Clark

Members-

Posts

308 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Clark

-

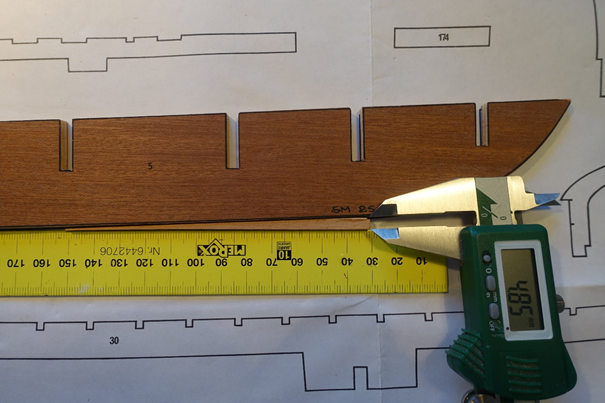

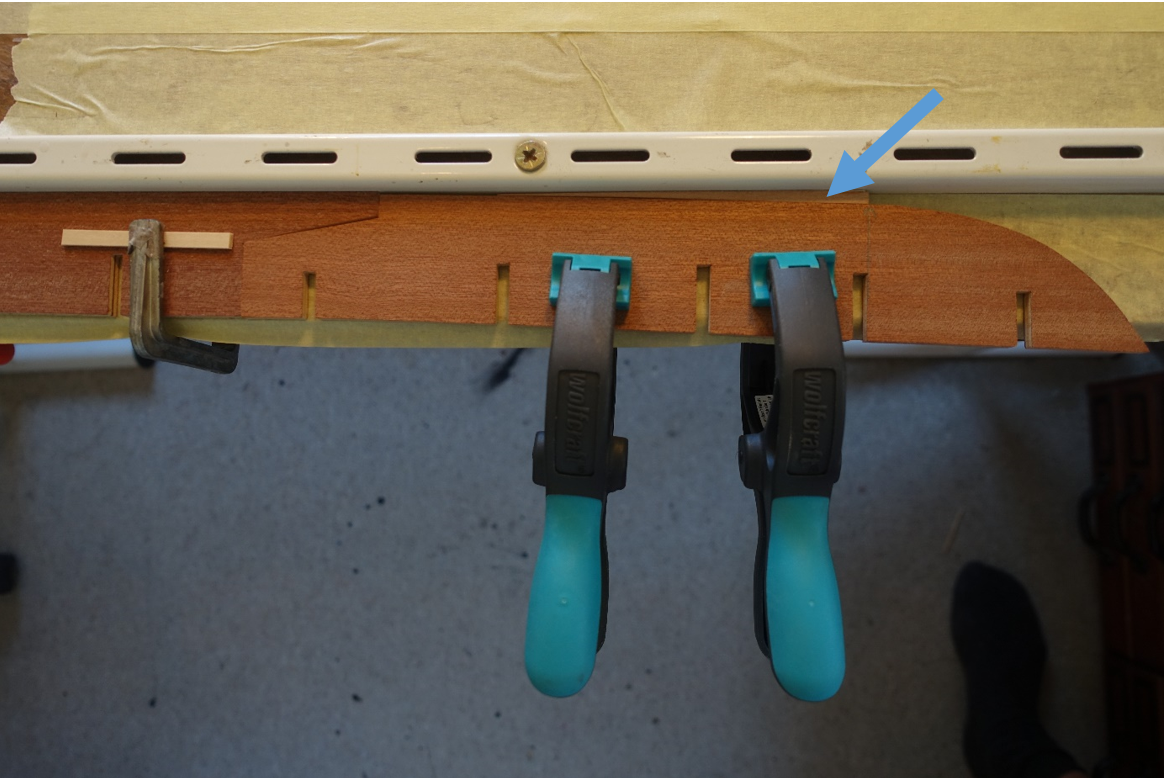

Corona gave me some time to be spent with the ship. I proceeded in planking and reading some more literature about galleys. Regarding the ship, before attaching the last strips, size, bending and position of a “garboard” strip was tested. (I do not know if a garboard was ever used in this type of ships). Finally I decided to use a walnut strip 10 min wide as “garboard”. This because the keel is deflecting ~5mm from the middle to the bow and also to the stern which means that about 5 mm of width get lost when keeping the garboard in a straight line. After slightly attaching the garboard strip with the screw clamps, the remaining gap between the last regular strip and the garboard strip was measured according to the method described above. Garbord strip was then completely watered for about 30 min and again fixed in place to get the bending at the stern and the bow. It dried overnight and kept the bending.

- 112 replies

-

- corel

- reale de france

-

(and 1 more)

Tagged with:

-

Hello Frank, thanks a lot. Meanwhile I browsed through the plans and found the picture showing the chain plates. I thought that the shrouds are fixed on the panks of the gangway. Thus you are completely right to enforce the planks. I am glad that you are going ahead to help me to avoid mistakes. Clark

- 510 replies

-

- reale de france

- corel

-

(and 1 more)

Tagged with:

-

Frank, it looks perfect. I m still thinking about the holes you made for the shrouds. How were the shrouds fixed? Below the outer gangway is nothing. There are still some ropes in middle visible. Are these the ones for pulling the carriage of the main cannon. If yes, do you have any idea, where they were put on? Still admiring your work. Clark

- 510 replies

-

- reale de france

- corel

-

(and 1 more)

Tagged with:

-

Thanks Frank, I will not paint the hull since I a a fan of wood structure to be visible. Regarding your blog, I can imagine that lot of patience is needed. Clark

- 112 replies

-

- corel

- reale de france

-

(and 1 more)

Tagged with:

-

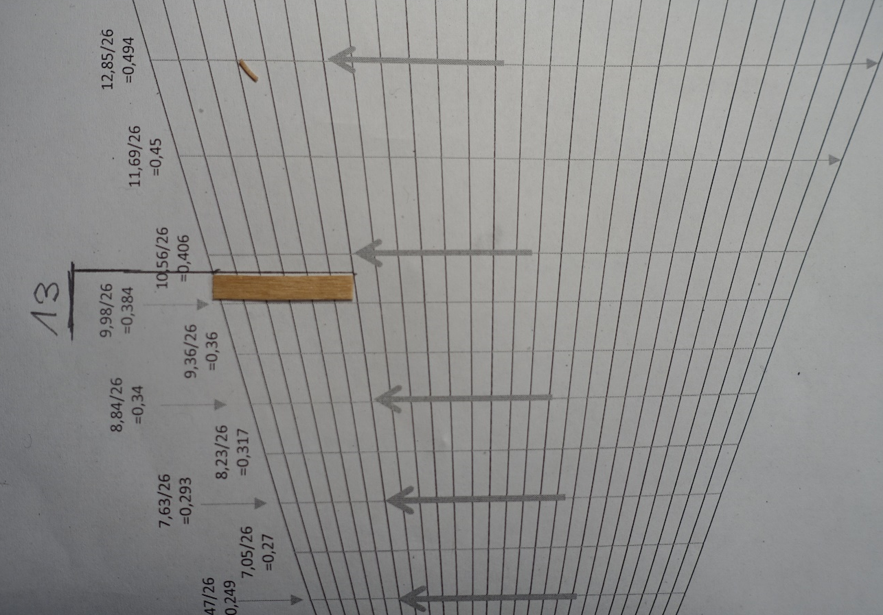

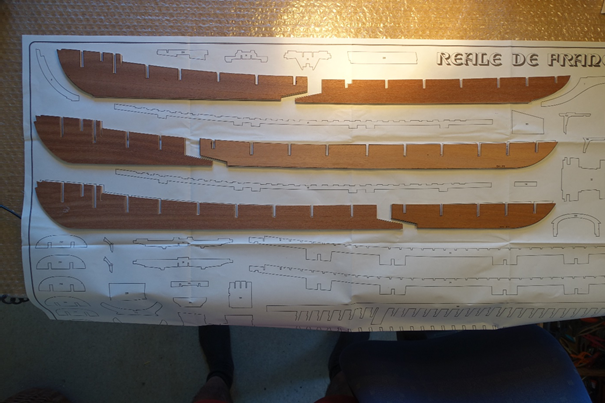

First planking is ready. I have started with the second planking. The walnut strips for the second planking provided by Corel are of very different color. Finally I decided to put them in an almost regular color pattern which does surely not reflect the original appearance. First strip of second planking was attached like the first strip of the first planking. For calculating strip width of the second planking, I attached a help strip, distance from upper strip in the middle of the hull (frame 16 and 18) = width of 6 strips ~24 mm. Towards the bow the help strip was gently attached on the hull and fixed thereafter with painter tape and wood clamps. Distances between first strip and help strip were measured at the different frames by attaching and cutting small tanganjika wood strips. Measured distances were divided by 6 to get the correct width of one single strip. For calculating the width I made a width calculator with ppt according to “Planking Fan for - Lining Off a Hull” by Chuck Passaro (see http://modelshipworldforum.com/ship-model-framing-and-planking-articles.php). There are excellent hints on the same link for cutting and applying planking strips. After gluing the first 6 strips on each side, the measuring was repeated again by attaching a help strip. Bending of the walnut strips at the stern and the bow was done by soaking the strips in water for ~10 min and using a modelcraft electric plank bender thereafter. The strips were dry fitted, tapered again and glued. They were fixed by using painter tape and the screw clamps. I mainly used watered PVA (~10% H2O). PVA was filled into a syringe and applied via a cannula. This method left enough time to get the tape and clamps fixed with one strip tightly attached to another. CA was only applied at the bow and stern end of the strips.

- 112 replies

-

- corel

- reale de france

-

(and 1 more)

Tagged with:

-

I can only agree Mark: perfect work. Thanks for your suggestion to enforce deck planks for shroud rigging. Regarding shroud fixation in the traditional ships, mounting in only one layer of deck planks is surely much too weak. I will probably come back to your suggestion when I am at this point (which will definitely take some time). Clark

- 510 replies

-

- reale de france

- corel

-

(and 1 more)

Tagged with:

-

I have started with the first hull planking. First strip of the first hull planking was tapered and glued. To fix the plank tightly to the deck line it was fixed using standard painter tape. I use painter tape very often to fix strips etc. since there are no residuals of glue when removing the tape. For keeping the strips tightly to each other, tape was used further on. For fixing the strips on the frames or on the filler, I made some small screw clamps out of 2 mm walnut wood. The screw clamps also helped to keep the bending at the stern.

- 112 replies

-

- corel

- reale de france

-

(and 1 more)

Tagged with:

-

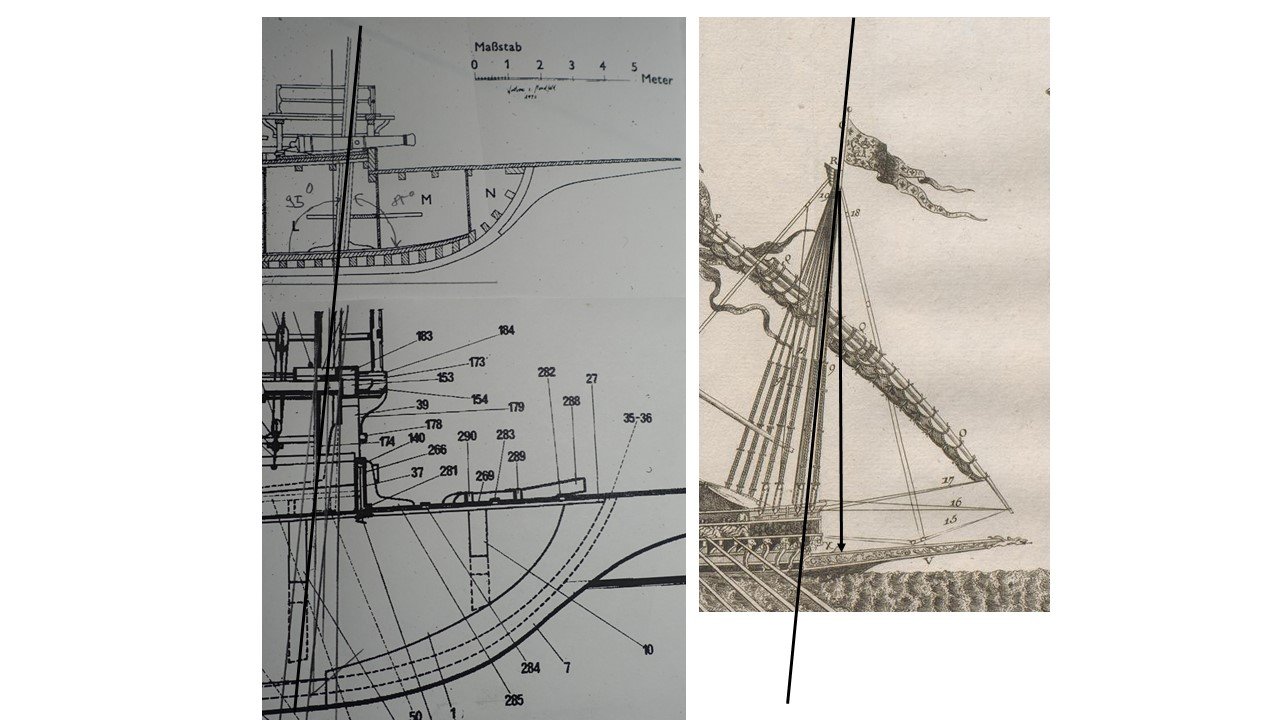

Hi Frank First of all, thank you for your response regarding fixatiion and angle of foremast. I would fully agree with you that the fixation shown in the Corel plans is not strong enough. The plan of Fleur de Lis provides a much better solution. Meanwhile I tried to gather old paintings and drawings of this galley type but none of them really shows the way the foremast was fixed. I have finished a xebec last year with a very strong and multiple layered fixation of the foremast. I cannot believe that the fixatiion of the Reale foremast is much weaker than that of a xebec. Regarding the angle of formast in galleys, I found a mixture of perpendicular till almost 10 degree deflection in the paintings and drawings. Maybe one of experts in mediterrian ships may give some hints. Hi Michael, I have just started to build the Reale. It is really a challenge. But the excellent blogs of Frank and the others give you many hints. Moreover it makes really fun to think about the process as already mentioned by Frank. Clark

- 510 replies

-

- reale de france

- corel

-

(and 1 more)

Tagged with:

-

Just one comment to my calculation: 9-10 degree deviation sums up both the devation of the foremast (6-7) and the slope of the deck (3-4).

- 510 replies

-

- reale de france

- corel

-

(and 1 more)

Tagged with:

-

Hi Frank, thanks for answering such rapidly. Meanwhile I tried to transfer the foremast decline shown in the Encyclopédie of Diderot and d'Alembert grafic into the corel plans. Althought the waterline may be not congruent, it shows that the formast deviates 9-10 degree from the vertical axis (my degree digits on the plan are not correct, forgot to erase them). I think that deviation is necessary due to the special handling of the lateen sails. Similar deviation can be seen in xebecs and dhows. The upper left picture shows part of the Mondfeld plan of La Dracene with a similar deviation from the vertical axis. I do not know why Corel did not follow the old pictures but I think definitely that it is a mistake. Regarding the fixation of the foremast in the main deck I cannot imagine that it is strong enough to counteract the enormous force produced by the big sail. The number of shrouds is also limited. In addition: one side of the bitt is open also weakening the fixation. Thus I am quite convinced that the plan of La Dracene is quite correct: fixation of the formast at the keel line. Do you know why the foremast could be both on the starboard and port side?

- 510 replies

-

- reale de france

- corel

-

(and 1 more)

Tagged with:

-

Frank, when looking on the old plans, it seems that the foremast in galleys was not vertical but declined toward the bow. Did you calculate the decline when drilling the tubes in the bitts? The question arised when I was thinking about my best way to proceed. Morever, in the plan I saw, the foremast is fixed at the inner side of the keel. Thus there should be a hole in deck sourrounded by a support. Can you delineate that from your plans of the Fleur? Clark

- 510 replies

-

- reale de france

- corel

-

(and 1 more)

Tagged with:

-

Hi Frank, the books shows and describes "La Dracène" (1675) but there is a table in the book on the cannon diameter used on galleys. As for the "Coursier", the cannon above the keel line: 36 pounds cannonball; 16.00 cm diameter cannonball; 290 cm length of barrel. // Cannons in La Reale: 36 pounds, 24 pounds (244 cm), 18 pounds (229 cm). Link to a picture of La Reale can be found in my blog. Clark

- 510 replies

-

- reale de france

- corel

-

(and 1 more)

Tagged with:

-

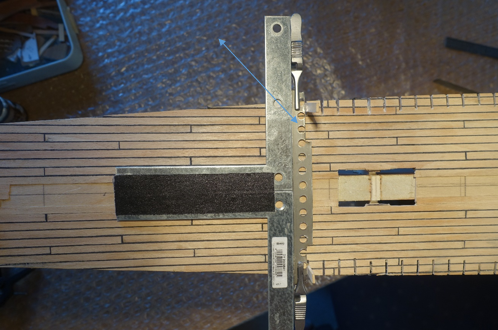

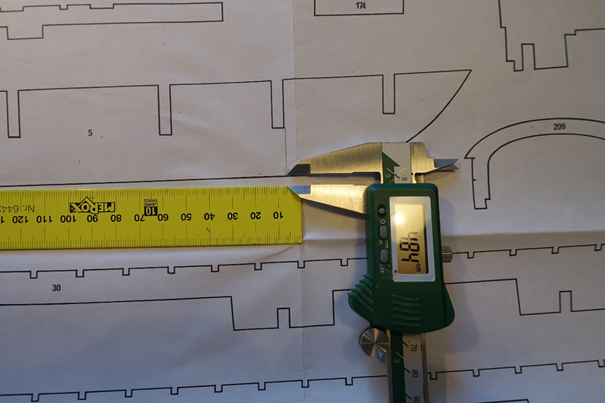

Deck is dry now fitted and glued. Filler blocks and frames were tapered again to follow the deck line. Deck was planked using the tanganjika strips provided by Corel. Unfortunately, I did not remember the difficulties, I had before with that type of taganjika strips. They are very thin (0.45 mm) and sanding has to be done with great care. Caulking is simulated by black paper (0.25 mm thickness) strips glued between the wood strips (Ratio width caulking/ width plank~1:20). After cutting the paper strips, sanding was first done in the direction from bow to stern to avoid darkening of the wood by dust of the black paper. Next the slots in the decks were cut. To cut the deck slots in regular intervals, a simple metal template with exactly 8.00 mm depth (=distance between the 1.5 mm slots, double arrow in the picture) was made. The metal was tightly clamped on the deck planking to avoid splintering of the wood when cutting the slots. As already said, the thin tanganjika wood is tricky. Rectangular fit and congruency between starboard and port side was controlled by a rectangular metal. Meanwhile I got a hint to a picture of the old Reale. The ship is described in the Encyclopédie of Diderot and d'Alembert, an ancient voluminous Wikipedia. There is so called “planche” showing La Reale. Link: https://www.e-rara.ch/zuz/content/pageview/7088914 . Although this might not really help in building the model it gives an impression how the ship was handled and flagged. I am still wondering how the war prisoners (oarsmen) were treated. Did they have to stay at the oars day and night?

- 112 replies

-

- corel

- reale de france

-

(and 1 more)

Tagged with:

-

Hi Frank, Hi Hubac; meanwhile I received an answer from the University of Duisburg (not Düsseldorf). It describes a picture of Encyclopédie of Diderot and d'Alembert. Is this the same you took your pinterest photo from? Frank, do you have the book of Mondfeld (picture)? There are plans inside form which you can delineate the size of cannons. Clark

- 510 replies

-

- reale de france

- corel

-

(and 1 more)

Tagged with:

-

Frank, perfect as expected. Is there a special scroll saw you are working with? Please do not misunderstand me: the outcome results from your skills but a good saw may help. Clark

- 510 replies

-

- reale de france

- corel

-

(and 1 more)

Tagged with:

-

Thanks Frank, I got the feeling that adjusting the keel in the vertical axis might be a bit difficult since it is not very high and thus may not have sufficient length to attach right angels. I noticed that you have constructed a very sophisticated apparatus ("overkill") probably due to the same thoughts. Hope you can enjoy the following days despite the tough year you had. Clark

- 112 replies

-

- corel

- reale de france

-

(and 1 more)

Tagged with:

-

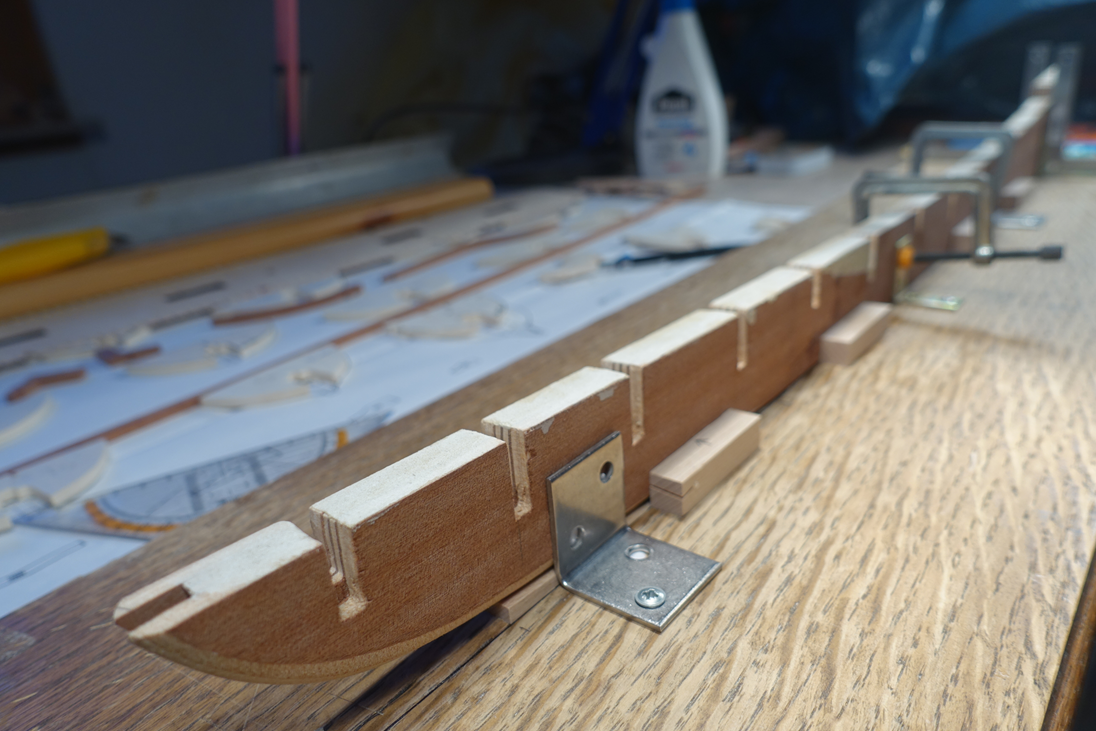

Keel is now roughly tapered. The first tapering seemed to be easier to me with no frames in the keel. Fine tuning will follow when frames are glued and sanded. Keel was mounted into a slipway made of wood blocks and right angle metal winkles for later adjusting the frames in the correct position. Frame and keel slots were slightly sanded in that the deck lines of the frames touched the outer lines of the triple frame with no difference in height. It came out that the frames delivered by corel are quite correct. Only minor sanding was necessary. After gluing the frames, deck lines of the frames were again corrected/sanded. Deck line was controlled by attaching strips. Hull side of the frames were roughly sanded after attaching strips and looking to their slope. In two frames, strips 0,5x5mm had to be glued on one side since they did not get in contact with the strip attached. These frames were sanded again. All in all it was a permanent interplay between controlling, measuring and sanding, everybody knows. Filler blocks and wood filler are now added to the first two bow gaps and the last two gaps at the stern. Sanding and controlling the hull line at the bow and the stern again and again. I got the feeling that this sanding and filling procedure is easier without the deck and deck planking attached. There is a good description of producing filler blocks in the forum (http://modelshipworldforum.com/ship-model-framing-and-planking-articles.php…). In contrast to the descriptions mentioned I dry measured size and shape of the filler blocks directly in the ship without making templates. I trust on eyeballing. Ship is now put backwards due to Christmas. Some of children and grandchildren are coming and we are also visiting those living a bit far away.

- 112 replies

-

- corel

- reale de france

-

(and 1 more)

Tagged with:

-

Hi Frank, fun is garanteed. I look forward to follow your progress. It is really an impressive ship, isnt i? Clark

- 112 replies

-

- corel

- reale de france

-

(and 1 more)

Tagged with:

-

Hi Frank, I am not as experienced as Hubac s Historian. But just on logical grounds: I would draw the ropes for the middle carriage the other way around the wheels: outside in. At present the ropes get in close contact with the carriage wich would damage them (when the ship would really be in fight). Clark

- 510 replies

-

- reale de france

- corel

-

(and 1 more)

Tagged with:

-

Thanks Gimo, where is your Reale now? Clark

- 112 replies

-

- corel

- reale de france

-

(and 1 more)

Tagged with:

-

Hi Frank and Hubac's Historian, thanks a lot for helping me. The painting is really helpful in building the ship but unfortunately it is probably not the one described by Vitz. It can be read that the starboard side is shown and not the portside. Moreover it is probably a drawing and not a painting. Meanwhile I figured out the the text copied is part of a thesis written at the Universtity of Duesseldorf (near the river Rhine, near France??). I will try to get in contact with the University to figure out the sources. Can you send me the link, where the painting of the Paris Museum can be looked at? There is no accdess via the website of the museum at least the way I tried. Thanks a lot Clark

- 510 replies

-

- reale de france

- corel

-

(and 1 more)

Tagged with:

-

I am going to join the club of modelers constructing or having constructed the ship. Frankly speaking, their construction and kit reports (gimo, Bender, fmodair, schiffebastler) urged me to order the kit. Mainly the very sophisticated report of Frank (fmodair) increased my wish to build the ship. I do not have the skills of the others mentioned. Thus this blog is mainly to those who rely on the material provided by Corel. Content of the kit is well described in construction reports of the club members. Most of the material seems to be of good quality but I am already wondering how to amend the plywood pieces. As mentioned I will probably manly rely on the material provided by Corel. However I like to see the wood structure of the models implying that I will use color paint very rarely. We will see. It seems to me that although Corel put some efforts in the written instruction manual, there is still enough space for improving. False keel is a triple one and made of six pieces which have to be glued overlapping to produce a keel three layers thick. To keep the keel straight I fixed and clipped the parts of the keel flatly on a shell with a metal rail below the keel pieces. Since the lower line of the keel is deflecting, small wood wedges were put under the bow and stern side of the keel to get the distance from the metal rail (arrow). The get the three overlaying pieces in the correct position, small wood stripes 4x4 mm were put into the spaces for the frames/bulkheads. After gluing the keel, frames were dry (!) fitted by filing the slots of the keel and filing the slots of the frames. Bottom side and deck side of the keel was treated with wood filler and sanded. Frames, false deck, the pieces of the true keel and other supports were dry fitted. Some minor sanding had to be done for this. Next step will be tapering the keel and adusting the frames.

- 112 replies

-

- corel

- reale de france

-

(and 1 more)

Tagged with:

-

Hi Frank, I have inserted part of text I found above. Vitz refers to Belin and Goussier as the artists behind the painting/drawing. Any idea? Clark

- 510 replies

-

- reale de france

- corel

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.