-

Posts

2,770 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by AON

-

-

Two weeks have passed and not a lot to show.

I managed 3D modelling and 2D drawing up quite a few frames only to realize I had a compounding error in them as the lower scarph joints rise in elevation on the real Elephant's plans but not in my version. Made corrections over last weekend and then caught some bug Monday that had me down for the rest of the week. Head ache, muscle aches, chills, unbelievable fatigue but none of the more nasty possibilities. I cannot recall the last time I was sick on work days. I normally get sick on Friday at about 6 PM and am miraculously cured by Monday in the wee hours of the morning.

Feeling considerably better today so I went downstairs and cut the keel and false keel pieces and then the scarph joints in the keel pieces.

Immediately buggered the first attempt ... and after all those practice runs a few weeks ago!

Then I began cutting the boxing joint in the forward most keel piece and was quite happy with the result.

Began to cut the mating joint in the lowest stem post section... checked, double checked, triple checked, marked the waste half with with an "X"... and yes I then cut it wrong.

So now I have two pieces that without question need a "do over".

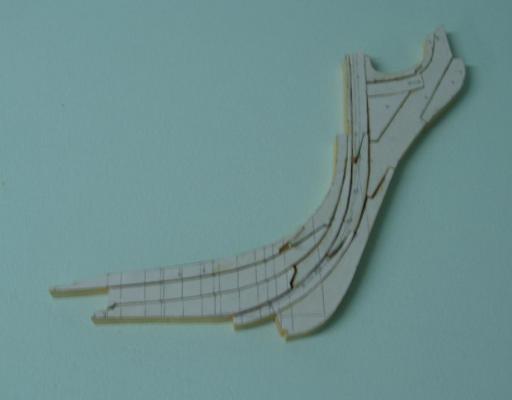

Templates cut and glued to some drops from earlier cuts.

-

I prefer to support the local mom and pop stores while they still exist, so like E-Bay, the Pro Bass Shop would be a last resort.

I am also not a fan of the automatic check (yourself) out stands in some stores as I believe the more people use these the more other people will be out of work.

I miss the days when the pump attendant filled'er up, washed the windows and checked your oil... I also miss the $0.35 admission to a movie when the rest of my 50 cents bought me a pop (or soda) and small bag of pop corn.... those were simpler days... of course I was 13 then.

-

I also worked on the remaining pieces of the Stem Post assembly.

Glued up, cut out and sanded.

Then dry fitted them all together.

Then I glued up the Keel and False Keel templates to wood read to cut.

I had thought I'd need an oscillating drum sander to make sure I managed square curved surface sanding but I noticed one member posted his using his drill press... so I did a similar rig on mine

- kees de mol, druxey, mtaylor and 1 other

-

4

4

-

Did my glue test with the 40 lb test fishing monofilament line (0.0235" diameter) to be used as faux 1-1/2" diameter bolts in my assembly

I took a scrap piece of hemlock and drilled 4 holes using a #70 drill (0.0280" diameter)

I cut off 4 pieces of line and scuffed up the length of two of them, leaving the other two naturally smooth

#1 was the un-scuffed line coated with wood glue, inserted in the hole and worked up and down a few times (as EdT discribed in his build log of Young American)

#2 was wood glue on a scuffed line

#3 was 10 second Gorilla Super Glue on a scuffed line

#4 was the Gorilla glue on a smooth line

I let them set for 5 hours

I then tried to pull them out with a pair of pliers.... they all held there place.

I clipped off the lines close to the surface of the wood and sanded both sides of the wood.

Only #1 could be pushed out meaning the glue did not penetrate any appreciable distance along the length of the hole so sanding removed the glue.

I am not a fan of the Gorilla Glue and am happy the wood glue work well on the scuffed surface of line.

I also noted the end of the line in the sanded version didn't look all that bad.

I will continue to call around to see if I can get this line locally in BLACK as opposed to the translucent GREEN before I resort to E-Bay.

-

-

So the new question since yesterday (via PM) has been whether to continue on as I have been with the upper scarph joints in the futtocks or use chocks throughout with the frames being "scarphed" to receive the chocks? (Notice the twist in the usage of the term scarph joint)

The decision process… gathering of facts.

1. The contract reads as I had posted earlier.

2. My NRG mentor suggests they would likely have followed the contract… but had two weeks earlier recommended a book of ship construction that will explain the wood shortage and effect on ship building. I have ordered it but it is at the very least a six week delivery and unfortunately it will not arrive for at least another four more weeks.

3. Another very respectable and experienced modeler has mentioned via PM that there was a shortage of compass timber at the time and so scarph joint construction in the upper frames were being replaced with chocks so the timbers would be slightly shorter in overall length.

4. Construction of the English Man of War 1650-1850 by Peter Goodwin states on page 16, 17, 18 that chocks were used (c. 1710-1811) up to but not including the fourth futtock to top timber joint due to the wood supply problem.

5. The Bellona, the forerunner of the Arrogant Class ship seems to have been built with chocks per “Bellona - Conway - Anatomy of the Ship - The 74-gun Ship” (although depicted incorrectly)

6. If the Bellona was ordered on 28 DEC 1757 and was possibly/likely chocked and the first of the arrogant class ships, HMS Arrogant, was ordered on 13 DEC 1758, it would stand to reason that they would be of a similar construction. Therefore HMS Bellerophon (ordered 11 JAN 1782) a full 25 years later (during even more of a wood supply problem) would not likely be built in an older style.

At this very early time in my build I intend to leave one half uncovered (deck and hull) with a portion of frames removed to expose the interior and lower decks. So all the frames on one half of the build will be exposed to some extent for viewing of chocks or alternatively scarph toes from above.

The decision seems obvious when viewing the facts. I need to revise/redraw my station joints made to date to be chocks below the top timber / fourth futtock joint which will be a scarph joint.

Luckily I love to draw and in this day and age (and particular endeavor) it does not include erasing.

-

One more small item to share... the HMS Bellerophon Ship's Crest (from the last ship of that name and as assigned to the Sea Cadet Corps before they decided to add the three maple leafs to the bottom to differentiate the cadet corp from the real thing in the early 80's). I do not believe the earlier ship's had crests as they had figure heads (?)

I'm cleaning out my hard drive and back up and found a really nice clear image.

-

Druxey,

Same sheets mentioned for Don above...

1) ... no chocks to be any larger on any Floor Timber than will admit...

2) Lower Futtocks ... to have chocks across the heels of them... and that they scarph on the Second Futtock...

3) Second Futtocks... Scarph... to the Third Futtocks

4) Third Futtocks ... give scarph to the Fourth Futtocks

Seemed to differentiate clearly where there were chocks and where there were scarphs so that is what I think I did if I read it correctly.

If I'm wrong please let me know.

If I'm right please don't stop asking!

Alan

-

Good evening Don,

The information is in the contract on the 4th and 5th sheets.

Floor timbers 26 ft in length at midships; molded at the heads 13-1/2"

Lower Futtock molded at the heads 12-3/4"

Second Futtock molded at the heads 12-1/4"

Third Futtock molded at the heads 11-5/6" and in and out at the Gun Deck 11-1/2"

Fourth Futtock molded, or in and out at the range of the Upper Deck Water Ways 10-1/2"

Top Timbers molded at the top in midships 5-1/2", abaft 5-5/8", at the Beakhead 6-1/4", at the Fiferail from the Second Drift to the Stern Timber 4-1/2", from the Drift Forward in the Wake of the Timber Heads 5-1/2"

I just use a polyline to blend between the points.

Alan

-

Slipped out at lunch and bought 1 yard of 40 lb test monofilament fishing line at 0.024" dia x 64 = 1.536" dia

I will do some glue testing over the next few days

It was indeed 3 cents a yard so 109 yards would be $3.27

I'll have to start making some local calls for a supply of Black as this stuff is Green ... mind you it does seem black when viewing the cut end... hmmm

-

I looked again and didn't see the length .... and then I realized I needed to scroll down!

Doh

Some days I do things my dad would do... and he was just being old.

OMG

I'm old!

-

Ed

Thank you for the link.

Those prices are considerably less.

Did you purchase the spool or the box?

Any idea what length (feet) was supplied at that price

Alan

-

Druxey,

Sorry for the late reply.

Although I've seen a few references showing in different ways (Cross chocks and scarph joints; cross chocks, futtock chocks; cross chocks, futtock chocks and then scarph joints at higher elevations), but I believe the contract reads scarph joints at the futtocks with the exception of the floor timber to futtock joint which would be the next or adjacent frames which can be seen in the first image / sketch.

When I get home tonight I will re-read those sheets (and they can be tough to understand), scan and post.

Would they call a chock a scarph joint?

Alan

-

On another note... rather than cut monofilament line off my fly reel I called "the" tackle shop and they sell 40 lb test line at 3 cents a yard (seems cheap to me... I am expecting it to be 30 cents when I get there).

The 40 lb test is extremely close in diameter to my 1-1/2" diameter bolts or AWG 22 gauge copper wire. Unfortunately he only has GREEN (a very popular colour) but good enough to test gluing it into wood.

If it works for me I can buy the black line at Canadian Tire, but it ain't cheap. Compared to copper wire and blackening I suppose it is a wash.

Let you know how it works out.

-

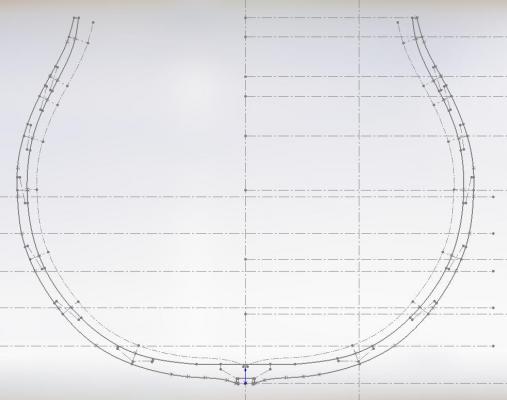

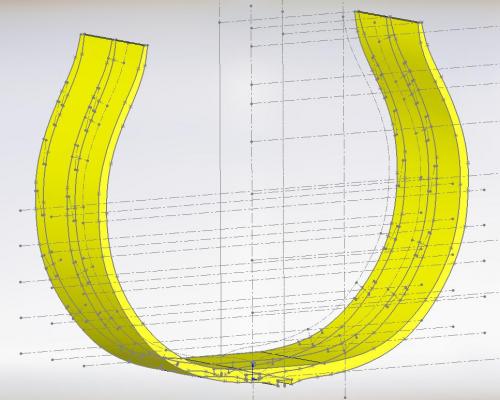

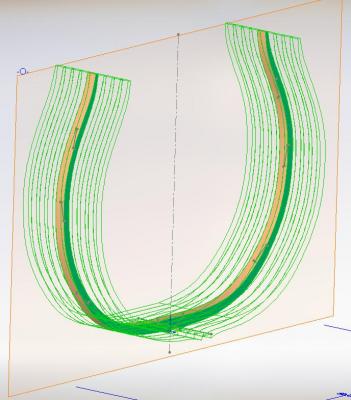

Unfortunately I will not get to working on cutting more wood until the weekend as my evenings are quite short making it difficult to get into it.

So I spend the short time through the week working on my frame templates.

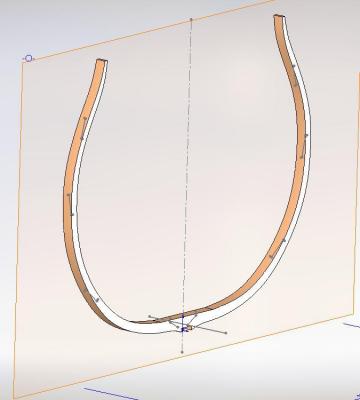

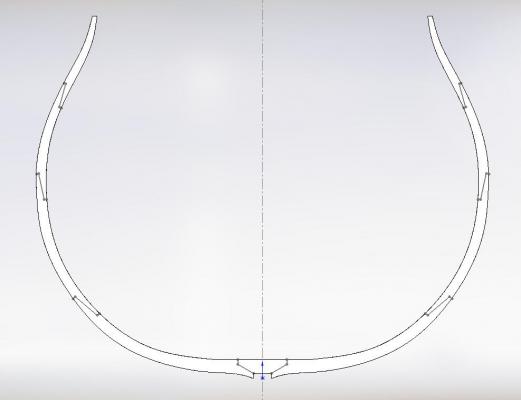

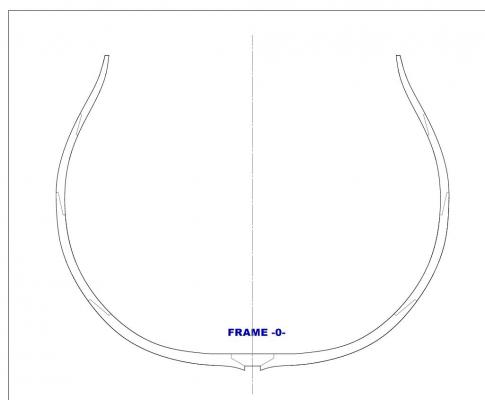

Here is a description of what I am up to in my creation of frame templates following the train of thought of an earlier posting some time ago (POSTING #102 on PAGE 7) when I was working things out.After outlining the complete frame (see earlier posting) at the particular station I now trace in the cross chock and all the various scarph joints for the adjacent four frames up to the next station. They are used as a reference on the other frames. As frame shapes begin to change drastically I will need to geometrically create the proper offset to relocate them.I then loft the hull (or more correctly a one piece solid frame) between stations. In this sample it is at dead flat out both directions to ( B ) and ( 2 )I then draw in the “spaces” between the frames and cut them away to reveal the individual frames. In this location the spaces are a mere ¼”. In the pic below the adjacent frames are turned off to reveal only one that I will be working on.I then open (or create) the plane cutting through the centre of the frame and open a sketch and trace the cross chock and particular scarph joints for that frameFinally, looking straight onto the frame I see the frame shape and cutlinesI will insert this “section” view of this frame on my template sheet to be printed to 1:64 scale. Once again as the frame shape begins to change drastically I may see the hidden lines depicting the cut angle... we will have to wait and see.It is a long drawn out (excuse the pun) exercise but I will have what I want in the end. A few done but many more to go.I may not post anymore on the making of frame templates except to possibly show progress on the cant frames and aft and also to post PDFs of the drawings when I am done. (Don't want to bore anyone) -

Unfortunately I am the touchy feely kind of learner, where lessons better learnt by doing... so I'd rather not find out the hard way but I am sure I may somewhere down the road.

As for merit points... that is for boy scouts and girl guides....... I was a Sea Cadet!

I was taught to lead by example of which two men come to mind (Lt. Ken Garner and Cdr Admundson) as having made an impression of the type of leader I hope to be one day when I finally do grow up.

So I came in to work because someone might be depending on me to do the right thing.... while all those wooses I work with slept in because it's a blizzard out there. Hello, this is Canada, it snows here in the winter!

- Kusawa2000, mtaylor and druxey

-

3

3

-

-

Okay Druxey and Mark.

I had planned on cutting and dry fitting the whole shabang before gluing anything.

But now I'll be wondering how I'll drill and bolt (pin) the pieces properly when it is one large assembly I'll be swinging around

I was thinking I would do the three sub-assemblies

- stem post assembly

- stern post assembly

- keel, false keel and rising wood

Then I'd put these sub-assemblies together

It must be possible as 'youse guys' (as we say in Ontario) have surely done it.

5am, time to shovel snow or I'll never get to work today.... hmmmm, that would make more time for modeling.

Alan

-

Thank you Mark

That was my initial thought but I didn't want to jump in and bugger that piece also so thought it was best t walk away and come at it fresh.

It is nice to have someone who knows what they are doing come to the same conclusion

I think I'll stack the one on the other and attempt to trace the correcting cut line

I suspect it will not take much.... but not tonight

Alan

-

Ed,

I was a bit concerned about my choice of using the rubber cement because of your comment regarding not being a fan of it. So far it seemed to have worked well ... but it is quite early in the game yet.

On another note, I will be cutting some monofilament line from my fly rod reel to test using it as per your response to my PM. Possibly it needs to be roughed up a bit for the glue to anchor in. Of course it is much lighter and GREEN as opposed to the black line you just used on your YA to simulate the bolts. If it works I'll need to purchase a supply of black line.... that or copper wire and blackening.

Alan

-

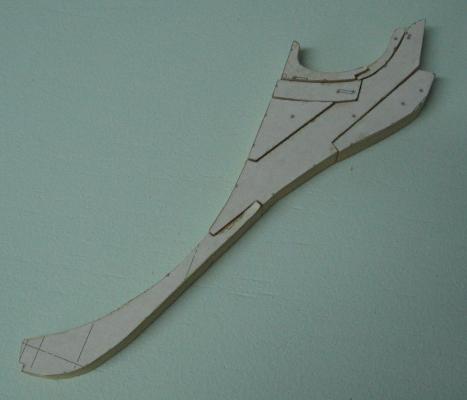

Today I finally started... sort of

- milled down a strip of hemlock to the larger (inboard) thickness of 2'-2" (= 0.406" at 1/64th). I managed to get 0.4045"

- rubber cemented my templates to the strip of wood

- rough cut out my very first piece staying close to or just outside the line

- cut all other pieces

- sanded into shape and fitted together

Everything looks reasonably good when clamped finger tight ... except for the Gammoning Knee pieces. The outer (forward) half does not sit correctly.

Flipped it over to inspect the reverse and again it is those two piece

When I remove them they fit together nicely all on their own. Time to walk away and come at it fresh another day. Not sure if this piece is salvageable or not.

I am obviously no cabinet maker and think I might need a small oscillating drum sander to assure I get a level sanded edge on those inside radii.

I took a lesson out of TFFM. I milled a piece of oak to use as my chiseling base when cutting the scarphs and it made a big difference.

(Thank you David and Greg for a wonderful reference)

- Don9of11, hexnut, harvey1847 and 3 others

-

6

6

-

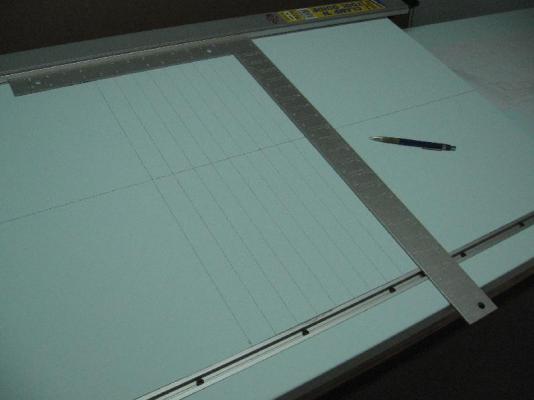

I finished up my modelling table last couple of weekends

- glued and dowel pinned trim on the edges, planed and sanded the edges

- primed and finished painted both tops and also the underside of the tilting half only

You will notice it blends in nicely with the workroom walls (I had paint left over)

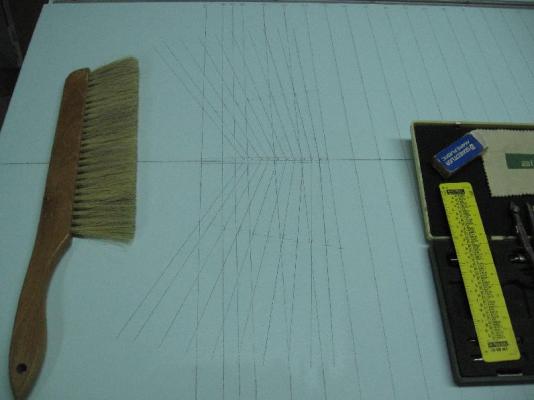

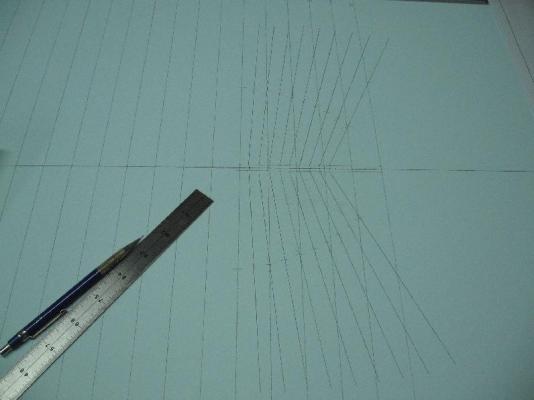

Then I worked on marking the tilt top with reference lines for the model build

- center line

- station lines

- fore and aft cant line angles

Debating whether I should mark the frame locations

I chose to draw it rather than lay a print down as this would have been closer to how the actual build would likely have been done (in my mind anyway).

I will spray seal it next weekend so the pencil marks stay clean and unsmudged

Presently it is stored under a sheet of plastic to keep the dust off

I also pulled all the nails from my second pile of eastern hemlock lathe I salvaged from my son's home.

I now have at least twice this amount (likely more) to do my model.

Although I continue to draw up the frames to make my templates (which a sampling of will be posted down the road) ... it looks like I'll be finally cutting some wood and starting the build tomorrow.... I cut out a few pieces from my printed template of the bow (from the gripe upwards).

I will start by milling down some of the lathe and rubber cementing the templates to it to cut out... just like they did in the 1700's???

-

Hope you are prepared for a flood of messages

Absolutely stunning, beautiful, what a masterpiece....... WOW!

-

HMS Bellerophon 1786 by AON – scale 1:64 – 74-gun 3rd Rate Man of War - Arrogant-Class

in - Build logs for subjects built 1751 - 1800

Posted

Hello Mark,

Thank you for visiting and for the suggestions.

I have the set of the three draughts of HMS Elephant and one of Goliath.

I also have copies of the build contracts for HMS Bellerophon and Elephant.

Being an old time draughtsman in this new age computer drafting world I've chosen to draw a 3D image to create a model of the hull and then 2D templates to start my build. I finally get to use my old instruments again, but down in my workshop.

I hope you will visit again and include a link to your build as I should like to see how you come along!

Alan