-

Posts

272 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by KennyH78

-

JJ, if you hadn't told us that the QGs structrure was 3D printed, one would not be able to tell that. Fantasic job in making it look like its all been made of wood.

-

JJ, lookig really good! You have to look really hard at the QGs to see that they were 3D printed.

-

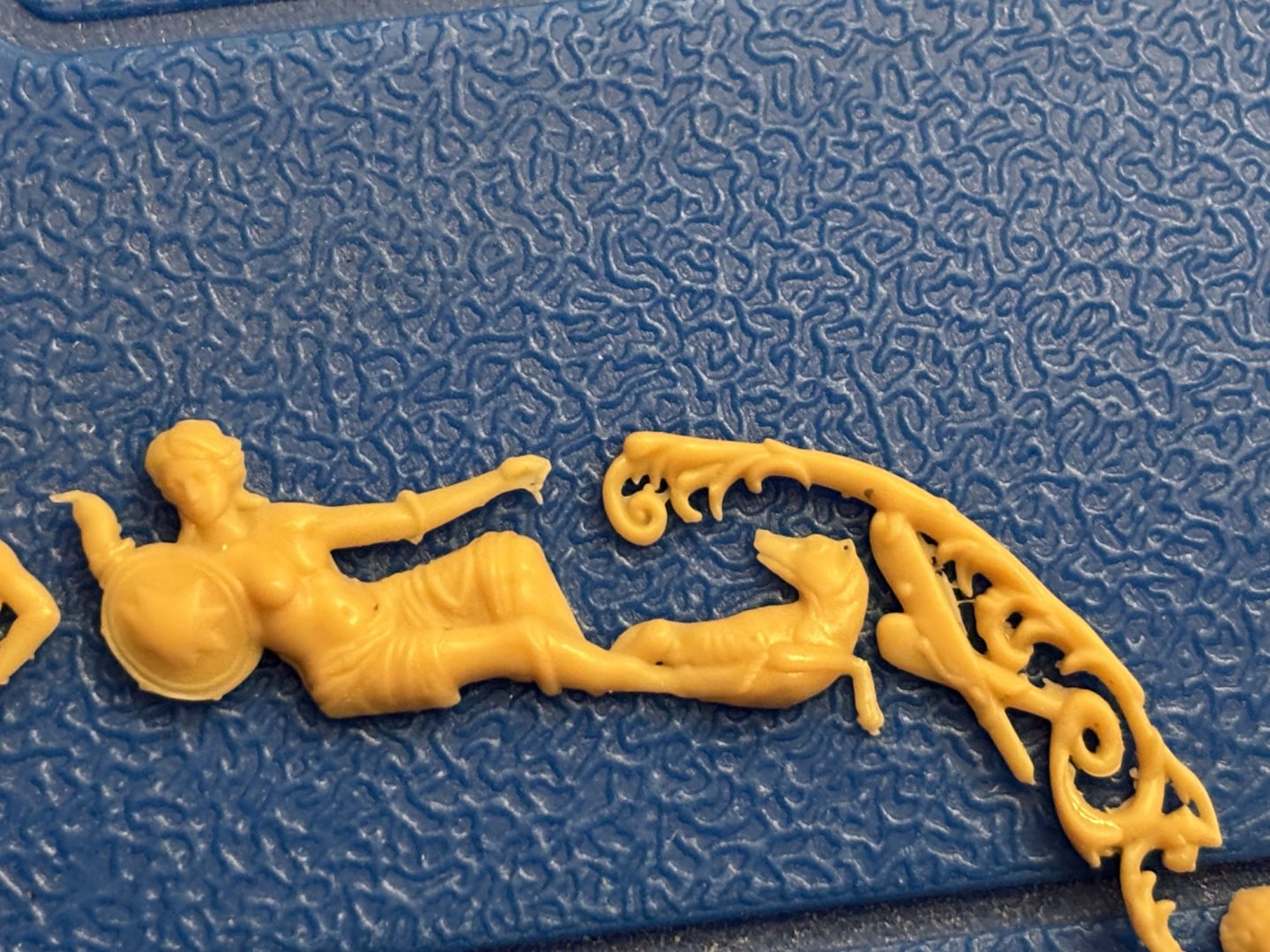

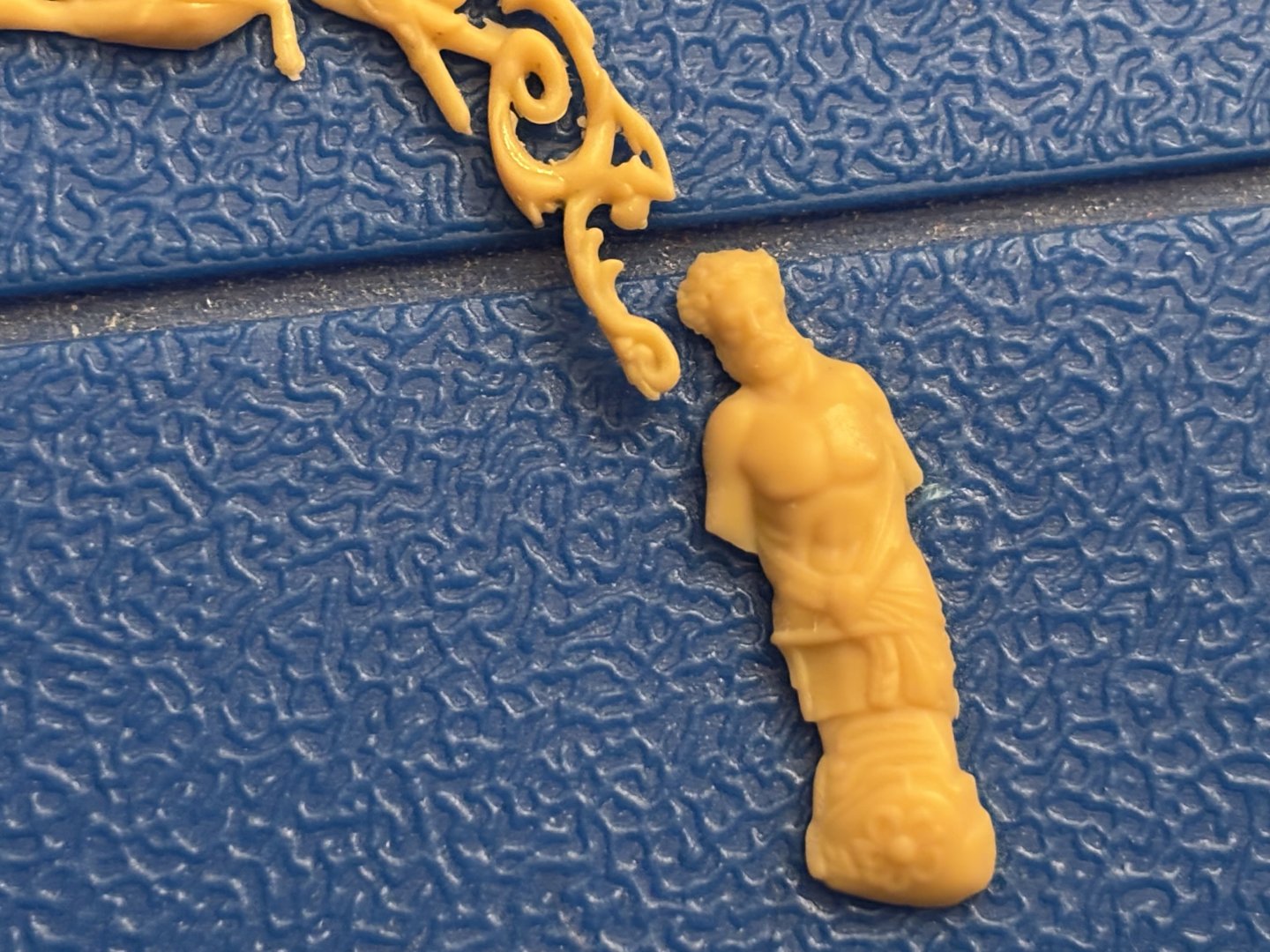

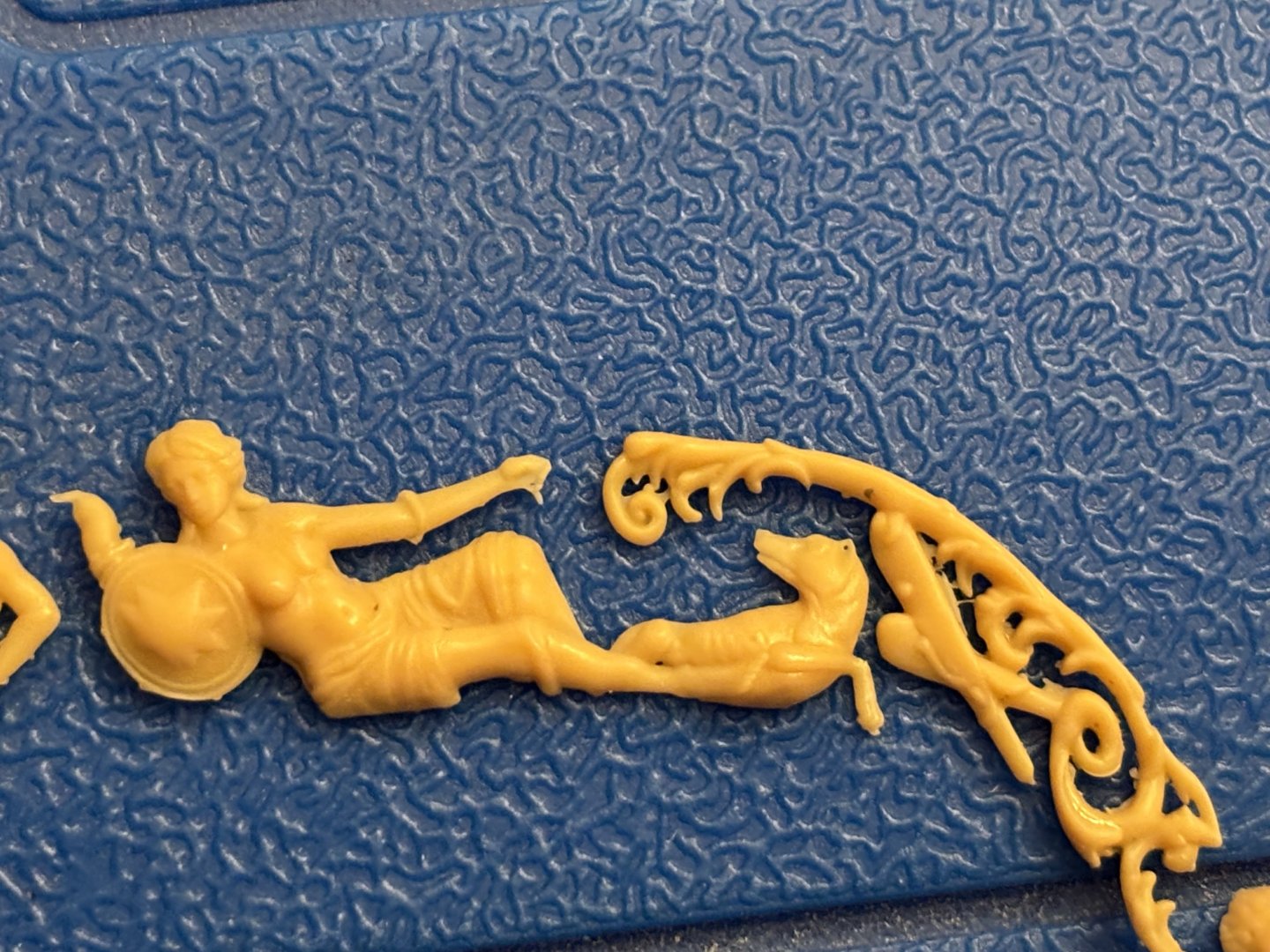

Here are the files for the 7 main carvings on the stern of the USF Confederacy. Let me know if there are any issues with them. Confed Stern Carving 1.stlConfed Stern Carving 2.stlConfed Stern Carving 3.stlConfed Stern Carving 4.stlConfed Stern Carving 5.stlConfed Stern Carving 6.stlConfed Stern Carving 7.stl

-

New Decoration for 3D printing

KennyH78 replied to GustavG's topic in 3D-Printing and Laser-Cutting.

These figureheads are awesome. What program(s) do you use to create your stl files and bas reliefs? -

Igor, your prints looks awesome! They definitely look better than the white metal one supplied in the kit from Model Shipways. I am still trying to sort out how to make up some stl files for the stern carvings that look good for my build. You wouldn't be willing to share where you got your prints from, would you?

-

I have been playing around with meshy as well and think that I have come up with a better figurehead than the white metal one suppled by Model Shipways for the Confederacy kit. I did a test print and am happy with the results so far. although I need to make him a little taller. The final print will be done in a beige/tan color. I may also try to model in the indention for the stem before doing the final print. As you can see, the meshy product is 10 times better than the kit supplied one.

-

Filament Dryers for 3D Printing

KennyH78 replied to Kevin-the-lubber's topic in 3D-Printing and Laser-Cutting.

Thanks for sharing this tip. I know that FDM printing is not widely used in our hobby, but I have been trying to find ways to use them along with my resin printer. I will definitely look into picking up a filament dryer for my FDM printers. -

She is starting to look like a miniature ship. I got the decks, bulwarks and stern piece attached. The keel is also on the model, but isn’t glued in yet. I will get it permanently attached before the bottom edge of the keel is removed so that she can sit on water in the bottle. Next up is the task of painting the hull.

-

Glen, as others have said; hitting the “wow” button doesn’t convey the amount of awe factor for your build. This is truly exceptional! How are you going to top this build?

- 156 replies

-

- Queen Annes Revenge

- bottle

-

(and 1 more)

Tagged with:

-

Glen, the stand you made for the model is gorgeous. Can't wait to see the completed SIB on the stand.

- 156 replies

-

- Queen Annes Revenge

- bottle

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.