-

Posts

675 -

Joined

-

Last visited

-

Scottish Guy reacted to a post in a topic:

For Beginners -- A Cautionary Tale

Scottish Guy reacted to a post in a topic:

For Beginners -- A Cautionary Tale

-

Pitan reacted to a post in a topic:

Le Coureur 1776 by captain_hook - CAF - Scale 1:48

Pitan reacted to a post in a topic:

Le Coureur 1776 by captain_hook - CAF - Scale 1:48

-

FrankWouts reacted to a post in a topic:

HMS Winchelsea - FINISHED - 1764 - by Chuck (1/4" scale)

FrankWouts reacted to a post in a topic:

HMS Winchelsea - FINISHED - 1764 - by Chuck (1/4" scale)

-

FrankWouts reacted to a post in a topic:

Sloop Speedwell 1752 by Chuck - Ketch Rigged Sloop - POF - prototype build

FrankWouts reacted to a post in a topic:

Sloop Speedwell 1752 by Chuck - Ketch Rigged Sloop - POF - prototype build

-

Old Collingwood reacted to a post in a topic:

Sam's Study by masa - FINISHED - Robotime - Scale Approx. 1/12

Old Collingwood reacted to a post in a topic:

Sam's Study by masa - FINISHED - Robotime - Scale Approx. 1/12

-

dunnock reacted to a post in a topic:

HM Bomb Vessel Granado by captain_hook - Caldercraft - Scale 1/64

dunnock reacted to a post in a topic:

HM Bomb Vessel Granado by captain_hook - Caldercraft - Scale 1/64

-

billocrates reacted to a post in a topic:

HMS Victory c.1765-1791 by Steve Anderson - FINISHED - 1:64 scale

billocrates reacted to a post in a topic:

HMS Victory c.1765-1791 by Steve Anderson - FINISHED - 1:64 scale

-

Obormotov reacted to a post in a topic:

HMS Victory by guraus - scale 1:48 - plank on frame

Obormotov reacted to a post in a topic:

HMS Victory by guraus - scale 1:48 - plank on frame

-

captain_hook reacted to a post in a topic:

HMS EURYALUS by Matiz - FINISHED - scale 1:56

captain_hook reacted to a post in a topic:

HMS EURYALUS by Matiz - FINISHED - scale 1:56

-

captain_hook reacted to a post in a topic:

HMS EURYALUS by Matiz - FINISHED - scale 1:56

captain_hook reacted to a post in a topic:

HMS EURYALUS by Matiz - FINISHED - scale 1:56

-

captain_hook reacted to a post in a topic:

HMS Winchelsea by scrubbyj427 - 1:48

captain_hook reacted to a post in a topic:

HMS Winchelsea by scrubbyj427 - 1:48

-

captain_hook reacted to a post in a topic:

Le Rochefort by No Idea - 1/24th Scale - First POF Build

captain_hook reacted to a post in a topic:

Le Rochefort by No Idea - 1/24th Scale - First POF Build

-

captain_hook reacted to a post in a topic:

Armed Virginia Sloop by CiscoH - Model Shipways - 1:48

captain_hook reacted to a post in a topic:

Armed Virginia Sloop by CiscoH - Model Shipways - 1:48

-

That is a nice little boat, well done! And great photos too.

- 62 replies

-

- Saucy Jack

- vanguard models

-

(and 3 more)

Tagged with:

-

Thank you guys for the support. I don't want to give up but this task will definitely slow me down quite a bit and I have to move on carefully as I don't have much scrap wood for spare parts left. Precut-planking sucks! @Beckmann Yes, I use a heat-gun for pre-bending the planks. But clamping them helps a lot to fix them in the right position until the glue has dried. @Chuck Thank you. I will keep that solution in mind if I fail to use the precut-planking properly. @mtaylor Yes, you're right - per aspera ad astra.

-

captain_hook reacted to a post in a topic:

Le Coureur 1776 by captain_hook - CAF - Scale 1:48

captain_hook reacted to a post in a topic:

Le Coureur 1776 by captain_hook - CAF - Scale 1:48

-

captain_hook reacted to a post in a topic:

Le Coureur 1776 by captain_hook - CAF - Scale 1:48

captain_hook reacted to a post in a topic:

Le Coureur 1776 by captain_hook - CAF - Scale 1:48

-

captain_hook reacted to a post in a topic:

Le Coureur 1776 by captain_hook - CAF - Scale 1:48

captain_hook reacted to a post in a topic:

Le Coureur 1776 by captain_hook - CAF - Scale 1:48

-

Today I have started planking the outside with the first two planking rows on the starboard side. This is pretty much testing my patience and perseverance. No. 25 consists of four parts and no. 24 of three parts. No parts is fitting exactly from the start as they are longer and wider as needed. So you’re able to make custom adjustments but this takes a very large amount of time. As the cnc-milled rabbit is only about .5 mm deep you have to taper / flatten all parts of no. 25 to fit into that rabbit too. Took about 3 hours to finish one row and there are 23 more rows to go … I caught myself thinking about starting another project several times and this might be the final task to decide if I will continue building this model next year or just switch to a more suitable project like the Cheerful which has been waiting for me in the shelf for about 3 years now. As the cherry stripes are slightly rotated around their own axis from center to bow and center to stern to fit the hull several clamps are needed to fix them in position until the glue has cured. Another problem is that the plans do not show exactly where the overlap of the clinker-planking begins for each row - so it’s about 3 cm at the bow and 5 cm at the stern for no. 24. So that’s it all for this year, have to help my wife preparing the New-Year-Party. Stay tuned .. and happy new year! Andreas

-

As there were plenty of other things to do before Christmas I didn‘t quite find the time for modeling - but I will return to my build in a few days and start the planking then. Here in Germany there was some snow falling down last week but now it is just raining all day. But I heard a lot in the News about a heavy blizzard running through the USA and I hope all of you living there are ok and able to stay save until it is gone. Seems like Santa Clause has also visited my workshop and left a little Christmas tree there. I wish everyone on MSW a happy Christmas and - if you have any - a nice holiday. See you all here next year again ..

-

captain_hook reacted to a post in a topic:

USF Confederacy 1778 by WalrusGuy - Model Shipways - 1:64

captain_hook reacted to a post in a topic:

USF Confederacy 1778 by WalrusGuy - Model Shipways - 1:64

-

captain_hook reacted to a post in a topic:

The Hayling Hoy 1760 by Seventynet - FINISHED - 1:48 scale - First fully framed model

captain_hook reacted to a post in a topic:

The Hayling Hoy 1760 by Seventynet - FINISHED - 1:48 scale - First fully framed model

-

These VM kits are like some sort of 3D-puzzle. It is amazing how kits have evolved trough the years - compared to early Caldercraft kits like the Cruiser brig. Nowadays most of the hard work has already been done for the modeler. But James's skills may the building of the prototype look a lot easier than it actually is. BTW I liked the unpainted one a lot more - such a shame to cover all the nice wood ..

- 473 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Nice start! Good luck with your new build and hope you will recover soon. I also lost my modeling-motivation for about a year and still have to force myself to start the next intended step. But when the first 30 minutes have passed I‘m into it again for hours. But you‘re right - a small project is a good way to get experience of success and light the fire again ..

- 55 replies

-

- marisstella

- batelina

-

(and 1 more)

Tagged with:

-

I have done some more small steps that have to be done before planking of the ship will start. I prepared all supplied planking strips and removed all the laser char with 120 grit sanding paper. I had to exchange four planking strips as well because of small defects in the cherry wood and used them as templates for new ones made of scrap wood. There are 25 planking rows on each side and the planking layout used on one side is mirrored on the other. That is a lot of work ahead and I hope to finish both sides before Christmas. And I closed the gaps between the inner and outer planking left and right of the frames that are still viewable with small pieces of scrap wood. On the real ship this may have been done to prevent things falling between the planking sheets. At last I sanded the stern planking to the final shape. I‘m still a little scared about the clinker-planking but will start with that major step the next days. Stay tuned ..

-

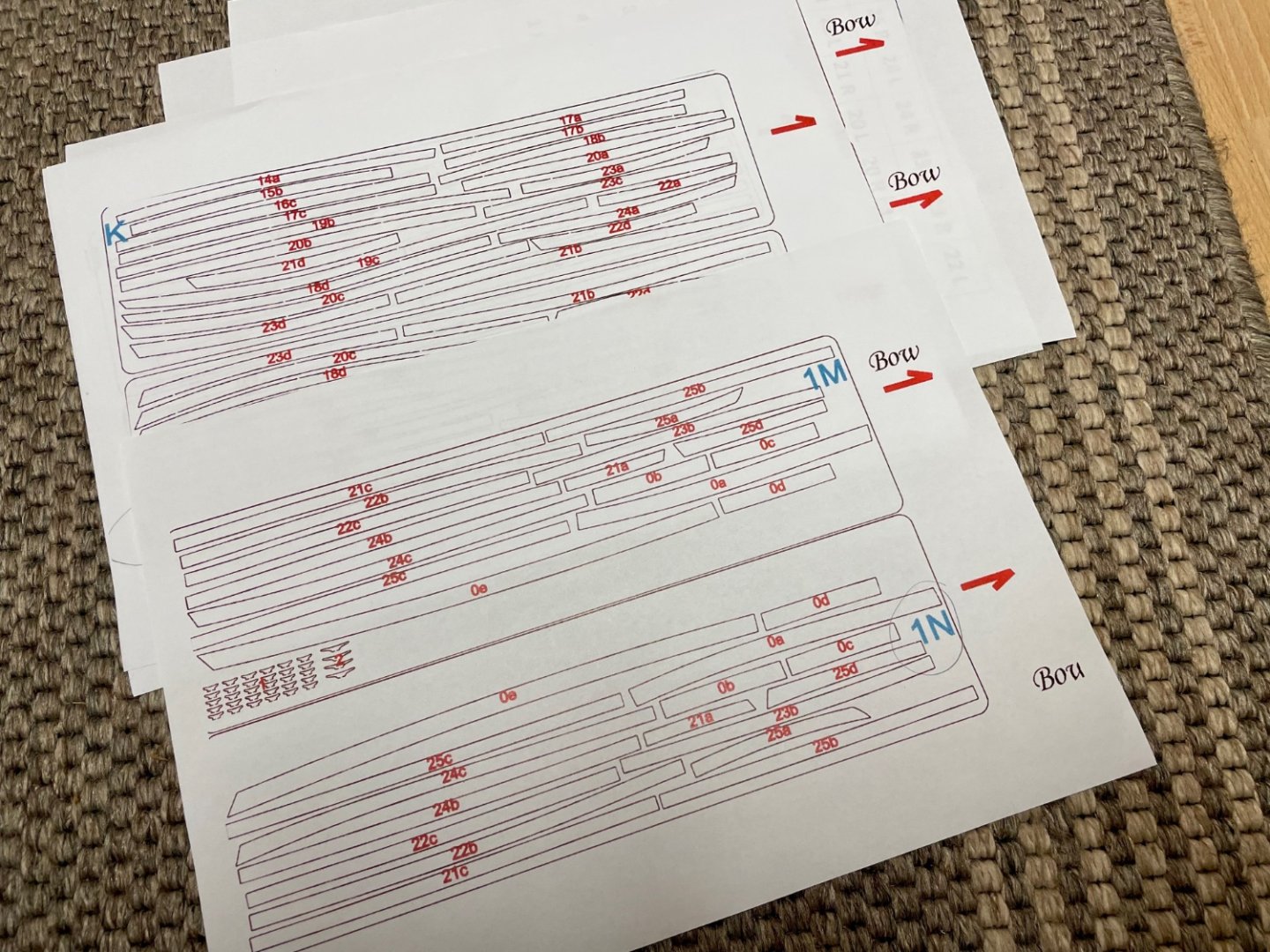

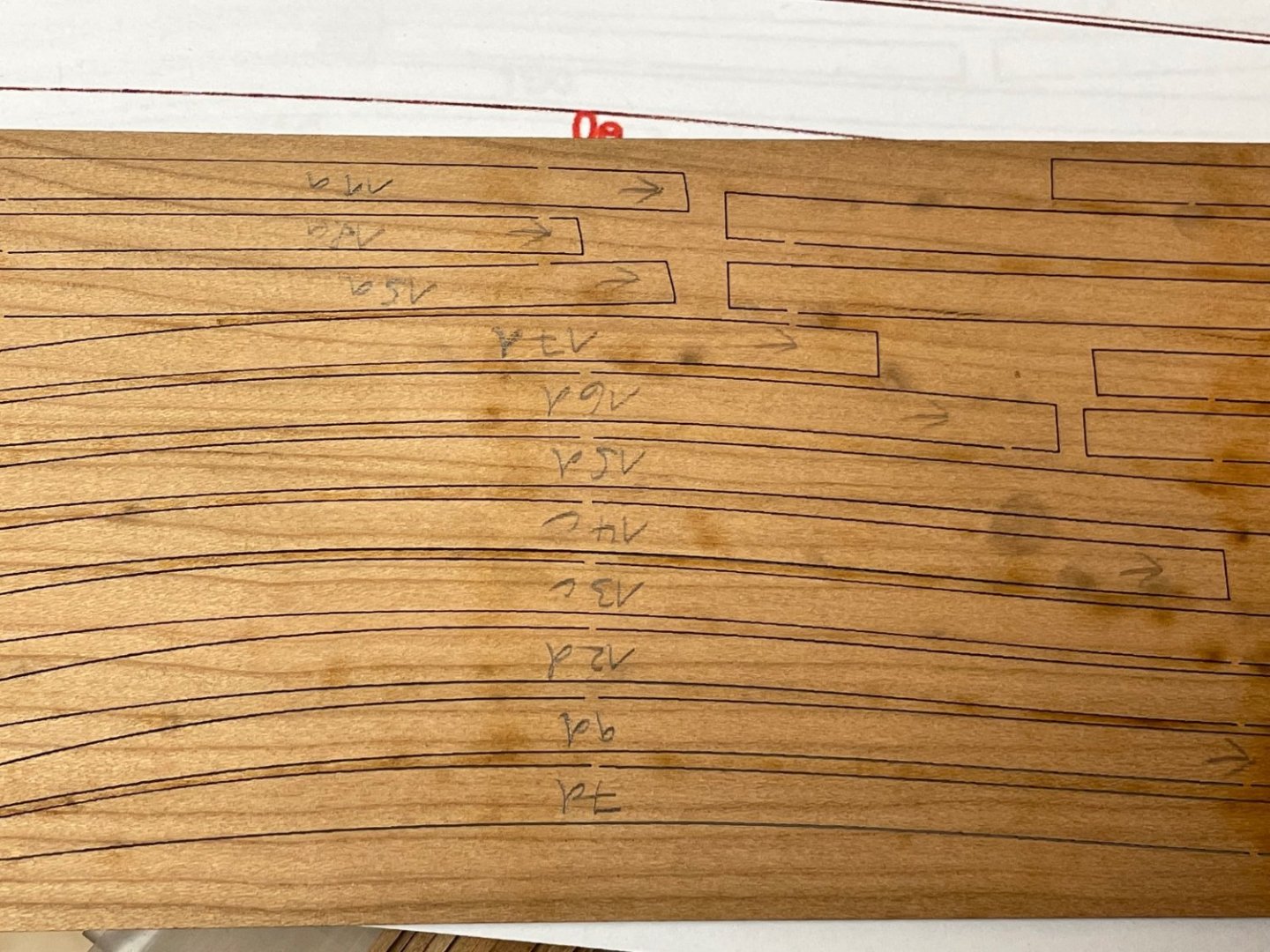

I did some preparation prior to planking the sides, this will help me ensure that the precut-parts are not mixed up later. I first enlarged all the precut-planking parts list pages from the manual for better reading the numbers and orientation, then transferred all part numbers and a small arrow to indicate the directions to the bow onto the lasered parts with a pencil. Then I carefully released all the precut-planking parts out of the sheets and selected them by the corresponding planking row, usually 3 or 4 parts per row. - starting with an A at the bow to C or D at the stern. These parts will need some cleanup, removing of the laser char as well as some adjustment to fit the hull later. And I may substitute strips with defects by parts made of scrap wood if necessary. As I have plenty of plastic bags laying around in my workshop I used them to group all parts of each row. I also scanned the plan showing the planking run on bow and stern with my computer, printed these areas on heavy paper, glued them temporarily onto the keel with some tape and transferred the planking run by pencil to indicate the width of each plank there. After this preparation I‘m now ready to start planking with the first 2 rows No. 25 and 24 bottom-up on port side. I‘m a little scared .. For me this will be the most difficult construction step as this will be my first clinker-planked ship, every part still needs to be brought to shape and there is little scrap wood for spare parts. I hope not to mess it up. Stay tuned ..

-

Ah, and I forgot to tell: It is far more easier to cut the hole for the rudder at this stage (before you plank the stern) than doing this as the manual suggests far more later. I did it using a drill and several needle files before planking the stern and reshaped the hole after I finished the planking. You can check the shape of the hole with a scrap wooden strip (4mm x 5,3mm) - if you can turn the strip inside the hole the shape is just right.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.