-

Posts

269 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by KennyH78

-

Truely amazing work, Glen! This has me wanting to attempt a SIB build although I probably won't be able to achieve anything is spectacular as your build.

- 156 replies

-

- Queen Annes Revenge

- bottle

-

(and 1 more)

Tagged with:

-

She's a beaut, JJ! Very impressive model; can't wait to see what chapter 3 has in store.

-

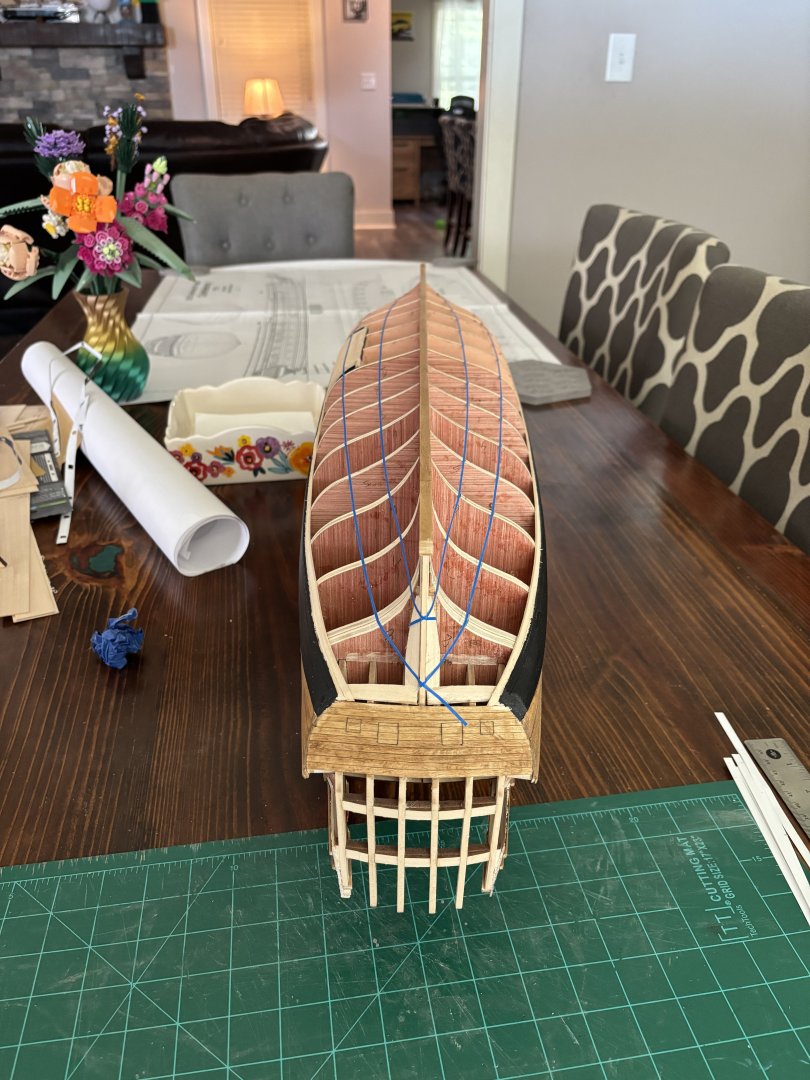

Planking on the starboard side is progressing at a steady pace. I hope to have it finished up by the end of the weekend. So far, the first belt is completed and the second belt is 1-2 strakes away from being halfway done. Once her hull is fully planked, I will need to switch gears and show Chuck’s Medway longboat some planking love.

-

WOW! I just can't help, but be amazed by the level of detail you are able to show at such a small scale. Really can't wait to see the completed project.

- 156 replies

-

- Queen Annes Revenge

- bottle

-

(and 1 more)

Tagged with:

-

She is looking really nice. I love the CNC'd figure head and stern carvings. I think I may not have mentioned this before, but I love how you combined POB and POF model into a hybrid model!

-

Finished planking the port side of the hull today. I also gave that side a rough sanding with 80 grit and 100 grit paper to smooth out the planks. I will come back with 180, 220 and 320 once the starboard side is completed. I am debating on applying a coat of WOP to the planks to help protect them. All in all, I am quite happy with how it turned out, especially since this is the first big hull that I have planked. Anyways, here are a few pics of the port side.

-

vaddoc, I am going to pull up a chair and follow along. I also watched Leo's YouTube series on rebuilding Tally Ho and thought about building a model of her. There is something about her story that just draws you in. I may still attempt a model, but that is a long way off; I need to learn how to draft a set of workable plans for a build from the lines plans first.

-

deck planking options

KennyH78 replied to manning16's topic in Building, Framing, Planking and plating a ships hull and deck

I like the look of the holly against the cherry; but that is just my humble opinion. I like the contrast of the two woods together. Although the boxwood would give the model a nice subtle look on the other hand. As others have suggested, do some testing to see which looks better to you. -

Got the first belt on the port side finished. I think I will continue on the port side before I move onto the starboard side. So far I am happy with how it is progressing. I did have to redo some of the planks at the stern because it didn’t look right to me. I toyed with the idea of just letting it be, but ultimately decided that I can do better and that I would be happier if I just went ahead and fixed the planks. I sure am glad that I did.

-

Been lurking for a while, following along silently; but I have to say that your SIB is coming along nicely. I am quite amazed as to how anyone can make a model that detailed in such a small scale and then make it fit into a bottle. Well done, Sir!

- 156 replies

-

- Queen Annes Revenge

- bottle

-

(and 1 more)

Tagged with:

-

Looking really good, JJ! Following your progress on the prototype makes it very tempting to get one of your production kits.

-

Chris, she is almost ready to raise sail and get underway! Looking real good, better than mine, lol. Any thoughts on how you plan to display it when finished?

- 38 replies

-

- 18th Century Longboat

- Model Shipways

-

(and 1 more)

Tagged with:

-

Planking below the wales has begun. First thing I did was to line off the hull and separate the hull into 3 belts. Then I started planking the first belt on the port side. I am about half way through with this belt, it will consist of about 9-10 planks. So far I am pretty happy with how the planking is progressing.

-

Work area pictures only

KennyH78 replied to Johnny Mike's topic in Modeling tools and Workshop Equipment

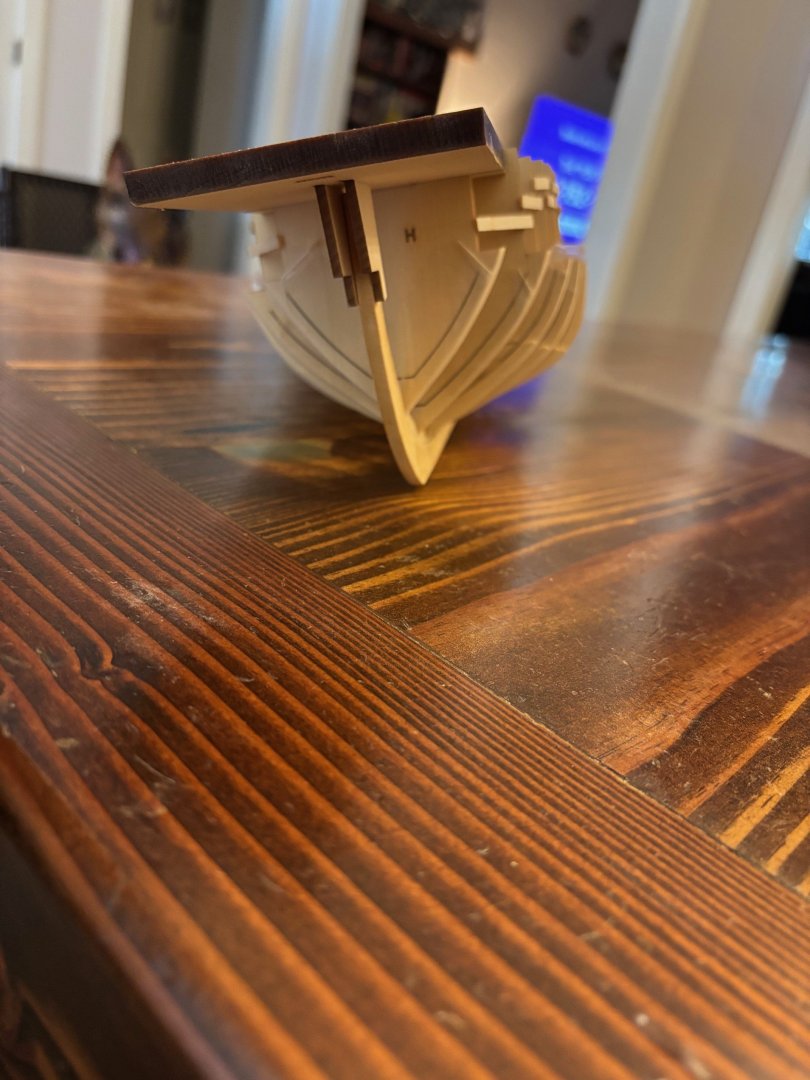

My temporary spot at the dining room table. Eventually, I hope to have my own hobby room once my oldest finds his own place. The power tools reside in the garage turned into woodworking shop. -

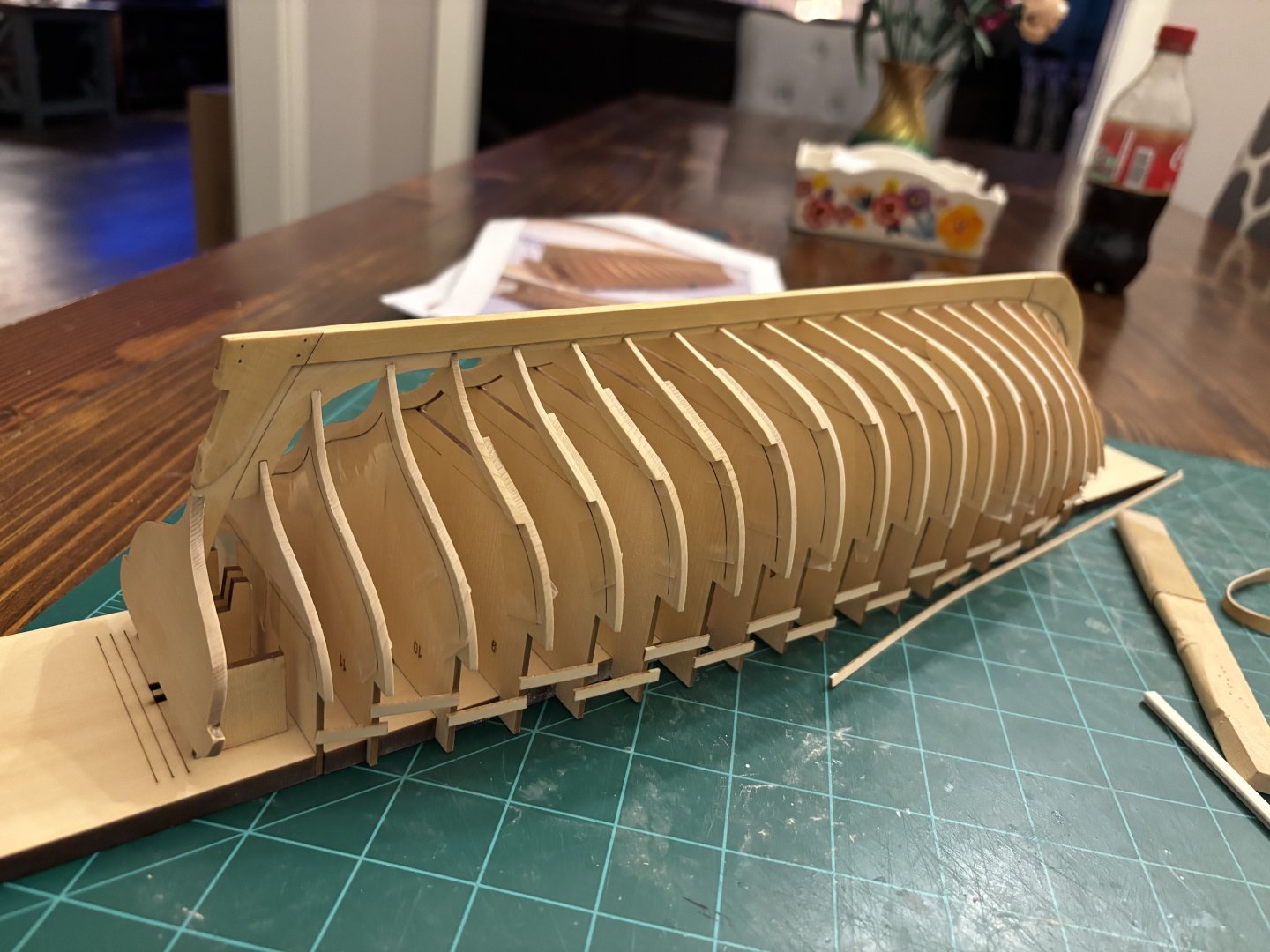

Finished fairing the port side of the hull. I’m pretty happy with it. I took my time and used a variety of tools (as seen in the last pic) to get the job done. The foam blocks worked great on the middle frames and then I used a combination of the sanding sticks the white foam sanding files, all 320 grit, at the bow and stern. Now I just need to repeat the process on the starboard side.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.