-

Posts

151 -

Joined

-

Last visited

-

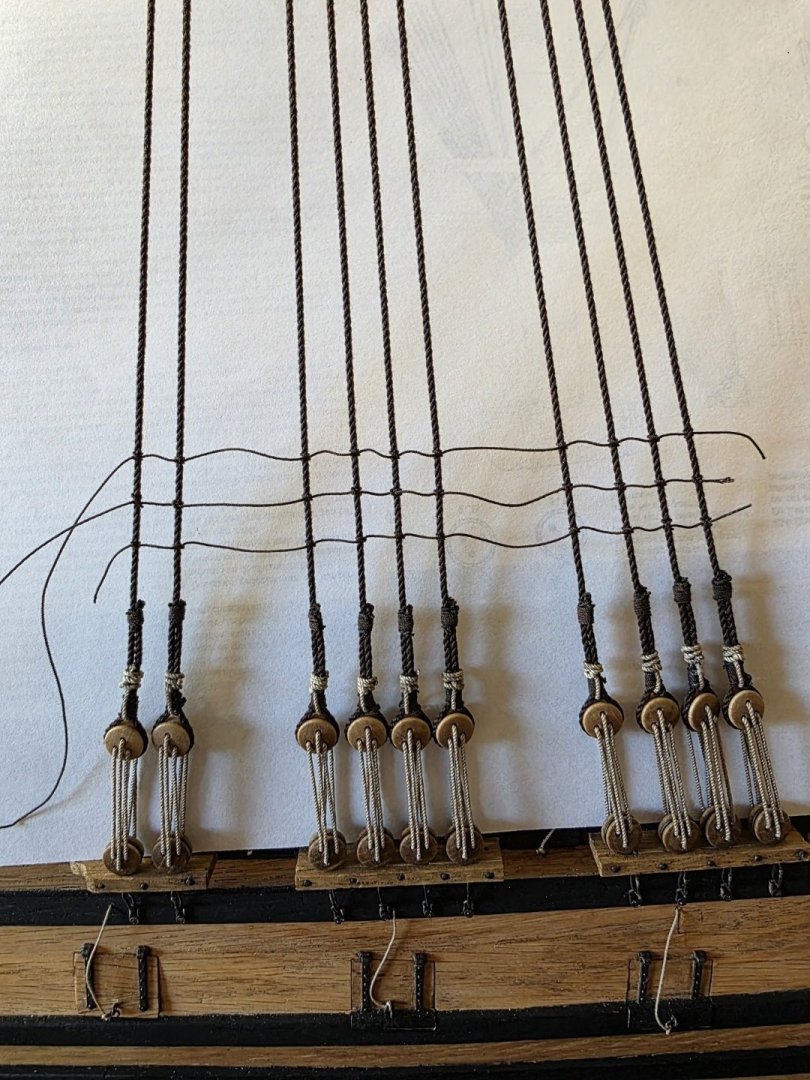

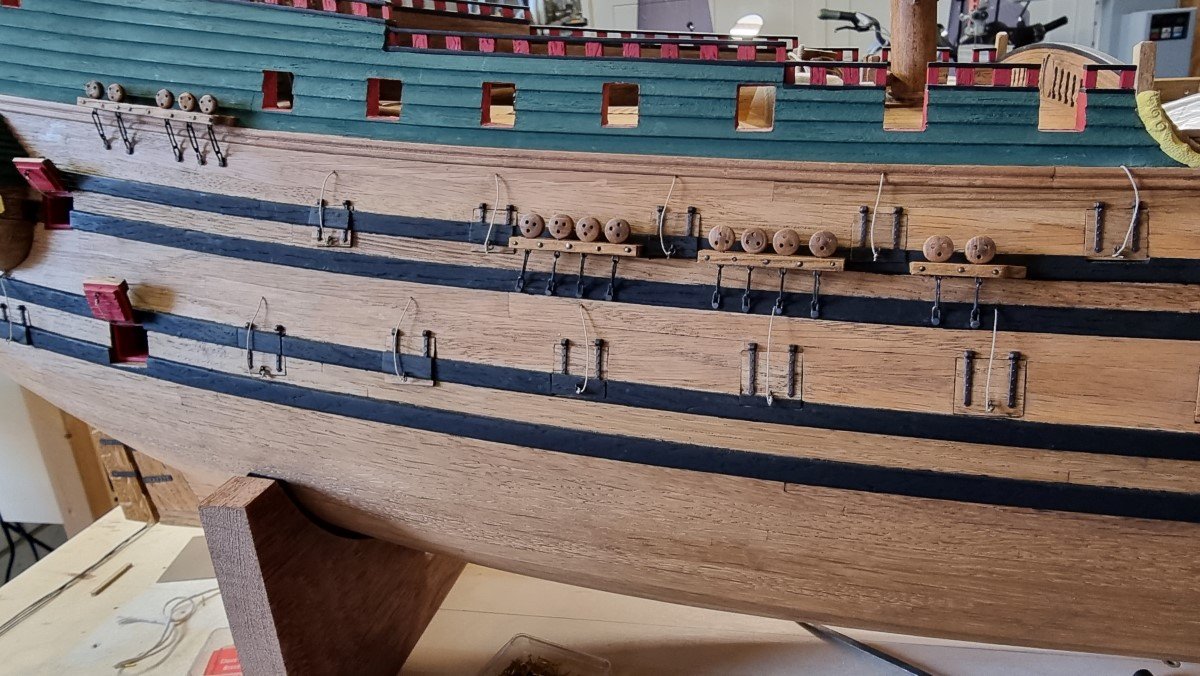

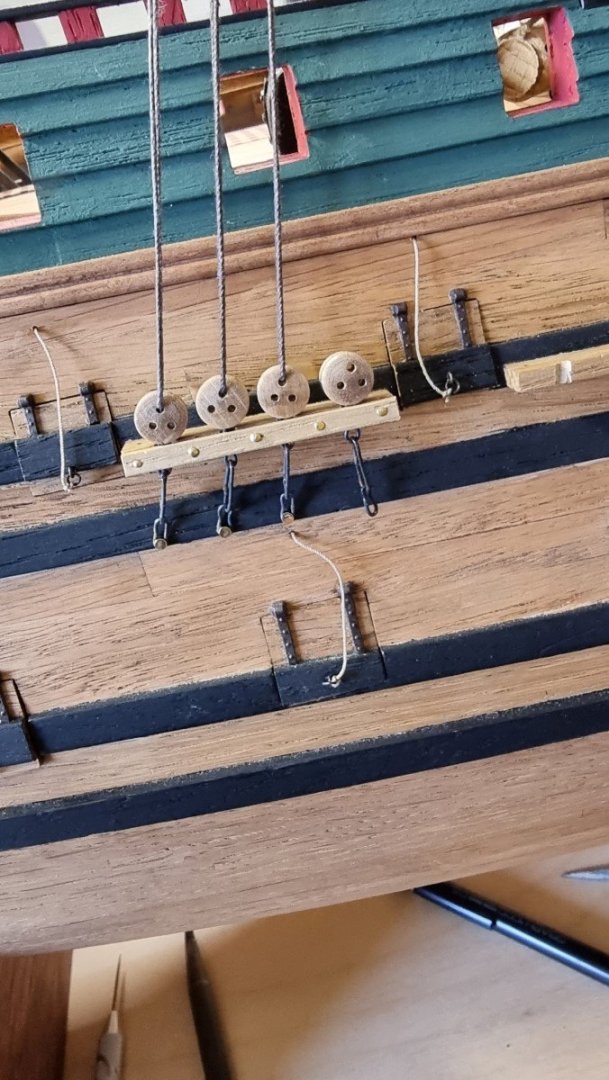

I have started again as said. As the ship has been finished from 'wood' point of view I started the rigging. I will not finish the ship in full. I intend to do a sort of 'while laying in harbour for great maintenance". So no sails, guns out. That means I will rigg only the main rigging. I have no experience in knotting so it will be learn by doing... Enjoy the day. Hans.

-

YankeeD reacted to a post in a topic:

CNC used for making parts for ship parts building?

YankeeD reacted to a post in a topic:

CNC used for making parts for ship parts building?

-

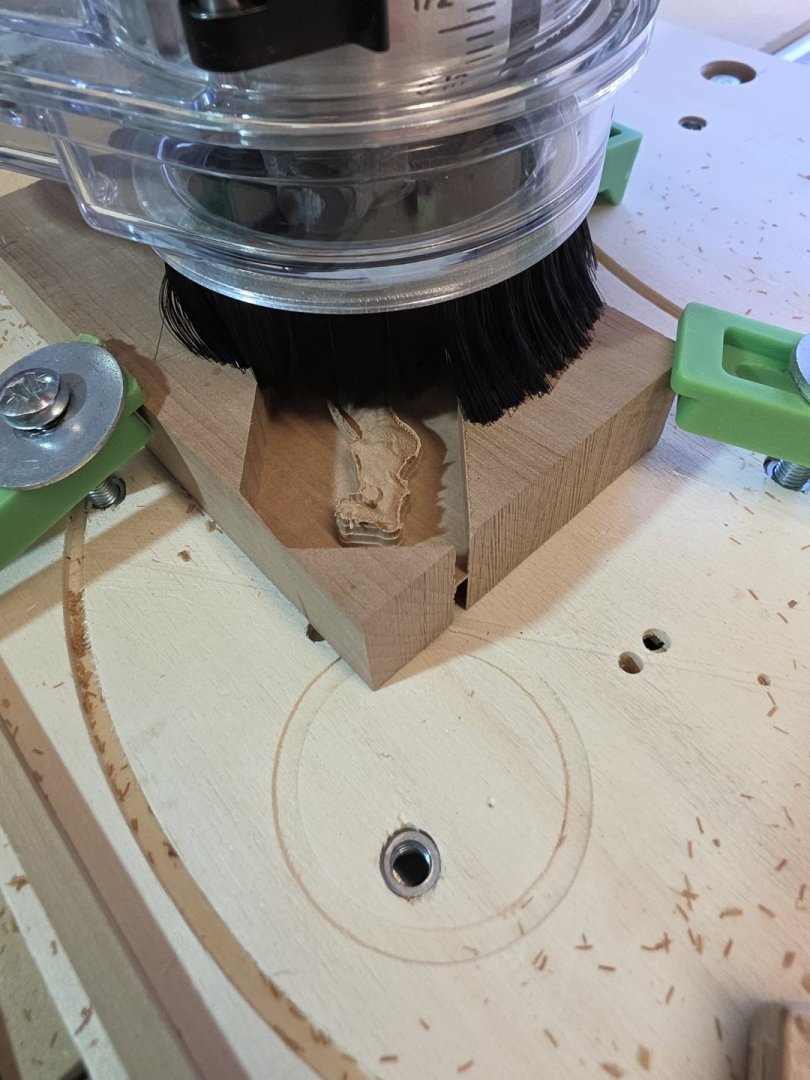

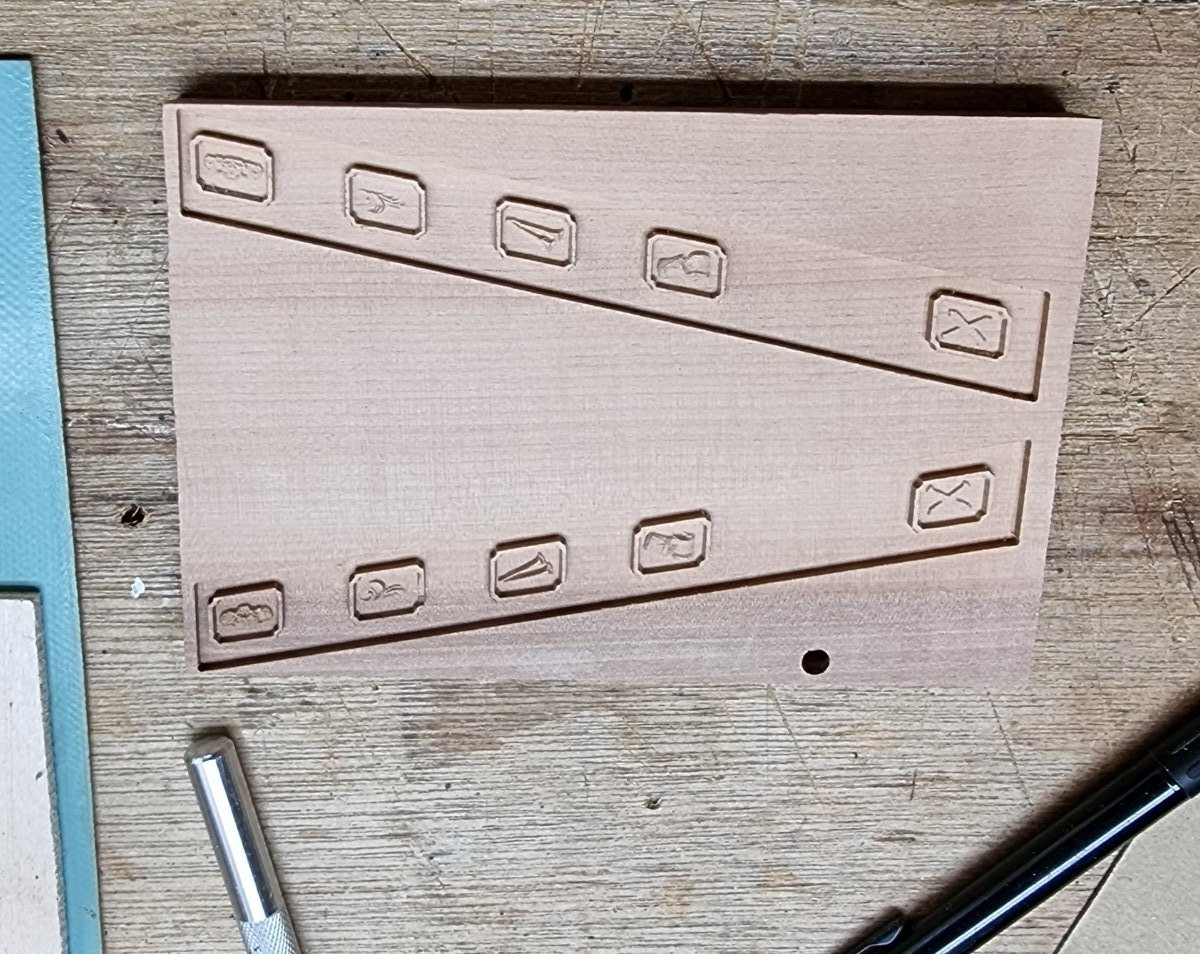

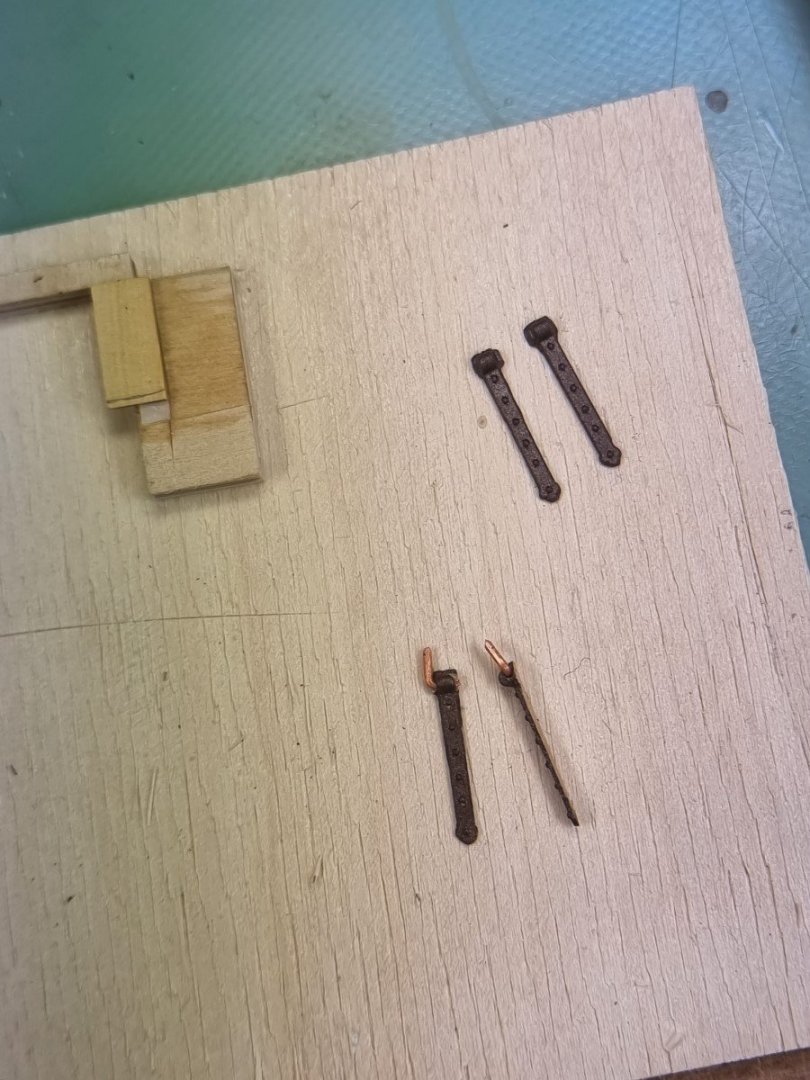

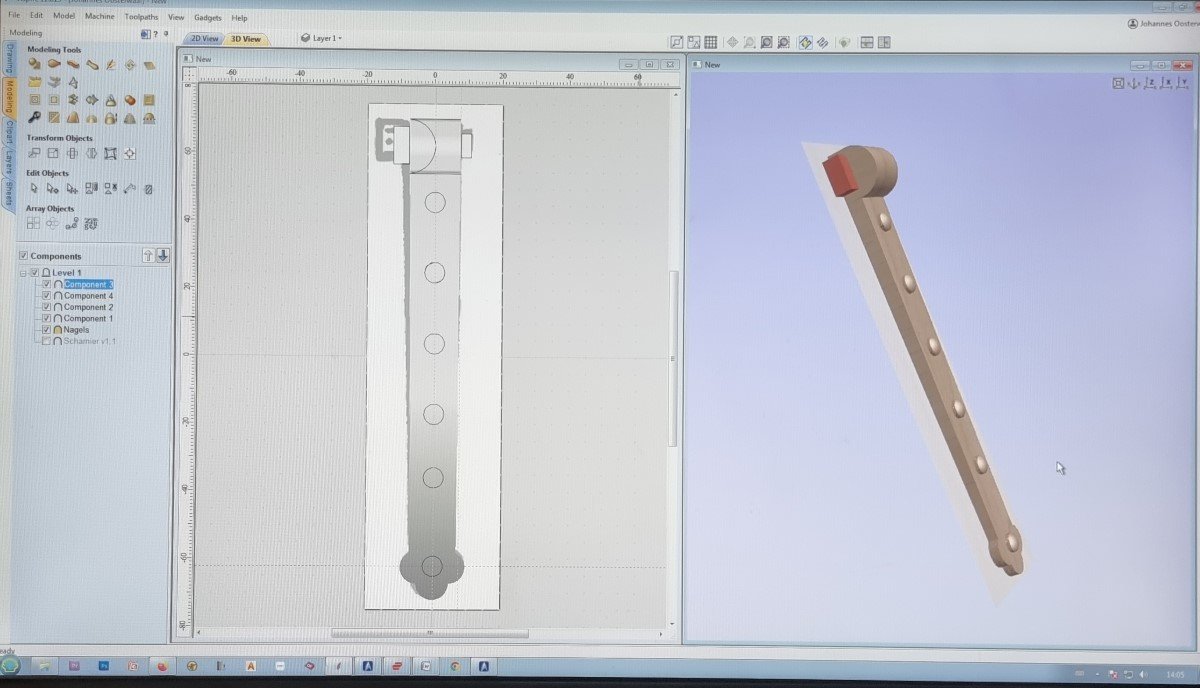

I like the prover very much. For the money its absolutely giving value. I started with the 3018 but found that too 'lightweight' and sold it off to buy the 3040. I use flip over technique. so I design two sided and turn the piece on the table. Easy, once you know how to do this. Just some random pics to show you.

-

YankeeD reacted to a post in a topic:

HMS Winchelsea 1764 by Frank Wouts 1/48

YankeeD reacted to a post in a topic:

HMS Winchelsea 1764 by Frank Wouts 1/48

-

YankeeD reacted to a post in a topic:

HMS Winchelsea 1764 by Frank Wouts 1/48

YankeeD reacted to a post in a topic:

HMS Winchelsea 1764 by Frank Wouts 1/48

-

YankeeD reacted to a post in a topic:

HMS Winchelsea 1764 by Frank Wouts 1/48

YankeeD reacted to a post in a topic:

HMS Winchelsea 1764 by Frank Wouts 1/48

-

YankeeD reacted to a post in a topic:

Hobbymill.EU / precision milled exotic woods

YankeeD reacted to a post in a topic:

Hobbymill.EU / precision milled exotic woods

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.