-

Posts

2,652 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by JSGerson

-

K - Thanks for one of many welcome backs. It does feel good to be back at my shipyard. As for relying on my progress, well let's just say I'm not known for my speed. My next big milestone is the installation of the gun deck cannons. However, in order to do that, I wanted to install all the eye-bolts the cannon rigging will require into the model first. As it turns out, some of that hardware is embedded into the knees that support the structural beams for the spar deck. In order to install those knees with the required hardware, I am now in the process of forming the all those structural beams so I can fit the knees. tight against the bulwarks and the beams. Each one is a custom fit due to inconsistencies inherit in my woodworking skills. Not only that, Those eye-bolts aren't simple eye-bolt., They are double eye-bolts, so they have to be individually made as well. It seems that no matter what I have to do, I have to do something else first. So, to reiterate, you may grow much older at the rate I'm going. Jon

-

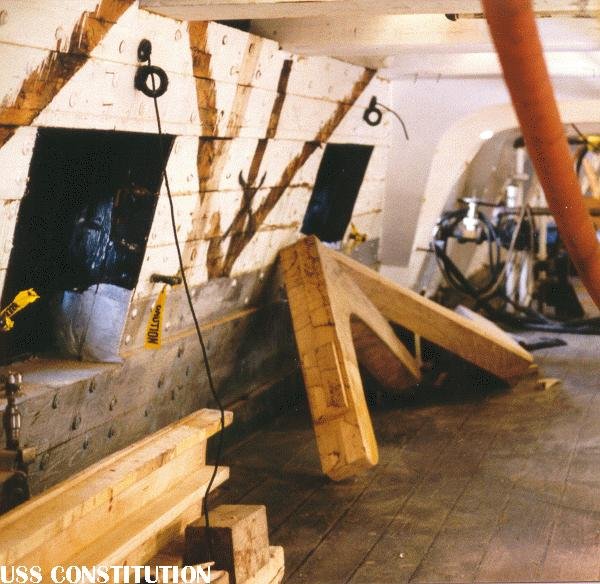

I just finished installing and painting the gun deck bulwarks. They didn’t come out as even as I would have liked, but by the time I add all the knees and bracings, guns, eyebolts, and furniture, these imperfections won’t be areas of interest to be noticed…I hope. Also, there still are a bunch of painting touch-ups on the waterways and inside the gun ports to be done. Right now, I think the diagonal knees and gun rigging eye bolts need to be installed next.

-

Just a quick note to let everyone know I’m finally back from surgery and rehabilitation. I had a large herniated disc in my lower back which required immediate removal. This was done through an incision in my abdomen by a surgeon who specializes in that sort of thing. A second surgeon worked from my backside to adjust my vertebrae angles with a wedge (screwed and pinned) where my disc used to be. And then the whole thing was fused together. All told they worked on me for six hours flipping me over four times. I was knocked out for eight. After spending 3 nights in the hospital working with occupational and physical therapists learning to walk with a walker, I went straight to a rehabilitation center for two weeks for addition therapy. By the time I left I had no need for any walking or stair climbing/descending assistance…for the most part. Surprising, I had very little pain as a direct result of the surgery. Of course, the pain killers might have something to do with that, but I don’t take anything during the day. I then spent a bit of time going through all my snail-mail as well as email, paying bills, etc., reacquainting myself with friends and family and the cat, who has not left my side since I returned. I’m just getting back to the Conny and will give you an update as soon as I hit a small milestone.

-

Thanks for the kind thoughts everyone. This will be my second, and more evasive trip to the surgeon. My first was 39 years ago and that worked great, so I have high confidence this time. JT, I know it's going to be painful due to my first surgery experience, but hopefully that pain will be the result of the incisions, etc., as opposed to my spinal defect (herniated disc) that is suppose to be corrected. I will be very happy if I'm back on my feet and on my own in 12 days like you. Jon

-

The bulwarks continue with short unpainted pieces in between the gun ports working upward. The excess wood that protruded into the gun port spaces were filed and sanded off. The bulwarks are no completed yet, but I will be taking a break for Thanksgiving week. The following week I will out of commission beginning that Wednesday as I prepare for lower back surgery which will require the services of two surgeons performing separate specialty tasks. I’ll spare you the details but suffice to say, I’m going to be poked through the front side as well as the backside. I don’t know how long recovery will be. The doctors re-assured me they do this all the time and they are confident of a successful outcome.

-

I glad you started yours before I did so that I would have another great log to follow. It is amazing that even after seeing what, and how you and many others did, I still managed to come up with new and original mistakes and do-overs. She sure is a great looking model. Jon

- 1,354 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

I purchased the Model Expo USS Constitution Paint package, so I'm using their #MS4801, "Bulwarks Dark Green." I had not used much acrylic paint prior to the Conny build, so I can't comment as to how it compares with other brands. Other than the simple clean up, I'm not a big fan of acrylic. I find it does not spread evenly, and drys too quickly. out of the jar. Adding water is very critical - a little too much, it is too loose and it won't cover well. Too little, and the paint layer is too thick. Maybe it's because I have so little experience with it and I'm just not using it right. My sister, who is an excellent artist and paints ultra realistic, uses it all the time and get phenomenal results. I'll see her this Thanksgiving and hopefully get some pointers. Jon

-

The first bulwark plank installed was a piece the full length of the visible gun deck placed flush with gun port sills on the port side. This acts as a baseline for the subsequent plank levels. The next plank was a pre-painted white, short piece placed at the aft end in between the waterway and the sill baseline plank. Because these planks must be custom fit due to the slight spacing irregularities between the waterway and the baseline plank, short pieces ease the fittings. It was pre-painted because painting these planks after installation so close to the green waterway would have been very difficult trying to avoid white paint spillover. The remaining planks will be painted white after installation. As you can see (or not?) the joints between the planks are all but invisible.

-

With the gun port netting detail dropped, I can now move on with the gun deck bulwarks. Looking at other builds, I’ve seen some builders make these bulwarks out of full width sheets of basswood or plywood because the surface is to be painted white, making any planking wood seams disappear. I find planking easier than custom fitting large pieces of inflexible wood. Once again, due to the poor visibility and the painting of the gun deck bulwarks, my choice of plank length will be based on ease of installment and not of historical size. The first thing I did, was paint the inside walls, sills, and headers of the gun port black. The subsequent planking will cover over any black paint spillover.

-

I think I might be able to help KHauptfuehrer. An excellent build log that shows all of the steps of mast and yard making, among a host of other details is Blue Ensign's Pegasus. In this case, start looking a post #112. As for the wood, if you don't want to buy dowels again, I would definitely NOT use basswood as it a bit too soft and doesn't hold an edge well. Boxwood is my choice. It's a bit harder, very fine grain, can hold an edge, and is still easy to work with. I hope this helps Jon

-

I've been trying to get a response from the USS Constitution Museum's website and Public Historian (or anyone) about the gun port netting. All I get is silence. Was it added as a modern safety devise like the sprinkler systems, lighting, etc. or is it part of the ship's fittings? In other words, do I make it part of my model or not?

Thanks

Jonathan

-

Because the kit does not supply planking for the gun deck, and I’m trying to save a few bucks, I purchased a 1/8” x 4” x 24” piece of basswood instead of buying precut strips. Using my Byrnes saw, I plan to slice the wood into 1/8” x 3/64”. Other build logs I seen have indicated 1/8” x 1/32” and 1/8” x 1/16”, so I’m in the ball park. Another thing I’ve noticed is just about nobody has incorporated the netting inside the gun port openings (both decks); I assume for its delicacy and difficulty of fabrication and installation. I may have a simple solution for that. My first try at a proof of concept seems to have worked. Using a piece of laser cut scrap wood from the ship’s boats, I cut out an opening to represent the gun port. Then with a very thin layer of PVC glue, I glued a piece of black tulle over the “gun port” opening. Tulle is a sheer (often stiffened silk, rayon, or nylon) net used chiefly for veils. I had bought some when I made my Rattlesnake. I got a lifetime supply in both black and white colors for $0.30 Then I planked it as I would the bulwarks. Because this was a proof of concept, I wasn’t too concerned with the squareness of the edges at the port opening, but this will be a precise operation when done for real because there will no opportunity to square up the edges with a file as the opening will be “closed” with the net. Finally, an opening was made in the net for the gun barrel by cutting the central portion with a fine sewing scissors. I thought about using a hot metal rod to melt a round opening but discarded that idea as too imprecise and very prone to error with one false hand tremor. The outside hull would be planked as you normally would. On the actual model, the interior of the port openings would have to be painted black prior to the net being installed. The bulwarks are to be painted white, so care must be taken not to get any white paint where its not intended to be.

-

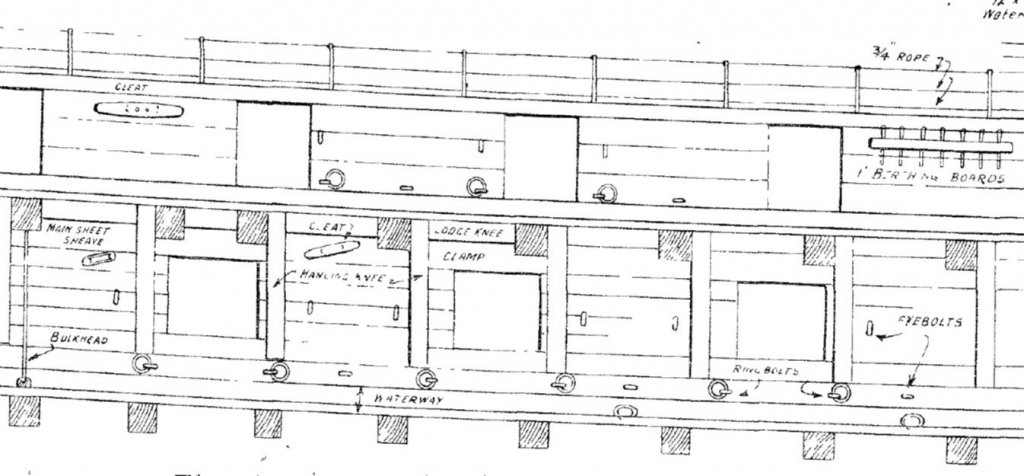

Gun Deck Bulwarks I have a US Navy plan titled Gun Deck & Inside of Bulwarks by G.F. Campbell with no identifying number or date. Based on the drawing letter style, I would guess it’s from the 1927 restoration. I believe this is when the waist was incorrectly covered over by the bulwarks. It shows it took 3 bulwark planks to extend from the spar deck gun port sill to its header. At the same time, it took four planks to do the same on the gun deck. Today, based on photographs, they are both the same at four planks which is also reflected in the kit plans. The kit calls for 3/64” thick spar deck bulwark planks. Per direct measurement from the plans (as it does not specify), the planks are 3/32” wide, thus 3/32” wide x 3/64” thick.

-

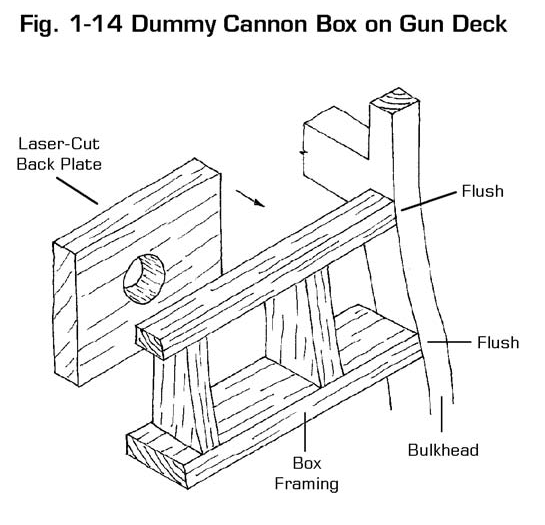

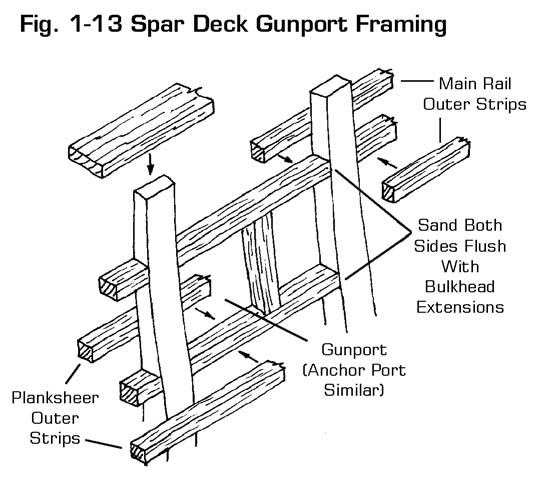

The next set of gun ports aft of the bow and the last two gun ports forward of the quarter galley will have the dummy guns because they won’t be seen (hopefully) through the opens in spar deck. All these ports will have their lids closed so that the gun boxes won’t be visible. The kit instructions show the box piece being added to the framework and states specifically that they should be mounted vertically. The diagram shows the gun port wall back edges perfectly vertical, however mine are like the spar deck diagram. In order to make them vertical, I added a small piece of wood to the base of the box. I also had to trim the far aft pair of boxes because they butted up against the captain’s cabin which wasn’t part of the kit’s plans. Those with sharp eyes will notice that I have marked the port openings with black chalk, so I don’t stick the cannons in the wrong openings or plank over them.

-

Gun Port Boxes for Dummy Cannons Another week, another hurricane, OK, tropical storm (Michael). I got wind and rain, but luckily no damage. As noted way earlier in my log, I plan to use some dummy guns on the gun deck. The first pair of gun ports in the bow won’t have any guns at all, as there is no room for them to operate. They may be some confusion when looking at the ship from the outside, because it appears there are guns with a tampion in their barrels poking out through the gun port lids. The tampions are there only to plug the muzzle openings created by the lids. You can see one lying on the green floor beam in the first image.

-

My first attempt, if you remember, was the decking in the captain cabin which I printed on paper and glued to the plywood. Not very realistic but then most viewers won’t even see the that interior. This attempt was made using Minwax Gunstock 231 as the first coat. This has a rosy hue to it. Then, I applied Minwax Golden Pecan 245 to tone down the red and add some depth to the stain. Finally, I added Minwax Polycrylic Clear Satin as the sealer. I got a good simulation of planking, but maybe just a smidge too much red. As it turned out, the color did match to captain cabin. Once more, the viewer will have limited access and dim lighting conditions as well. In any event, it is what it is. The ladder stanchions have not been repaired yet, and I might delay the repair till the last possible moment so that I won’t damage them any further.

-

Gun Deck Stained & Sealed I tried to stain the Gun Deck as close to the color of the actual ship as I could. I have a number of images and each one is slightly different than the next due to the various lighting conditions of artificial lighting and indirect daylight among other things. One of those images is shown below.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.