-

Posts

3,980 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by KeithAug

-

Good tip - thank you Eberhard. Also thank you. Excellent work Phil.

- 476 replies

-

- minesweeper

- Cape

-

(and 1 more)

Tagged with:

-

Thank you for all there Christmas and New Year messages, much appreciated. Well the grandchildren are gone and the weather has turned very wintery. The workshop is currently at 5 deg C - 41 deg F so my time working is somewhat limited. I have however been progressing the aft guest cabin. I needed a couple more bedside lights. I also started gluing the mahogany doors to the various panelled walls, followed by door knobs, handles, lamps etc. I also made the large mirror ( currently protected by blue masking tape). With the panels completed I was able to glue them in place with PVA - using more Starbuck sticks and various clamps to hold them. The side panels for the bunks and the various door fronts, shelves etc, went in next. The step (bottom left in the next photo is my best guess at what this area looks like. As explained earlier I don't have any photo's of this location. Next a bit more carpeting. The floor has a slight step in it, presumably to accommodate the curvature of the hull or to trip up the mother in law. (see later comment). With everything in place I did a few shots with the phone camera (restricted by quite limited access). Once again I forgot to clean out the dust. The following it the best shot I could get of the portholes. I then glued in the external port holes (made earlier). Re the floor step. I once spent 2 weeks in the Caribbean on a Dufour charter yacht. I learned to hate it. One of its design innovations was to mount the hot water tank below the starboard bunk. This would have been fine in the arctic but in the Caribbean it rendered it totally unbearable. Unfortunately I drew the short straw and hence spent the fortnight sleeping on deck. This however wasn't its most wonderful design feature. The designer had managed to place a shallow step right across the middle of the cabin (presumably to gain a little addition head height). The step was perfectly positioned to catch the unwary crew member every time they either ascended or descended the steps to the deck. Everyone at some time ended up sprawled across the cabin floor or with their heads wedged between the ladder rung, both events being accompanied by choice expletives.

-

Yes John - we spend all our spare time on the beach at this time of year - very bracing. Happy new year to you and all your countrymen. The kids have just watched the Harbour Bridge fireworks before being packed off to bed. So good of you all to arrange 2026 early to facilitate our child care arrangements. We still have 4 hours 15 minutes to go to 2026 so haven't even started on the booze yet.😀

-

I will take your word for it Phil. It looks quite tricky to me. Amazing job on th stack.

- 476 replies

-

- minesweeper

- Cape

-

(and 1 more)

Tagged with:

-

Very interesring to see how some of the internal features match side to side and how others don't.

-

Very nice progress Jon and compliments of the season to you.

- 46 replies

-

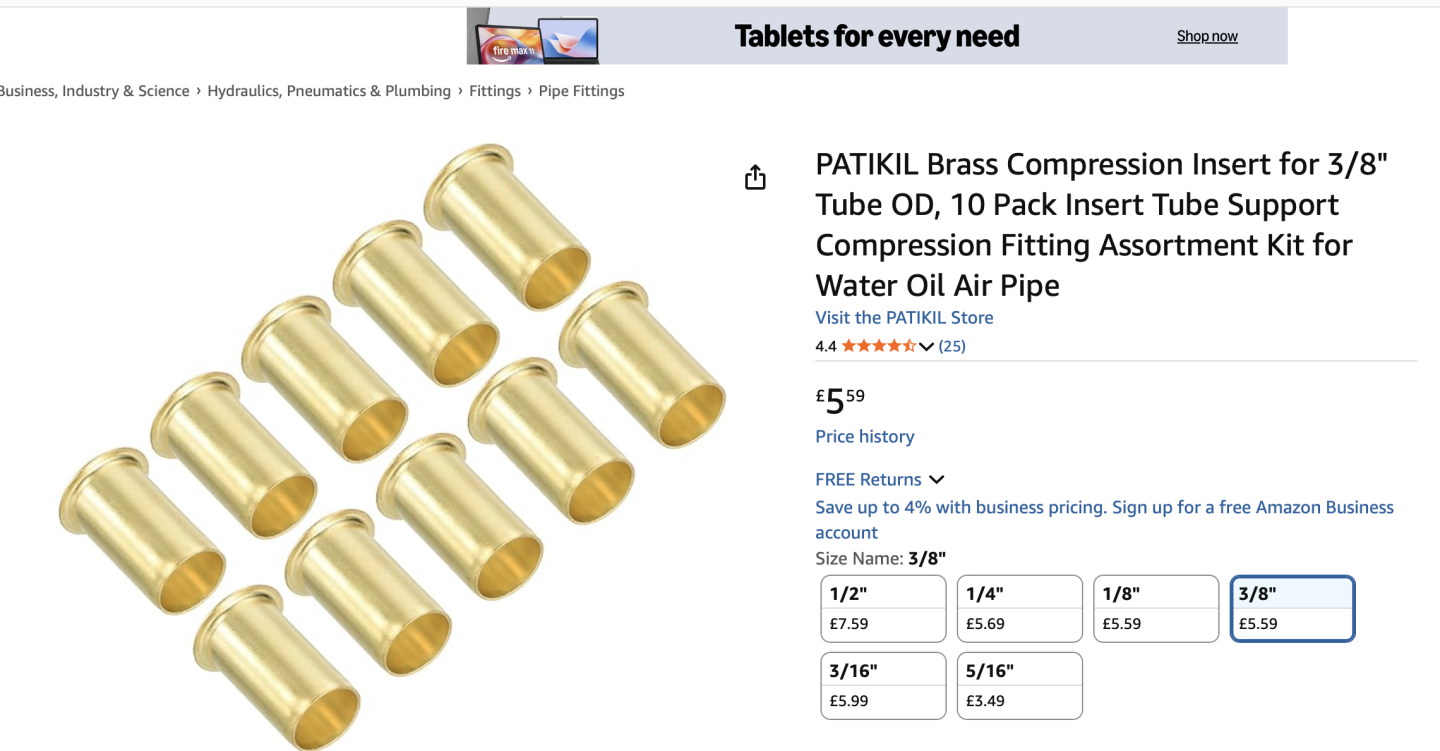

Yes on line ordering can be problematic. My wife ordered what she thought was a pound of sprouts, we had a delivery of 1 sprout, but to be fair it did have a price tag stuck on it. That would never happen if you went into a shop.

- 38 replies

-

- William Atkin

- Sloop

-

(and 1 more)

Tagged with:

-

Yes that works. I have something similar but have managed to incorporate dust extract. Cheep and cheerful usually works well.

- 38 replies

-

- William Atkin

- Sloop

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.