-

Posts

269 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by KennyH78

-

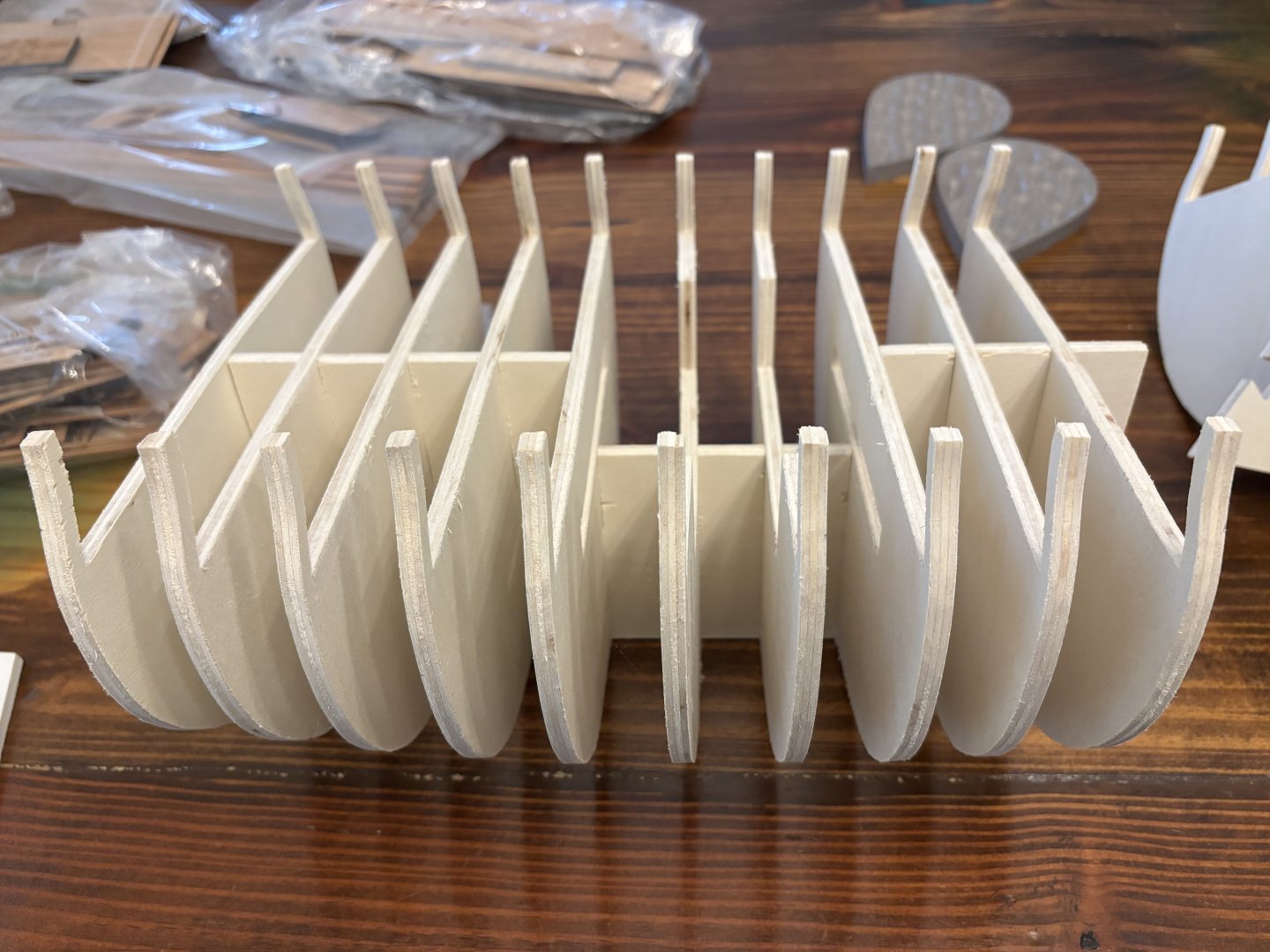

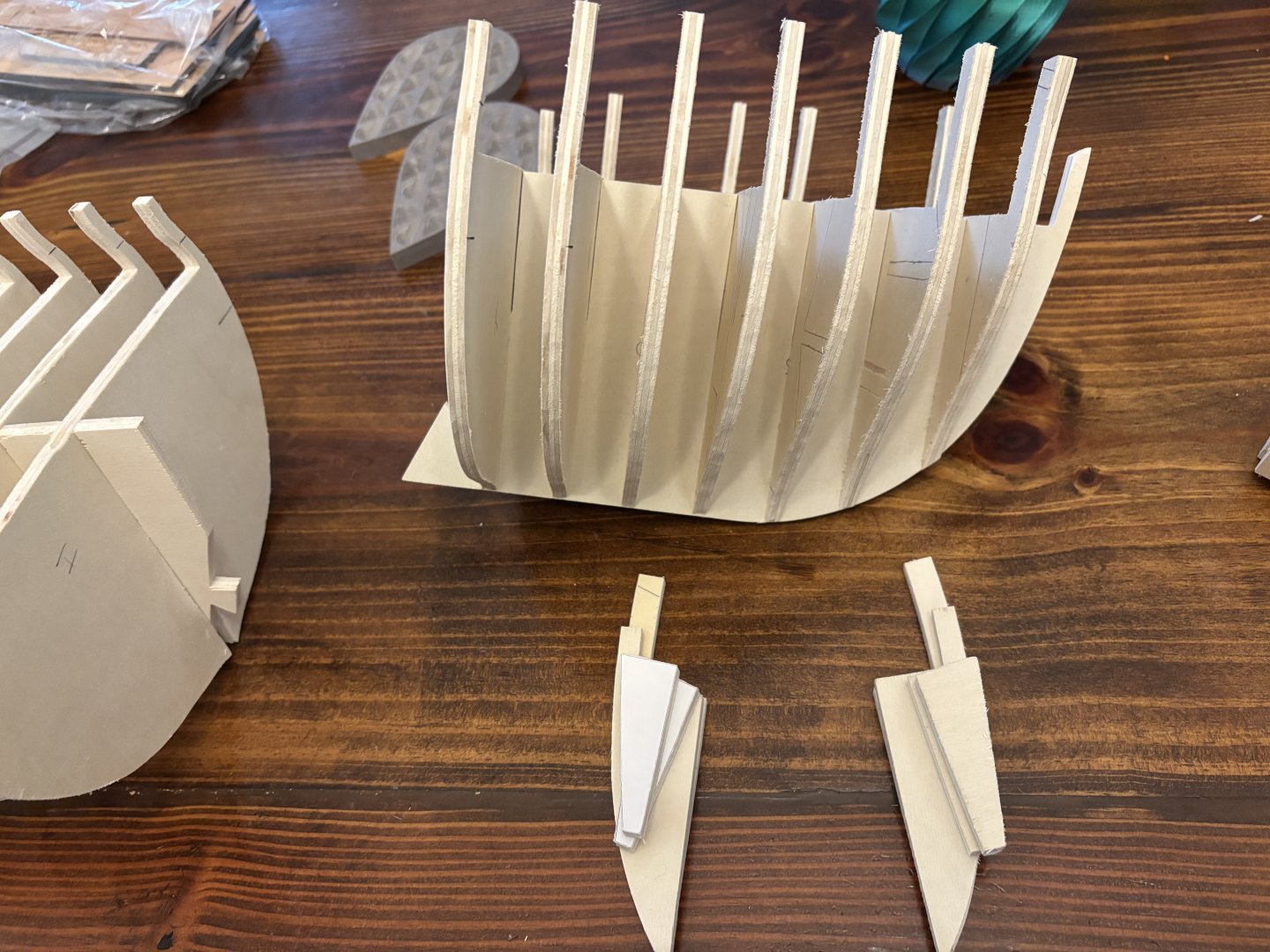

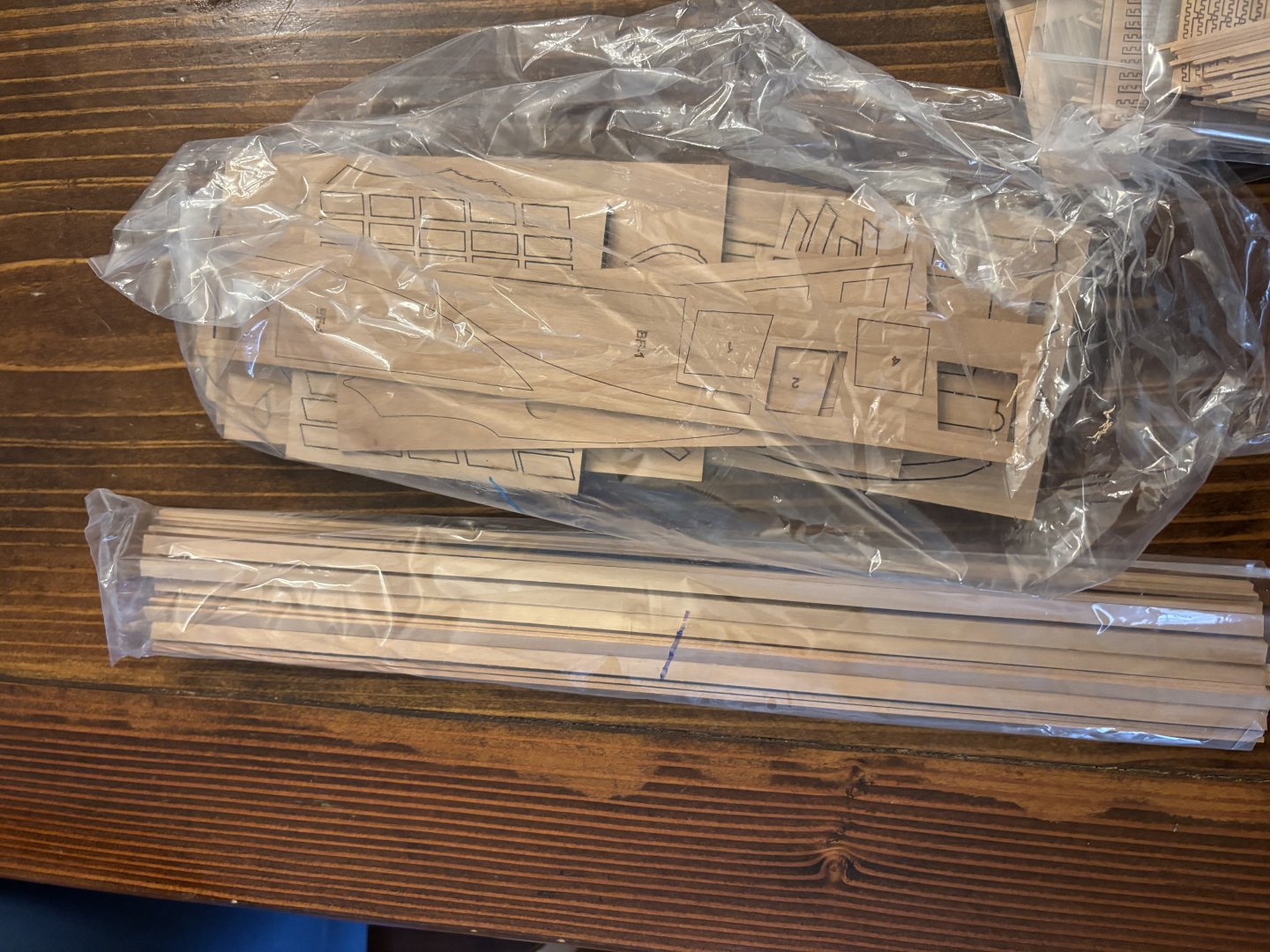

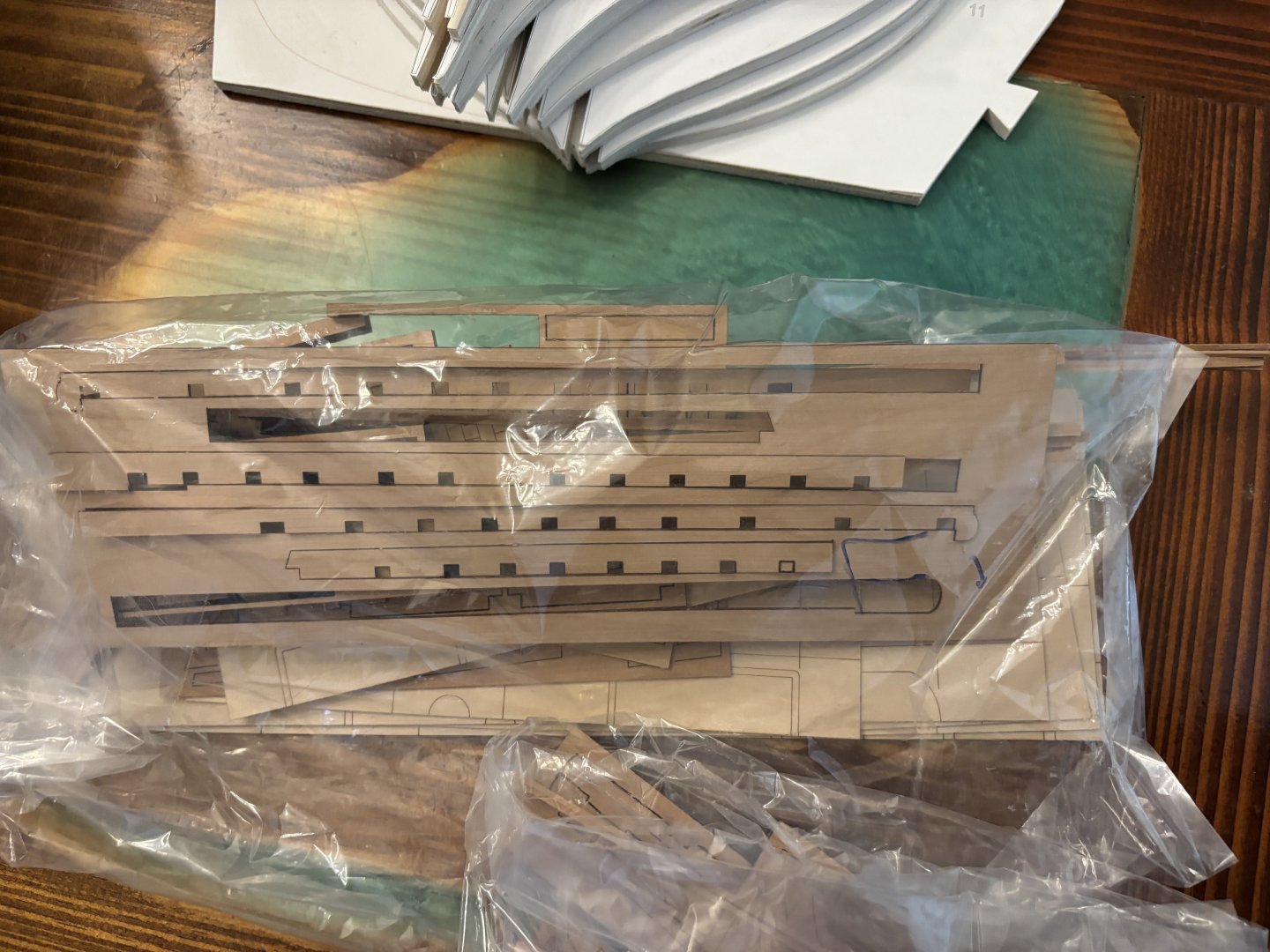

I am looking to sell my cut out frames and false keel along with chapters 1-5 for Chuck’s HMS Winnie build. I am selling it because I don’t think that I will be able to get back to the build before all of the rest of the chapters are sold out on his site. I also have the figurehead kit going with it as well. Most of the frames have already been fitted to the false keel (none of the frames have been glued to the false keel), the aft section still needs some final fitting done. I’ll separate the frames from the false keel pieces before shipping. I am asking $300 plus shipping for the whole lot. PM me with any questions you may have.

-

Glenn, the boarding ladder came out beautifully. And no one would have know about the slight mishap when turning her over if you hadn't mentioned it. A testament to your work and attention to detail!

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

She is looking quite exquisite! Beautifully done!

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

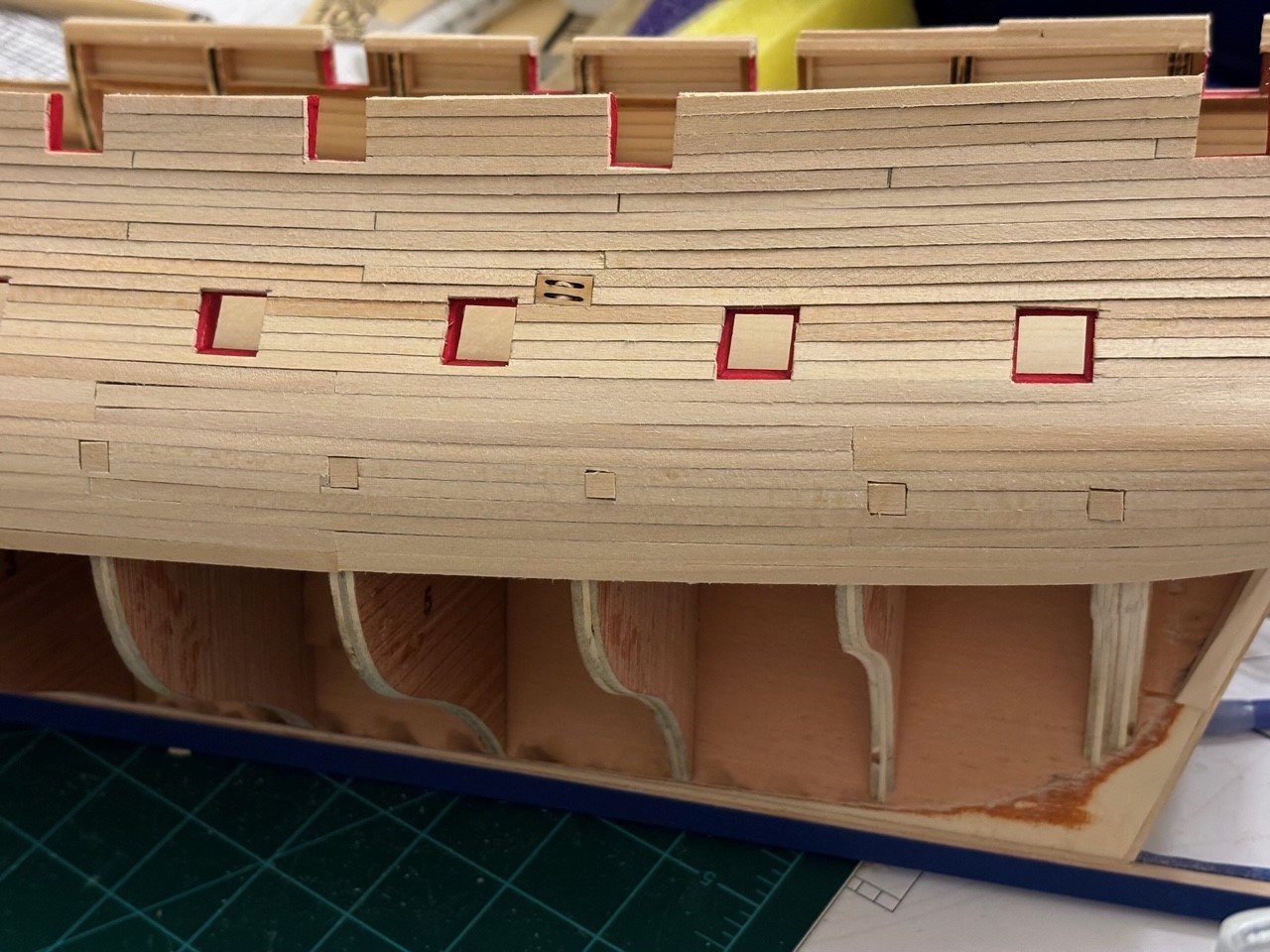

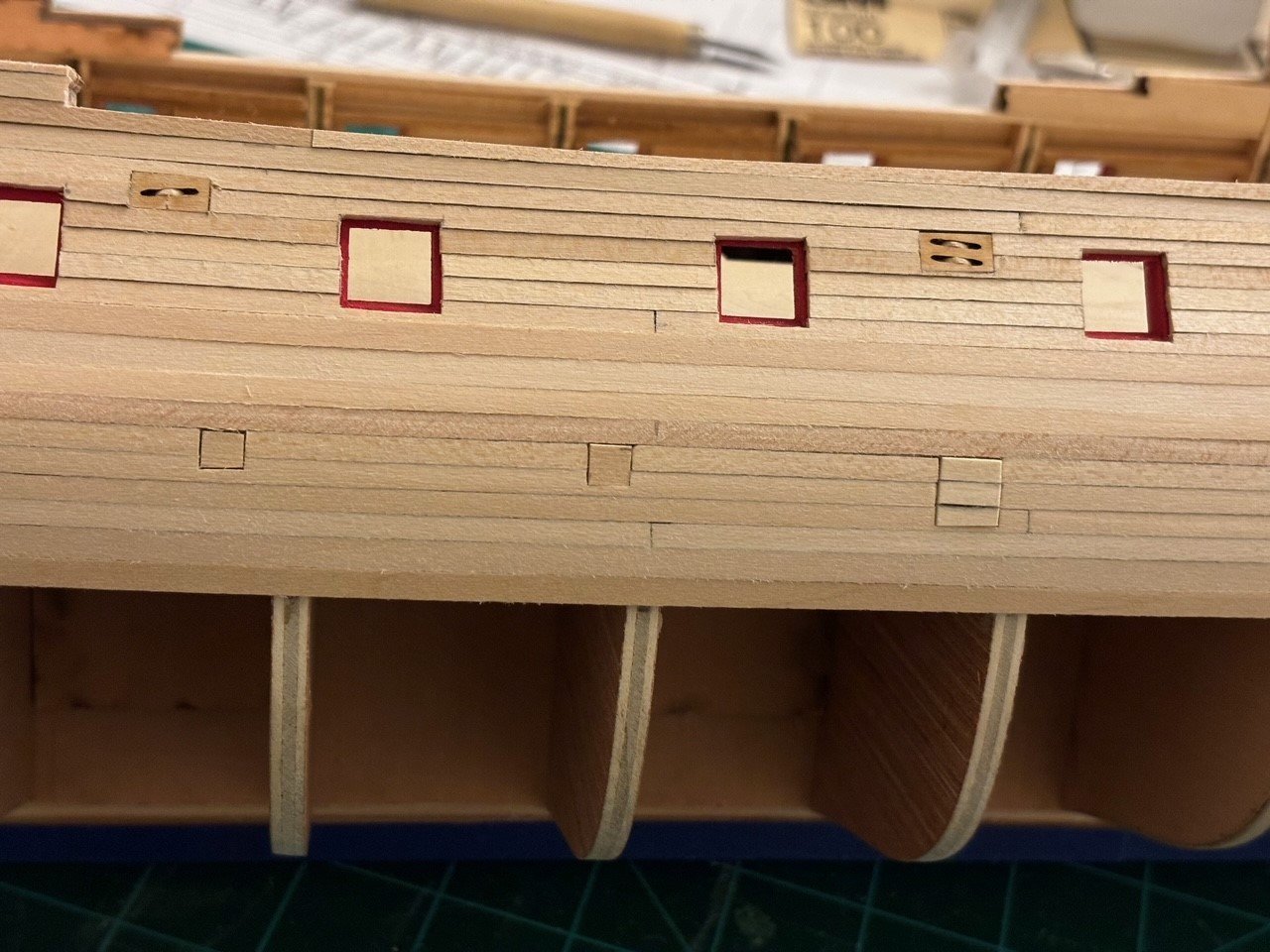

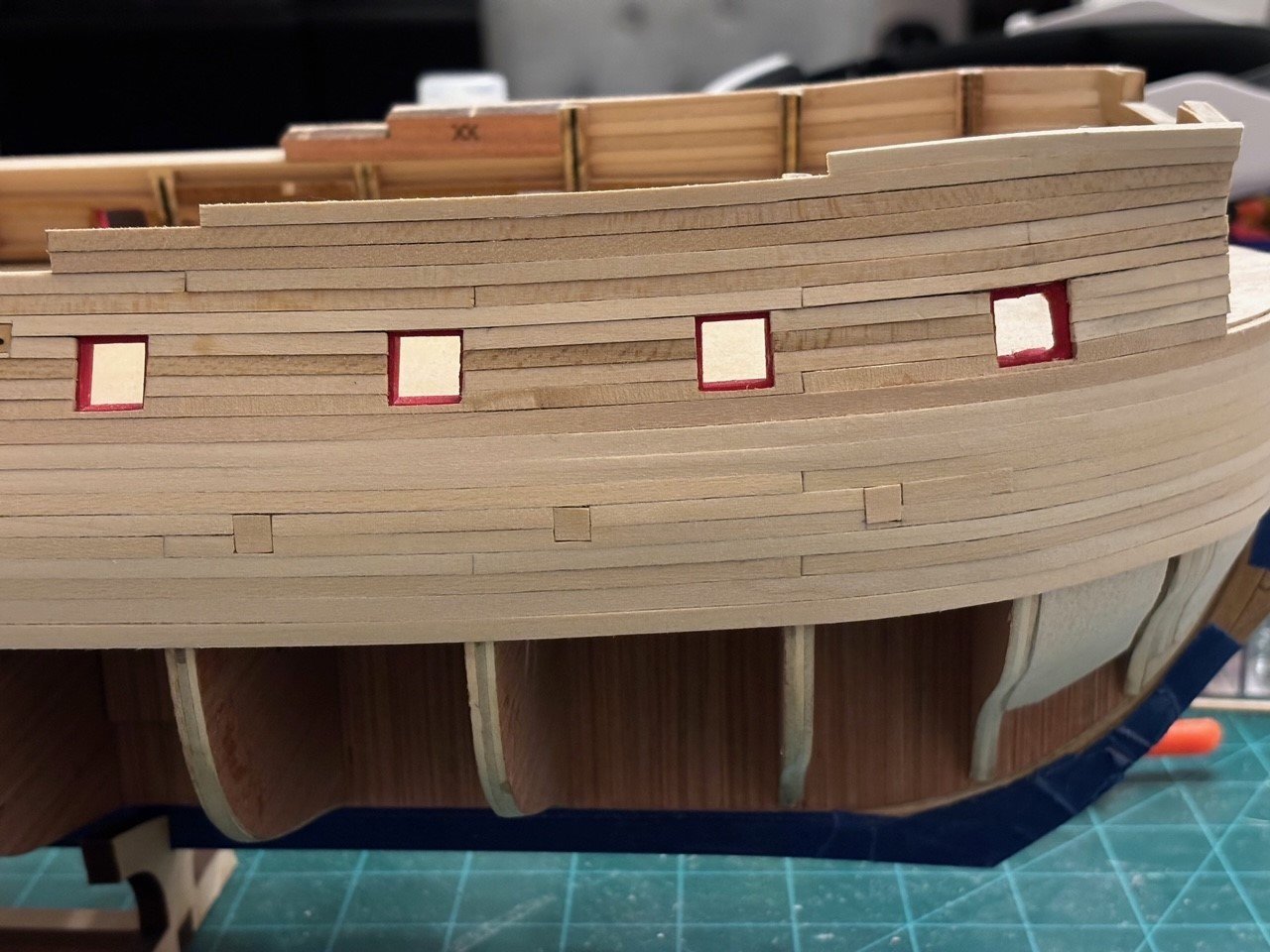

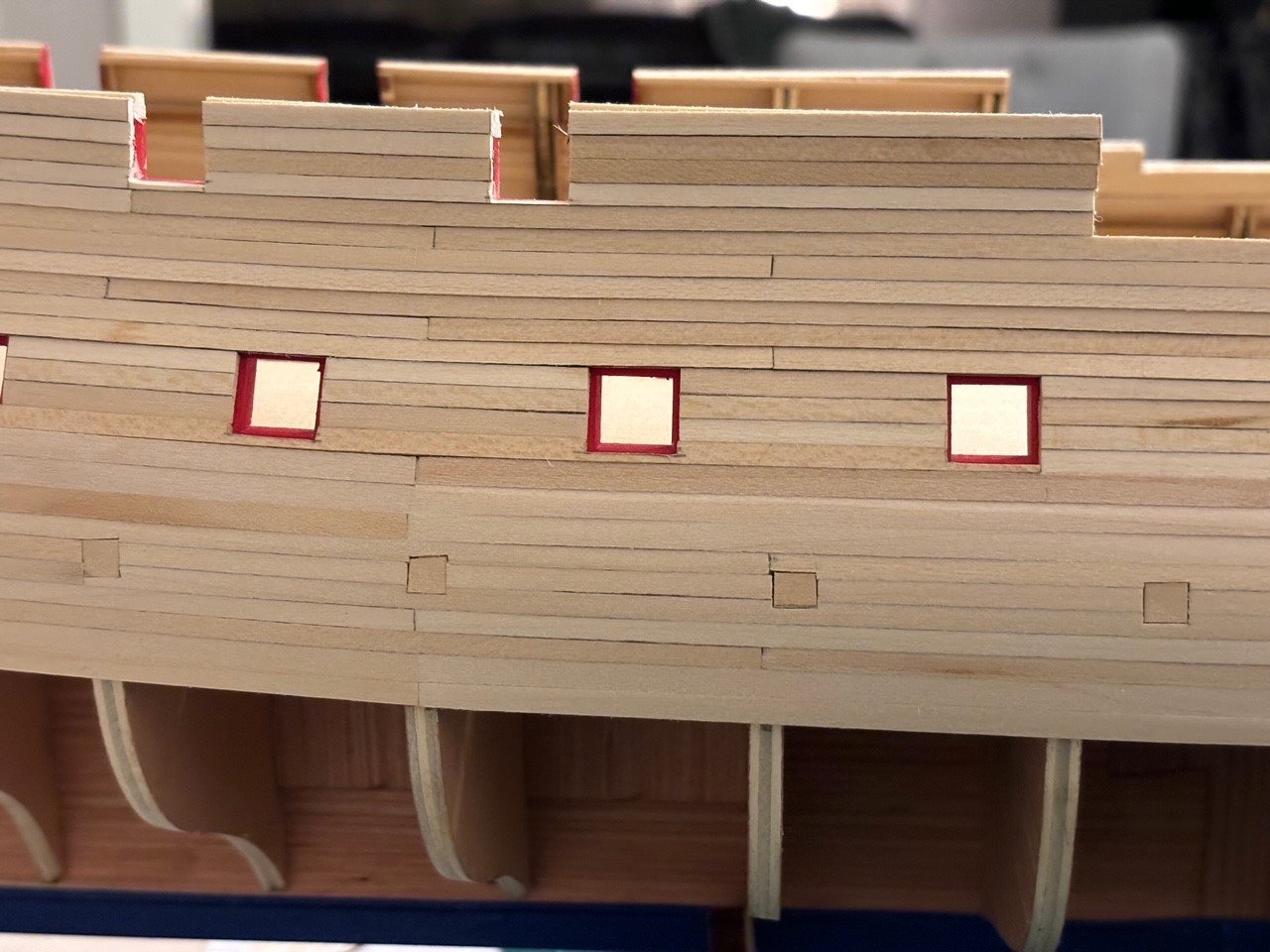

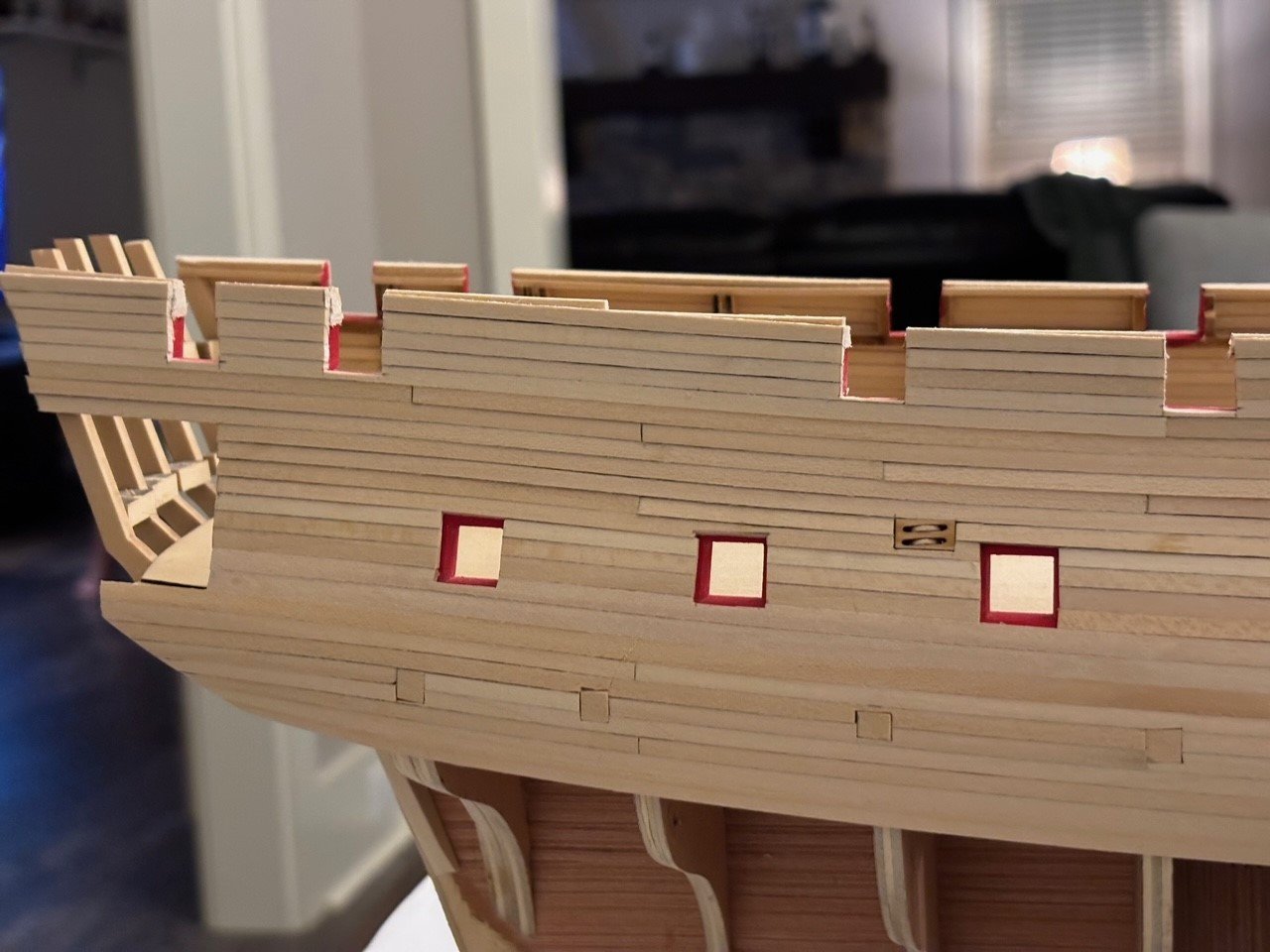

Starboard side is now planked up the sheer. The port sweep and ballast port lids have also been installed. The port side sweep ports and ballast port lids have also been installed. Next task is to do a rough sanding on the planks, install the remaining 3 blanks for the main wales on both side and then install the second layer on the main wales, channel wales and black strake.

-

JJ, coming along nicely and I must second the comment by Allan on the attention to detail. Your model will look stunning next to your Winnie. That really sucks, I hope that you are able to get your timber back. Seems like you just can't trust anyone anymore these days. That is why I have cameras set up all over the exterior of my house.

-

Looking really good. Glenn. She is shaping up to be a very superb model.

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Why am I always late to the party? Simply amazing with the design and build so far, I will be following along intently with my bucket of popcorn and chair.

-

Finished up the planking above the wales on the port side. It just needs sanding to smooth it all out before adding the second layer for the channel wales and molding and sweep port covers. I'll sand it after I finish up the starboard side. To get the rabbet consistent on the gun ports, I used my guitar string set up rule since it provides measurements down to 1/64 of an inch. I have also decided that I will be painting the hull the above the wales instead of staining it. I like the look of the painted hull better.

-

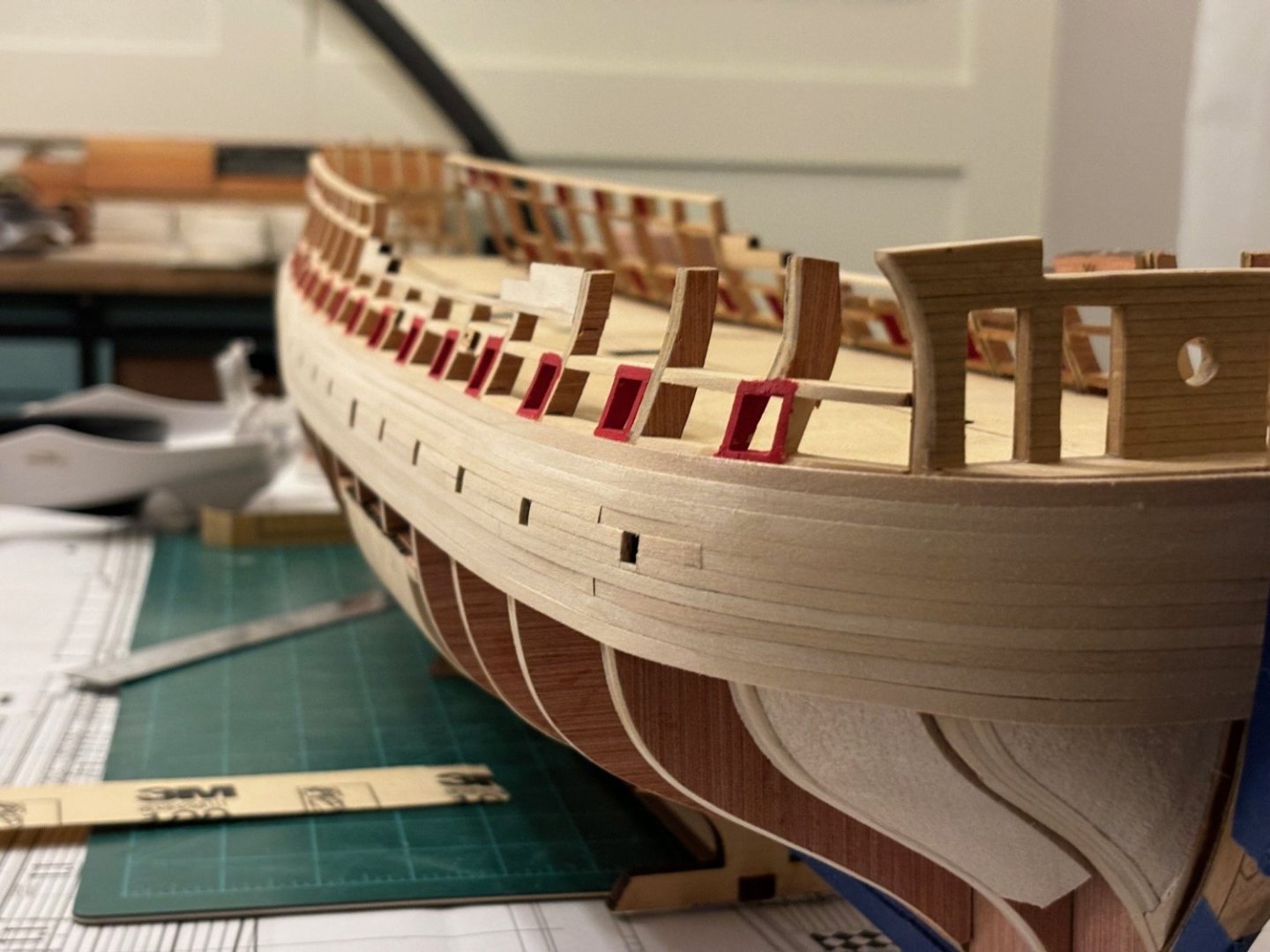

Had about an hour's worth of shipyard time today, so I decided to do a rough sanding on the planks that I already installed on her. I am very happy with how it turned out. I also cut some replacement 5/32 x 1/16 strips from some sheets that I picked up from Hobby Lobby (got tired of waiting on Model Expo to mail out the replacements I requested over a week ago). As always, thank you for all the likes and all comments and critiques are always welcome.

-

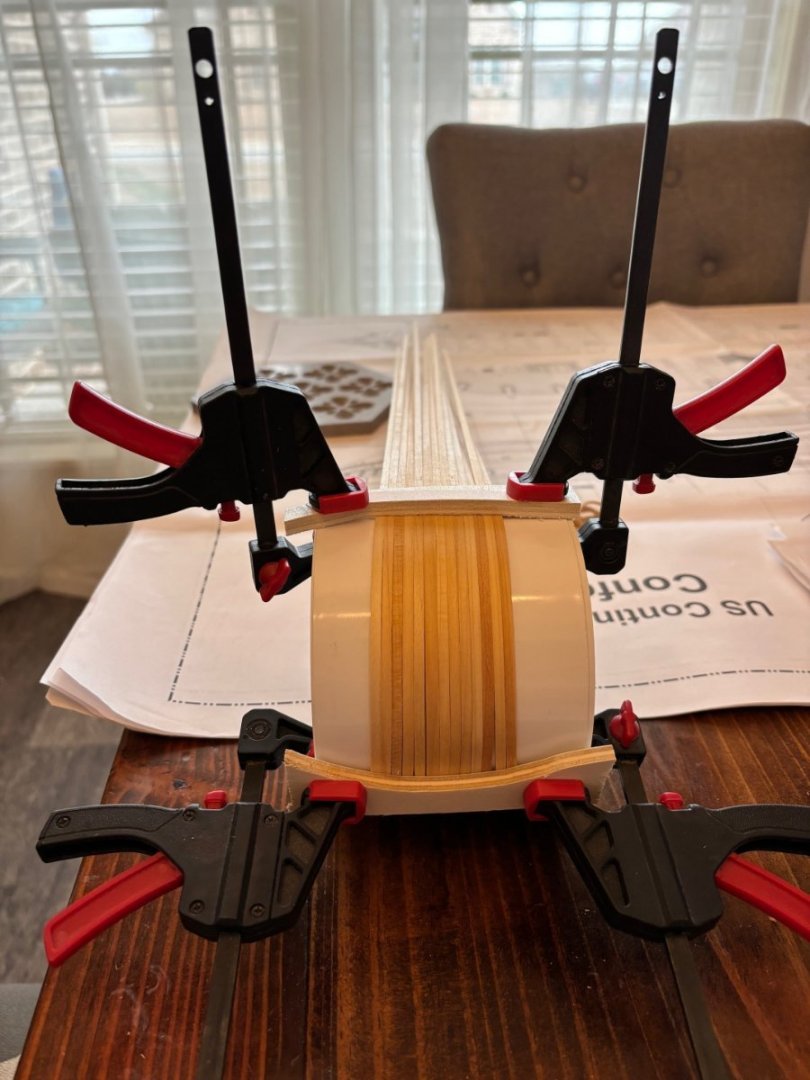

Still waiting on the replacement timbers from Model Expo; boy are they slow. I did get them to email me the templates needed for the sweep ports. I got those printed out and cut out and marked the hull with the locations of the sweep ports. Then I commenced to planking once again starting with the first layer of the top strake of the wales and black strake. Then it was 5 strakes of planking above that followed by 3 strakes of the first layer of the channel wales. Next step is to give all of these strakes a rough sanding before continuing on with the planking above the wales. So far I am much happier with the planking the second time around. Only time will tell if I will be painting or staining the hull. Got the idea of using a piece of 4 in PVC tube to bend the planking material from another member's build log. I must say that it worked out great.

-

Just awesomely fantastic! Right on par with Chuck's prototype in my opinion. I will definitely use your log as one of my resources for my build.

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Glenn, I just finished reading through your entire log (took a while) and I must say that your Winnie is a work of art! I will definitely use your log along with Chuck's and a few others as I start my journey down the path of the HMS Winchelsea Group Build.

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Reading through Glenn's log as I begin my journey on my own build of the Winnie; I have been saying the same thing as I sit on Amazon adding things to cart and checking out.

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

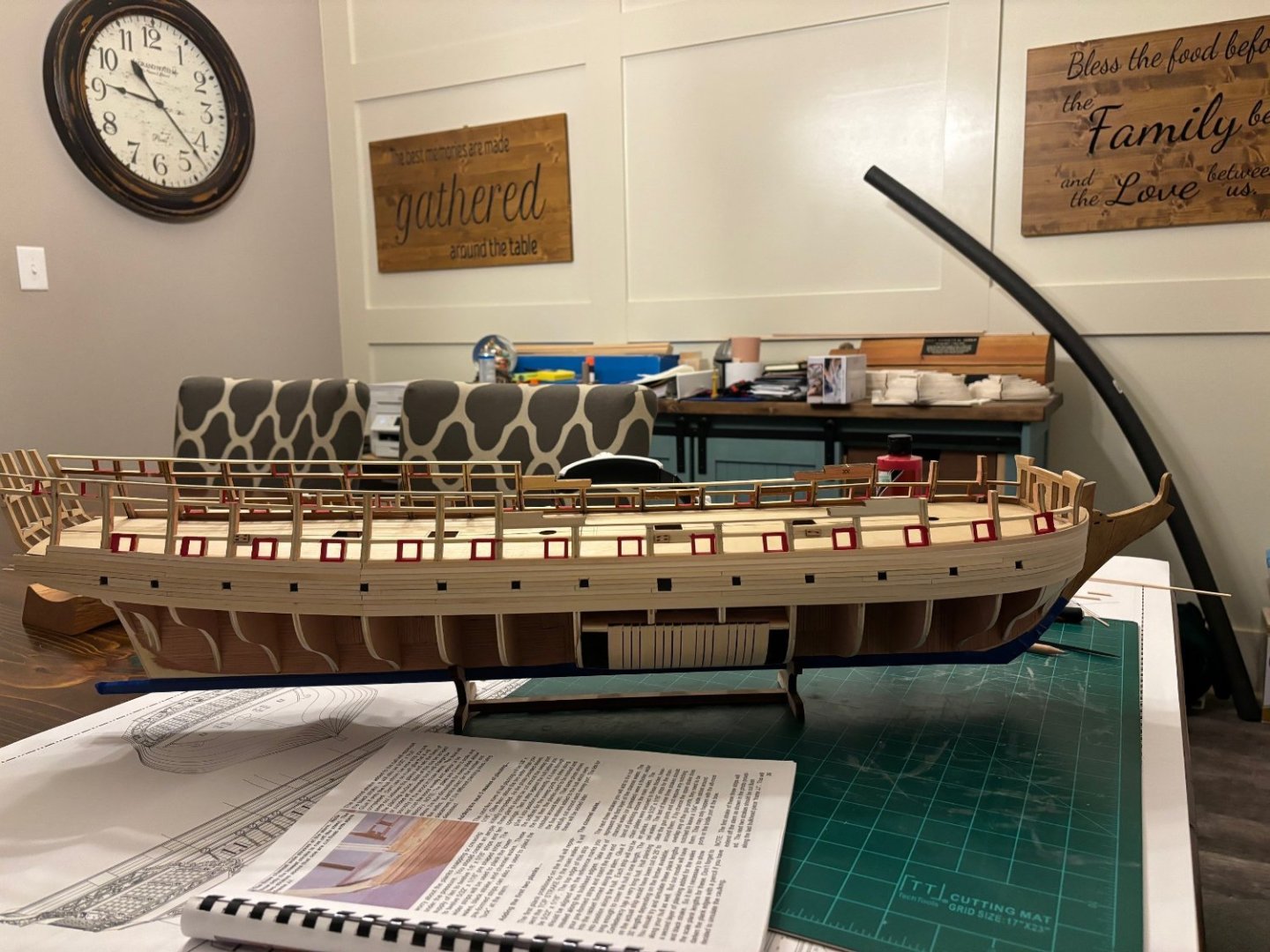

So the more I look at the planking so far, the more unhappy I am with it. Plus the sweep ports do not have a nice flow to them on the port side. So I have decided that I am going to rip off all of the planking and start again. I have already requested extra planking strips and sheet 5 of the plans for the templates from Model Expo. My plan is the rip off all of the planks currently on the model, lightly sand to get the bulkheads smooth again and then redo the port sweep locations and restart the planking process. In the meantime, I will practice planking a hull with the NRG's half hull planking kit that I purchased. I am trying to figure out the best way to get the nice smooth curve for the planks at the bow. I may even decide to use a different type of wood other than the supplied basswood. I have a couple of billets of roasted maple, a nice big billet of maple and some cherry that I can mill down into planks for the hull. Any and all comments and suggestions are welcomed and encouraged.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.