-

Posts

302 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by jburchfield1@wowway.com

-

Looking good. Now comes planking

- 335 replies

-

- 18th century longboat

- Finished

-

(and 1 more)

Tagged with:

-

I'm working on the last 2 planks on the 18th century longboat and boy are they a mess! This is my own fault, I was not precise enough when sanding to the tick marks but, My question is this..... Do you plank in one direction (either sheer to keel or keel to sheer) or do you plank in both directions (top down and bottom up) meeting in the middle of the hull?????? Any pros/cons to either plan?

-

Soon enough you'll never know it was broken. Excellent work!

- 335 replies

-

- 18th century longboat

- Finished

-

(and 1 more)

Tagged with:

-

In today's world most companies have forgotten that "the customer is always right". I don't mean that literally of course, however, it appears that most companies are of the opinion that "it's only one customer - so what". And since it's almost impossible to get large groups of people to "band" together (for any reason whatsoever) that the companies believe that they are immune to any boycott or at risk of loss of their customer base. There are a few exceptions. Model Expo for one has the most amazing guarantee that I have ever seen. They will always get my business (what little I can throw their way), but for the most part companies no longer care about customers (unless maybe it's a start up company).

-

thanks guys! More pics in a couple days.

- 132 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

I understand what you are saying Mike, but when I look at my model and I try to visualize those tapered planks on the top and the downward slanting planks on the bottom my brain see an empty "V" or triangle at the stem when I've planked all the way up. But regardless of what my mind say's I'm gonna finish planking this one and see what I get. I do know tho, that from now on I'm probably gonna do the garboard plank the other way around. When I look at the way your planks run in your earlier photo (almost straight) I think I like that look better. Although, maybe it depends on the ship. You'll notice that mine is a lot darker. Actually it's darker than I planned, but I'm going for that "in service" look as opposed to looking new. Also, I just naturally like darker woods.

- 132 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

- 132 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

Okay, here's a couple of pics to look at. It seems to me that most of the other longboats I have looked at the planks are running straight by the 3 or 4th course after the garboard plank. Mine does not look the same, (at least in my eyes). Can you tell from these pics if I'm doing something wrong? PLEASE, anybody/everybody don't hesitate too correct me/state your opinion. I WANT to learn. By the way, the two planks above the garboard plank( toward the shear) were not edge bent, they were cut by hand from a wider sheet.

- 132 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

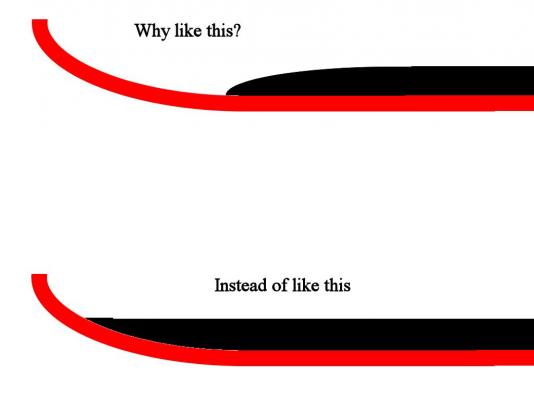

It makes more sense to me to make it like the bottom one. I did it like the top one because that seems to be the way most have done it and it's what the instructions show. Getting the next plank up (from the garboard) is where I'm having so many problems. I finally (just today) cut that plank out of a wider strip in order to make that bend/curve which seems to be working for me. I just wondered why everybody seems to be doing it like the top half of that picture instead of doing it like the bottom half. Seems to me to make much more sense and makes things easier all around. But since I've just started with this I don't know why and my brain REQUIRES that I know WHY I am doing something.

- 132 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

Thanks Grant - No way in "heck" am I gonna let this whip me. BUT, I do have a question for anybody that knows. I've been trying to figure this out since I first start trying to plank (back three boats ago!) Why oh Why is the garboard plank done like the top half of the picture instead of the more logical (to me as an amateur) bottom half of the picture?????? I was looking at a video on YouTube the other day that showed it being done like the bottom half of that picture on a full size sailing boat, but everything I've seen done here has it like the top half.

- 132 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

Musta been the cat! You gotta cat?

- 335 replies

-

- 18th century longboat

- Finished

-

(and 1 more)

Tagged with:

-

Actually Floyd, I'm a loooong way from fast. First off, this is my 3d attempt at this boat so I've had some practice at putting the keel and bulkheads together. Also, finally figured out the fairing thing. Second, I've actually been working on this part since Tuesday morning when I got the parts, but since I don't have a camera yet, didn't see the need to post each step. Now though, I'm starting the "harder" part of planking, and I'm getting a camera sometime next week, so things will probably get much slower. For some reason, had a lot of trouble with the planking concept, shaping, soaking, spacing, etc. (probably my in-ability to "visualize" anything - I have never been able to form a mental picture of anything ) so been doing a lot of re-re-re-reading and testing to figure it out. Got my fingers crossed this time.

- 132 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

K, got my replacement parts. I have completed installing the bulkheads, and added the 2 sheer planks. Got the balance of the bulkheads divided today and starting the rest of the planking tomorrow. Think I've figured out all my trouble spots, so hopefully this time - SUCCESS! Will have a camera some time next week so I can post pics - but I'm still here and still trying.

- 132 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

Chuck, let me say first that you are the most "entertaining" poster I've seen yet on this site. Haven't been here long, but love reading your posts. If you install the Chrome browser (it's free and doesn't conflict with ANYTHING windows) you can view that link that was listed earlier without issue (no account needed). I just clicked on the link and it opened for me. Chrome is MUCH more internet friendly than anything else I've ever used.

-

I agree so far. I've been working on the brass parts for the mast and have had no trouble with them. Maybe they are just to small/fine to need it.

- 132 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

While waiting on some replacement bulkheads/keel parts, I'm working on some of the other parts. My question is about the brass - is it common practice to always anneal the brass? and does that simply mean to heat it red-hot and let it cool naturally? That seems to be true, just want to make sure.

- 132 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

Thanks Dan, I'll give that a try. I have messed up two hulls now (two separate kits) so in addition to learning some tips from Mike Y's build and my build, I think I'm ready to try again. Instead of buying another kit (just for the hull) I've decided to also try some "scratch" or maybe "bashing" and went out today to buy a 3/32 for the false keel and bulkheads, a 1/16 for the transom and some more 1/32 x 1/8 for the planking. Cut up one of the plan sheets for the parts I need, and I'm gonna start cutting tomorrow. Hopefully, get some pics/progress up here soon. Unfortunately, my d*$>n truck stopped running (I've got an F150 and the computer thinks I was trying to steal it) so that trip is gonna cost me a couple hundred bucks, but I REFUSE to give up on this. Even with all my "failures" and re-do's and start overs, I'm learning a lot and I really love this craft (art?).

- 132 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

See, this is why I'm having so much trouble with planking. Once I can do this right, I'm sure it will make perfect sense, but so far............ I is so confoosed! I've looked at bunches of pics on the web of longboat hulls and it "appears" that all the planks run almost straight from stem to stern, which is what would happen if planked the way that Mike shows, but most of the pics on here show the planks curving up at the stem and tapering almost to nothing.

-

Excellent photos and step by step. Just one question - did you use the same card template for all bulkheads or did you make a new template for each bulkhead? Maybe that's where I went wrong, because I made a new template for each bulkhead (but still using the same number of planks) and that made them very, very narrow on the front bulkhead.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.