-

Posts

96 -

Joined

-

Last visited

About Andrew J.

- Birthday May 27

Profile Information

-

Gender

Male

-

Location

Central New York

Recent Profile Visitors

-

Andrew J. reacted to a post in a topic:

Elizabeth Howard by Jond - 1:48 - The White Ghost - Schooner

Andrew J. reacted to a post in a topic:

Elizabeth Howard by Jond - 1:48 - The White Ghost - Schooner

-

It’s not clear from your write up at what point you removed the tape, but in case you haven’t heard this tip before, I’d like to suggest that you remove the tape while the paint is still tacky. If you remove it after the paint is completely dry, the paint is more like to chip away along the edges. Beautiful ship!

- 34 replies

-

Andrew J. reacted to a post in a topic:

Elizabeth Howard by Jond - 1:48 - The White Ghost - Schooner

Andrew J. reacted to a post in a topic:

Elizabeth Howard by Jond - 1:48 - The White Ghost - Schooner

-

Lightning 10980 reacted to a post in a topic:

Lightning by Andrew J. - Scale 1:12 - centerboard sloop from Sparkman & Stevens plans

Lightning 10980 reacted to a post in a topic:

Lightning by Andrew J. - Scale 1:12 - centerboard sloop from Sparkman & Stevens plans

-

Altduck reacted to a post in a topic:

Lightning Sailboat by Andrew J. - Dumas - Scale 1:12

Altduck reacted to a post in a topic:

Lightning Sailboat by Andrew J. - Dumas - Scale 1:12

-

Andrew J. reacted to a post in a topic:

Lightning Sailboat by Woody S - from Dumas plans

Andrew J. reacted to a post in a topic:

Lightning Sailboat by Woody S - from Dumas plans

-

Andrew J. reacted to a post in a topic:

Lightning Sailboat by Woody S - from Dumas plans

Andrew J. reacted to a post in a topic:

Lightning Sailboat by Woody S - from Dumas plans

-

FriedClams reacted to a post in a topic:

Lightning by Andrew J. - Scale 1:12 - centerboard sloop from Sparkman & Stevens plans

FriedClams reacted to a post in a topic:

Lightning by Andrew J. - Scale 1:12 - centerboard sloop from Sparkman & Stevens plans

-

FriedClams reacted to a post in a topic:

Lightning by Andrew J. - Scale 1:12 - centerboard sloop from Sparkman & Stevens plans

FriedClams reacted to a post in a topic:

Lightning by Andrew J. - Scale 1:12 - centerboard sloop from Sparkman & Stevens plans

-

FriedClams reacted to a post in a topic:

Lightning by Andrew J. - Scale 1:12 - centerboard sloop from Sparkman & Stevens plans

FriedClams reacted to a post in a topic:

Lightning by Andrew J. - Scale 1:12 - centerboard sloop from Sparkman & Stevens plans

-

FriedClams reacted to a post in a topic:

Lightning by Andrew J. - Scale 1:12 - centerboard sloop from Sparkman & Stevens plans

FriedClams reacted to a post in a topic:

Lightning by Andrew J. - Scale 1:12 - centerboard sloop from Sparkman & Stevens plans

-

berhard reacted to a post in a topic:

Lightning by Andrew J. - Scale 1:12 - centerboard sloop from Sparkman & Stevens plans

berhard reacted to a post in a topic:

Lightning by Andrew J. - Scale 1:12 - centerboard sloop from Sparkman & Stevens plans

-

FriedClams reacted to a post in a topic:

Germania Nova 1911 by KeithAug - FINISHED - Scale 1:36 - replica of schooner Germania 1908

FriedClams reacted to a post in a topic:

Germania Nova 1911 by KeithAug - FINISHED - Scale 1:36 - replica of schooner Germania 1908

-

mtaylor reacted to a post in a topic:

Germania Nova 1911 by KeithAug - FINISHED - Scale 1:36 - replica of schooner Germania 1908

mtaylor reacted to a post in a topic:

Germania Nova 1911 by KeithAug - FINISHED - Scale 1:36 - replica of schooner Germania 1908

-

Retired guy reacted to a post in a topic:

Germania Nova 1911 by KeithAug - FINISHED - Scale 1:36 - replica of schooner Germania 1908

Retired guy reacted to a post in a topic:

Germania Nova 1911 by KeithAug - FINISHED - Scale 1:36 - replica of schooner Germania 1908

-

Absolutely ridiculous how beautiful this is. There's just something I really love about this style of rig. I love how you've done the sails; the wire reinforcements definitely seem to provide the desired effect. Are you familiar with the movie Joe vs. the Volcano? One of Tom Hanks' and Meg Ryan's lesser-known and underappreciated romantic comedies. At one point they're sailing on the Pacific on a similar vessel, called the Tweedle Dee in the movie (Spike Africa in real life). There's this one shot at sunset with a lovely sweeping string motif that has always really struck me. Seeing your last couple updates of the sails all coming together reminds me of that.

-

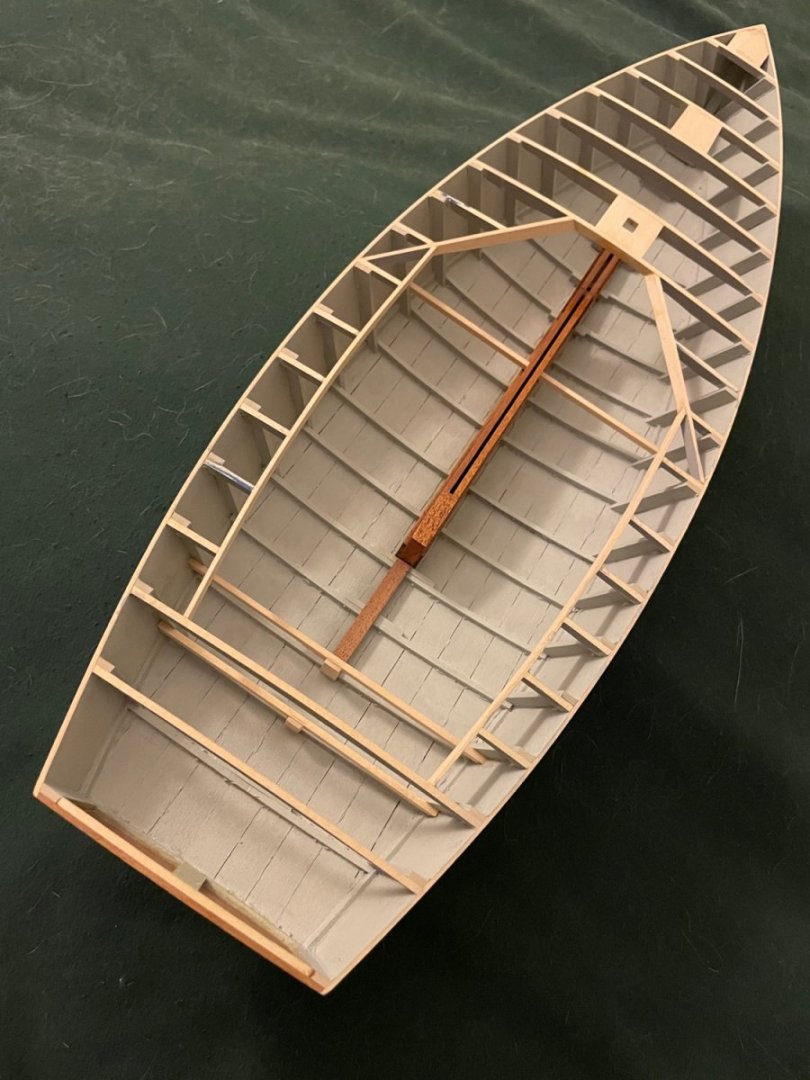

The most significant progress on the boat itself in almost a year and a half! I made the floorboards Friday night, installed most of them on Saturday, and just finished up a few minutes ago! The outermost ones aren’t as straight as I might have liked, but I think those ends will be obscured well enough by the seats so I won’t worry about it too much. I’ll throw some polyurethane on them throughout this week, hopefully, and then the seats will be next!

-

Andrew J. reacted to a post in a topic:

Lightning by Andrew J. - Scale 1:12 - centerboard sloop from Sparkman & Stevens plans

Andrew J. reacted to a post in a topic:

Lightning by Andrew J. - Scale 1:12 - centerboard sloop from Sparkman & Stevens plans

-

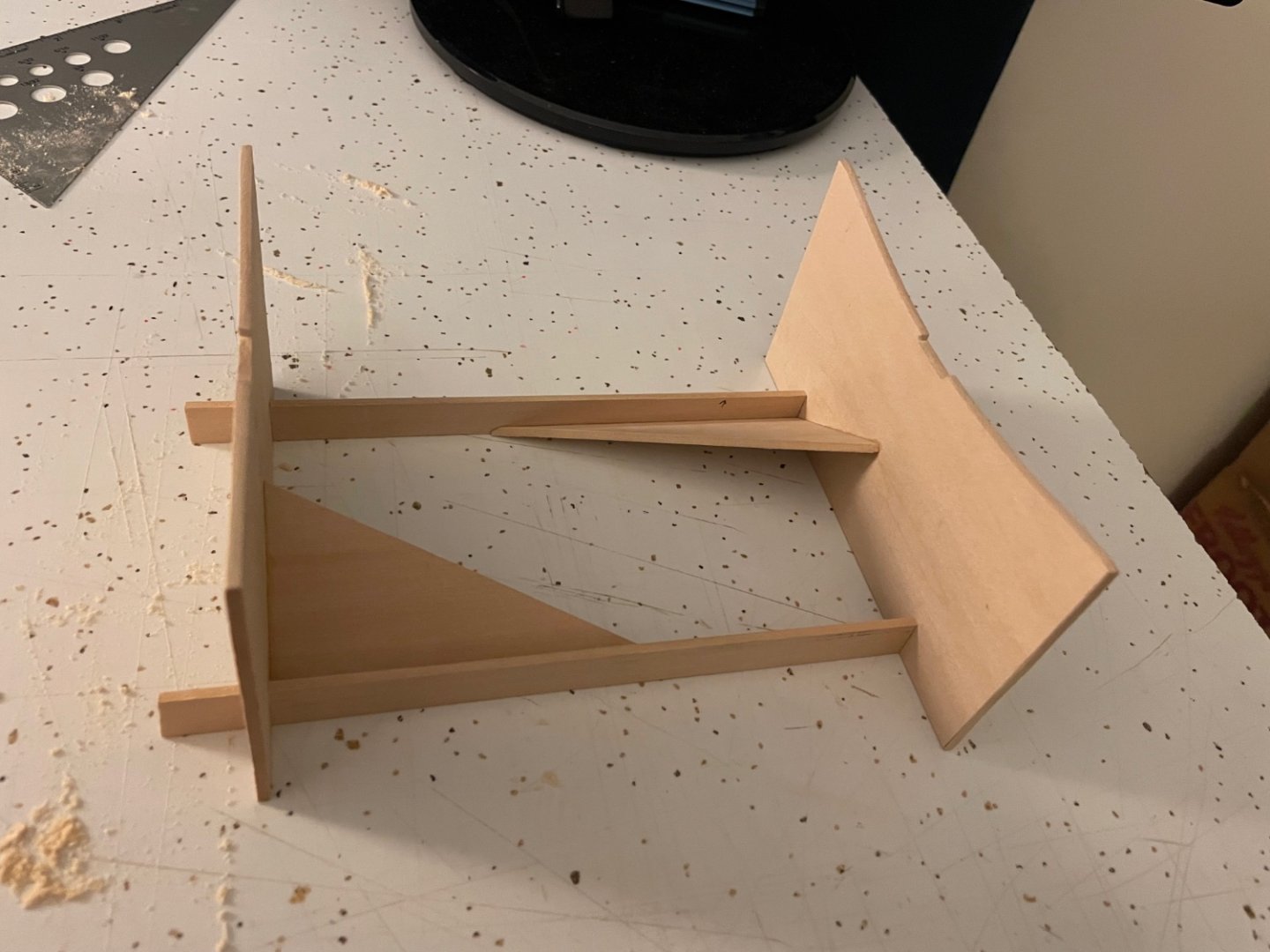

My first boat related project in many months! I finally felt an urge to put something together and I felt compelled to build this rudimentary stand. I’m still working out in my head how I’ll do the final display, but I wanted to put this together to get some idea of how the cradle will work and where on the hull the supports will line up. It’s hard to say now where the center of gravity will be when it’s finished, so this may change, but for now I have them at frames 4 and 7. This temporary stand will come in particularly handy when it comes time to mark the waterline. The waterline is parallel to the baseline in the plans and this stand makes the boat level, so I should be able to set up a pencil in a jig at the right height and scribe the waterline all the way around. It’ll be a long time yet ‘til she gets any paint, but I’m really looking forward to that. But I also need to try not to get too caught up in steps that far ahead and focus on what needs to be done first, so please wish me luck.

-

That is the most immaculately detailed and rigged model ship I’ve ever seen. I’ve just been a lurker on this log for a while, but it’s been amazing watching it come together!

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

Andrew J. reacted to a post in a topic:

Glory of the Seas 1869 by rwiederrich - FINISHED - 1/96 - medium clipper

Andrew J. reacted to a post in a topic:

Glory of the Seas 1869 by rwiederrich - FINISHED - 1/96 - medium clipper

-

I have to confess I was already planning on doing a similar color scheme to yours even before you posted your build log. I was thinking dark blue topsides with a light tan or cream deck, but with copper anti-fouling paint on the bottom, so that will be a good way to tell them apart if I ever finish mine It'll be a long time yet until I get to painting, but do you have any tips on marking the waterline? You really nailed it!

-

Andrew J. reacted to a post in a topic:

Lightning Sailboat by Woody S - from Dumas plans

Andrew J. reacted to a post in a topic:

Lightning Sailboat by Woody S - from Dumas plans

-

I feel like I should find a new adjective, but "absolutely stunning" is always the first thing that pops into my head when I see what you've created here. Looking forward to seeing what you do for a stand. I'm thinking of trying something with plexiglass or lexan, kind of like the display stand I got for my Lego Millennium Falcon, so it looks like it's just floating there.

-

Andrew J. reacted to a post in a topic:

Lightning Sailboat by Woody S - from Dumas plans

Andrew J. reacted to a post in a topic:

Lightning Sailboat by Woody S - from Dumas plans

-

Andrew J. reacted to a post in a topic:

Lightning Sail Boat by dsmith65 - Dumas

Andrew J. reacted to a post in a topic:

Lightning Sail Boat by dsmith65 - Dumas

-

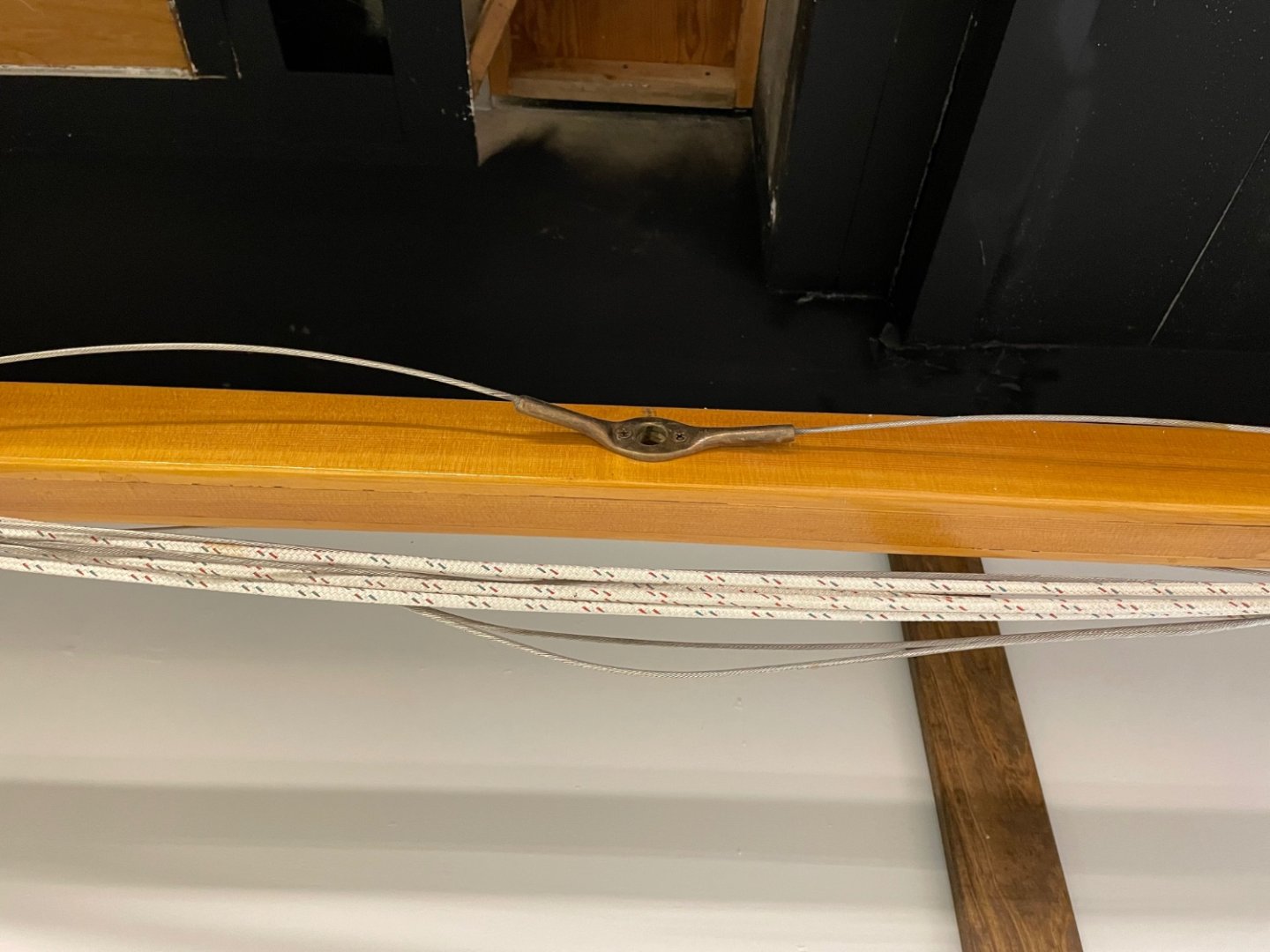

Upon inspection of #167, it appears several aspects of my build already differ from methods used by Skaneateles. I’m still happy to call my model a proudly home built boat with a nod to Skaneateles styling, particularly in the design of the seats and the custom headstay fitting. It’s going to be a challenge fabricating the mast hardware, it’ll be interesting to see what I can come up with!

-

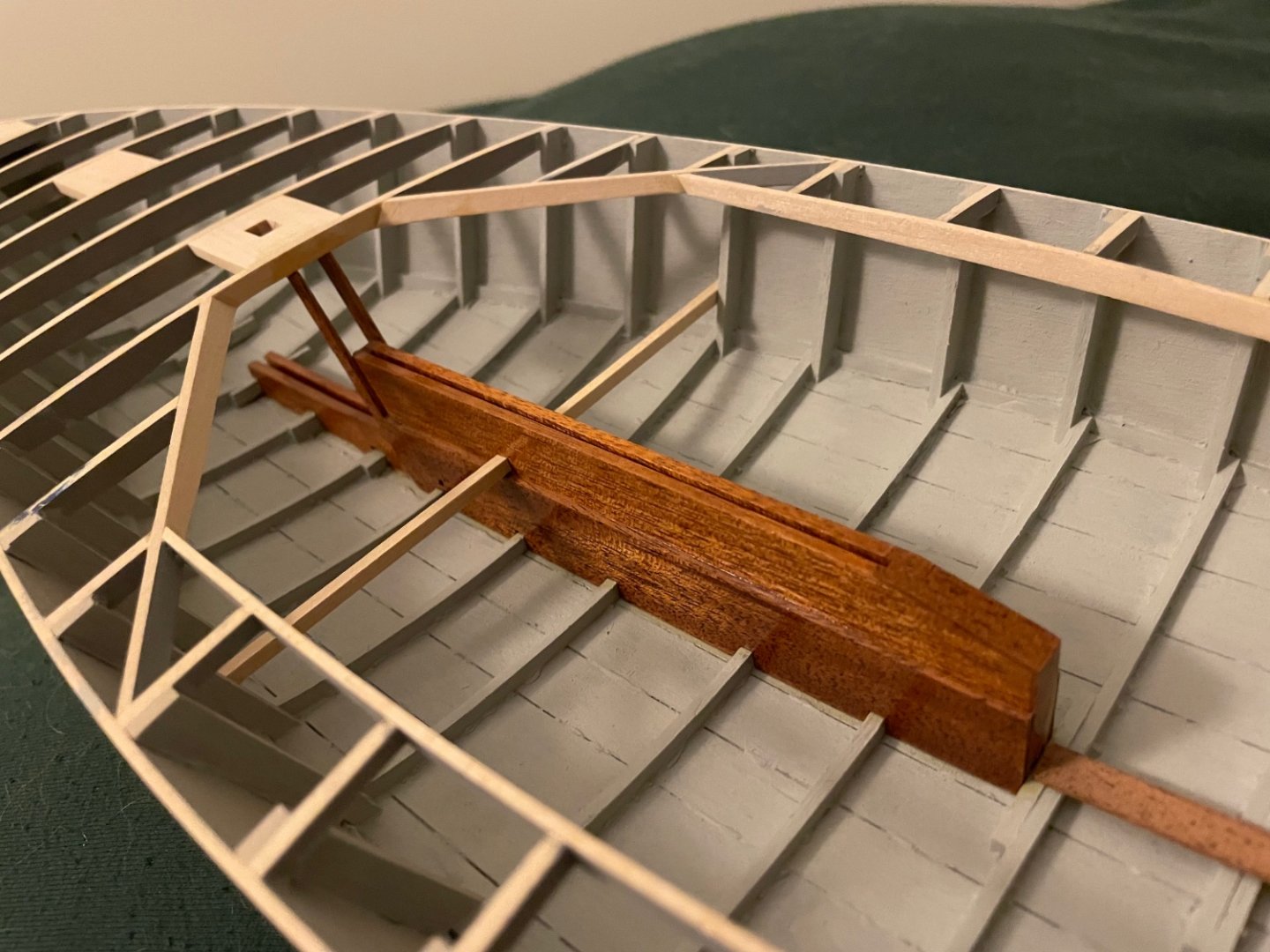

It’s still been a number of months since I actually made any progress, but I just realized I had done some work on the centerboard trunk since I last updated here, as well as the beginnings of the seat supports, so I figured I’d share. I’m going to the Finger Lakes Boating Museum tomorrow to see #167, which was meticulously restored a few years ago. It’s a Skaneateles built boat exactly like I’m trying to recreate, so I’m looking forward to taking lots of hi-res close ups for reference! It’ll be interesting to see what kind of differences there are between it and #1 since that was the prototype and 167 is a full on production run boat.

-

Andrew J. reacted to a post in a topic:

Glory of the Seas 1869 by rwiederrich - FINISHED - 1/96 - medium clipper

Andrew J. reacted to a post in a topic:

Glory of the Seas 1869 by rwiederrich - FINISHED - 1/96 - medium clipper

-

Unfortunately it's been quite some time since I made any progress. I really have to be in the right head space to work on it, and I don't want to work on it just because I feel like I have to. Seeing your progress is a great inspiration though, so my motivation might be coming back soon. We shall see! I don't have access to a lathe or any kind of fancy tools like that, so if there's any chance you might be up to creating another one of those centerboard drums for me, I would be happy to pay you for your time and skill. Please feel free to private message me if that's something you would be willing to do.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.