/2 so I'll go with 1-3/4”). I went down to the dungeon and scoured through my scraps. Although I was ready to plane and glue and clamp two or three pieces together I found one piece of maple about 1-7/8” thick. I planed this down to 1-3/4” to create a flat surface. I then planed one edge.

I then traced the template shape onto the block of wood, cut of the “ends” to shape with my band saw and now I am ready to shape with chisels and rasps

I envision drilling two holes to glue and screw this to the hull. I will insert two dowels to hide the screws and use this as the mount similar to the model/ image I borrowed.

-

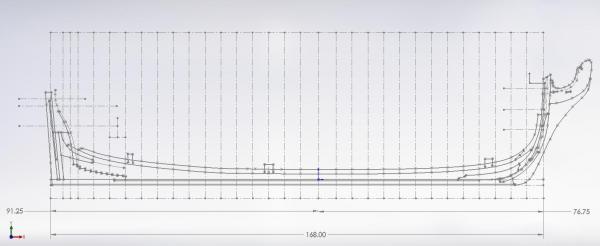

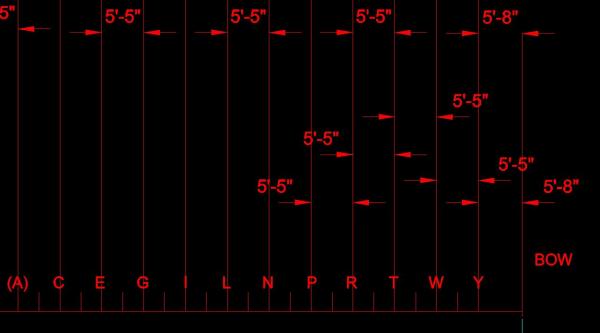

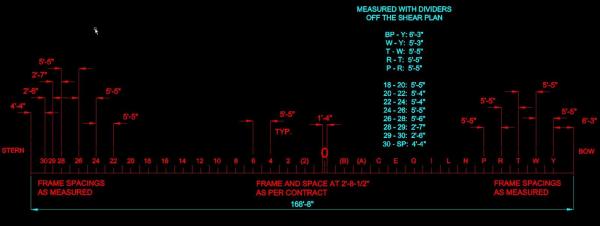

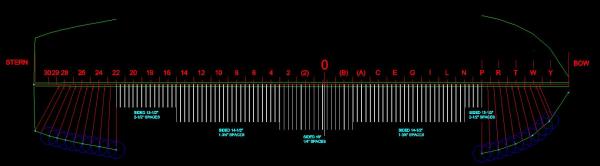

I’ve completed the sketch that nails down my station lines!My first sketch is a combination of double frame and space (2’-8-1/2” x 2 = 5’-5”) plus the spacing I measured to the bow and the stern perpendiculars.This left me with an overall length of 168’-8” which is 8 inches too long.My second sketch was after I noticed the bar scale on the plan read exactly 170 feet under the Bow Perpendicular. Having suddenly realized this I could read the nearest full dimension next to the dead flat position, draw the 1/12th divisions at the dead flat and measure with some degree of confidence the location of the dead flat. This meant whatever was left over at either end was “it”. Now I had my stations (reasonably) properly located. (I must keep reminding myself that I am not building a Swiss time piece!)My final sketch was to help me visualize the timbers, spacing (gaps) and cant frames.Now having a better visual understanding of this part I will be adjusting my model next week, get my hull completed and then, possibly, soon, begin making some templates for an actual build!Thanks goes to my NRG mentor whom I am certain must have been getting annoyed with my stubbornness. (I must keep reminding myself that it will not be full scale!)

- fatih79, Elmer Cornish, mtaylor and 1 other

-

4

4

-

-

I should expand the explanation

The (original TIFF and so) PDF images I was measuring off of are "stretched" (due to the original source) and so inaccurate as would be measuring off a (the) print. The lines on the PDF are a wee bit thick when I zoom in to measure so that probably doesn't help.

My Solidworks model reflects these inaccuracies and so lines are manipulated

If I were to trace off an imported image I get the same inaccuracies because the original image is stretched

If I stretch the CAD tracing I would make from the image the curvature/straightness of the lines are compromised and require manipulation

No matter what I do I've got to nudge things over and turn them about to make it look right and since I want to try to salvage what I've done to date ....

My NRG mentor suggested measuring off the print with dividers and so I've given it a try

It can't be any worse than what I've done so far and actually gives me repeatable dimensions where as the zooming in on the PDF to electronically measure rarely gives me the exact same dimension twice (a program tolerance issue)

I am doing it all on a reference sketch in DraftSight because I need a "clean sheet" and my SolidWorks model is too distracting so I keep it closed for now.

All will be transferred to the model once I get it straightened out.

-

links don't seem to work for me

-

-

Good morning Druxey

Your words about paper stretch from much earlier were very much on my mind when measuring.

I attempted measuring directly below but the 1/12th divisions are not there

Then I measured at the end nearest the station where the divisons are located

Then I compared a few at the opposite end scale

I was thinking I'd re-measure and draw out the bow and stern heights of breadth in 2D Draftsight off the half breadth, draw the cant frames and see how that compares for frame and space... then I can comfortable make a decision

Alan

HMS Vanguard by RMC - FINISHED - Amati/Victory Models - scale 1:72

in - Kit build logs for subjects built from 1751 - 1800

Posted

I will admit that one lay rope being stronger than the other seems like a load of cow dung to me.

I have never heard it before and of course anything you discover on the inter-web should be taken with a large dose of salt.

I've be looking through my dad's Manual of Seamanship BR67 Vol. 1 1937

page 95 Chapter 3

Cordage

Yarns are made of Hemp laid up right handed

Strands consist of a number of yarns formed together, the number depending on the size of the rope formed; those intended for right-handed rope are formed left-handed, and vice versa.

A Hawser Laid Rope has three strands, and is laid up the opposite way to the strands. They are usually right-handed. The size of rope is measured by its circumference.

Hemp can be white or tarred. It is used for running rigging, hemp hawsers and small boat cables. The tarred variety is used when subject to continuous exposure to weather and sea.

it then goes on to explain how to determine the strength of rope and does not suggest one lay is stronger than another.

If someone has more information on uses for opposite hand rope I'd love to know!

I just know my use of both handed steel wire rope on hoists (1975/76) kept the hook centered and laid naturally into the grooves on the drum.