-

Posts

1,491 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Kevin Kenny

-

https://vimeo.com/user15853815/download/367007440/d3abbf2100

- 1,134 replies

-

- 1,134 replies

-

Launching the ship

-

https://youtu.be/29mOXuVoE3o

-

Replacement motor for Preac saw

Kevin Kenny replied to Kevin Kenny's topic in Modeling tools and Workshop Equipment

Thanks all i will be ordering the replacement motor from ships Ahoy. In the mean time i as able to get the bushing changed and its back up and working. -

Replacement motor for Preac saw

Kevin Kenny replied to Kevin Kenny's topic in Modeling tools and Workshop Equipment

Kurt your suggestion is perfect. I sent the motor to a repair service but will order the replacement to pick up when i am in New York in November. thanks kevin -

Hi the motor on my Preac saw has died. Anyone know where i can buy a replacement motor? best regards kevin

-

Dive on the Naparima in Trinidad

Kevin Kenny replied to Kevin Kenny's topic in Nautical/Naval History

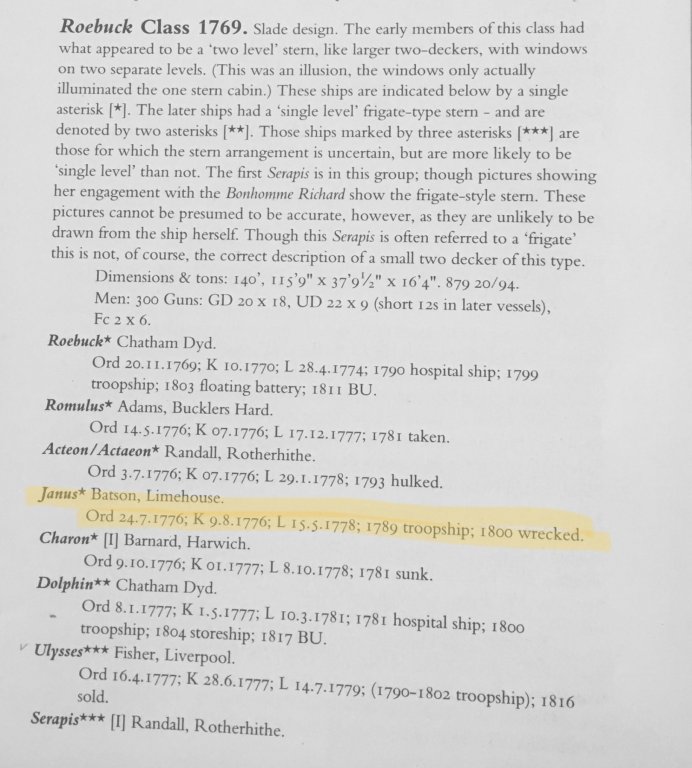

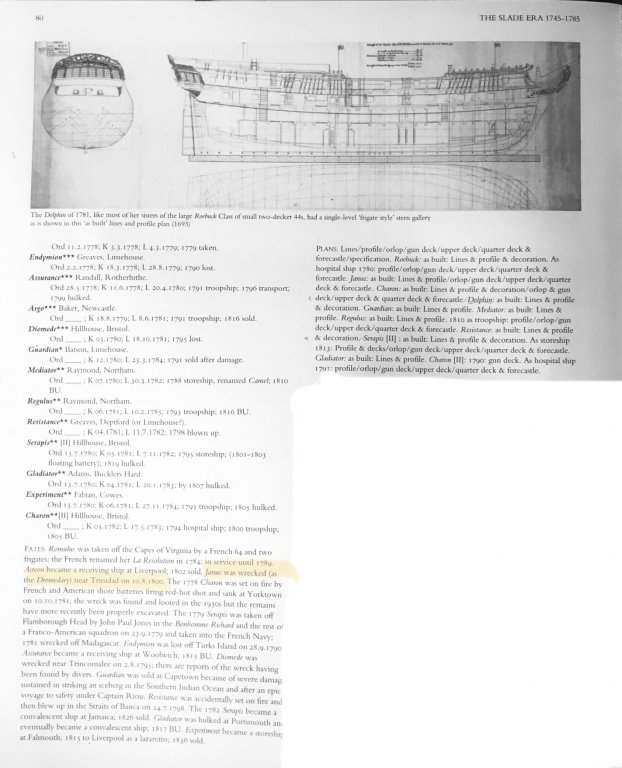

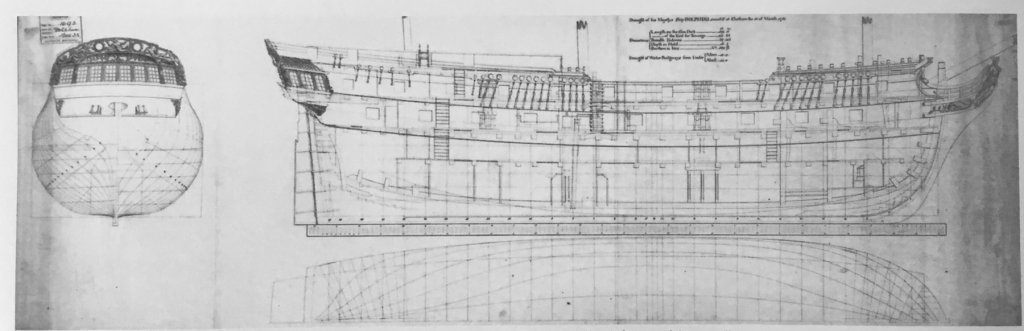

In my research i discovered that the ship is the Roebuck class, she was originally called the Janus. Ironically she is one of the ships i intend to build for which i have all the plans and data. -

Dive on the Naparima in Trinidad

Kevin Kenny replied to Kevin Kenny's topic in Nautical/Naval History

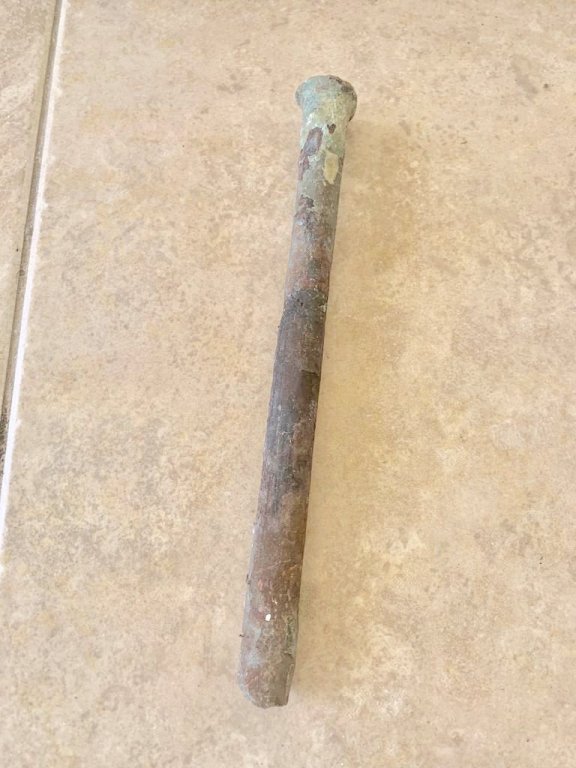

The divers have decided to give me the items that they dived up which I will keep and offer to a local museum at some time in the future. Here are three other artefacts taken many years ago. The first is a brick, the second a dead eye and the last is a block -

Dive on the Naparima in Trinidad

Kevin Kenny replied to Kevin Kenny's topic in Nautical/Naval History

Some of the bronze pieces that were recovered from the wreck of the HMS Dromedary which sank in Trinidad in 1800. The horseshoe shaped piece looks like it came from the bow at the keel, the bronze pins would have come from various timber connections, not sure where the ring came from nor the teeth piece. Perhaps someone may have a better idea??? -

Dive on the Naparima in Trinidad

Kevin Kenny replied to Kevin Kenny's topic in Nautical/Naval History

-

Today some friends of mine helped me dive on the SS Naparima and unfortunately the current was too strong and the divers nor the ROV were able to get to the wreck. So that the day was not a total wast of time they dove on another wreck that is well known and retrieved some brass pins and a brass ring that was sitting on the bottom. The wreck has some 20 cannons on the bottom and lots of stuff spread all over the ocean floor. Unfortunately she has been pilfered over the years and today is of little archeological value.

-

-

- 1,134 replies

-

- 1,134 replies

-

- 1,134 replies

-

- 1,134 replies

-

- 1,134 replies

-

I am not sure how you edit the title. If I find out I’ll get back to you

kevin

-

- 1,134 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.