-

Posts

757 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by the learner

-

I wish I had more time to Barbeque because I do love meat cooked on the barbie (not the doll)! Mark I will try your method though! Good news is that I got my bandsaw blade back repaired and had a second one made 6tpi instead of the 4tpi that I had repaired, I am hoping that I can get a smoother cut so back to work we go~ Thanks guys

-

I hope I do not have to chuck any glued up frames into the scrap box because they are defective! so far most of the scrap pile is jusy remnants from the frame cut outs left over scrap We have gas fire places here so that won't work perhaps in the barbeque but it too is gas! perhaps I can make a miniture bonn fire on the beach.

-

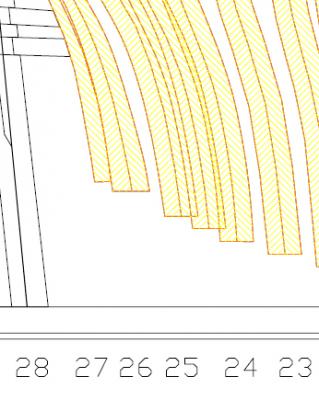

Hi all, there seems to be a frame overlap here on frames 24, 25 and 26 in the stern framing? am I looking at it wrong or are the frames trimed to fit here? as you can see there is not a good fit here...this if from anouthers post for refrence only and One more stupid sounding question! When attaching the frames to the keel should I be adding filling pieces for the floor?????

-

I like the rabet tool you developed, gives you something substantial to hang on too. cutting them out the frame pieces is like eating potato chips hard to stop. I have been doing 5 or 6 frames at a time breaks up the monotony of bending over the jig saw trying not to cut into the lines! I find that my oscillating sander does a good job on both the inside and outside curves. I was in Barcelona last year but missed the maritime museum! Does Madrid have a maritime museum there? I was there in ‘77’ but was not into ship models then. Guy

-

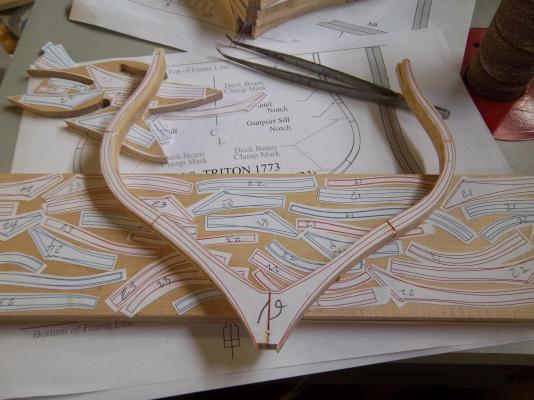

I have started building frames and I am working from stern to stem. I will make up all the frames before I attach to the keel and at the rate I am going its going to take a couple three weeks. This is the adhesive I use for applying the frame pattern pieces to the wood. I find this works better than rubber cement as it tends to stay better when cutting out the piece, but yep the pattern does not come up quite as easy. for the most part I just dampen the paper pattern with mineral spirits and it will lift off fairly easy but still have to clean off the adhesive residue. Placing the patterns on the frame blank board and a few frames in stock As I said before i will make all the frames before I prepare them for attaching on the keel. I have yet figured out how I will cut the angle on the heel of the cant frames to attach them to the deadwood. I will try and involve using the mill ..... we'll see! I will likely have to cut up a few new frames to replace the ones I screw up! I hope it is not too many! To be continued!

-

I have been building my Keel and framing from Maple and I like it! I have heard of others using this wood and all have good remarks about it. I likd the way that it sands and cuts but will burn because of the hardness. I have some pear and will likely use that in the internal construction. are you going to post the drawing of the rum bottle?

-

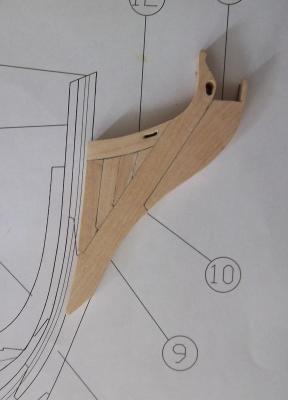

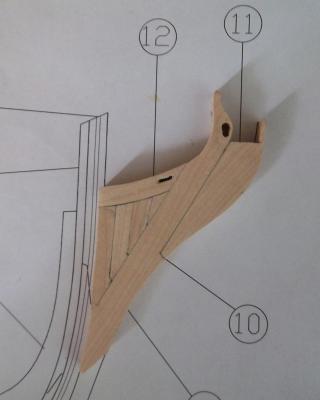

Hi guys! Thanks for the input, not trying to make this difficult but if you look at the drawing it appears that the thickness of the deadwood continues up the stem. I am going to taper it off about the same spot that it would be tapered off on the stern then deal with any additional removal of wood when I attach the frames and the hawse pieces. At some point, I would like to do some profile drawings to show these proportions more clearly. Sorry this is my first upright build so there are still a lot of things that I do not understand in the drawings. In the mean time, I made my first full frame at the stern to start that off.

-

Stumped! does any one from the previous build have pictures of the fore deadwood and the stem piece on how this is formed? I need to know if the thickness of the deadwood continues up the entire stem? The drawing tends to infer that but what few pictures posted on the current build does not display this. Yellow highlighted area! Photo removed because it is a copyright plan

-

Nice technique Ed, I like the layers with the glass between. You do not actually glue the wood to the glass?

-

Thanks Rdsaplala! The next addition I used the mill to shape all the flat sections not perfect but makes for tight joints. I do enjoy using it and should be fairly good at it by the time I start putting in the three piece beams. as this is my frist build of this type I am not going to spend a lot of time doing re-work unless I can not make it look decent...a little wood putty here and there should cover up those mistakes if done right!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.