PriceMachine&Design

Members-

Posts

23 -

Joined

-

Last visited

-

thibaultron reacted to a post in a topic:

Long Term Paint Storage

thibaultron reacted to a post in a topic:

Long Term Paint Storage

-

PriceMachine&Design reacted to a post in a topic:

H.M.S. BOUNTY by Jerry's Admiral - FINISHED - Amati - Scale 1:60

PriceMachine&Design reacted to a post in a topic:

H.M.S. BOUNTY by Jerry's Admiral - FINISHED - Amati - Scale 1:60

-

PriceMachine&Design reacted to a post in a topic:

H.M.S. BOUNTY by Jerry's Admiral - FINISHED - Amati - Scale 1:60

PriceMachine&Design reacted to a post in a topic:

H.M.S. BOUNTY by Jerry's Admiral - FINISHED - Amati - Scale 1:60

-

PriceMachine&Design reacted to a post in a topic:

H.M.S. BOUNTY by Jerry's Admiral - FINISHED - Amati - Scale 1:60

PriceMachine&Design reacted to a post in a topic:

H.M.S. BOUNTY by Jerry's Admiral - FINISHED - Amati - Scale 1:60

-

PriceMachine&Design reacted to a post in a topic:

H.M.S. BOUNTY by Jerry's Admiral - FINISHED - Amati - Scale 1:60

PriceMachine&Design reacted to a post in a topic:

H.M.S. BOUNTY by Jerry's Admiral - FINISHED - Amati - Scale 1:60

-

mtaylor reacted to a post in a topic:

Tool for Shaping Brass Strip

mtaylor reacted to a post in a topic:

Tool for Shaping Brass Strip

-

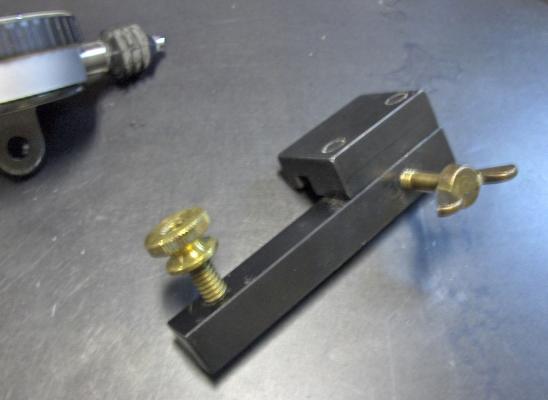

Tool for Shaping Brass Strip

PriceMachine&Design replied to mikiek's topic in Metal Work, Soldering and Metal Fittings

you could try checking K&S , they use to sell brass u-channel in small sizes as well as square tube -

mischief reacted to a post in a topic:

Holding Small Items

mischief reacted to a post in a topic:

Holding Small Items

-

PriceMachine&Design reacted to a post in a topic:

Carving from Belgorod

PriceMachine&Design reacted to a post in a topic:

Carving from Belgorod

-

PriceMachine&Design reacted to a post in a topic:

Carving from Belgorod

PriceMachine&Design reacted to a post in a topic:

Carving from Belgorod

-

PriceMachine&Design reacted to a post in a topic:

Carving from Belgorod

PriceMachine&Design reacted to a post in a topic:

Carving from Belgorod

-

PriceMachine&Design reacted to a post in a topic:

Carving from Belgorod

PriceMachine&Design reacted to a post in a topic:

Carving from Belgorod

-

PriceMachine&Design reacted to a post in a topic:

Carving from Belgorod

PriceMachine&Design reacted to a post in a topic:

Carving from Belgorod

-

PriceMachine&Design reacted to a post in a topic:

Carving from Belgorod

PriceMachine&Design reacted to a post in a topic:

Carving from Belgorod

-

mtaylor reacted to a post in a topic:

Long Term Paint Storage

mtaylor reacted to a post in a topic:

Long Term Paint Storage

-

Canute reacted to a post in a topic:

Long Term Paint Storage

Canute reacted to a post in a topic:

Long Term Paint Storage

-

hornet reacted to a post in a topic:

Long Term Paint Storage

hornet reacted to a post in a topic:

Long Term Paint Storage

-

I've used a product called Bloxogen before that works okay......and then I realized the argon bottle on my mig welder was a cheaper alternative, just set it to purge and a few trigger pulls into the container is all that's needed. I used to go through a lot of Alumilite plastic in a product I made but lost alot of it on the shelf and the argon kept it alive for a very long time.

-

mrjimmy reacted to a post in a topic:

Can't Find Thin Brass Strips

mrjimmy reacted to a post in a topic:

Can't Find Thin Brass Strips

-

GLakie reacted to a post in a topic:

Can't Find Thin Brass Strips

GLakie reacted to a post in a topic:

Can't Find Thin Brass Strips

-

thibaultron reacted to a post in a topic:

Can't Find Thin Brass Strips

thibaultron reacted to a post in a topic:

Can't Find Thin Brass Strips

-

Canute reacted to a post in a topic:

Holding Small Items

Canute reacted to a post in a topic:

Holding Small Items

-

Can't Find Thin Brass Strips

PriceMachine&Design replied to mikiek's topic in Metal Work, Soldering and Metal Fittings

you could try looking for machinist/mechanics brass shim stock also, goes down to a couple thousands in thickness. I bought a jewelers roll press years ago which has been handy for reducing stock thickness although you have to do a lot of annealing between passes with brass and copper. -

New mini-mill... CNC and impressive

PriceMachine&Design replied to mtaylor's topic in Modeling tools and Workshop Equipment

just took a somewhat closer look , so apparently the first 280 backers of the kickstarter raised 355k(!) and paid $1.270.00 each for their machines,19 of which have just been shipped.Now the cost has gone up to 4k .....darn it! .....I'd pay 1.27k for it without a second thought and I already own 3 cnc 3 axis mills but I think 4k is a bit much for this little guy. Although they use a very nice NSK spindle , not cheap, I've never heard of their machine controller and im not real impressed with lead screws and nuts on a cnc for this kind of money, although Sherline does the same.Fusion 360 is apparently free anyway and its not correct to call it 5 axis as its actually 3+2, just saying , the real 5 axis software is still under development....and im sure (?) will not be "free". I would encourage those interested to try the Fusion software out first, watch some u-tube vids on it etc. and see if you can follow along with the user interface or "GUI". Programming 5 axis stuff is in the realm of the seasoned professional which is why the somewhat rare 5 axis equipped pro shops get the BIG money. I've been programming and machining (2.5 and 3D ) for almost 20 years and the thought of doing a 5 axis part gives me a major head bender LOL. Maybe they have it all figured out now so those with no experience can set the thing on the desk and make an engine block with a few key strokes?.....not very likely, but we can dream and it will probably happen someday. (A friend of mine just bought one of those Phantom drones, never flown one before and the NEXT DAY !after it arrived was making professional grade flight videos....AMAZING!) I cant wait to see how these first 19 owners make out, if I had to make a prediction I'd say at least half the buyers will bail out after trying to program a part or 2........my theory being that a lot of the kickstarter funding comes from excited deep pocket folks looking to spend their cash on worthwhile young minds...a good thing I believe...........now where's my second hand pocketNC? -

New mini-mill... CNC and impressive

PriceMachine&Design replied to mtaylor's topic in Modeling tools and Workshop Equipment

I've seen this before, neat little 5 axis.......but...you would be shocked at the cost of a Cad/Cam program capable of programming 5 axis work, it will cost more than the machine for a good one.....and there is no realistic chance of hand coding a 5 axis machine. You can certianly machine an engine block without all the wizardry of a 5, it just takes a little longer and does not look as cool doing it -

for way lube why not use ...well.. way lube I'd recommend Mobil Vactra 2 which is available on ebay in quart bottles for as I remember around $10.00, I use this on all my cnc machines and lathe .I also use it to coat the surfaces lightly, never a rust problem.Thinking it may not be the ideal for a lathe used for mostly wood though .

-

VandaLay Hold it Plus

PriceMachine&Design replied to Nirvana's topic in Modeling tools and Workshop Equipment

they import laytex- 19 replies

-

- VandaLay

- Industries

- (and 6 more)

-

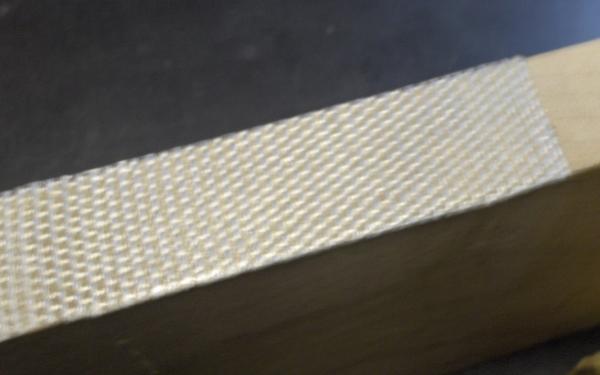

It does work really well for small odd stuff and keeps your fingers away from the blade. Its actually 42 feet ,not inches, of tape for 10 bucks which is hard to beat compared to the other double sided tapes out there. Im using it on my mills also rather than a vacumn table which is iffy on the small parts, one caveat is if your milling through a part like the window frames its best to use the glued up or another work holding method as the glue from the tape likes to ride along on the end mills.There are 3 grades of carpet tape I've found , plastic, cloth and fiberglass being the most expensive but much stickier and its also easier to remove by pulling up the glass weave then clean with some L thinner. The pieces I've cut so far have been slabs big enough for machining the stern parts and they were coming off the saw with only a thou or so variance in thickness and a surface finish that only needed a very light quick sanding, a new blade is good insurance for this. This boxwood is not fully seasoned yet but I've been microwaving the stock a bit after sawing and so far it seems to work fine with these small pieces, im a little impatient when it comes to watching things dry LOL.

-

Well I had to figure out how to get useable lumber out of those boxes of odd shaped cutoffs, I've not done that much woodworking since the 80's having worked mostly in metal the last 25 years so im rusty and have forgotten a lot of tricks.I found this one on youtube and it works great.Had to make an indicator holder for my little saw I bought way back then, a maple carrier board and a zero clearance throat plate, buy some tape and off to the races. This tape is only 10 bucks for 42"s and it STICKS, I use L thinner to clean up. So you start by getting a flat edge on your work piece, sanded,jointed or sawn, attach it to the board and zero your indicator and make a first pass, there after just add the saw kerf and desired thickness.....I've been able to cut as thin as 10 thou using this. It will work until I have my little bandsaw back online and tuned up but I think this might work better anyway....and I still have all my digits

-

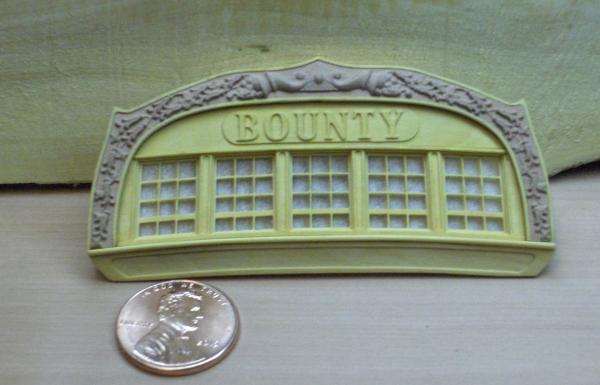

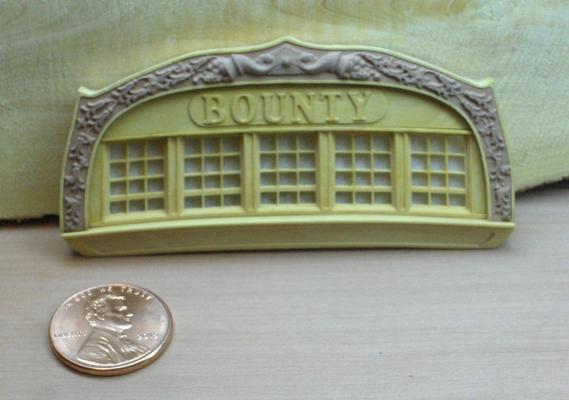

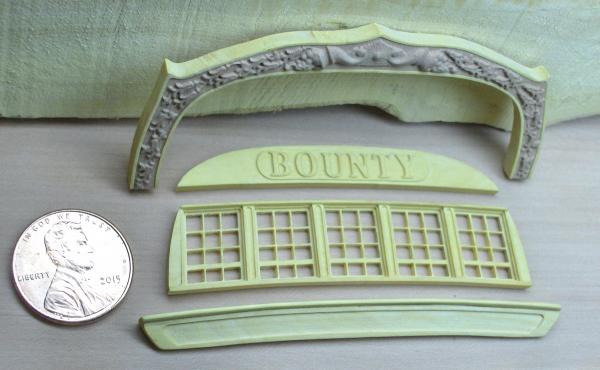

Hi Lionfish liking your start on the ship and wanted to add that I remember having read somewhere years ago that they found the remnants of copper bottom plates when diving on the Bounty's wreck so I think that would be a correct choice. I've just finished a carved stern assembly for the ship for a scratch build im starting but its in 1-64 scale, I plan on making them in 1-48 also but I don't think it would translate down to 1-110 to well , the window frames at 1-64 are only about 0.015" thick. I have some pics of it in the scratch build forum if your curious.I've accumulated a lot of photos etc. of the current Bounty's if you cant find something let me know,Kev

- 34 replies

-

- bounty

- constructo

-

(and 2 more)

Tagged with:

-

Hello , thought I would share this here since its all your fault im doing this , too much inspiration on this web site, thanks...I think. After spending the last month or so off and on completing a stern replacement for a model I had bought at auction years ago that needed a complete rebuild, what was I thinking?, i have decided tentatively that my time might be better spent doing what I really want to do which is a POF ship.This would be a first POF for me and depends on whether I can find the Hahn or other plans available.I had purchased the Mamoli kit, which is very nice, to help refit the ship and thought I could do a little better on the stern and quarters than what's supplied, everything else in the kit is really very good. So my plan so far is to scratch build the hull and use what fittings I can. Recently a friend gave me a large pile of English boxwood (!) so im thinking swiss pear and boxwood mostly, I do also have some gaboon ebony also for trim. Here are some photos of the stern to get started......some where in those boxes of wood is the rest of the ship hopefully.

-

id like to ask about this also, what glue is most recommended for longevity ? Im wondering what all those 200 year old models are held together with, hyde glue is the only thing I can think of from that period that was in use and it seems to have worked well for instruments and furniture.Curious if anyone has used it for a model?

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.