-

Posts

322 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by schiffebastler

-

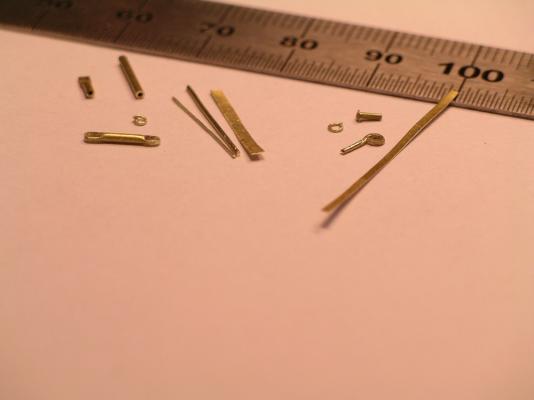

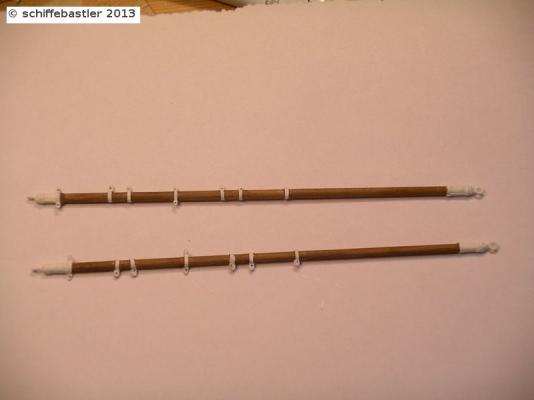

Now, a small continuation. The martingale boom usually is not spectacular but it still took me some time with all the small parts. On the first picture you can see some of the parts, e.g. the 4 reels with an width of 0,4 mm. On the top there is a metal part to connect the boom to the bowsprit. The parts are soldered together. Below there is a golden part at the end of the boom. I produced this from a small part of brass and painted it with golden colour. Here you can see the final boom with all parts, also some metal part which contains eyelets where chains are connected later. So far today, Bye Joachim

-

Thank you Michael, it is really necessary to produce own ropes. The kit contains only 2 types of ropes, a black and a brown one... For the Amerigo I need about 10-12 different types and those I cannot bye with the necessary size and quality. As mentioned before, I could not use any rigging plan of the kit, the reality is quite different from these. So it took lots of weeks, and still will take weeks to achieve good and correct plans of the rigging. Now I start with the bowsprit. So far it is still a very rough shell. One of the unimpressive parts are the thimbles where I need hundresds of different sizes. How you can see on the picture, I use brass tubes in different sizes from 1 to 3 mm diameter. With two drill machines I sand a small groove in it and cut it. On the picture you can see the biggest ones. The bowsprit contains of 3 spares, the biggest two on iron and the last one on wood. There are different reels which have to be put into the spares. Theese have a diameter of 1,2mm. Beside of theese there also needed a lot of metal parts in order to connect the parts of the bowsprit together and fix ropes on it. But as you can see, all parts are not ready so far. And now, to get a first impression of it .... Bye, Joachim

-

Again and again I am astonished about the fantastic results you achieve with your work. Based on a good kit you manage to achive a much higher level than any kit could supply. regards, Joachim

-

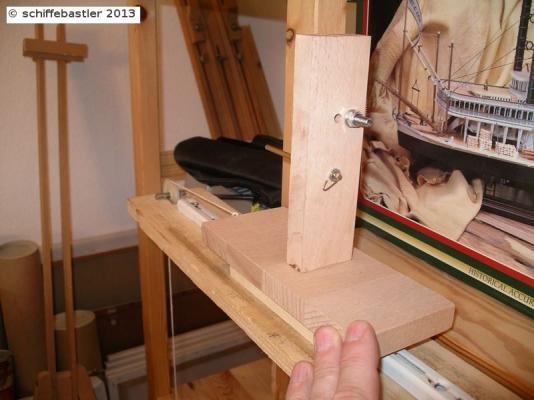

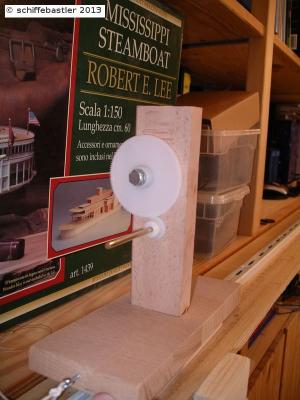

And now, the next preparations, a jig to serving ropes. Due to the fact, that the Americo Vespucci contains steel shrouds I need a jig to serving these ropes. I took the plans from Jürgen Nicklis, but enlarged it a bit. It can be used manually or by adapting a drill machine. Here you can see some examples. In the middle the basic rope which was build of three strands. It has a diameter or 0,8 mm. The upper rope was produced by using a drill machine, the handling is not easy and the result is not good enough. The lower rope is build with manual usage of this jig. It is much better to control and it looks better. But still it needs some practice. Bye, Joachim

-

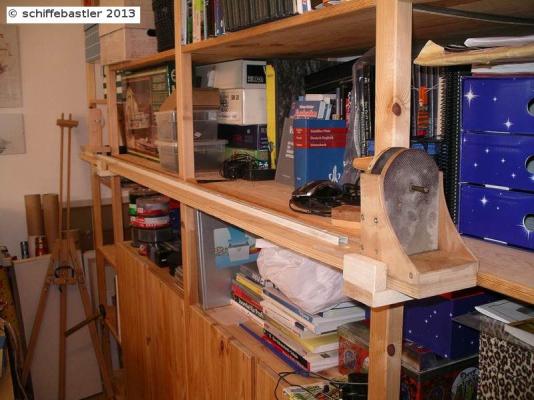

Hello everybody, now a continuation of the Amerigo. The last few weeks I made some tests concerning rigging and I finalised the calculation of thickness of the ropes. For doing this, I based on the lists and calculation rules from Wolfram zu Mondfeld within his book "Historische Schiffsmodelle". First of all I build a rope walk for producing own rops according to the needs. Here you can see the rope walk, fixed on a shelf. And as you can see, the fist results are ready for waste... At the end I succeeded with some examples of the major type of ropes, needed for the Amerigo. Bye, Joachim

-

Hi Michael, I love your courage for modifications, and you are always right doing this! Hope after Christmas I will have a bit more time for my own build log. Now, I wish you a Merry Christmas, Michael Regards, Joachim

-

Hi Michael, congratulations to your new machine! I am sure, after some attempts with it, you will realize wonderful results. Concerning rigging, I see no major problems for you. In the past you showed us so much skill, therefore I am sure, you will also solve the rigging perfectely. Bye Joachim

-

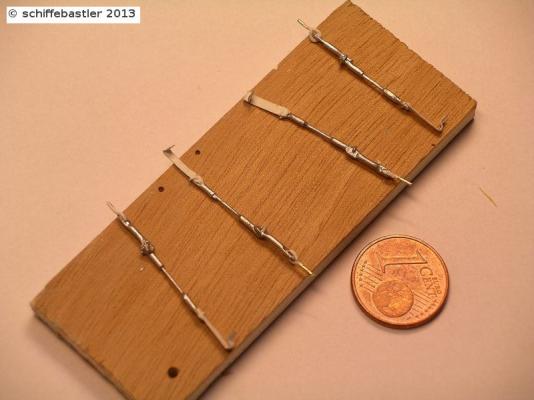

Hi Wacko, thank you for your interest. And of course I like to show you some details. On the enclosed pictures you can see some spare parts, on the left the basic parts of the lashings and on the right some of the basic parts of the fittings for the spares. I used brass plates with a thickness of 0.1mm and cut strips of it with a width of 1 to 1.2 mm, depending on the needs. The clamping screws I build of small brass tubes with an outher diameter of 1mm and an inner diameter of 0.5mm. After cutting parts with a length between 5 and 8 mm (depending on the type), I could easyly press the end of the parts, hone down it and drill a hole (0.5 mm) in it. The connection of the parts of the clamping screws is build with 0.5 mm wire. The connection of the parts is done with rings of 0.3 mm wire, wich I had to build. Similar material is used for the fittings of the spares. The connection is build of small rings which have been honed a bit and connected with small parts of nails. Hope, my description is not too confusing and my english is not too bad, but unfortunately I made no photo while assembling the parts. Bye, Joachim

-

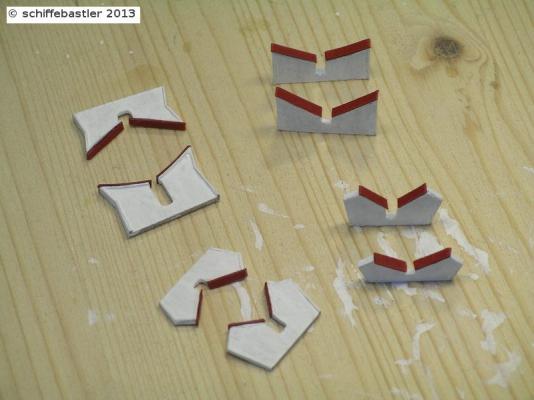

And now the last update for today. These are the last parts before finally starting with the rig. On each front side of the ship there is fixed one spare (sorry, don't know the right english word ...). These are fixed with a head fitting and can swing outside. They are used to attach the boats whenever the ship lays on road and the boats have been launched. In this case a handrail is fixed on top of the spare and the ladders are fixed. Then it is possible to go into the boats via the leashes or the ladders. You can see this on this picture. Also this video shows, how it is used (after 40seconds video). But the spares are also used in order to fix the studding sails, which you can see on this picture. Now, how I made these parts. Fixed on the ship here you can see the head fitting on the back the spare is fixed at the side of the ship with a special fitting, which can be opened. And again a picture of the whole spare Bye, Joachim

-

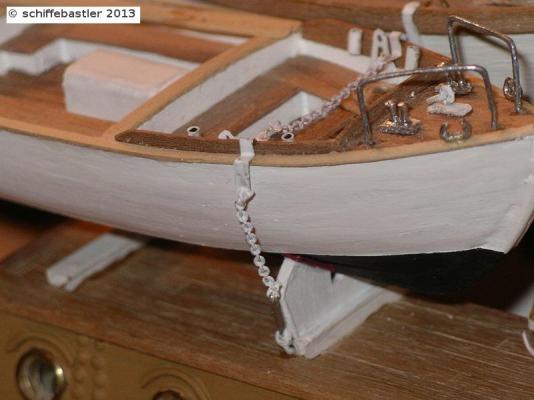

and now again some lashings for the open boats, which are build very similar to the others but contains chains and are also tightened together with chaines. All of the lashings have not been within the kit and had to be designed according to pictures of the ship. First a picture which shows the size of the parts. and now the lashings for the open boats Bye, Joachim

-

After the boats had tested the clamps, the had to be removed again, because there have to be build individual lashings. They are build of metal strips and fixed on top of the boats. The lashings are tightened with clamping screws. The parts are really small, e.g the metal strips are 1.2mm wide. Bye, Joachim

-

Hello everybody, the last post has been long, long time ago.... but it is going on now. Perhaps, somebody will find the way again to the Amerigo... Now the last things, which have been made. First of all the boatclamps. Again they are build according to pictures from the ship. They have to be fixed on the frames on deck. And then the boats test their clamps. Bye, Joachim

-

Hi Michael, I really love that pictures of the whole ship, it looks wonderful! Regards, Joachim

-

Congratulations, Michael, there is no doubt about your decission to rebuild these parts, great result!! It looks also much more realistic, well done, I like it ! Regards, Joachim

-

Oh wow, great Work! Really interesting to follow your way, optimizing the Corel-based model. Up to now, I have not realised this problem in the Corel-model. I think your result is the best possible and will follow the next steps with great interest. Regards, Joachim

-

Hi Michael, these small things make the difference between a good model and an outstanding model! It is really interesting to follow your log. Regards, Joachim

-

Hi Michel, being back from my absence, I had to read a lot through your build log. After a long summer holiday, I came in contact with a horrible computer virus, destroying all of my computers! And it took me several weeks now to solve any problems with it.... But now it was really great for me, to see your wonderful build growing and going to be better and better! At the end it will be a marvelous ship! Best regards, Joachim

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.