-

Posts

620 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by captgino

-

Just caught up to your build. Nicely done and great craftsmanship.

- 128 replies

-

- model shipways

- new bedford whaleboat

-

(and 1 more)

Tagged with:

-

Very interesting build. Great job so far!

- 62 replies

-

- bosphorus

- tersane model

-

(and 1 more)

Tagged with:

-

Hi Zoltan, Well... I looked around on the plan and documentation and I was not able to confirm which size to use 3/16 or 1/4. Since I used 1/4 for the first layer, I decided to use this one as well. I like the look of it. Does it seem too big?

- 194 replies

-

- armed virginia sloop

- model shipways

-

(and 1 more)

Tagged with:

-

- 194 replies

-

- armed virginia sloop

- model shipways

-

(and 1 more)

Tagged with:

-

- 194 replies

-

- armed virginia sloop

- model shipways

-

(and 1 more)

Tagged with:

-

Thank you, Larry. I will bring it to our next club meeting for close-up inspection

- 194 replies

-

- armed virginia sloop

- model shipways

-

(and 1 more)

Tagged with:

-

Good eyes Brian. I saw it after posting the picture. It would have driven me crazy. I had also put all the tool away...

- 194 replies

-

- armed virginia sloop

- model shipways

-

(and 1 more)

Tagged with:

-

- 194 replies

-

- armed virginia sloop

- model shipways

-

(and 1 more)

Tagged with:

-

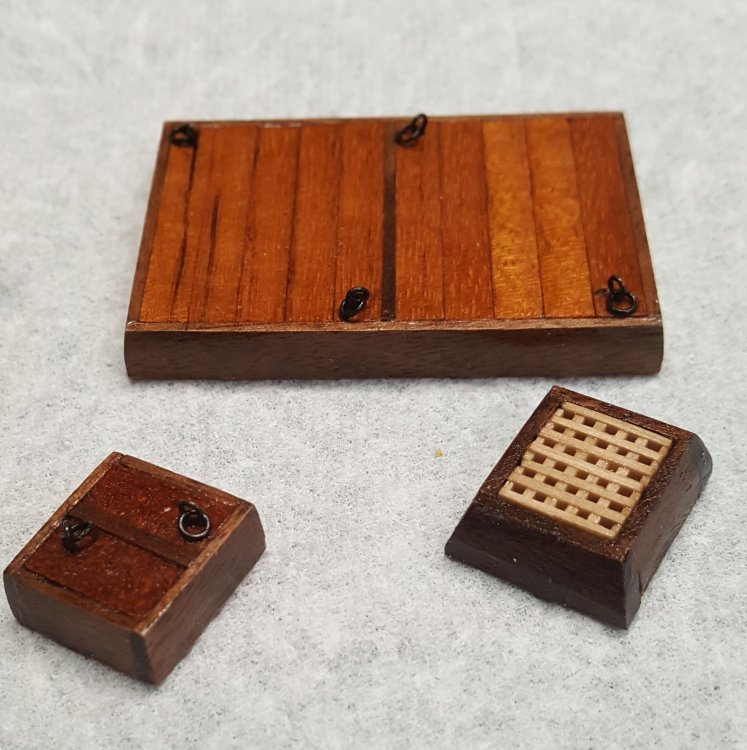

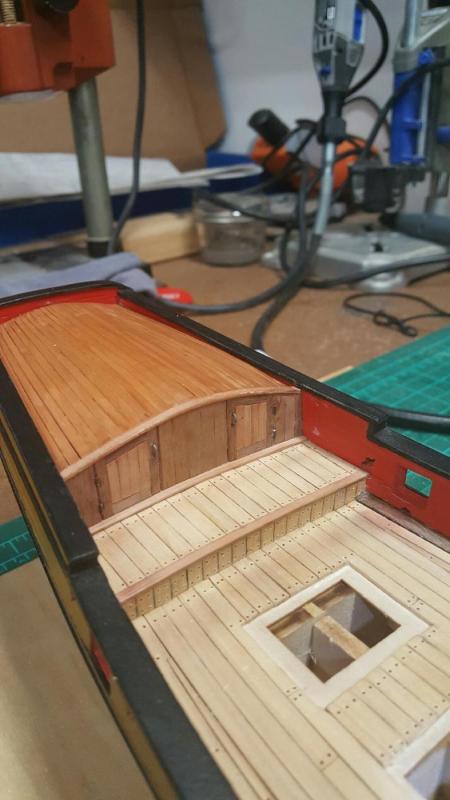

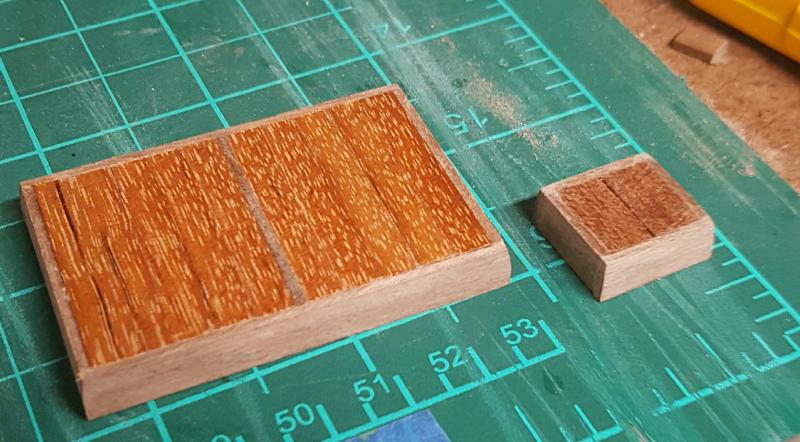

Worked on the cabin this weekend. Poop deck made with cherry wood. I use one coat of natural vernis on the top. I am going to wait for the rest until I finished the treenail. Love it.

- 194 replies

-

- armed virginia sloop

- model shipways

-

(and 1 more)

Tagged with:

-

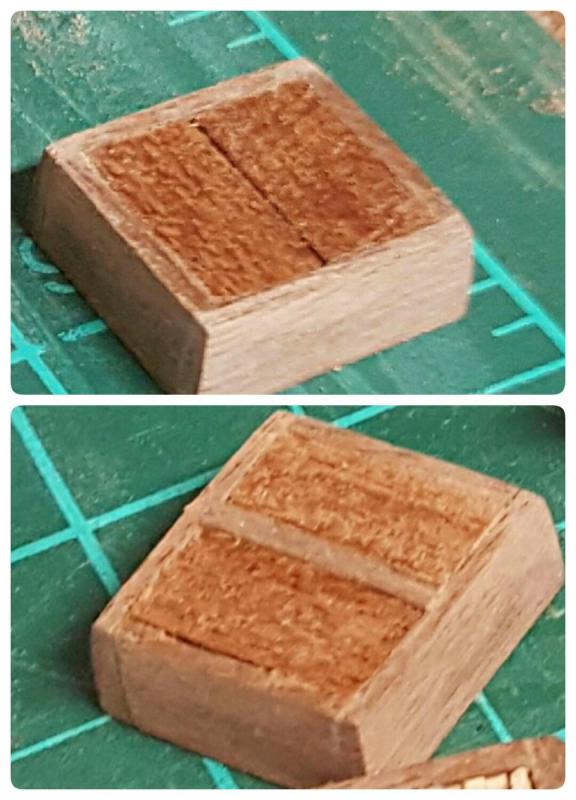

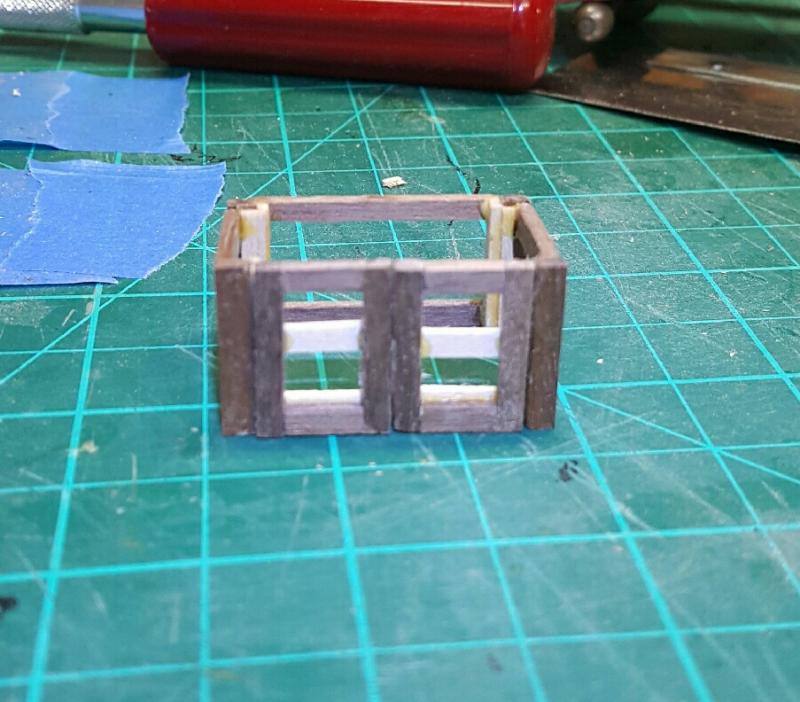

Almost done for the deck furnitures. I only need to do the fake hinges on the companionway. Thinking about doing fake rivets for it. Looks like I need to get a soldering iron... In the mean time I worked on the decking. I am using boxwood. A few mistakes. - My pattern is every 4 and with the size of the deck I think every 3 would have been better. - I did the first few planks with a small incorrect angle and with the width of the strip of wood used I am a bit off. I contemplated redoing everything but due to budgetany consideration I am going to have to live with it Still learning how to properly plank....

- 194 replies

-

- armed virginia sloop

- model shipways

-

(and 1 more)

Tagged with:

-

- 194 replies

-

- armed virginia sloop

- model shipways

-

(and 1 more)

Tagged with:

-

- 194 replies

-

- armed virginia sloop

- model shipways

-

(and 1 more)

Tagged with:

-

- 194 replies

-

- armed virginia sloop

- model shipways

-

(and 1 more)

Tagged with:

-

She looks great! Very nice status update.

- 701 replies

-

- phantom

- model shipways

-

(and 1 more)

Tagged with:

-

Rails are done... Next nerve racking step is to drill the sweep port and the bow sprint hole. Is there a specific method or recommendation you would suggest? Thanks.

- 194 replies

-

- armed virginia sloop

- model shipways

-

(and 1 more)

Tagged with:

-

Thanks Joe! You are too kind. You are making some great progress yourself.

- 194 replies

-

- armed virginia sloop

- model shipways

-

(and 1 more)

Tagged with:

-

Small update. Custom fitted the main rail on my AVS. The one provided by the kit was not adequate. I cut the new rail out of 1/16 walnut and did the first stain with ink. I have some touch up to do with the paint but I have decided to wait until I drill the sweep ports to do it.

- 194 replies

-

- armed virginia sloop

- model shipways

-

(and 1 more)

Tagged with:

-

- 194 replies

-

- armed virginia sloop

- model shipways

-

(and 1 more)

Tagged with:

-

- 194 replies

-

- armed virginia sloop

- model shipways

-

(and 1 more)

Tagged with:

-

- 194 replies

-

- armed virginia sloop

- model shipways

-

(and 1 more)

Tagged with:

-

- 194 replies

-

- armed virginia sloop

- model shipways

-

(and 1 more)

Tagged with:

-

- 194 replies

-

- armed virginia sloop

- model shipways

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.