Rick01

Members-

Posts

652 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Rick01

-

Main deck now finished, although there are a number of buckets to add at a later date. Personally I can't see that 1/2 dozen wooden buckets would be sitting loose on the deck so that will need some thought.I varied the hinges and latch on the chest using a heavy black cartridge paper instead of trying to blacken the brass they suggest. I also placed all three medium size barrels in the crate and put a lashing around them to secure them. Who leaves a barrel on its side to roll around the deck as the plans illustrate? Rick

- 35 replies

-

- Artesania Latina

- Sultan

-

(and 1 more)

Tagged with:

-

Generally looking good, but the footropes on the main spar look a little "low" from this angle. Ideally they should be set so that man using them would be able to lean against the spar at waist height. So they should work out at a scale drop of around 85~90 cm approx. 14 mm +/- I think. I've always had problems with them myself and have found that to get a realistic hang to them a 50/50 solution of PVA glue and water will help set them properly. Rick

- 362 replies

-

- Amati

- Lady Nelson

-

(and 2 more)

Tagged with:

-

Whilst you've got reasonable access to the mast you may want to think about adding a rest to the mast for the yoke to sit on. This is how I've fitted one to s tripped down version of the Lady Nelson. ... and here's one on a replica of a similar period ship. It'll make life easier when fitting the boom. Rick

- 362 replies

-

- Amati

- Lady Nelson

-

(and 2 more)

Tagged with:

-

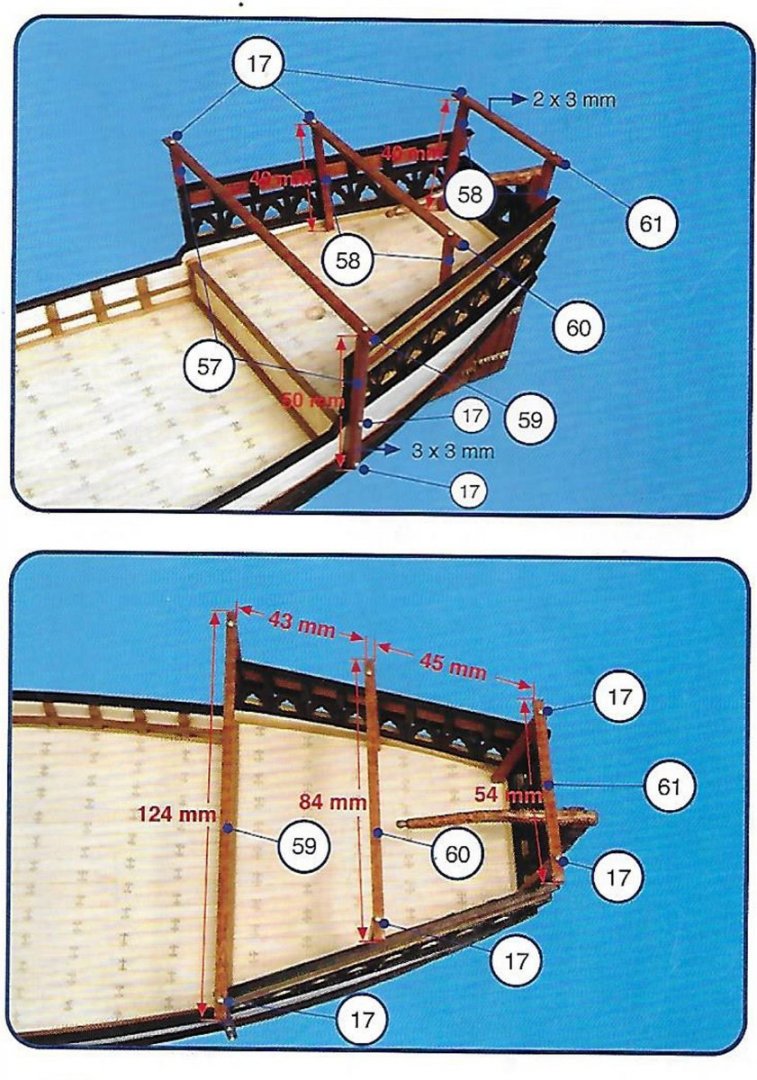

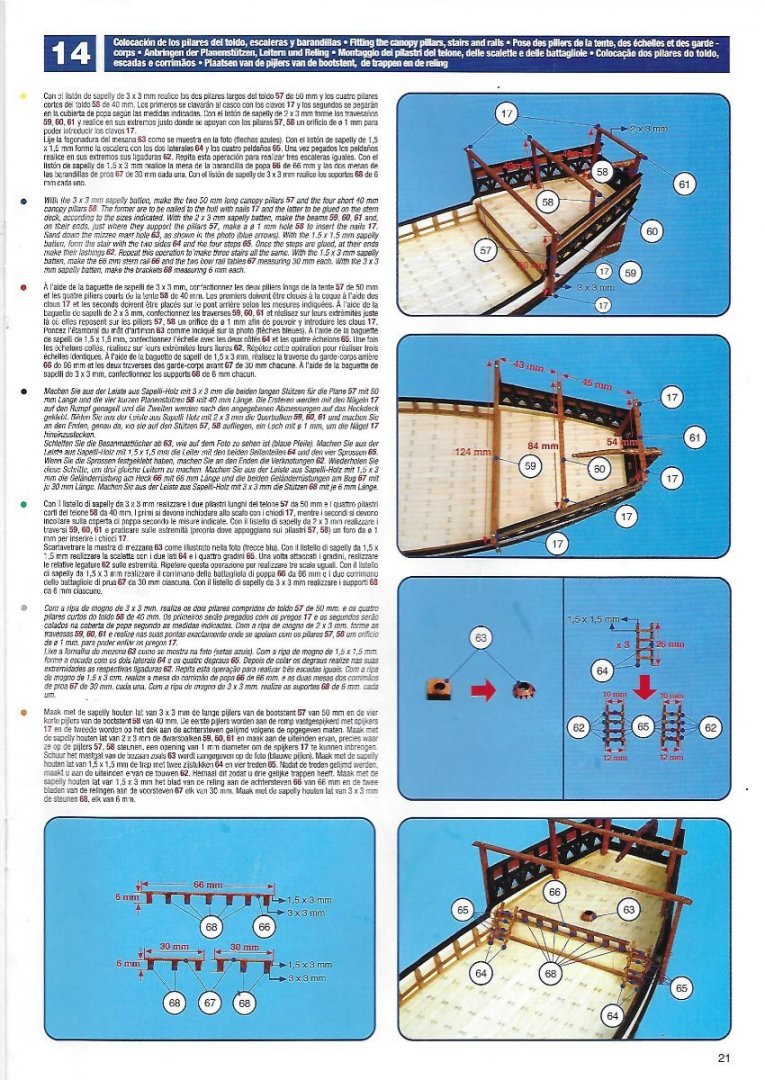

Hatch covers and a few other items now fitted, including the rudder, here I've used a stiff black paper to simulate the actual mounts. PVA glue then penetrates the paper, stiffening it further and attaches it securely to the hull. Interesting point here - I assembled the rudder/tiller exactly as shown, but when mounted the tip of the tiller is approximately 2 metres above deck level!! As the rudder is only resting in the mounts, it'll be easy to remove and shorten the post that the tiller sits on. When fitting the transverse items (page 14 and 15) measure the actual widths on your model. I found that my gunwales were slightly wider than the sample used for the instructions, which necessitated making these "beams" longer. Rick

- 35 replies

-

- Artesania Latina

- Sultan

-

(and 1 more)

Tagged with:

-

I don't see the cleats on the lower section of the mast, did you forget them? It can also be a bit of a pain fitting the boom and gaff as attaching the parrel beads to the yoke jaws will be a bit more fiddly. Standing rigging itself does look good. Rick

- 362 replies

-

- Amati

- Lady Nelson

-

(and 2 more)

Tagged with:

-

May I suggest that you complete fitting the bowsprit, boom and driver gaff before fitting any rigging. You'll find it much easier than trying to work round any existing rigging, particularly the boom and gaff. I have built this model although I don't have the build on this site. Rick

- 362 replies

-

- Amati

- Lady Nelson

-

(and 2 more)

Tagged with:

-

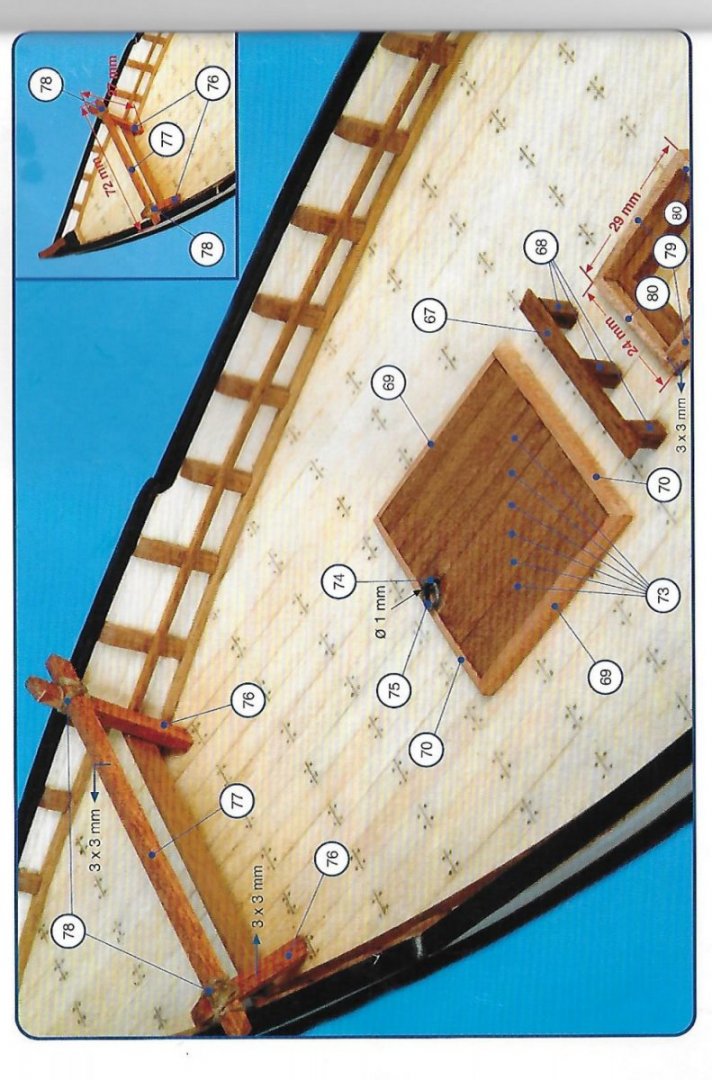

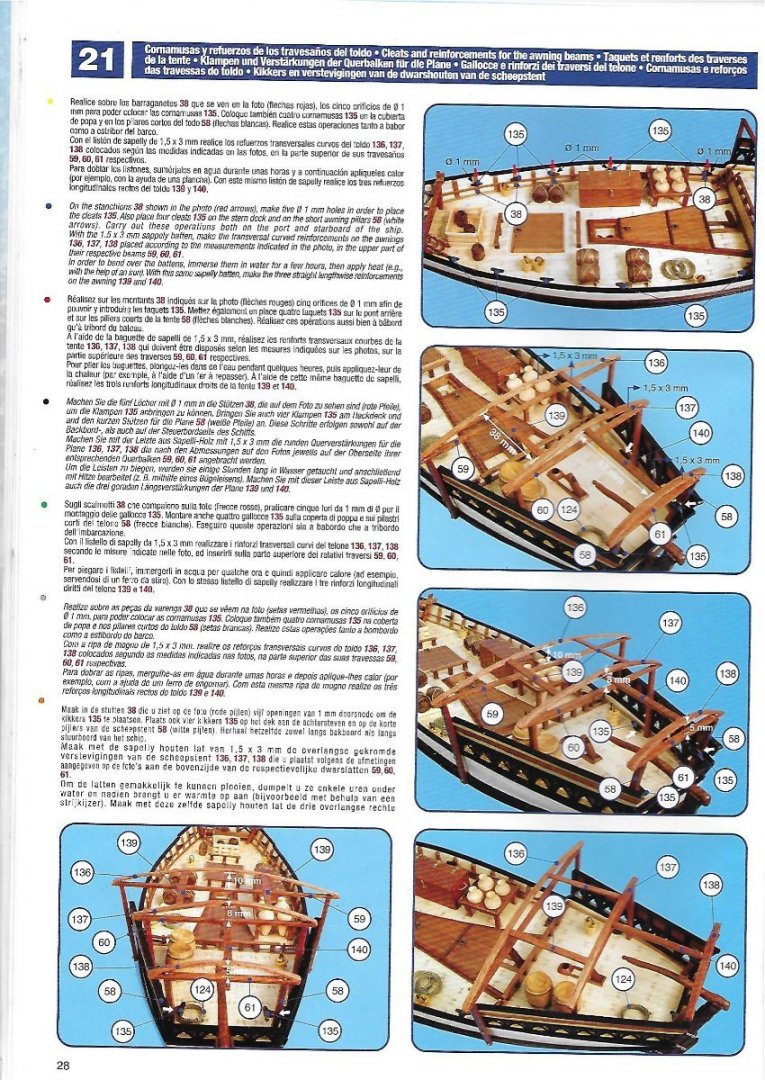

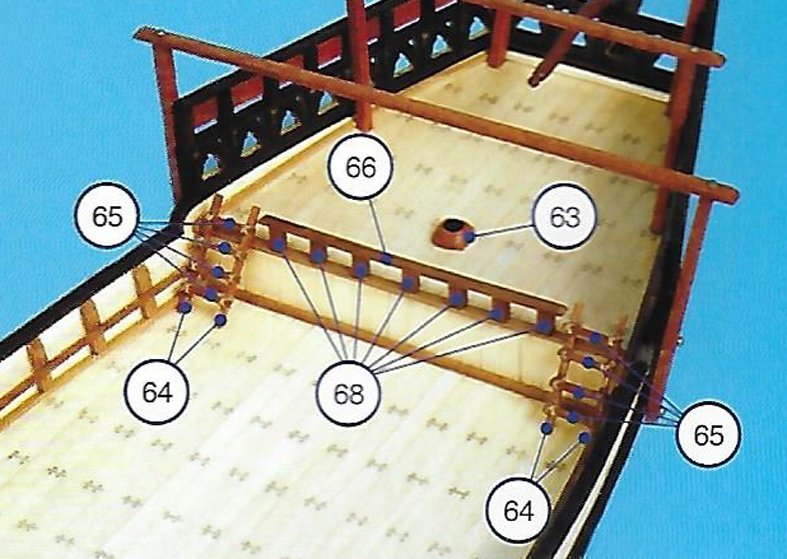

Some deck furnishings fitted now. You'll see that shall cleats have been added to the deck and the back upright. According to the instructions these are not added until page 28 of the manual. However as you can see, at that point the deck is pretty crowded and fitting them would be a pain. On page 21 you are instructed to assemble 3 ladders of equal size. Here's what happens to the 3rd ladder. Pretty obviously it should only be 3 rungs high, in my case I'll have to cut it down as I can't see that a ladder of that height is correct. Finishing the deck furniture is the next job, but It'll take a while as I do have a few other things I'm involved in. Rick

- 35 replies

-

- Artesania Latina

- Sultan

-

(and 1 more)

Tagged with:

-

I've got a little further and now have the aft structure holding the canopy half finished. I started with the decision to site the first upright inboard rather than outboard as shown in the plans. I've been unable to find any photos showing this method of construction and it doesn't make sense to hand an upright off the bumper strips. I first made a template to match the curve of the fretwork, then assembled a jig from scrap MDF to match the template. Six lengths were then cut and soaked for 24 hours before clamping in the jig for a similar time. I forgot to photograph the template before assembly but this does show how I did it. As the deck slopes upward the pencil marks on the template indicate where the curve stops an the upright changes to a straight piece (hope that makes sense) . Once they had dried, it was just a matter of matching them to the upright sections of the fretwork and gluing. Next was the cross pieces. I would suggest that you don't cut them to length until you've checked that the spacing across the uprights corresponds to that shown on the plans. I just measured each pair, added 8 mm (4 mm overlap each side) and the glued rather than tried drilling as I'm not known for great accuracy with a drill. This then is the end result. Rick

- 35 replies

-

- Artesania Latina

- Sultan

-

(and 1 more)

Tagged with:

-

With a few other things to be completed around the house I'll be giving the ship a rest for a short while. However I have sorted out the rudder, again varying how I've treated it compared to the instructions. Firstly I tapered it slightly as it did seem to be a rather ugly and over thick plank. Then instead of the brass (as I didn't have any brass blackener around) I used black cartridge paper soaked in PVA glue to form the retainers for the rudder pins. As for the pins themselves, my hands aren't steady enough to effect the drill holes they recommend, I made grooves in the rudder, set pins in the grooves and glued the retainers over them to hold the whole assembly in place. I haven't added imitation bolts as I don't feel that they realistically would be visible at this scale. With the oil/wine jars, again the instructions leave them as unpainted wood (looks pretty bad to me). I've used a mix of Tamiya Acrylic flat paint XF-68 Nato Brown and XF-15 Flat Flesh, with the flesh as the base colour and then adding the brown until I had a terracotta effect that I was happy with. Finished off with a VERY light brush of brown to weather them. The holes in the rack holding them will need careful enlarging to have the jars sitting reasonably well and getting the legs perpendicular was fun! Rick

- 35 replies

-

- Artesania Latina

- Sultan

-

(and 1 more)

Tagged with:

-

I've now completed the decorative work on the stern area, The lower fretwork is very fragile and snaps as soon as look at it, one section has around four repairs in it. Fitting to the bulwarks is not the easiest as it requires a slight curve to match the profile but of course has to be very carefully coaxed into position. The upper decorative panel is slightly easier in that you should curve it and its capping rail to match thee run of the bulwarks before attempting to mount it. You'll notice that according to these instructions the uprights on the top panel don't match the similar "ends" of the lower fretwork. To me this doesn't look correct so with mine I spaced the uprights to match the lower assembly (see below). Close-up photos really make the work look rough!! Rick

- 35 replies

-

- Artesania Latina

- Sultan

-

(and 1 more)

Tagged with:

-

Staunchions fitted as per instructions. One error here however. I should have spotted it and possibly the instructions should have mentioned it. The gunwales thickness is approximately 4.2 mm whilst the cap rail is only 3 mm! Searching further in the instructions, I found a photo that shows the top of the staunchions as having been beveled back to the edge of the cap rail. So some careful sanding back will now be needed. Rick

- 35 replies

-

- Artesania Latina

- Sultan

-

(and 1 more)

Tagged with:

-

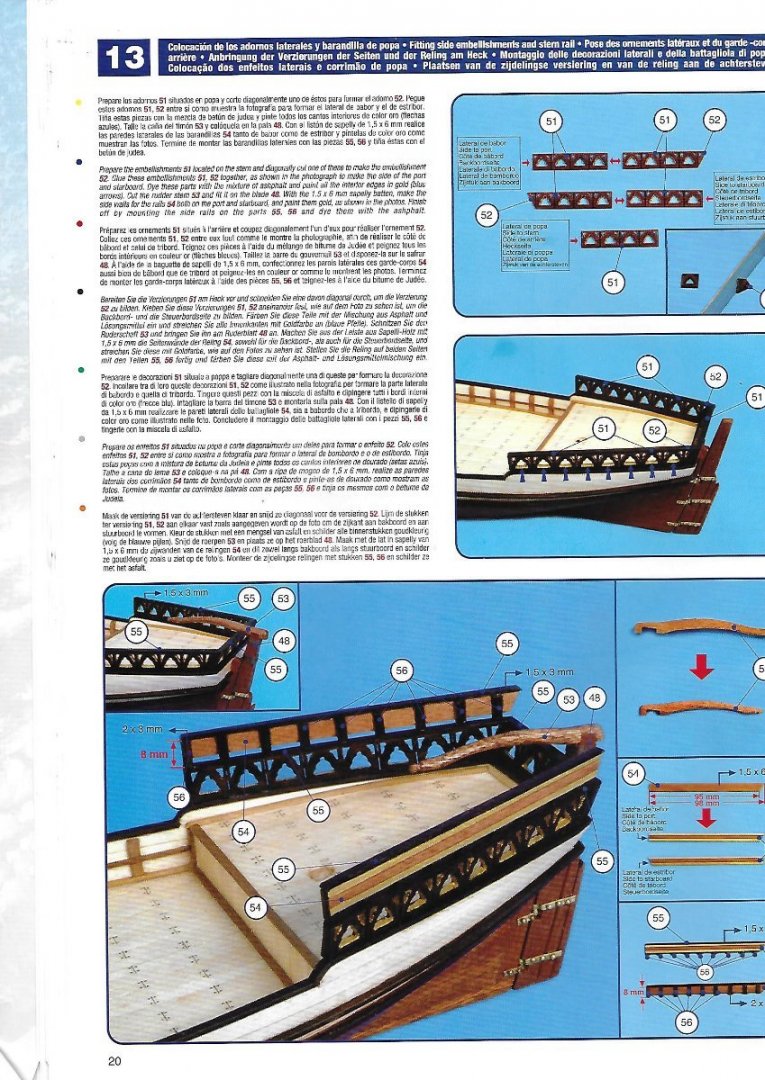

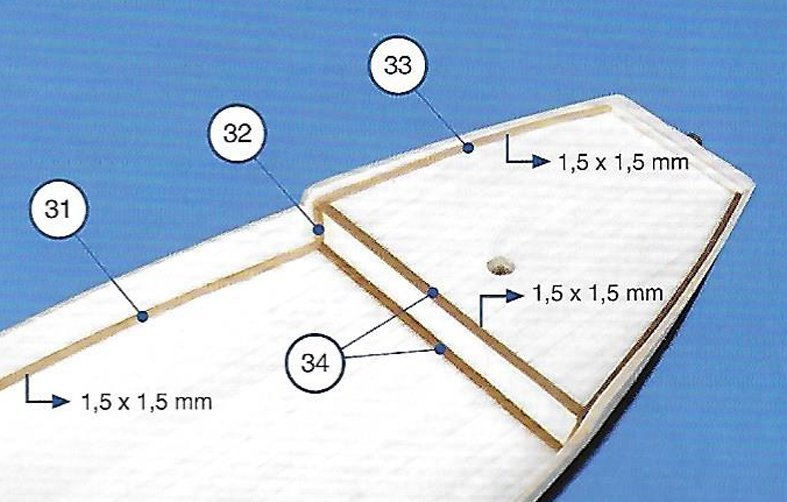

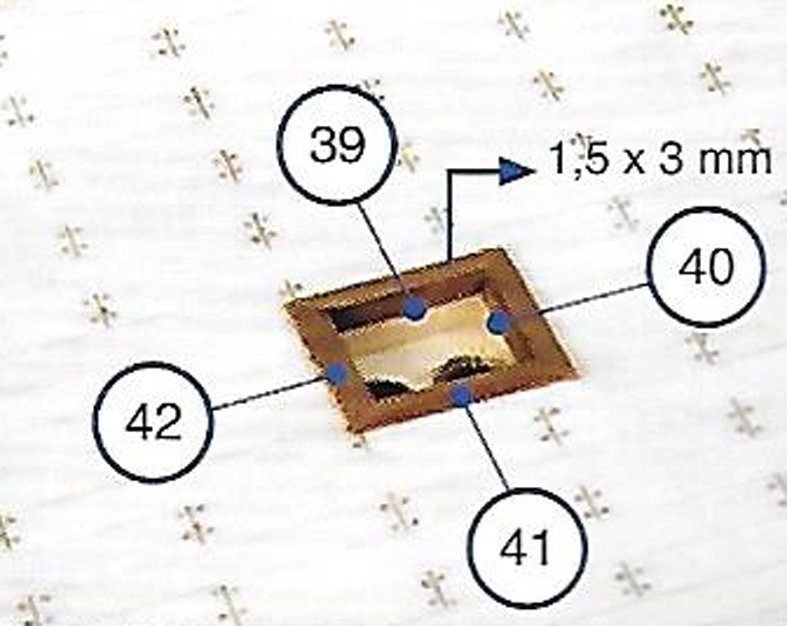

Now has the trim added on the decks to finish off the decking. This is where the need to read ahead seems to happen. The trim on the aft deck is 1.5 mm x 1.5 mm but reading ahead to page 21, there is a "fence" installed across the aft deck sitting on the trim. The uprights (part 68) being 3 mm x 3 mm, this would mean that these would be half on, half off this trim section. This really didn't make sense to me so I've placed a 3 mm x .6 mm length over the existing trim (I'd already fitted the 1.5 mm x 1.5 mm and wasn't going to attempt to remove it). Then the edging around the "small deck" in which the main mast sits is very tight and requires a support post angled back at 88 deg. in the forward hole which braces the main mast. This shows that the inner edges are to have a 1.5 mm x 3 mm insert, but as can be seen here the tolerances are very fine even without the insert. I've chosen to ignore parts 39 & 40, only fitting 41 & 42 as the tolerance was to fine for me to get the correct angle on the brace. Next step will be to again read through the instructions and to try and anticipate any more of these little hiccups. Rick

- 35 replies

-

- Artesania Latina

- Sultan

-

(and 1 more)

Tagged with:

-

Well I've now fitted the fenders after staining contrary to the instructions. The plan calls for a 4mm gap between them, this was easiest done by temporarily fitting a 4mm wide strip of planking between the two fenders (left over from another job), then removing once everything was dry. Decking next. Here I decked both fore and aft decks with single length planks as the maximum length appeared to be 15 ft (assuming the plans are somewhere near correct 😉 ), for the main deck I used 12 ft scale lengths rather than the 6 ft the suggest as this really didn't make sense to me. These were individually cut and laid rather than lay full length then mark off with pencil as recommended. Done their way the deck looked to perfect, manually it has a bit of variance with colour etc. The deck will now need sanding and I'll add a single coat of a satin finish water based varnish to protect the surface before the next step. Obviously I still need to tidy this up before moving on to adding various bits of "trim". Rick

- 35 replies

-

- Artesania Latina

- Sultan

-

(and 1 more)

Tagged with:

-

It's a slow process due to a few personal matters but I will finish this! I've now completed the planking, it's very different to my previous work with cutters and there are a few patch and fill items on the hull but from a metre away they don't show and as I don't feel competent to strip it down and re-do I am happy with the result. Photography isn't my best subject but you can get some sort of feel for the end result here. Bumper strips are next on the work list - here the plans show them being fitted pre-stained but the instructions go on to tell you to stain after fitting!! Generally I feel the instructions are not exactly brilliant and do need careful reading well ahead of anything you may be working on. Decking comes next. Here they just suggest laying down full length planking then marking up into shorter lengths using pencil, no real clues as to the lengths that one would expect on real decking nor any suggestions as to waterways along the gunwales. I can't find any good photos on-line for the real thing so finishing the deck will be guesswork at this point. Rick

- 35 replies

-

- Artesania Latina

- Sultan

-

(and 1 more)

Tagged with:

-

I've just started the second planking, not my favourite bit as I much prefer rigging. However it has to be done and currently I'm moving slowly with a couple of strakes a day being fitted. Pinning a reluctant section in place. Only another 10 per side to fit. I commenced tapering after the second stake was fitted and on the second strake after the garboard plank, so far it's going smoothly. Rick

- 35 replies

-

- Artesania Latina

- Sultan

-

(and 1 more)

Tagged with:

-

I'm afraid I was a bit slack with my first few photos, but hopefully after this things will improve. The next problem I found was at bulkheads 8, 9 and 10. When laying a strip of wood along the bulkheads 9 had low spots so that I either had to remove masses of wood in order to get a smooth line or pad it out. I chose to add a small section of .6 mm Lime and then when it came to 1st planking sand the padding to adjust the flow. Without that I had a dimple appearing in the cladding. At the same time it was obvious that the planking did not follow a line based on the tops of the bulkheads or the decks which is apparent from the following photos. From there I had fun trying to plank it as the flow of planking at the bow didn't exactly follow what I've been used to with previous models. It does look a bit like a dog's breakfast but I preferred to experiment on the first layer rather than completely stuff up the final planking. I did search Google for photos of actual dhows, those I found of similar size and showing reasonably clear planking seemed to follow a system of "if it fits/fills the space" then that's OK. Rick

- 35 replies

-

- Artesania Latina

- Sultan

-

(and 1 more)

Tagged with:

-

I haven't put a build up for some while now - life get's in the way at times. But I've now ventured into slightly different craft to my usual style, it was the lines that interested me in this one. Firstly excuse the really bad photography - absolutely NOT my best subject. Everything was nicely packaged and it all seems to be there. The parts fit well with no play and the centre piece was straight. Decks also dropped in easily and sat flush to the bulkheads. Here however I started to have problems, looking at the fit here you'll notice that the deck projects past the last three bulkheads on the lower deck. The other side is perfect and the centre line matches the centre piece (sorry forgot to photo from above). I had to sort this out at the point of 1st planking. Instructions leave a bit to desire, plenty of photos but so small that detail is poor and without a large magnifying glass those of us with senior eyes have trouble working out what they are attempting to show. Rick

- 35 replies

-

- Artesania Latina

- Sultan

-

(and 1 more)

Tagged with:

-

You still need to make a case for it, otherwise dusting will be a major pain! 😉 Rick

- 92 replies

-

- artesania latina

- le renard

-

(and 1 more)

Tagged with:

-

Looking good! One hint for your next build - with the blocks, try to sand the edges slightly to get rid of that square look. It's a real pain but it is worth it. Some people tumble them but I've never been good enough to make my own tumbling machine so it's a matter of gripping the block in fingers or tweezers and gently sanding the edges. Rick

- 92 replies

-

- artesania latina

- le renard

-

(and 1 more)

Tagged with:

-

A tip for making iron work such as shown on your anchors - matt black card cut in strips and soaked in PVA glue works wonders. It's all I use where strips of black iron are needed. Rick

- 114 replies

-

- Lady Nelson

- amati

-

(and 1 more)

Tagged with:

-

Here's what happens when you've kept the plans, have a pile of left-over timber and get bored. Using the original plans, I re-modelled the deck layout, fitted heavier armament and jiggled a few other bits and pieces. 🙂 Must say I like the idea of the party ship! Rick

- 114 replies

-

- Lady Nelson

- amati

-

(and 1 more)

Tagged with:

-

Actually if you check the Gallery for contemporary models you'll find a number of variations for naval cutters, mainly in the deck furnishings, with one or two around the windlass. 😉 Rick

- 114 replies

-

- Lady Nelson

- amati

-

(and 1 more)

Tagged with:

-

One of the best bits about this kit is that it isn't a model of an actual ship. This means you can get a bit inventive if you want to and no-one can say "that's wrong" unless of course you start playing with ideas from another era. Rick

- 114 replies

-

- Lady Nelson

- amati

-

(and 1 more)

Tagged with:

-

Check a few other builds for a comparison, generally they would appear almost straight on a 1/64 scale model. With mine I've always tried to get the sag right out of the ratlines. Rick

- 92 replies

-

- artesania latina

- le renard

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.