qwerty2008

Members-

Posts

552 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by qwerty2008

-

I haven't been working on the Byzantium much lately, life has been kinda hectic the past few weeks and I haven't much felt like working on my models. I did however manage to finish up the 'copper' plating today. Sorry no pictures but maybe I can manage to do a float test soon.

- 366 replies

-

Reminds me of the time I almost lost my footy (inexpensive beginners model) Voyager. I was getting ready to bring her in when she slipped out of receiver range and took off strait into the wind towards the center of Lake Elsinore; luckily I was able to flag down a person on a SeaDoo to retrieve the tiny vessel. Lextin.

-

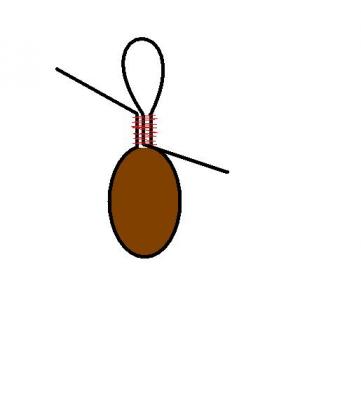

For full size blocks the rope would be made into a loop as per the illustration in post #3. For my models I fake it by hiding the overlap under the seizing. Lextin.

-

I haven't got much work done on the Byzantium the past couple of weeks due to working on the sloop Mediator. After planking half of the Mediator I am getting kinda tired of planking so I decided to switch back to the Byzantium and start coppering, well sorta. I made a plate press and started work making the plates last night, sofar I have made and installed over 200 plates completing the starboard side of the hull. The progress as of this morning. I also have painted the binnacle. Lextin.

- 366 replies

-

Håkan: Instead of soaking you could try using heat to bend the planks. I use a heat gun which is basically a glorified hairdryer except mine can actually set the wood on fire if left in front of it to long. I found that my oak planks turned to a rubber like consistency when heated making then very easy to bend. Lextin.

-

Mark/Canute: I don't currently have anything to seal the wood except some clear coat which I would rather not use on this model as it would give a waxy appearance due to how thick it goes on. I am open to suggestions as to what product to get when the time comes? Gaetan: the paint (spray paint sprayed into a jar) I used was solvent based but I do have a small can of water based paint that I can try as well. Patrick: no the red on the board is Sharpie. though I don't remember ever putting the mark on the board all the actual blood spatter turned brown after a day or so. I will hold off on painting the wales for now until I know for sure what the best method to do this is. I had originally planned to leave them natural (hence the use of a different wood then the planking) but I later realized that the model needed a little bit of contrasting color to make it stand out more, and to draw the eye away from any mistakes that I will inevitably make later on down the road. PS. I have applied another coat of stain which darkened up the color a little and covered up the blotchyness along the waterline. Lextin.

-

If your talking about what I thing you are then the solution is simple, pencil the edges of the planks, this will cause the joints between the planks to appear black as they were caulked and will even make the larger gaps appear black, I found this out when planking my own model today. Any gaps where air can pass thought I use wood filler such as plastic wood or homemade wood filler as described above by Mark but I add talc (baby powder) which improves the consistency making it better for sanding. Lextin.

-

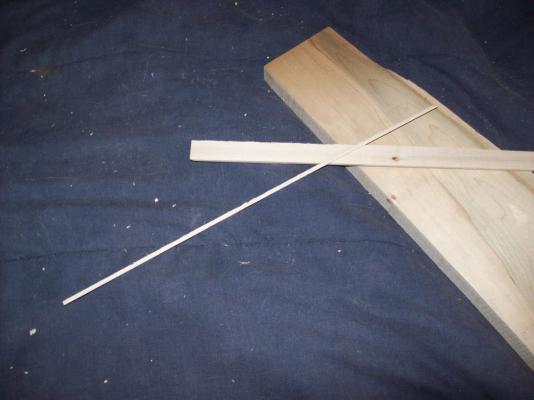

I decided to test some ideas for the wales so I took a scrap piece of oak and used india ink on a portion thinned paint on another and Sharpie marker on the last. Out of the the three I like the Sharpie the most but am afraid that it might rub off while handling the model. PS. Here is a picture of my new, safer rasping setup for the planks. Lextin.

-

Port Side Paint: (37:00 hours) When done with the planking I proceeded to stain the wood above the waterline and paint it white below the waterline. I still need to do some touching up on the color. Question: Should I paint the wales with thinned black paint or leave them natural? or even dye them with India ink? Lextin.

-

The Lower Planking Continued: (36:00 hours) Last night I decided to get back to work and since then I have planked the rest of the port side. two stealers where required in the stern. Lextin.

-

I cut off the piece that got pulled from under the skin then cleaned up the area with alcohol and applied antiseptic ointment before bandaging it with gauze and going to bed last night. Today it feels much better and barely (used as a relative term) hurts. Lextin.

-

Here is a picture of what it looks like now, the arrow is pointing at the part that was ripped out from under the skin. Lextin

-

She wont be coming along nicely at least not for the rest of today as I ripped my thumb nail off with a rotary rasp wile milling some more planks. My last sanding drum went kaput so I set up the rasp to thickness the blank for the next set of planks when my thumb got pulled between the rasp and the guide which was set at 1/8 inch. After it hapend I walked out to the living room to ask for a bandage when I passed out the first time, then after I stood back up I went down again when I came to it felt as if several days had passed since the incident. Basically I am trying to say that I wont be feeling up to working on the model anymore today. Lextin.

-

Thanks Nils, Patrick, and everyone who pressed the like button . Nils: Yes I will only be single planking the hull, the density of the bulkheads makes this fairly easy plus I got lucky when I made my planks as they are the perfect thickness to bend easily but not so easily that they show (unless of course you hold a lamp behind them as they are slightly translucent) the bulkheads. Patrick: I surprised myself with that one and hopefully I can keep up the rate as I would like to finish the Mediator before collage starts this fall. Lextin.

-

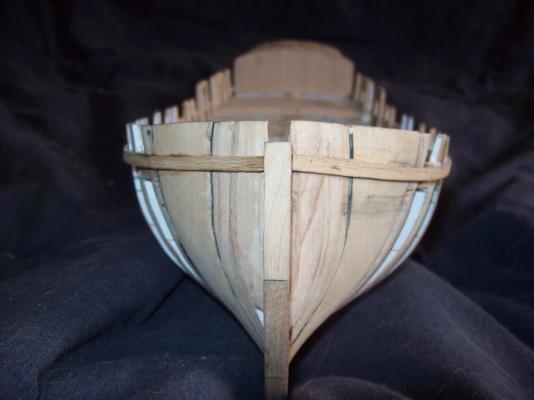

The Lower Planking: (30:00 hours) I have started on the lower planking and am moving from the wale down. I am trying to use the least number of drop planks and stealers as per Chucks videos. Lextin.

-

I have got back to work on the Byzantium and have made the rest of the gratings aswell as the binnacle. The pumps were made last week but forgot to post about them and this time I forgot to take pictures of them but you can see one in one of the other pictures. The compass was made from a .45 cal. shell and a .38 cal. shell, the lamp from a .25 cal. shell and the chimney from a .22 cal shell. I still need to paint the binnacle but other then that it is finished. I have also changed the ladder hatch to only have one ladder and a grating over the other side. Lextin.

- 366 replies

-

Quarterdeck Molding etc. (24 hours) The quarterdeck molding strip and the two planks above it have been made. The cabin roof may need to be made a little taller to accommodate the next molding and one more strake. Lextin.

-

Gunport Stripe (22:00 hours) I have installed the three strakes of planking above the wale, there's not much to say here except that there was a lot of gluing, clamping and waiting for glue to dry. Lextin.

-

The lower wales (18:00 hours) Today I made the lower wales, they were made in much the same way as the upper ones except that they where aligned against the planks above them. rather then by the gunports. I also fixed the port side upper wale because it was bugging me. The normal thickness planks are made from cherry which doesn't bend as well as the oak but because their so thin it don't really matter. The scuppers were made with a round file prier to installing the lower wale. The first normal thickness plank. My thickness sander. Lextin.

-

The upper wales: (13.00 hours) The upper wales were made in order to set the lines for the rest of the planking. I made them by first milling the oak planks on the bandsaw and running them trough my improvised thickness sander to make them uniform thickness. The bends where made by heating the planks over a heat gun (this would make the wood flex as if it were rubber) and and bending with my fingers constantly checking the fit. Lastly they were glued in place with PVA and clamped to dry. I could have done better on the port side but O-well that's in the past. Lextin.

-

making the keel: (12:00 Hours) The keel is done. I made the keel from cherry and the false keel from oak. Most the cutting was done on the bandsaw, I used the drum sander in the drillpress to sand the pieces right up to the lines then used a file to make the joints fit perfectly. I simulated calking by rubbing pencil on the inside of the joints prier to gluing. The entire keel was glued in place so that planking can commence. Lextin.

-

About the nameplate, it could give the effect that the hull was at some point repainted and the name was simply masked over leaving a square of old faded green around the name. Lextin.

- 956 replies

-

- andrea gail

- trawler

-

(and 1 more)

Tagged with:

-

Filler Blocks: (8:00 hours) I made the filler blocks for the bow and stern as well as the gunport sills. The sills where made by cutting a strip of wood to the with of the gunports and using the miter box to cut them square, then they where beveled to fit the openings and glued in place. The filler blocks where made by first marking the shape on a scrap piece of wood then cutting rasping and finally sanding them flush with the bulkheads. After everything was in place I went over the entire hull with a palm sander (Black and Decker Mouse) now I am down to the part where I just want to run my fingers along it feeling how smooth and even it is. Lextin.

-

Lately: between the hours of 7:00am and 10:00am. Just wait until I get burned out and stop building for months at a time. Lextin.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.