-

Posts

95 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Tossedman

-

I have just completed an order of wood from Hobbymill.eu and must say that I am very satisfied. Wood is of excellent quality and milled perfectly. Vahur was a pleasure to deal with, his customer service is excellent. And, there was a postal miracle. It took 6 days for the package to arrive from Estonia to Canada! Cheers, Todd

-

Cutters, Choppers, Guillotines, Slicers

Tossedman replied to MintGum's topic in Modeling tools and Workshop Equipment

I completely agree with all that tmp said. You cannot go wrong with the Ultimation sander and slicer if your budget can handle it. The blade is flat on one side and give square cuts only on the left side of the blade. It's marked on the cutter. The cutting blade is a single bevel blade that is used for carpet trimming. Love both the sander and the slicer. Gave away my NWSL chopper when I got the Ultimation tools and haven't looked back. Cheers, Todd -

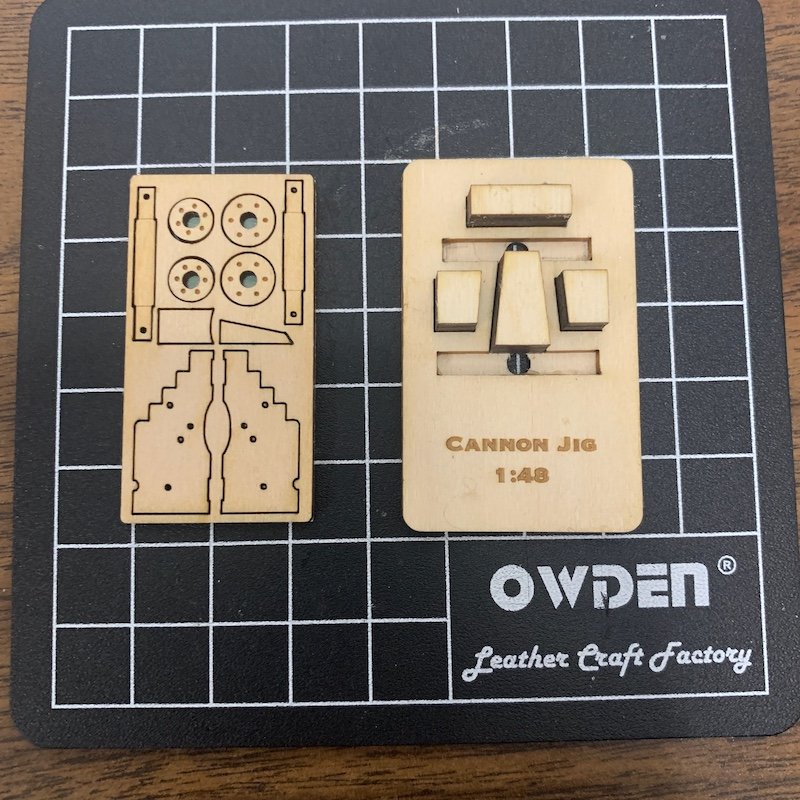

I had a Trotec Speedy 300 at work but have recently retired. Our local maker space has the same machine so I need to check them out. I've used Adobe Illustrator to great success over the past 10 years or so. The only thing I've used it for so far for model ships was for carronade carriages. Works a treat. Cheers, Todd

-

Yet Another Pandora 3D build

Tossedman replied to herask's topic in CAD and 3D Modelling/Drafting Plans with Software

That's really cool! Must have been some free beer up at the pub so the shipwrights have all left. Cheers, Todd- 119 replies

-

Yet Another Pandora 3D build

Tossedman replied to herask's topic in CAD and 3D Modelling/Drafting Plans with Software

Indeed!- 119 replies

-

3D Printing Cannons in Resin

Tossedman replied to thibaultron's topic in 3D-Printing and Laser-Cutting.

Looks great! I designed and laser cut an N scale engine shed. All of the parts such as window frames and mullions were separate so many more pieces than yours. It was fun to do. Learned a ton doing it. -

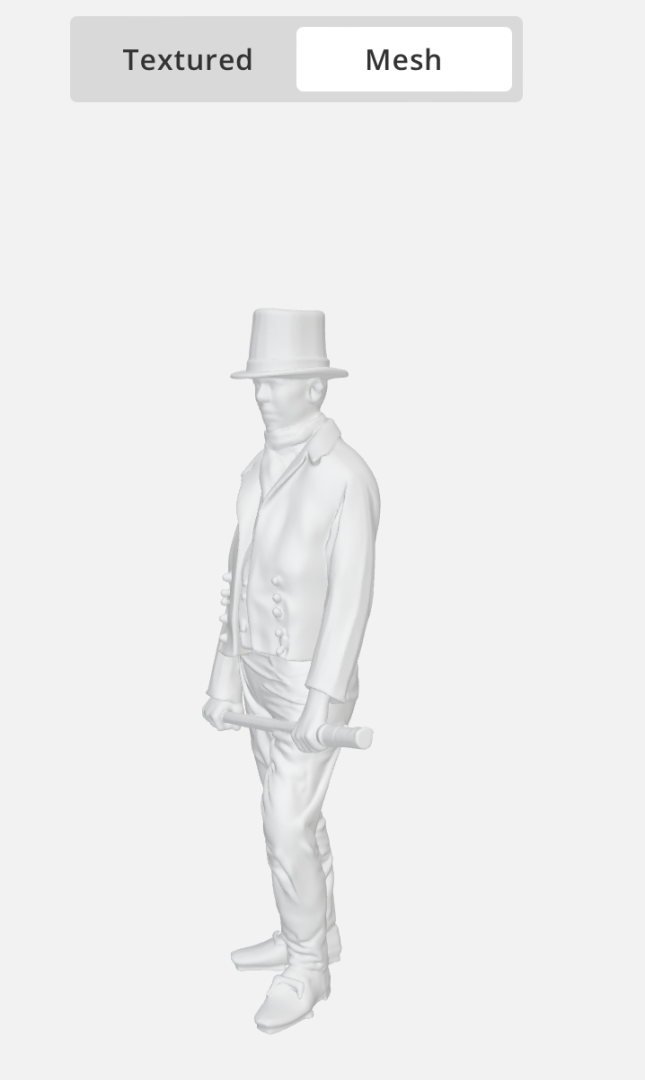

I was browsing YouTube as I am wont to do from time to time and stumbled across this: It got me thinking and I searched for an image of a Royal Navy sailor from the early 1800s. I stumbled across this image: http://history-making.com/product/bosuns-mate-1806/ Following the steps in the video I went to makerworld.com and I created a 3D model from the 2D image. Here's what was generated. I then downloaded the OBJ file and threw it into my FDM printer and came up with this. This is printed at 0.4mm layer height and has had nothing done to it other than take off the supports. It's 82mm tall but could easily be scaled down. Give this technology some time to mature and it could be amazing. Only thing is, how does copyright affect such things? Could be a smelly can of worms that are being opened here. Perhaps it will render old paintings that are long out of copyright into 3D models. We'll have to see. You should be able to 3D print yourself though. Just dress up and take a photo. Suddenly, you're at the helm of your model ship. Cheers, Todd

-

Hello from Calgary, Alberta, Canada

Tossedman replied to AboveTheWaterLine's topic in New member Introductions

Welcome from another Calgarian. Cheers eh, Todd -

I have both the Proxxon Bench Drill Press TBM 115 and the MICRO Compound Table KT 70. I use them both extensively and quite like them. I don't do any milling with this set up but it's great for drilling. I also have the PROXXON Precision Steel Vice PM 40 on the micro compound table. Great for repetition as I'll laser cut little jigs to hold pieces for accurate drilling. Cheers, Todd

- 53 replies

-

- Drill Press

- Milling

-

(and 1 more)

Tagged with:

-

Nicely done Ben. Impressive work!

- 399 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

3D Printing Cannons in Resin

Tossedman replied to thibaultron's topic in 3D-Printing and Laser-Cutting.

Looks great Ron! Are you designing with SketchUp? Your last image makes me think so. You're really making me think about getting a resin 3D printer with all of this great stuff you're designing. I think the through bolt should added afterwards along with all of the other wire eyelets, although you don't really see it when the barrel is mounted. I'm not experienced enough with resin printing to comment on whether to print as separate pieces or all as one. Looking forward to your finished design. Cheers, Todd

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.