-

Posts

578 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by mrcc

-

Hi Jan-Willem, I love your methodical approach... all in the goal of attaining historical accuracy! I think it is worth the work and effort. With regards to all the builds and kits on this forum, I think only the Model Shipways kit would get an "A" grade in that respect. Take care!

- 127 replies

-

- Bluenose

- Billing Boats

-

(and 1 more)

Tagged with:

-

Thanks Rick for your kind comment and sorry for getting back to you so late. I have taken a bit of a break and with me now not able to get email notifications about comments, I find that I am even further "out of the loop". With this posting, I have shown some of my efforts in creating ropes and hanging them.

-

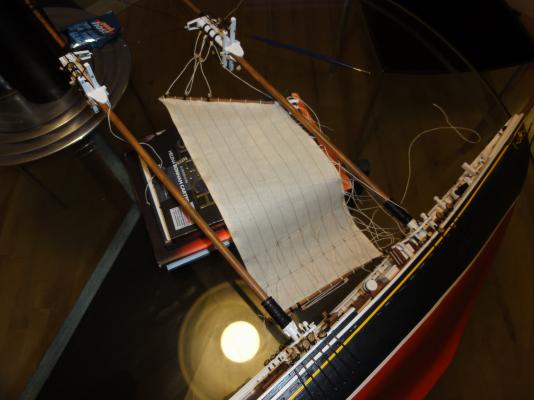

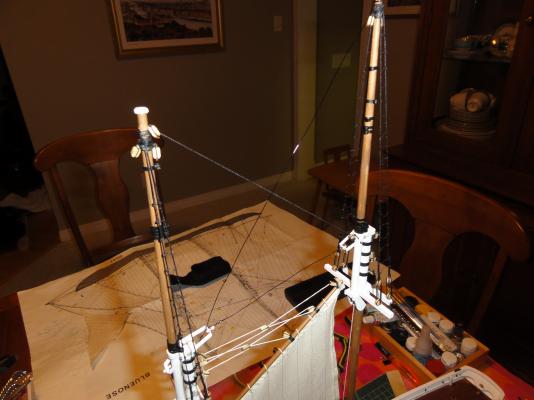

Thanks Popeye for the feedback, and my instinct was to do the shrouds absolutely last. This was my first attempt at rigging and I must say that I actually enjoyed the process and quite proud of how my Bluenose looks. ... mind you it is quite a simple rigging setup compared to the big frigates that you see on others' build logs.

-

I must say that as I get closer to completing this, yes though my second model started, this is my first completed and it is a very nice sense of accomplishment with lots of pride for me when looking at my "almost finished" Bluenose. I have certainly enjoyed the rigging more than I thought I would, perhaps because this kit was easier and more manageable compared to perhaps the rigging plans of more complex and larger models. And as I look at it at this stage, I certainly feel that the Billing Boats kit is decent as long as you take the time to add the "extra details" and that the plans and instructions provided are not all the bad... and of course it certainly does not hurt to look at such a beautiful and handsome ship as the Bluenose! Cheers,

-

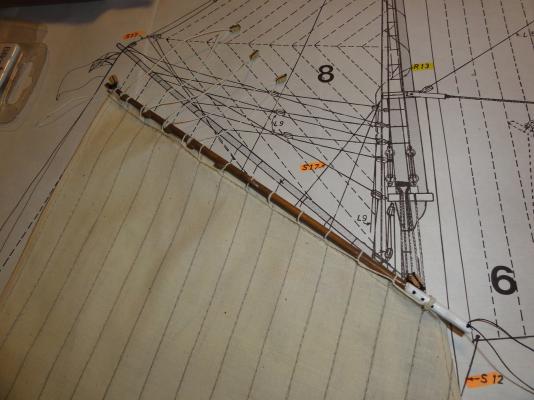

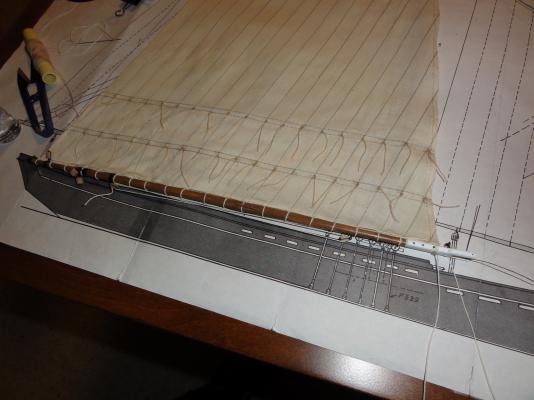

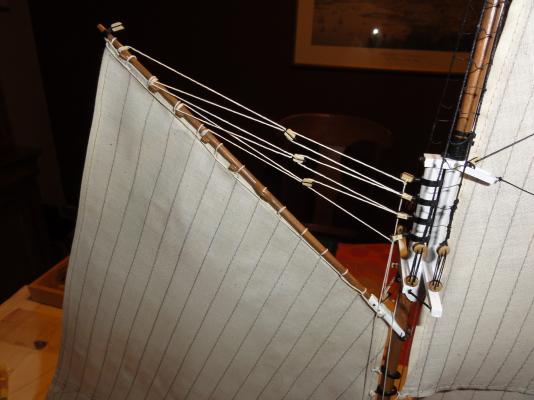

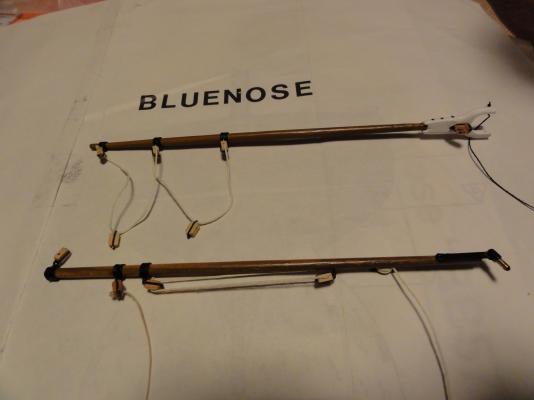

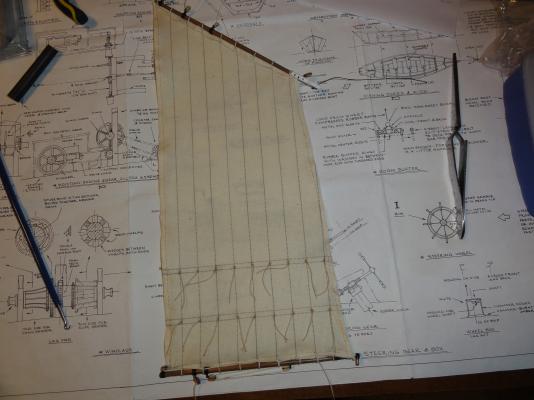

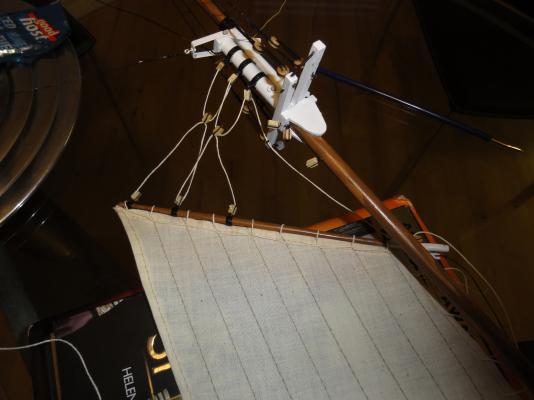

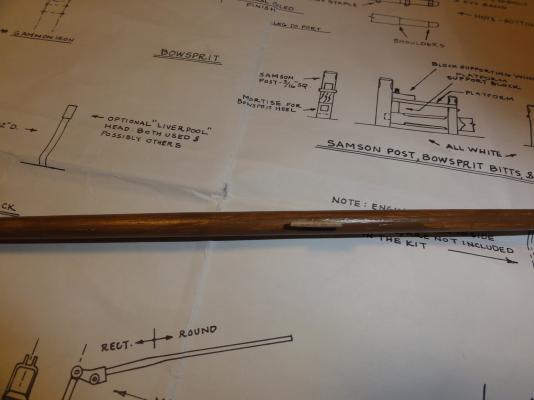

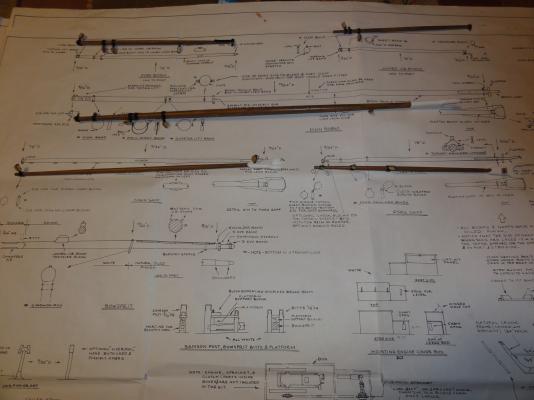

More progress to report... My approach to rigging has been to study the plans and add all the details prior to attaching the sails and here I have added the blocks and bridles to the main gaff. For this particular model, I then attached all the running rigging details to the sail and then attach the sails to the respective booms and gaffs, in these pictures, to the main boom and gaff. I always made sure that the running rigging lines had more than enough length to the line to anchor to the blocks on the masts and then let the lines fall so as at a later time (in the next few days) anchor them to the pins and blocks on the deck.

-

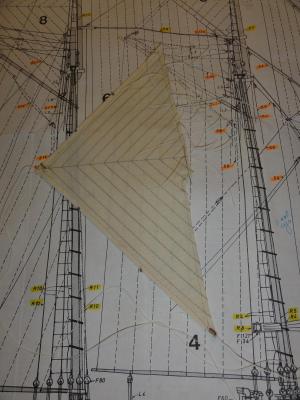

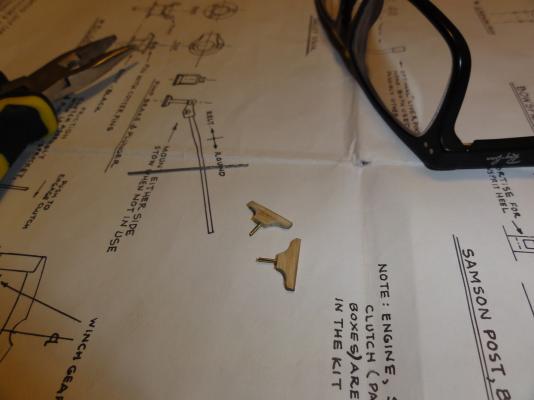

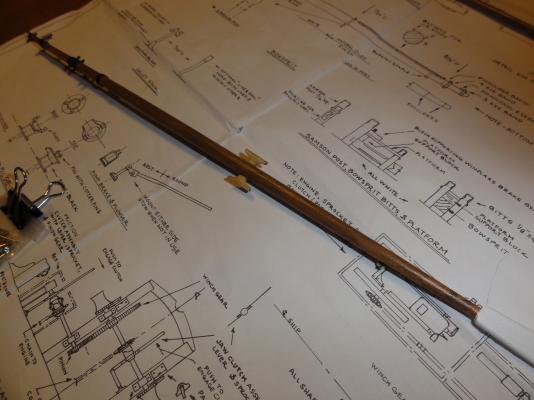

Thanks for all the likes... I also hope everyone had a wonderful Xmas season. I had completed a lot of the present work in early December, but with a week in Mexico and then with Xmas, only now have I had time to post some progress. I had my sails professionally sewn by a seamstress and with the details added to the booms and gaffs, using both resources from my limited Billing Boats plans and then the greater details added from the Model Shipways plans, I think both aesthetically and historically (at least I hope to think so), everything has turned out very well. The fore boom and fore gaff details were done first and then I added the block and bridles to the gaff before lashing the sails to them. I then further prepped the mast so as to do all the blocks and rigging lines before sails were added. And oh yes, all my stays between the foremast and mainmast were done prior to attaching the sail.

-

One problem that I see is that when adding cleats to the main boom... they appear out of scale to me. It is one thing when they are in your hand and you are sanding them down from a scratch piece of wood and they look small enough... until they are glued in and in place on the main piece. Is this another redo?

-

I also added a few extra details to the masts ie: ringbolts and spring stay bails (that's what the Model Shipways Plans called them anyways). The next item on my agenda was to set the masts... and I noticed lots of debates whether to glue them in or set them with the stays and shrouds alone. The problem for me was that when I made the mast holes and then the mast collars, I noticed lots of sway to the masts and thus went for the glue... I basically just eyeballed it... From the picture, it looks like I was using a heavy duty clamp but in fact was only using it to prevent the mast from leaning to the side. Everything looks good to me...

-

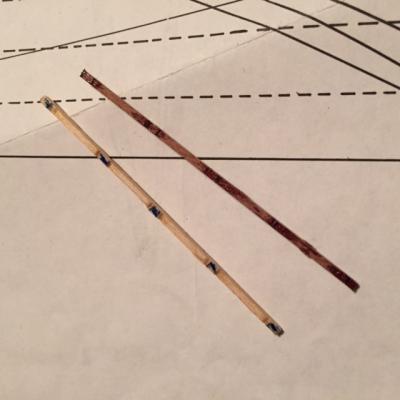

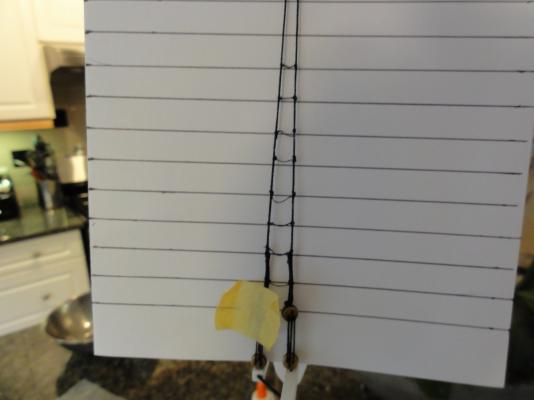

Seems like I am always good for a posting once a month... and since the last discussion I created my upper (topmast) shrouds going with the 0.75 mm thread from Caldercraft, also using regular cotton thread for the ratlines that is perhaps 0.15 or 0.2 mm in diameter in my estimation. I then compared the look to the previous mast that I had done, and quickly realized the redo was much better.

-

Thanks Jan-Willem, Bob for the wealth of information... much much appreciated. I will experiment and look again at this as I have to take down want I already put up (topmast shrouds) and look at this issue again with all this new information. With regards to the wire standing rigging, I know the bow details and just a couple of the lines of the lower masts were wire (according to the Billings Boat plans anyways).

-

Thanks so much for your advice Alan, Jan-Willem... I think 0.85mm would look "dead on" per the Model Shipways plans (to my eyes). The Billings Boat kit did not come with black rigging thread and what I bought at Michaels (craft store)was some regular thick black thread that is just to soft and light. The rigging thread from Caldercraft is nice and stiff, perfect in my opinion for this stage of rigging and shroud lines. At the end of the day, you have to go with what looks right and I think I will go with the 1mm shrouds and 0.5mm rat lines.

-

Thanks Alan for your reply... It is funny as when you look at the rigging with the mast set on the boat, it just looks funny and small to scale, and when you step back a bit and look at it, it almost looks like the shroud lines look "miniscule". I can only imagine that when you put the thinner ratlines on, those lines may completely "disappear"....? Thanks for your input, as this is my first rigging attempt, and I will have to think about this further. Much appreciated!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.