-

Posts

614 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Dimitris71

-

-

Hello Mike, I would like to wish you a happy new year . Good luck with your new project. I will follow with interest.

Regards

Dimitris

-

Very clean and nice build Dimitris. Looking forward to learning about how to apply that fiberglass for that finish.

Mark

Hello Mark, thank you for your nice comments and for visiting my build log. I hope I will be able to help but first I have to learn myself. I intend to do some tests with the cloth and the resin before applying the cloth to the actual ship.i will post photos from the progress of the fiberglass installation.I would like to wish you a happy new year.

Cheers

Dimitris

-

Hi Dimitris and Happy New Year

You're build is coming on fantastically.This beautiful vessel is a foreboding build in 1/84 let alone 1/100.I agree that fibreglass is the way to go for a permanent crack free hull.Cracks can appear years after construction otherwise.

Just a couple of bits of advise from my experience using this.I always use ZAP Epoxy finishing resin and fine woven cloth meant for RC aeroplanes This resin has a 3 hour set time,that isn't 'open' work time.However this is the only product I have found that gives you a 'comfortable' amount of time to complete the job.Cutting all the pieces of cloth before you start is a must to give yourself as much time as possible.Finally,you need to apply finish to your decks,the resin will bead on the deck at the upper edges of the hull.This will need sanding off when cured,the finish on the deck will stop a darker edge appearing on the planking when finished.

Kind Regards

Nigel

Hello Nigel, I wish you a happy new year . I want to thank you for your nice comments , for visiting my build log and also for the tips.I will purchase the cloth and the resin on Monday. I still have to check if the zap epoxy finish resin is sold here in Athens. If not I will buy it online.Until then i will read some things about the fiberglass and resin.

Cheers

Dimitris

-

amazing fine surface Dimitris,

I presume you were using a very fine structured glass roving web, with probably epoxy resin, which allows to a certain degree "3D flow" without throwing wrinkels.

The Advantage of that method is the resulting fine , even surface structure and with limiting the resin amount you can avoid time consuming sanding afterwards. In this way your hull gets a wonderful tight and rigid baseground for further applications of whatever you desire....

smart and well done !

Nils

I believe that the result is rewarding , i hope mine it looks the same after it's done.

Cheers

Dimitris

- kruginmi and Mirabell61

-

2

2

-

- tasmanian, Mirabell61, Elia and 4 others

-

7

7

-

- edmay, Elia, Captain Slog and 2 others

-

5

5

-

hello Dimitris,

I know what you`re talking about with those possible hailine fractures in the outside Skin. Sometimes they occur even months after the planking was done an, sealed and painted. Good experience was achieved with this "crack creep" thin-viscosic product UHU Holzfest, if you Need to secure thin cracks, and if already there, from getting larger.

If you are going to simulate steel plating, you Need a smooth outer Skin of the wooden surface underground. (that plating put on afterwards can also be structured before applying)

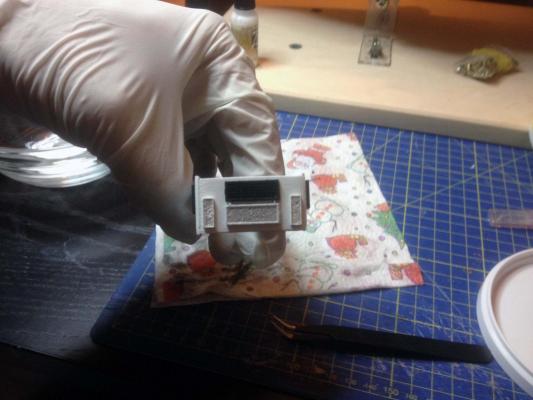

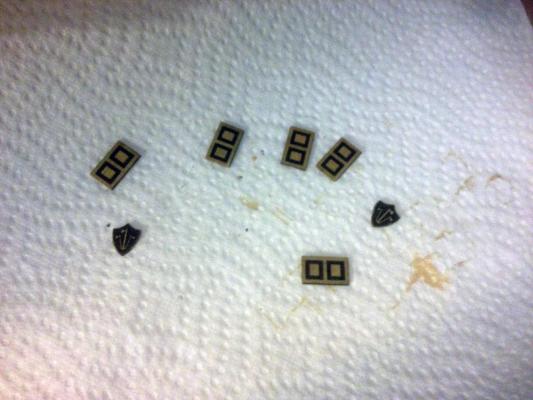

One pic without,- one with structure (here riveting structure)

happy new year

Nils

Hello Nils, thank you very much for the advise . Also i wish you a happy new year for you and your family. I will upload a picture later with a photo of Amerigo 1:84 which is already cover with fiberglass in order for you to see the result i am aiming for. By the way your job at Bohuslan is fantastic.

Cheers

Dimitris

-

Hello again! First of all i want to thank you Rich, Elia, Avsjerome2003, Lawrence , Nils, GuntherMT, Wackowolf , Edmay, Puckotred, SimonV, Brian, Captainslog, Tasmanian and Aussie048 for your likes and for visiting my build log.

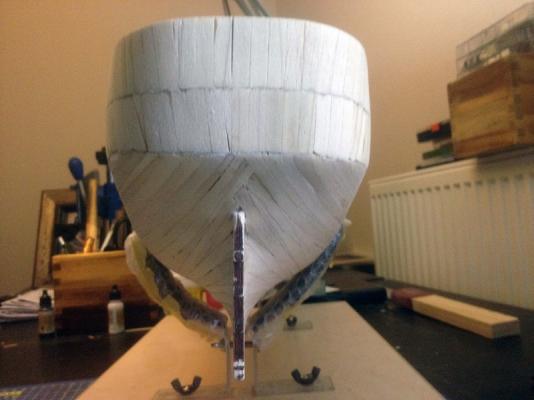

Elia and Nils, I had in mind to use fiberglass and resin to recreate the metal hull of the ship (it's the first time I'm using this type of material) and make the construction even more solid. I have read about this technique in some blogs and forums and it was recommended in order to avoid future hairline fractures.

Any suggestions or comments regarding this approach?

Thank you in advance.

- Mirabell61 and Elia

-

2

2

-

- canoe21, Mirabell61, mikegerber and 6 others

-

9

9

-

Hi Dimitris

Great job you are doing on your deck planking, it sure dose look good, well done. I also like all of the detail that you are adding to your ship, I do think a lot of detail adds so very much to ones ship. ENJOY.

Regards Lawrence

Hello Lawrence , thank you very much for your nice comments and for visiting my build log. I agree that details are what make the ship unique. At this ship i will try to add more details than at my previous build.(It was my first attempt).

Take care

Dimitris

-

Hello Carl, good luck to your new build. I will follow with interest.

Cheers

Dimitris

-

-

Hello Lars , excellent work so far. It's beautiful !! Keep up the good work.I would like to wish you merry Xmas and a happy new year.

Cheers

Dimitris

-

-

- tasmanian, canoe21, Captain Slog and 3 others

-

6

6

-

-

Hello Jerry, looking really good!!

:)

:)Cheers

Dimitris

-

- muratx, avsjerome2003, HIPEXEC and 5 others

-

8

8

-

Hi shipmates!!Thank you all for your likes and nice comments!! During the weekend i was able to do some progress on the build.. First, the planking on the deck has finished. It is sanded and painted . Second ,one structure that belongs under the stern deck is also done. The next one will be the installation of the stern deck . Also the planking and painting.I would like to wish you all a very merry Xmas and a happy new year.

Some photos...

Dimitris

- tasmanian, muratx, Captain Slog and 4 others

-

7

7

-

Hello Dimitris," starting well usually ends well" nice neat work ,the pictures are good,keep on enjoying your build,best wishes for xmas and the new year to you and your family.Edwin

Hello Edwin , thank you for your wishes , for your nice comments and for visiting my build log. Have a merry Christmas and a happy new year for you and for your family.

Cheers

Dimitris

-

Hi Dimitris

Just found your build log, great job you have did on your planking, you could have made the planking job a lot easier by using two short planks rather than one long one, but then you did OK, I normally shamper the plank edges to make them fit together, well just a bit late for your ship but just a thought for your next build. Looking forward to following, ENJOY.

Regards Lawrence

Ηello Lawrence , thank you for the kind comments and for visiting my build log. Thank you also for the tip , i will have it in mind for the next build

:)

:)Best wishes for Christmas and new year for you and your family!!

Regards

Dimitris

-

- GuntherMT, tasmanian, Captain Slog and 8 others

-

11

11

-

Hello Jerry, good luck to your new build, i' m sure you will do a wonderful job!!

Cheers

Dimitris

-

Dimitris,

Nice work.

Tiropita?

Cheers,

Elia

Hello Elia , thank you for the compliment.... Yes, tiropita , how did you know the word tiropita? Lol...

:)

:)

Cheers

Dimitris

Sovereign Of The Seas by NMBROOK - Scale 1/84 - based on the works of Van De Velde the elder

in - Build logs for subjects built 1501 - 1750

Posted

Hello Nigel, your work looks fantastic. The carvings are superb!! I am looking forward to seeing more...

Regards

Dimitris