-

Posts

3,986 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by KeithAug

-

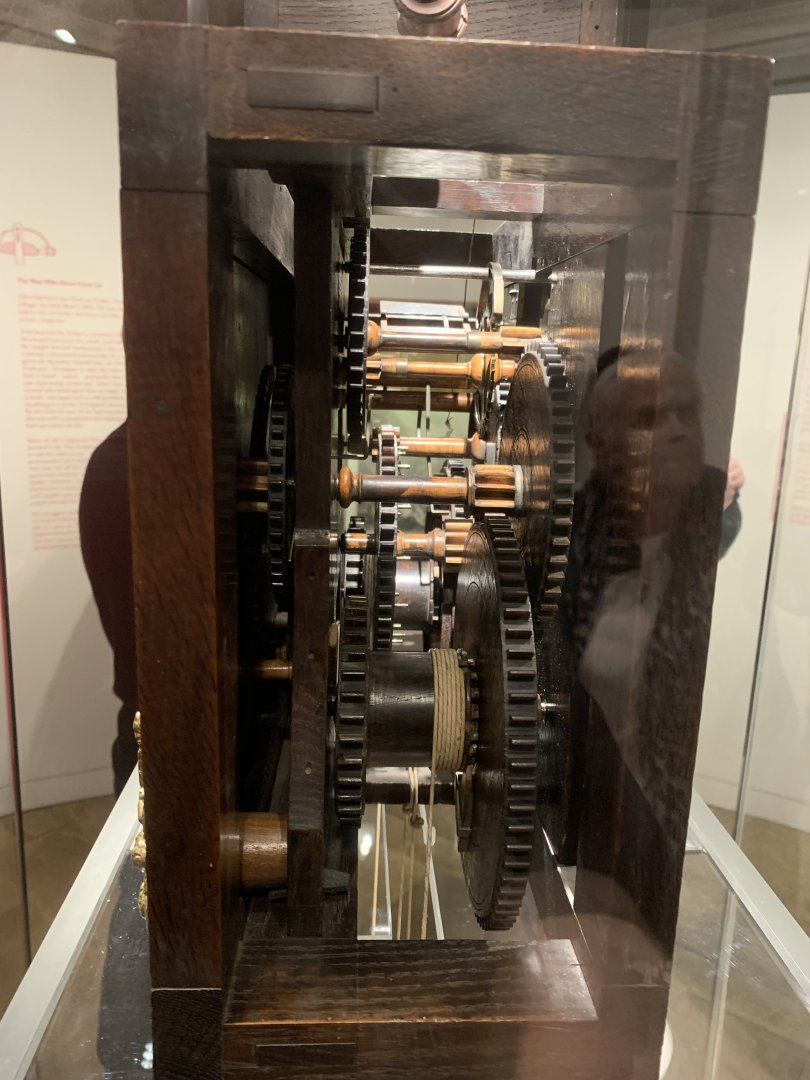

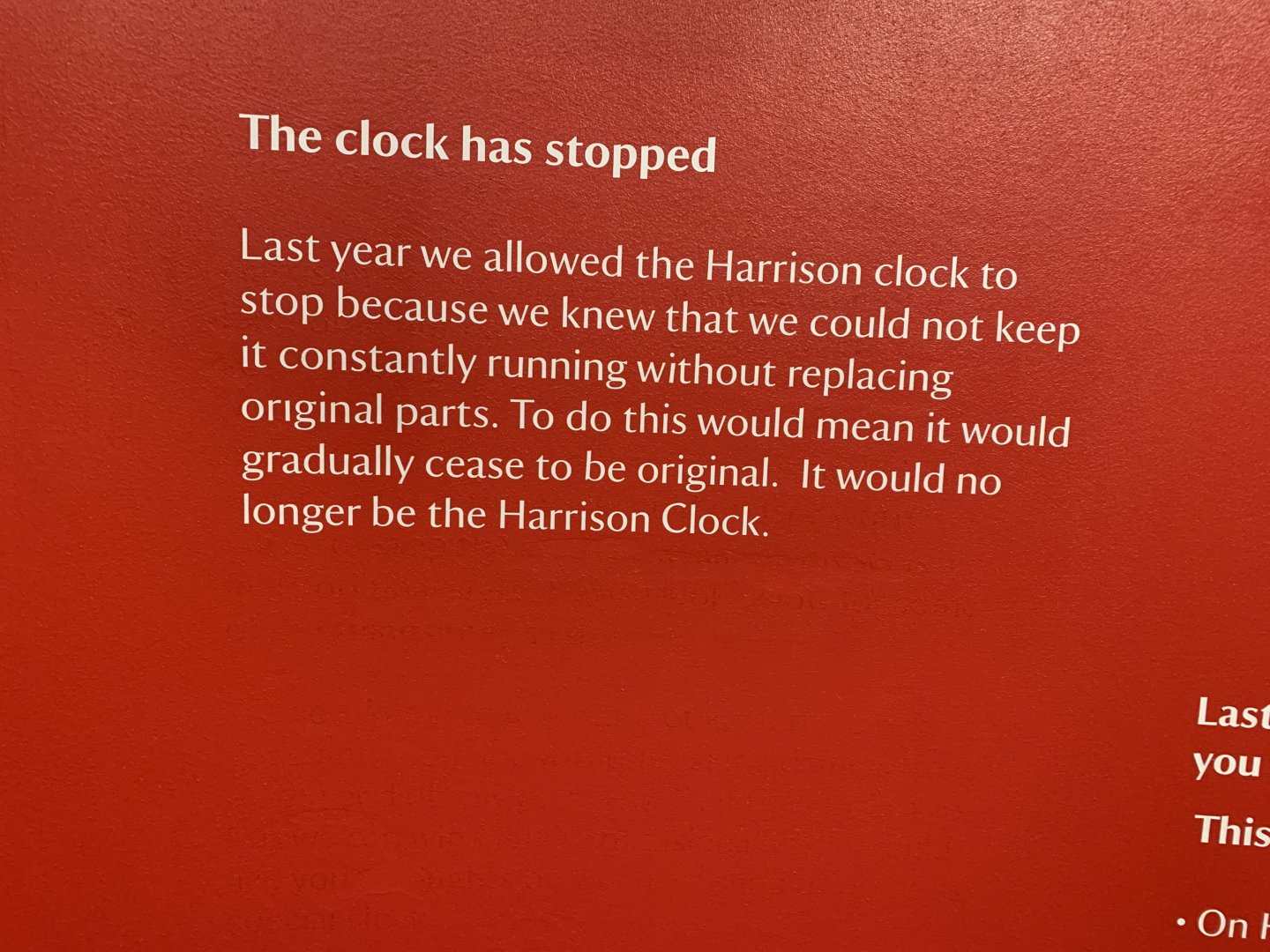

Fascinating - I hadn't realised all the internal detail was there. On a slightly different subject. I did take a few days off from contractor supervision over the summer. Here is a fine old clock which is a woodworking masterpiece - all the gears and spindles made of hardwood. It had run almost continuously for 300 years ( Made 1717) but alas recently it has been allowed to stop to preserve it. ~They don't make them like that any more! It is on display in Nostell Priory ( Yorkshire ) where John was the son of the estate carpenter.

-

I spent some time wondering how chairs with 2 legs work but fortunately I figured it out before asking and thereby exposing my stupidity. As you know I have some nice wooden chairs to make that I worry will be quite delicate. Brass ones seem to have their own challenges though. Nicely done. Following your prompt I did find some dollhouse chairs at 1:25 scale but none of the styles were an adequate match.

- 489 replies

-

- minesweeper

- Cape

-

(and 1 more)

Tagged with:

-

I cant think of many advantages of Covid - at least the modern versions seem to be somewhat less deadly. I too was amazed about the heaviness of her structural construction, no doubt built to last. the hull is very elegant.

- 33 replies

-

- gaff sloop

- restoration

-

(and 1 more)

Tagged with:

-

Tally Ho by AntonyUK

KeithAug replied to AntonyUK's topic in - Build logs for subjects built 1901 - Present Day

Interesting hull build Antony. It's always good to see alternative construction approaches as one can easily fall into tunnel vision. Very good progress.- 34 replies

-

- mixed materials construction

- Albert strange design

-

(and 1 more)

Tagged with:

-

Sounds interesting and i'll be particularly interested in how you master 3D printing. I look forward to seeing progress.

-

Thank you all for your warm welcome back. Phil - it tends to be 1:12 and not quite as "period" as might be appropriate. Pat - That's certainly the incentive but I think they also over charge the insurer for the work as well. I worry about the little old ladies (non PC) who get taken for a ride. I ended up writing a 40 page review of my experiences which included an item by item commentary on the builders work schedule of which about 1/3 was done inadequately and 1/3 wasn't done at all. The builders excuse was that the schedule - quote - "wasn't intended to be read literally and that it shouldn't have been passed to me in that form". However I did get it all done eventually plus £1000 from the insurer as a good will gesture. The insurers appointed consultants and the builders team all seemed to be on very friendly terms which I think "says it all".

-

A very pleasant catch up Phil. I loved all the internal and external fittings "most of all the cup". I am amazed 13 years of accounts tallied exactly - shows an eye for detail as one might expect from your work.

- 489 replies

-

- minesweeper

- Cape

-

(and 1 more)

Tagged with:

-

Unfortunately ours never really got that point! I think their motivation about wringing every penny of cost / profit out of the job overrode their thoughts on scope compliance. They didn't seem to get that doing it correctly once was less work than doing it badly twice. They were appointed by our insurer who seemed to be quite tolerant of their general approach to penny pinching. Yes - I popped up a bit unexpectedly - a bit like toast.

-

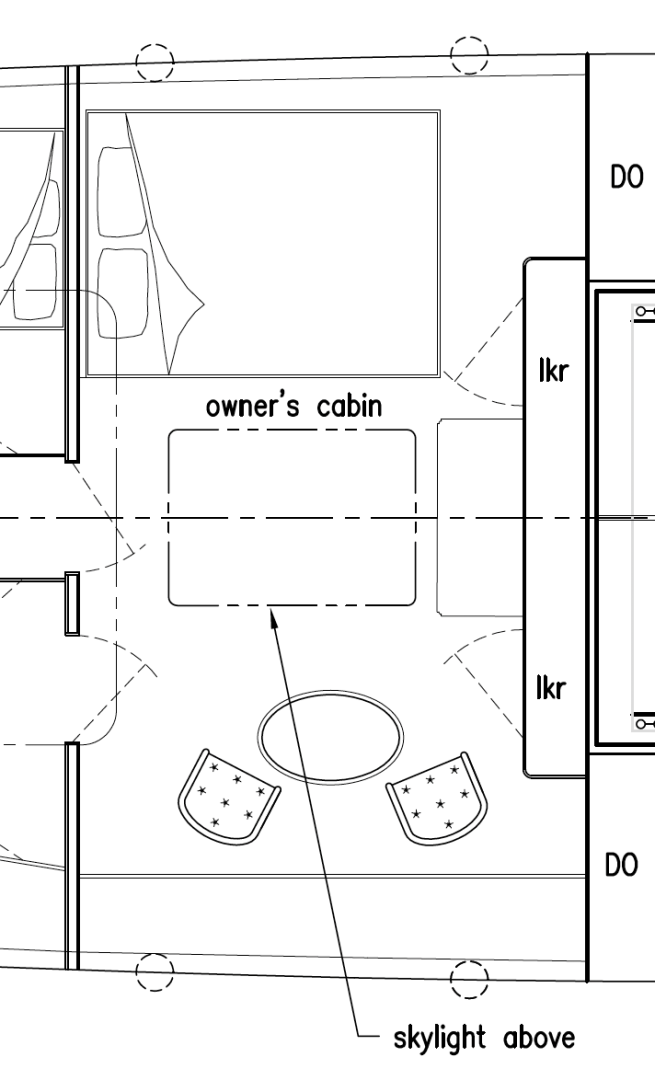

Firstly apologies for my prolonged absence and thank you for your concerns and encouragement re my renovations. Needless to say the building work went on much longer than first estimated. In the words of the site foreman "jobs always over run". The last part of the job (the replacement of a couple of french doors) is planned for next week ------ Hopefully! This will be the second attempt, the first doors were perfect apart from being the wrong colour, the wrong glass and the wrong size. Needless to say getting builders to follow the schedule and do what they were contracted to do was somewhat of a time consuming battle. I think their company motto is "What the eye cant see the client cant criticise". We moved back in 2 months ago and I have spent much of my time since then improving on their efforts. In the end it proved easier and less time consuming to "just do it myself". Ship construction restarted 2 weeks ago. Probably as a reaction to recent events I though I would spend some time modelling things that no one is ever going to see. I thought it would be nice to model all internal spaces where they are below sky lights or other points of access. It might amuse some future nanobot. I am starting with the owners quarters. The first job however was to do a little internal preparation. All the internal surfaces where the balsa backing had been installed were sanded to the profile of the frames using my improvised sanding stick. The owners quarters sit amidships with white panelled walls mahogany cupboards, lockers and a double berth. The arrangement is broadly detailed on one of the available plans. The plan isn't exactly correct but with the available photographs this isn't a problem. From earlier some of you might recall that I installed every second frame (actually all the odd numbered ones). The foremost bulkhed of the owners cabin actually starts at frame 44 so this had to be retrospectively installed. A lack of planning created unnecessarily rework. The rule and elastic band are holding the half frame in place while gluing. It wasn't possible to install the whole frame as on piece (I tried and failed). I needed to put the floor in (made from 1/32" ply). The dimensions were taken from the installed frames and drawn on a paper template. Installation through the deck frames was checked. A block of balsa was was cut to size to form the core of the double berth. To be clad in mahogany later. A template for the forward wall was shaped to fit at frame 44 with cut outs for the fitted cupboards on the starboard beam and shelf on the port beam. The template will enable me to make the white panneled walls. Pieces were cut from MDF to act as the cores of the cupboard and shelf (starboard and port beams respectively. When finished it should look something like this. The chairs are a bit worrying, I'll come back to those at a future date. if not succesful i can always leave them out. Hopefully I will be able to catch up with all your wonderful builds over the next week or two. Its good to be back.

-

Dear All Apologies for my absence. We have had the builders in doing some structural work for the last 10 weeks and as a result we have had to move into temporary accommodation. With agreeing the work scope, monitoring progress and making sure that the quality is up to scratch I haven't had much time for the more pleasurable aspects of life. The workshop is currently out of bounds as it is full for the stuff from the rest of the house. I can't see the shipyard reopening until autumn but who knows. The good news is that we have a tentative re-occupancy date of a week on Saturday so hopefully we will definitely be back home by the end of June!!!!!!! I hope you are all keeping well and i look forward to eventually catching up with your builds. I did re varnish the PVA damage hull before being evicted and it looked just fine. It would have been awful to have sent months worrying about fixing it.

-

House selling and buying - "Yuk" good luck Andy. Fascinating historical photos.

- 174 replies

-

- Vigilance

- Sailing Trawler

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.