-

Posts

60 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Jonesey

-

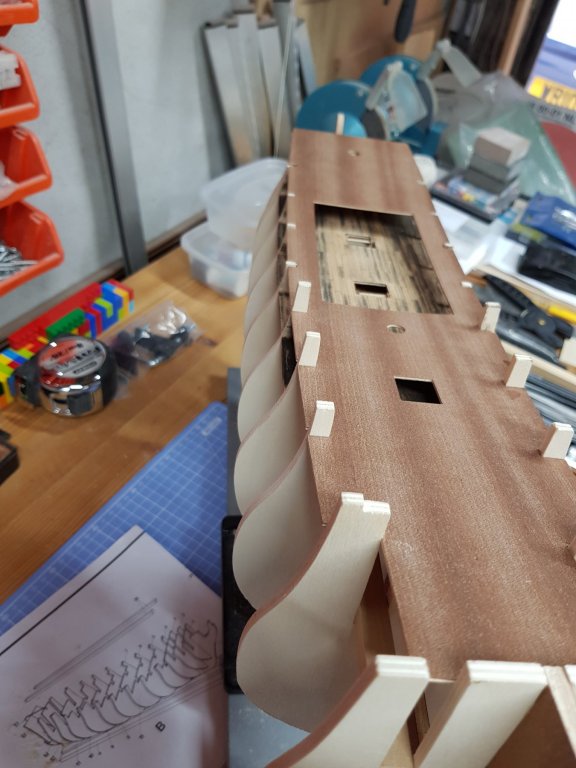

I can't believe it's been so ling since I posted, or indeed worked on the model Anyway, I've reached a milestone of sorts - the first layer of planking is now complete The hull is riddled with errors & mistakes, some avoidable, some entirely of my own making and some due to a total lack of experience This is my first ever attempt at planking See what you think

-

And as luck would have it, my usual supplier - Cornwall Model Boats - are out of stock 🥺

-

Thanks all. Looks like I ordered #1

-

Can someone tell me what the difference is between these 2 blades? I need some more of the larger ones, but the ones which arrived are the smaller ones Thanks

-

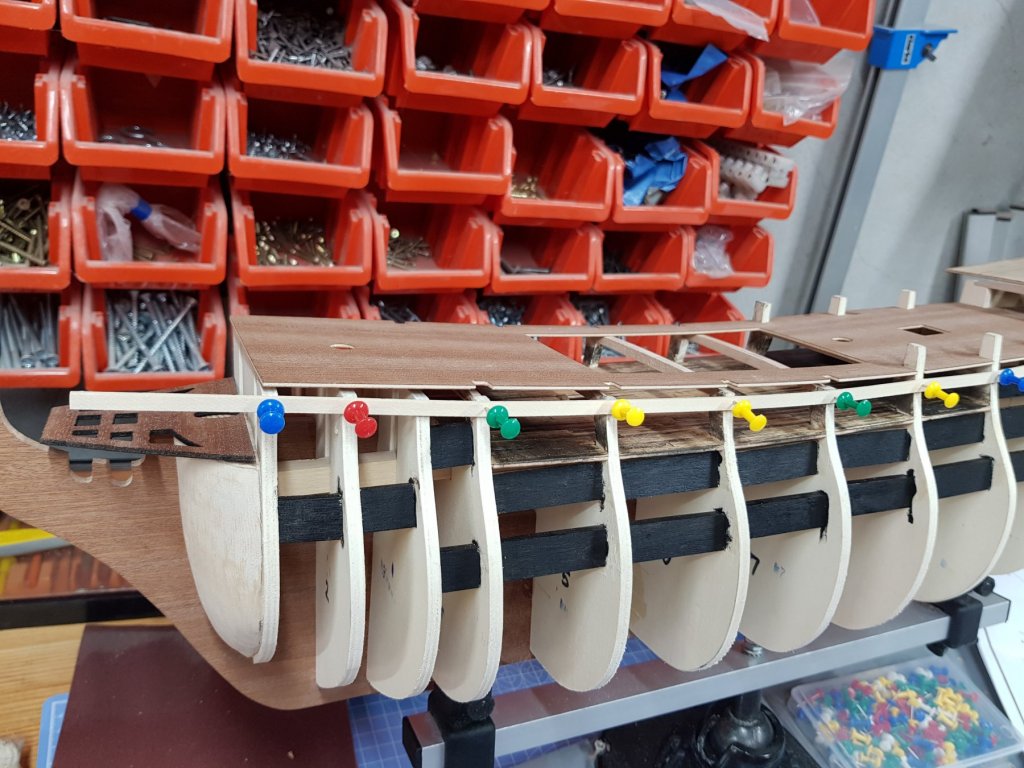

Hi Eugenio Progress has been very slow this last year - work & life always get in the way However, I've moved the shipyard from the garage to our old kitchen area which doesn't get any use and intend to carry on in the warm throughout the winter. My first layer of planking is progressing - I'm hopeful this is the most complex part of the build, but time will tell!

-

Your build looks absolutely fine so far, well done I'm delaying the option to fit copper tiles until I see how the first layer of planking turns out. I'm more or less at the same point as you on my Corel build but the really challenging parts are up next - lower hull/stern/bow I'd post some pictures but I'm currently soaking up the sun in Gran Canaria 😎

-

Had a bit of an accident tonight. I snapped off the top of one of the bulkheads 😕 After sanding the edges down there was a gap of about 2 mm which meant the piece I intended to glue back on was 2mm lower than it should be, so I had to make a small filler to raise it back up If it all sticks ok, it shouldn't be a problem as the top deck isn't glued down yet and the offending piece will be hidden on the outside by the hull planking and on the inside, it's covered by the top deck Set me back by another evening though.

-

Had a break from stern fillers today and did some other stuff Finished installing the gun port backings and painted them black. Cut, shaped and dry fitted the deck beams part 28 Tested the fit of one blank without bending, just to get a feel for how much bending is required All in all, I thoroughly enjoyed today's efforts The lower deck I've attempted to age it. I applied some walnut stain (which comes out black) then scraped it back to reveal the original surface. The walnut has really penetrated into the deck but looking it closely, it's left some lovely black lines in the grain after scraping I'm not worried about some of the blacker areas towards the front & rear of the deck as these areas will be hidden by the main deck

-

Thank you Vane for your kind words of encouragement I must admit it's a bit disheartening to ask questions which seem to be ignored by members of the community All I'm really trying to avoid is making mistakes but with some of these issues I seem to be literally making it up as I go along with little or no guidance I will keep on muddling through as best I can

-

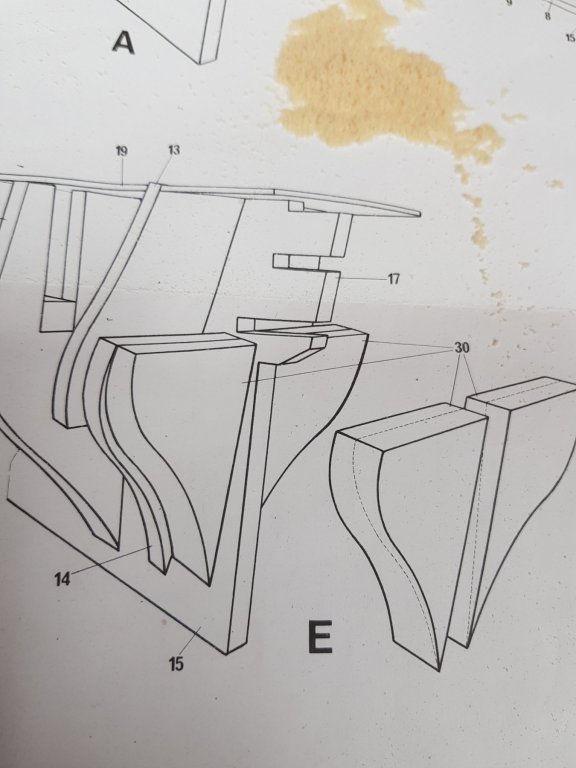

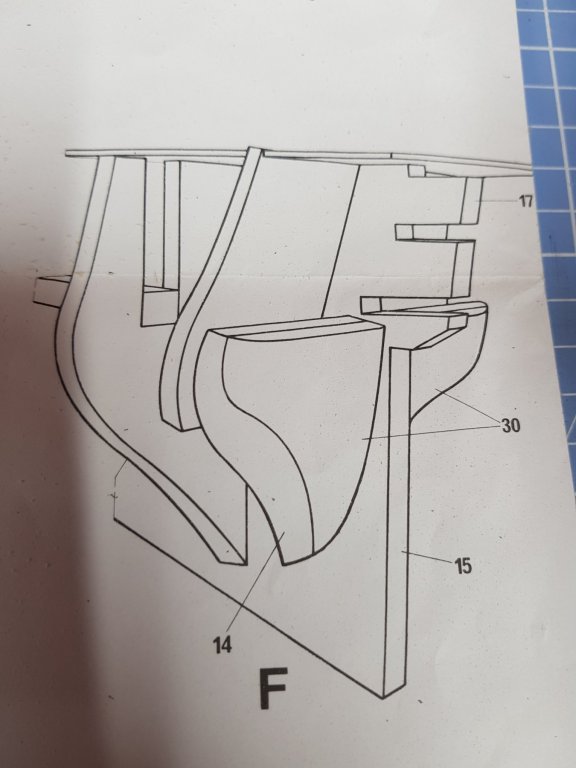

Which brings us to my issue. Looking at the plans, plates E & F show the placing of the stern fillers I'm concerned about how these actually get shaped into place Looking at the diagram in E, you can see the original piece supplied by Corel mounted on the frame. The piece shown on the right of the figure shows a dotted line which is meant to be carved out. So far so good Now compare it to the diagram labelled F looking vertically down, the piece is shaped with a nice curve where it attaches to frame 14 But in E, it's shown as a straight cut which doesn't make sense. Likewise, the taper of the bottom of the piece in F again shows a curve, but in E there appear to be more material left than is carved out in F Totally confused by this. I don't want to remove too much material as correcting this afterwards would be a major pain and I want to try and get this right. so, any ideas dear people?

-

Hi all It's been a while since I last posted so a quick update followed by my current problem. Work has been slow just having evenings & weekends to work in the shipyard, but I've done the lower deck planking, fitted the bow filler pieces, installed the gun port backing on the starboard side and have started work on the stern fillers

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.