Roger Pellett

NRG Member-

Posts

4,489 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Roger Pellett

-

There was a series of posts on March 12 on this same topic.

-

Heavy glass lenses called deadlights have been recovered from wreckage of warships lost during the War of 1812 on the Great Lakes. There seems to have been two varieties; a lens shape, and a prism. Both were intended to project light into spaces below. They would have been set into metal frames. The deadlight would have been flush with the deck and far more resistant to damage than a skylight. These would not have eliminated the need for a skylight in areas where more light was considered necessary or desirable. As a sidelight, we discovered deadlights in the steel hulled whaleback steamship Meteor launched at Superior, Wisconsin in 1896. In the compartment housing the rudder quadrant, the shell plating has been perforated with several rows of 2in diameter holes. A glass lens had been set into each hole and a similar perforated plate riveted in place to sandwich the lenses between the two plates. We later found out that the builders of the ship had patented this feature. Although the ship was launched with an electric “lighting plant” the need to capture sunlight in this space was still deemed to be important.

-

I have two models built by my father that might make it to 100 years. The First is a 1:96 model of a steam fishing trawler. It was built before I was born and I would estimate it to be 80 years old. After my father died it sat in my daughter’s apartment for a while and the rigging was damaged. I repaired the rigging and it now sits in my bookcase. Considering it’s age it is in beautiful condition. I hope to get it in it’s own glass case. The second is an unrigged 1:96 model of Flying Cloud. It is 75 years old. When we disposed of my mother’s things, the movers damaged it. I repaired it cleaned it, repainted the hull, and touched up paintwork on the deck structures. I also built a glass case to protect it. Both of these models were built from A.J. Fisher kits. A.J. Fisher’s fittings were made from brass and real boxwood. Although both of these models needed cleaning and repair the Materials that A.J. Fisher put into the kits and the materials that my father used to build them have withstood the test of time. I hope that each of my two children will eventually take and care for a model.

-

The following is from my wooden canoe restoring experience. It may or may not be applicable to the much smaller cross sections that we encounter. Wood canvas Canoes use wood for two structural elements; Ribs 5/16in thick x 2-1/2in wide, steam bent into a U shape, and Planking 3/16in thick x 3in wide. Material is Northern Cedar and in some cases Red Cedar. Stock for ribs is usually flat sawn as it is considered to be easier to bend. quarter sawn stock is preferred for planking.

-

Lloyd McCaffery’s Model are works of art that command commensurate prices. As such, his clients have a right to expect them to last 100 years. The same is true for many of the carefully researched and beautifully built models that we see in the scratch built section of the forum. Hopefully, these will eventually be acquired by institutions, collectors, or appreciative family members who are able and willing to care for them. On the other hand, there are the run of the mill POB kit models, often with crudely shaped hulls, over scale fittings, etc. (There are now on the market some kits that will produce beautiful, accurate models.). I continue to be surprised by builders of these models who obsess over minute details when the model itself is not an accurate representation of the real thing.

-

In the mid 1050’s the BF Goodrich Company built a tire plant in the Philippines. When the plant opened, my father, representing the Company attended the opening ceremonies and my mother went with him. They then sailed on the President Wilson, either Manila- Hong Kong or Hong Kong- Tokyo, I don’t remember which. This was back in the day when getting there was half the fun and this was the highlight of their trip. They brought me a bronze plaque with an engraving of the ship. I don’t remember where it is. Roger

- 11 replies

-

- president cleveland

- ocean liner

-

(and 1 more)

Tagged with:

-

Table Saws Once Again

Roger Pellett replied to Ron Burns's topic in Modeling tools and Workshop Equipment

Ron, I’d order a couple of spare blades for two reasons: 1. If you are working on a project and your blade gets dull or loaded up with resin, you can change blades, finish your work, and deal with the dull blade later. 2. If you bought a saw with a 1/2in arbor, as time goes by blades may become harder to find. Thurston used to be the go to US supplier but they no offer these blades. Jim seems to sill have a source for quality blades that will fit a 1/2in arbor. I’d also have him make me an adaptor to allow me to use blades with a common metric sized hole. Roger -

This forum is read by people that range from World Class professional model builders to assemblers of mass market kits. A recurring theme on the forum is “What amI going to do with my models when I am no longer around?” If you are assembling a USS Constitution or HMS Victory kit, there is a high probability that it’s never going to see the inside of a museum and your heirs may or may not appreciate trying to find room for it in their home. Therefore, you should enjoy yourself and not worry about what the model will look like in 100 years. If you are a professional you have already answered these questions.

-

Electric sanding belt file

Roger Pellett replied to Don Case's topic in Modeling tools and Workshop Equipment

I’ll give Moab an answer to his question with a story. Twenty years ago I got involved in the restoration of wood canvas. These projects all involved replacing the heavy canvas that had to be stretched over a fully planked wooden hull. Procurement of this heavy cotton duck canvas could have been a problem. Fortunately there is an excellent builder of new wood canvas canoes in Knife River, MN, a short drive from Duluth who was willing to sell me the canvas that I needed. On a trip to buy canvas, as I pulled into his driveway I noticed a table saw and a canoe trailer in his yard each with a sign that read $150. When I asked him about the saw, he said that it was a 10in Delta Contractor’s Saw and he was selling it because he had bought a new Saw Stop Saw. I wrote him a check for $150 plus the cost of the canvas. While wondering aloud about loading the saw into my SUV, he said, “How about a toofer, take the trailer too.” I got the saw home and managed to get it into my shop. 20+ years later it still runs as well as it did the day that I bought it. Unfortunately my wife and the lady next door conspired for me to “get rid of the ugly trailer” so I no longer have it. I remind her of this whenever she wants something hauled. This saw was bought from a professional canoe builder who had used it to cut miles of wood into canoe parts and I use it constantly. I doubt that any table saw on the market today sold through a big box store would give this kind of trouble free service. There are, of course, high quality table saws available from specialized woodworking dealers, but these sell for many times what I paid. Roger -

Electric sanding belt file

Roger Pellett replied to Don Case's topic in Modeling tools and Workshop Equipment

IMHO Anyone buying power tools, particularly stationary ones, should not overlook used ones built by old line manufacturers 40 years or so. Ones that have been well taken care will outlast their owners. Often new tools come with a lot of bells and whistles type features to attract buyers but are seldom used. Old tools are also usually belt driven so if the motor dies it can be replaced. Parts like bearings are usually commercially and they are assembled with threaded fasteners available at a hardware store. As far as I am concerned many new hand held power tools should almost be considered to be disposable. -

Assistance please required re rigging ends

Roger Pellett replied to brightonseagulls's topic in Masting, rigging and sails

Dave, When rigging model ships, clear nail polish makes a lot of things much easier. Get a bottle of the lacquer based stuff, not the acrylic. A little bottle with the brush in the cap sells for less than $2.00. It’s much nicer to use than CA glue and dries as fast. Used sparingly to secure knots, servings, etc it will be invisible. Roger -

Re: BobCleek’s Post #10 Copper sheathed ships did use copper and copper alloy gudgeons, pintals, and fastenings. This topic is extensively covered in Ships’ Fastenings: From Sewn Boat to Steamship by Michael McCarthy. When the Royal Navy began sheathing warships with copper they found serious wasting of iron gudgeons, pintles, and underwater fastenings. This problem had earlier caused them to abandon underwater lead sheathing. By the late Eighteenth Century they were using both “hardened copper” and copper alloy “rudder braces” and fastenings. For example, a copper alloy pintle has been recovered from the wreck of HMS Pandora. The composition of this alloy 87.3 percent copper, 6.9percent tin, .24 percent lead and 0.04 percent zinc. There also exists correspondence regarding the difficulties experienced in procuring the copper fastenings, pintles, gudgeons, and various underwater splice plates for the American Frigate Essex. Regarding the iron pintles and gudgeons on the Cutty Sark, she was a composite built ship; wooden planking on an iron structure. These ships had corrosion problems all their own. I cannot, therefore, comment on the iron rudder fittings abutting the copper sheathing.

-

Large home improvement chain stores, as well as well stocked hardware stores stock 1/2 pint cans of wood stain, both solvent and water based. MinWax is a brand that you often see. I am not endorsing this specific product one way or the other, but if you want to purchase a semi-transparent stain it should be easy to find. In my opinion, the names on the can are more about marketing than an accurate color description. Therefore, try on some scrap before using. These semi-transparent stains are nothing but pigment suspended in a liquid. The liquid allows you to spread out the color and then evaporates. It is therefore important to thoroughly mix the stain before using. When you open the can the pigment will be on the bottom. Roger

-

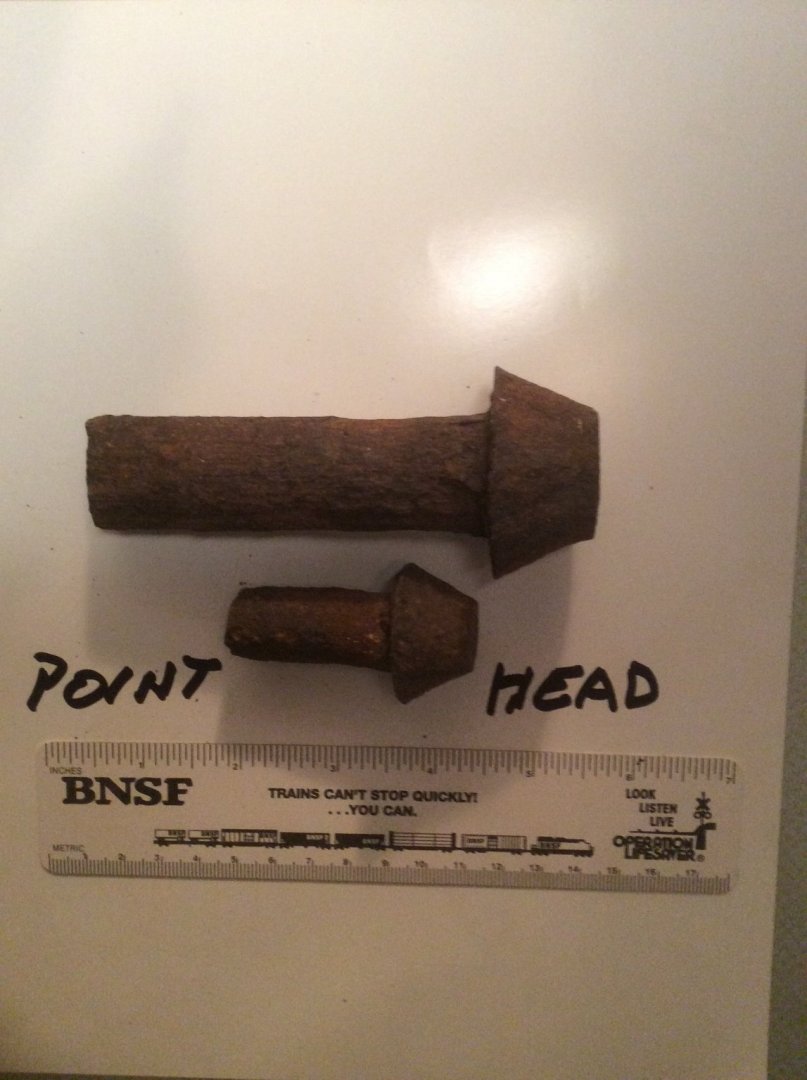

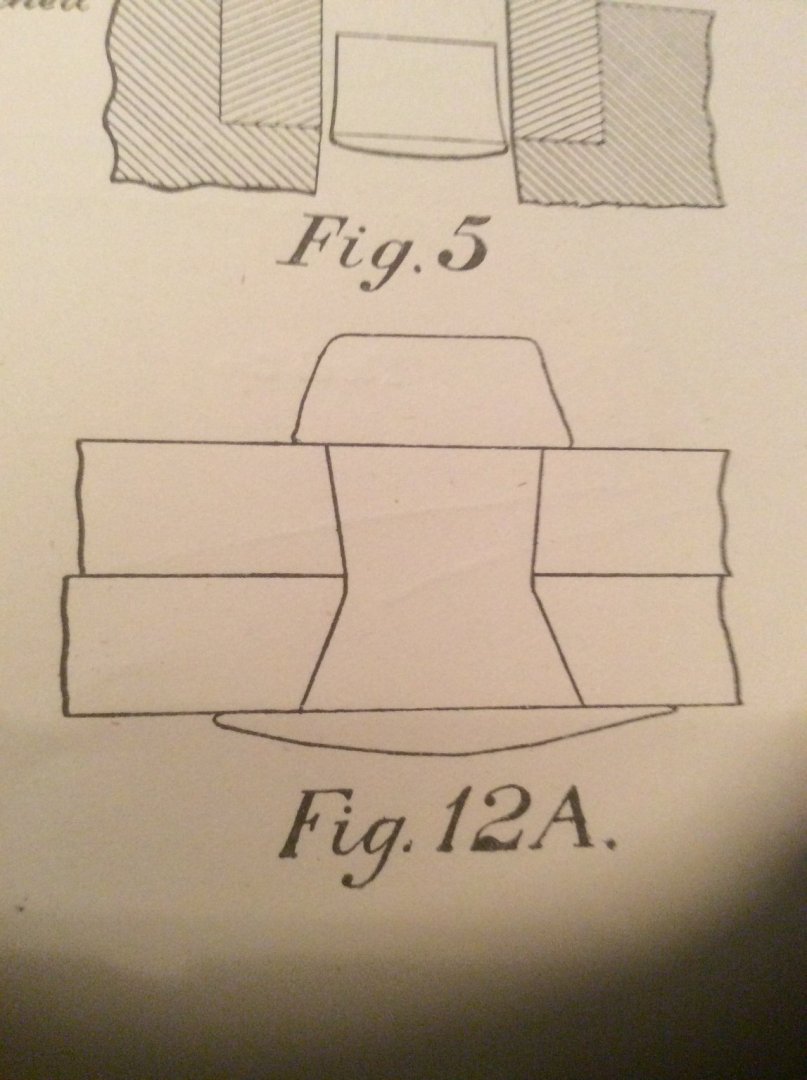

Rivets?

Roger Pellett replied to Nirvana's topic in Painting, finishing and weathering products and techniques

Here on the Lakes there are still ships operating where at least some hull seams are riveted. In fact, Fraser Shipbuilding here in the Twin Poets of Duluth, MN and Superior, WI still maintains the capability to produce riveted hull seams. The photo below shows a couple of unused pan head rivets that I kicked up in the parking lot where I worked. 100+ years ago, the plant made riveted marine boilers. The drawing was copied from Holms’ Practical Shipbuilding, 1916 Edition. When using pan head rivets to close a hull seam, the rivet with its large head is inserted from the inside of the ship. The rivet is hammered up from the outside. Punching the plate leaves the hole slightly conical and a properly hammered rivet completely fills up this conical hole. The result on the outside of the hull is a slight flat dome, maybe 1/8 in high. The inside of the hull is of course studded with the large pan heads. The rivet gets its strength by shrinking while it cools and the interaction between the metal flowing into the hole and the wall of the punched hole, not the slight bump on the outside of the hull. Snap rivets are another matter, here the domed heads on the inside and outside pull things together. I have noticed that fresh paint highlights the visual effect of these very slight bumps along the hull. Probably a reason for them being more noticeable. On museum ships than on vessels in service. Roger -

Rivets?

Roger Pellett replied to Nirvana's topic in Painting, finishing and weathering products and techniques

If you type in “simulated rivets on plastic hull” you will find a whole thread on this topic. Post 13 on this thread by me includes photos of actual riveted ships and rivets. The domed topped rivets that model railroaders like to count are called Snap Rivets, and aboard ship they are only used for joining relatively light metals like deck houses, smokestacks, etc. The rivets used to join heavy hull plating are called Pan Head rivets. These are nearly flush on the outside and are nearly invisible at most common modeling scales. -

Vasa, built by Dutch shipbuilders and launched in 1623 had deck planking laid in an irregular pattern, apparently to best utilize available lumber widths and lengths. Was this style of construction used by English shipbuilders, and if so when did they adopt planking rules utilizing standard plank widths and butt shifts?

-

Once ships began to be copper sheathed, iron would no longer be used underwater due to galvanic corrosion. Copper gudgeons, pintals and fastenings would be The norm. Later in the Nineteenth Century composition (brass) fittings made an appearance on warships in non load bearing applications, the “birdcage guards over hatches being a prime example. Brass chains, Never!

-

Trix X acto history?

Roger Pellett replied to FlyingFish's topic in Modeling tools and Workshop Equipment

Thanks Charles, Maybe 1902 Ad Man spin to explain why Stanley did not spend money to grind off the casting spruce? Roger -

Trix X acto history?

Roger Pellett replied to FlyingFish's topic in Modeling tools and Workshop Equipment

Thanks, that answers the question -

Trix X acto history?

Roger Pellett replied to FlyingFish's topic in Modeling tools and Workshop Equipment

Does anybody know what the little bulge at the back end of the Xacto and the Stanley Bullnose plane is for? -

What were your first tools as a child?

Roger Pellett replied to FlyingFish's topic in Modeling tools and Workshop Equipment

I also used to get into my father’s tools causing periodic banishing from his shop. I now enjoy using many of his hand tools. Although he died 35 years ago the tools remain as a connection to him. -

Table Saws Once Again

Roger Pellett replied to Ron Burns's topic in Modeling tools and Workshop Equipment

My 10in table saw cuts acrylic beautifully. It is not variable speed. I seldom use styrene and when I have I used a knife. -

What were your first tools as a child?

Roger Pellett replied to FlyingFish's topic in Modeling tools and Workshop Equipment

The first tool that I remember was a vibrating jig saw. You could actually touch the blade while the saw was operating without getting cut. It did cut wood. Roger

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.