-

Posts

1,484 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Kevin Kenny

-

got dome small needles and they were too small,

I just got some bigger needles and will try again to make some treenails using your method.

A question,

1. do i need to remove the angled point as the smaller ones bent.

2. what RPM do i need to drill with

-

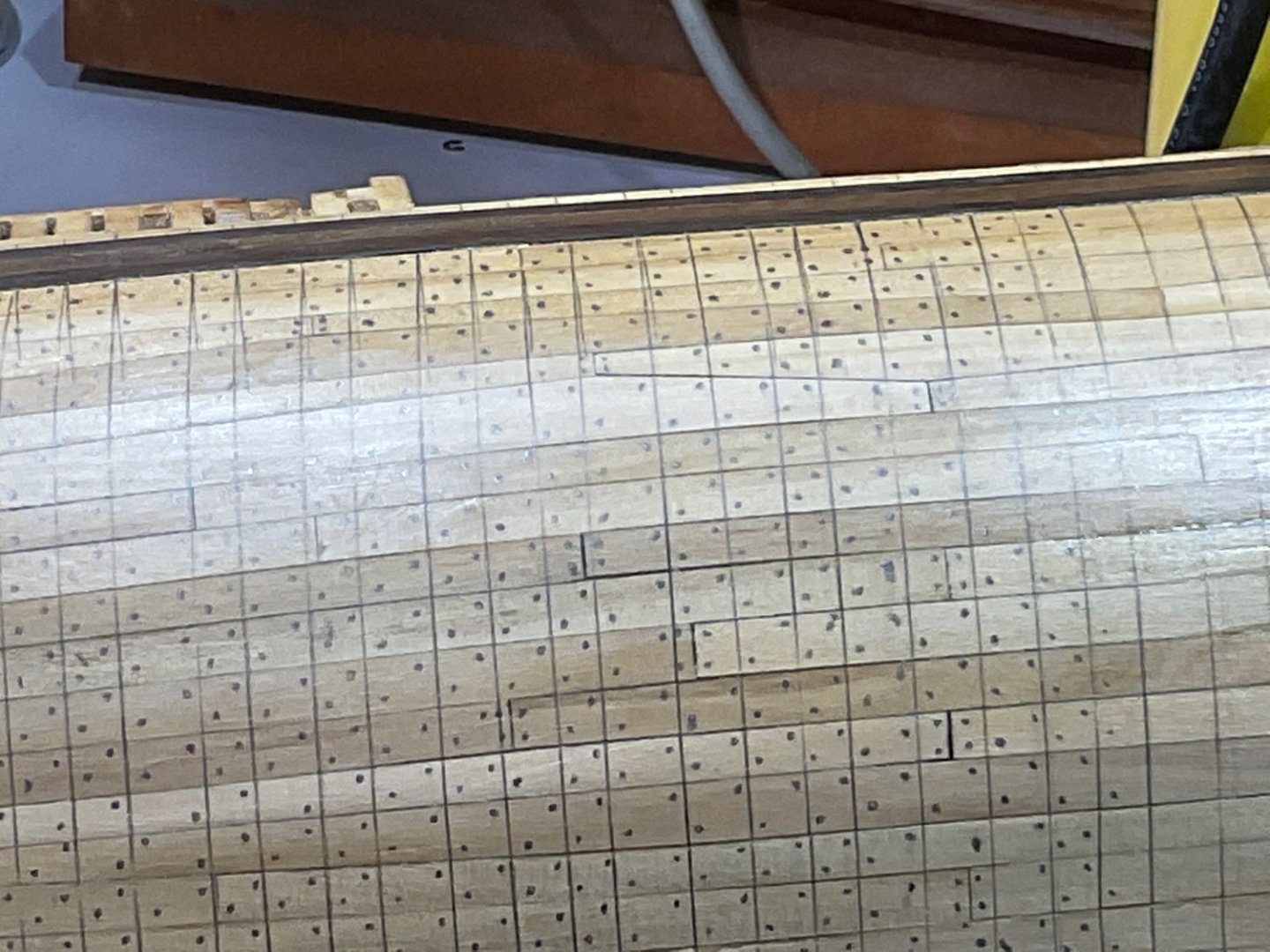

The layout has started. 3 hours in and i had to take a break. Just over half laid out. Another 3 hours to complete the pencil location of the treenails. Then to use a point to set the starter hole. Then drill and place the treenails.

- 1,127 replies

-

My rough calculation is its about 9000 individual tree nails.

- 1,127 replies

-

Alan What a wonderful paper. Thank you so much, it is every thing and more that I needed to know. I will read it a few times before i start.

- 1,127 replies

-

- 1,127 replies

-

- 1,127 replies

-

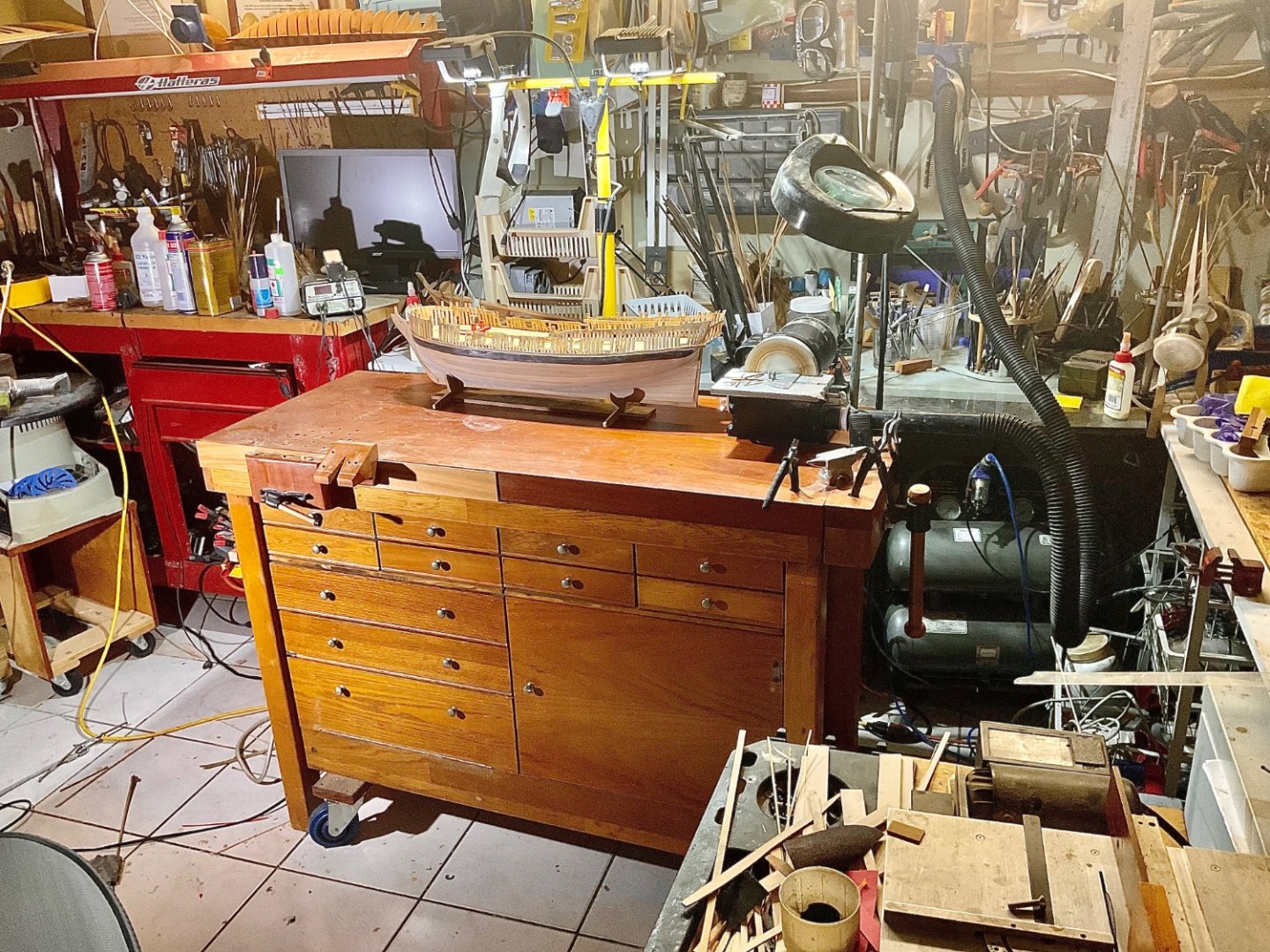

Still cleaning up but very happy with the job. It could have been better. The next one will be better. next tree nails and the rudder.

- 1,127 replies

-

I am soon to start my rudder. Anything i need to be aware of?

- 475 replies

-

-

I just followed the line on the plan. The first piece #22 was easy. I have my videos on this installation if you wish to take a look. Its at the stern that i really struggled.

- 257 replies

-

- pegasus

- Swan-class

-

(and 1 more)

Tagged with:

-

- 1,127 replies

-

- 1,127 replies

-

- 1,127 replies

-

- 1,127 replies

-

- 1,127 replies

-

- 1,127 replies

-

- 1,127 replies

-

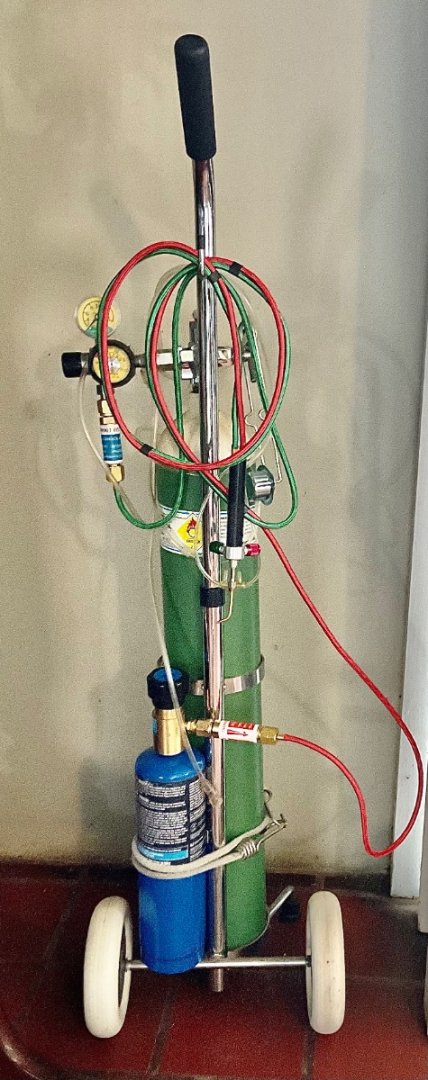

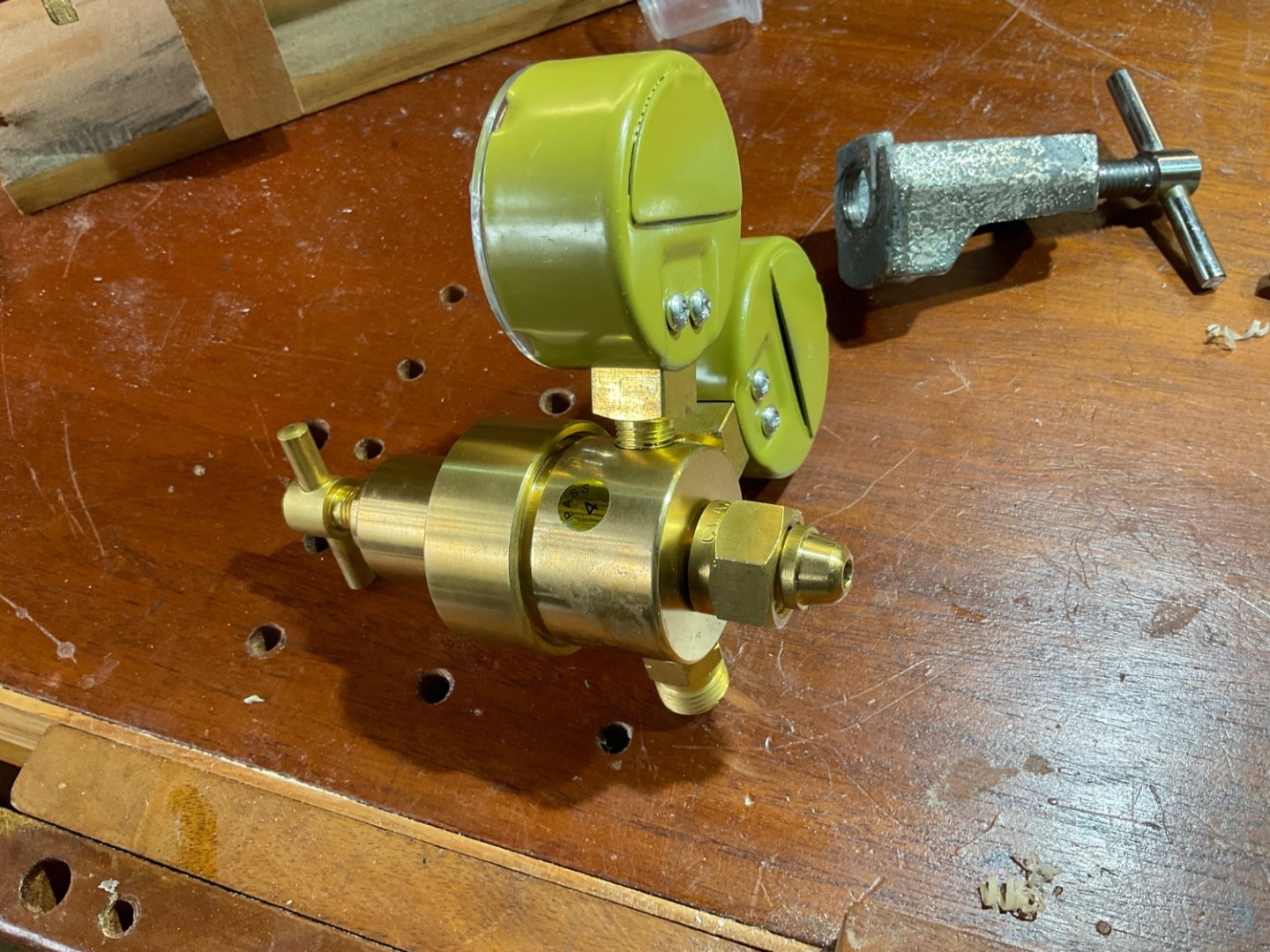

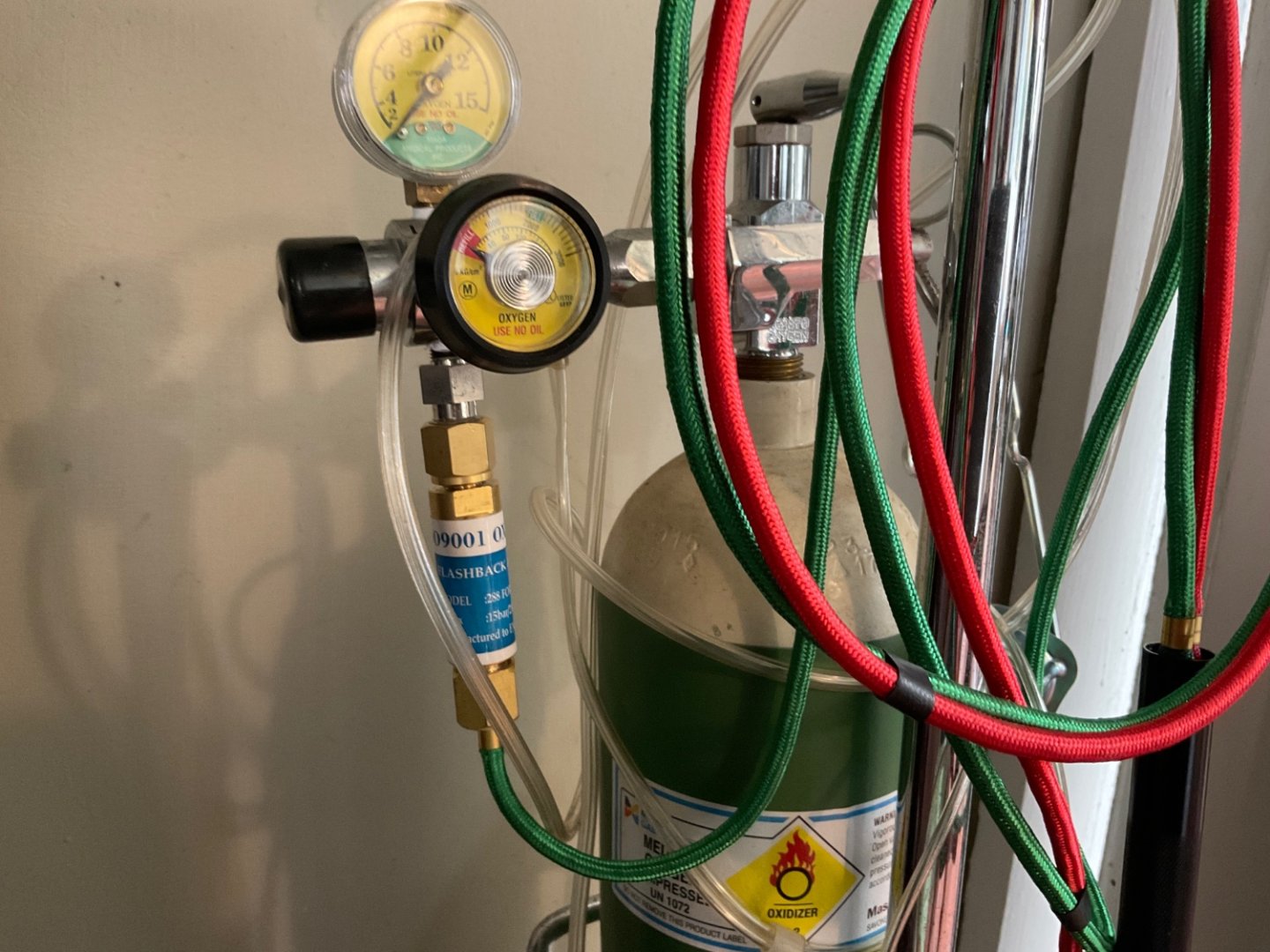

When you dont know what you are doing you can purchase all sorts of useless crap on line. I purchased the gauges along with the portable valves (just to cover my donkey) to set up the Chinese knockoff of the Smith Little torch. The oxygen worked fine but when i tried to connect the gas gauge (LPG) there was no local supplier that could accommodate me with the CGA 200 connection on the gauge. Then i went to at least 10 different wielding suppliers and non could help me find an adaptor. Thank goodness i purchased the small bottle valves. eventually i was able to hook up a medical oxygen bottle ( of which i have 2) to the Bernzomatic gas and got it to work. A real pain in the donkey

- 1,127 replies

-

I like it. I tried to do this with one of my models the Naparima. The problem is that after installing it the string did not work and i could not retrieve it to get it fixed. You might want to think about how you can retrieve it if it need to be serviced. kevin

- 257 replies

-

- pegasus

- Swan-class

-

(and 1 more)

Tagged with:

-

- 1,127 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.