-

Posts

100 -

Joined

Profile Information

-

Gender

Male

-

Location

Toronto, Canada

-

Interests

Wood Ship Modelling

Recent Profile Visitors

-

Do not secure mast in the corresponding hole in the hull till you are totally satisfied with complete mast with all sections assembled. You can pull the mast in and out the hole whenever you please and fill necessary. When you are satisfied - secure the mast in the hole.

-

Somehow I do not understand a) what the fellow modified the standard clips for b) how this can be applied for holding first planking strips

-

James H reacted to a post in a topic:

HMS Victory: Caldercraft or Artesania Latina

James H reacted to a post in a topic:

HMS Victory: Caldercraft or Artesania Latina

-

Y.T. started following Simple, low cost, small thimbles , HMS Victory: Caldercraft or Artesania Latina , jig for making uniform footrope stirrups and 5 others

-

HMS Victory: Caldercraft or Artesania Latina

Y.T. replied to darkening's topic in Wood ship model kits

I would select a smaller size one AL at 1:84. Caldercraft is 1:78 It is 5.5 feet long. -

Y.T. reacted to a post in a topic:

Young America 1853 by EdT - FINISHED - extreme clipper

Y.T. reacted to a post in a topic:

Young America 1853 by EdT - FINISHED - extreme clipper

-

Y.T. reacted to a post in a topic:

8" Mini Shear/Brake

Y.T. reacted to a post in a topic:

8" Mini Shear/Brake

-

Y.T. reacted to a post in a topic:

Making Slings

Y.T. reacted to a post in a topic:

Making Slings

-

Y.T. reacted to a post in a topic:

jig for making uniform footrope stirrups

Y.T. reacted to a post in a topic:

jig for making uniform footrope stirrups

-

Gregory reacted to a post in a topic:

Recommended First Machine

Gregory reacted to a post in a topic:

Recommended First Machine

-

Admiral Rick reacted to a post in a topic:

Recommended First Machine

Admiral Rick reacted to a post in a topic:

Recommended First Machine

-

If you ask me, I have no reason to question the product. I purchased Silkspan here: https://sigmfg.com/products/sig-silkspan-tissue As I said earlier. I will no longer consider any paper product for sails unless may be for furled sails. It is easy to tear and cannot be repaired if damaged. The full story of my Silkspan use attempt is here: https://shipsofscale.com/sosforums/threads/hms-victory-by-y-t-mamoli-1-90-scale.2397/post-467322

-

druxey reacted to a post in a topic:

Sail feedback request, Mondfeld method

druxey reacted to a post in a topic:

Sail feedback request, Mondfeld method

-

Gregory reacted to a post in a topic:

Sail feedback request, Mondfeld method

Gregory reacted to a post in a topic:

Sail feedback request, Mondfeld method

-

Canute reacted to a post in a topic:

Recommended First Machine

Canute reacted to a post in a topic:

Recommended First Machine

-

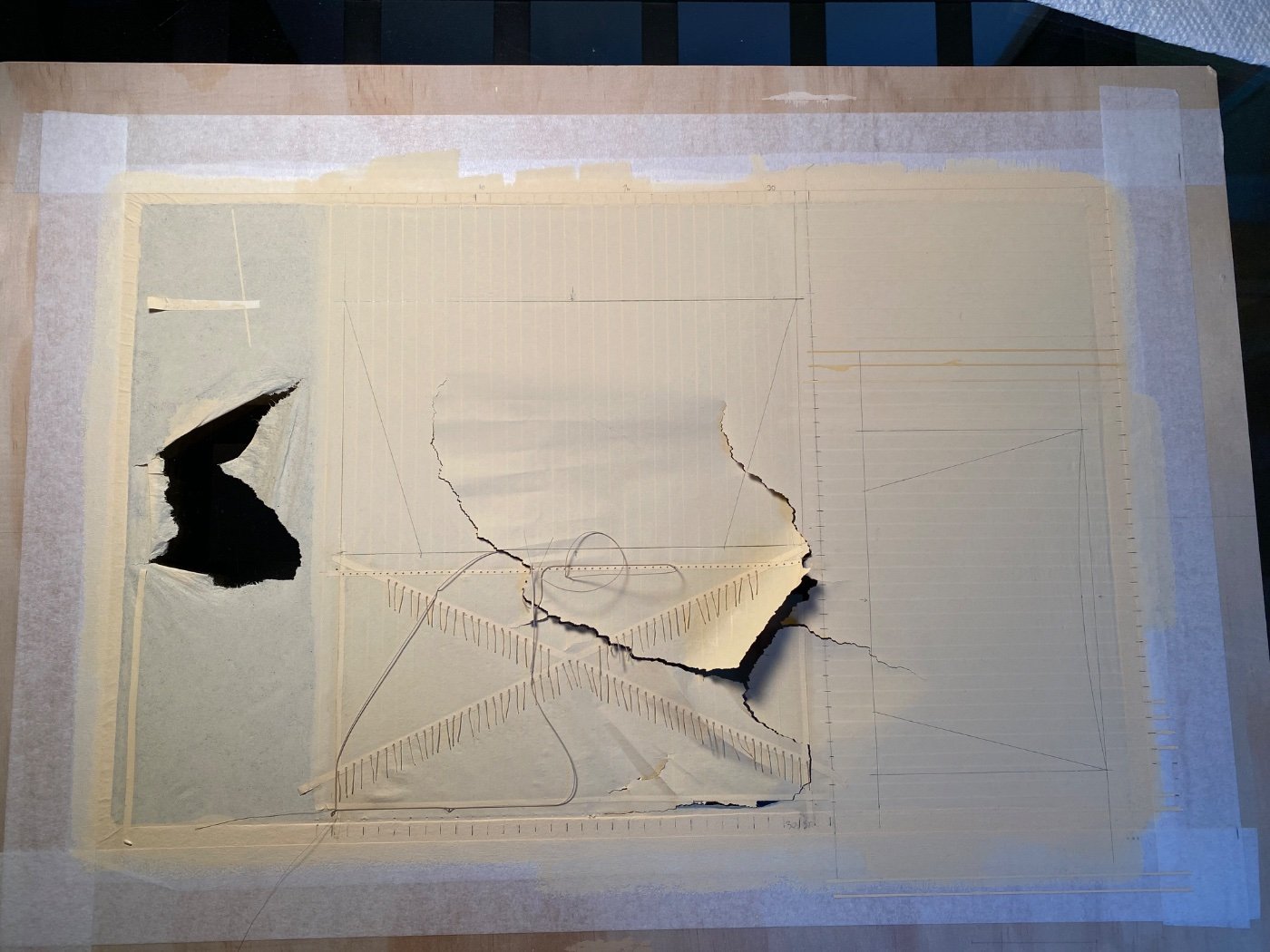

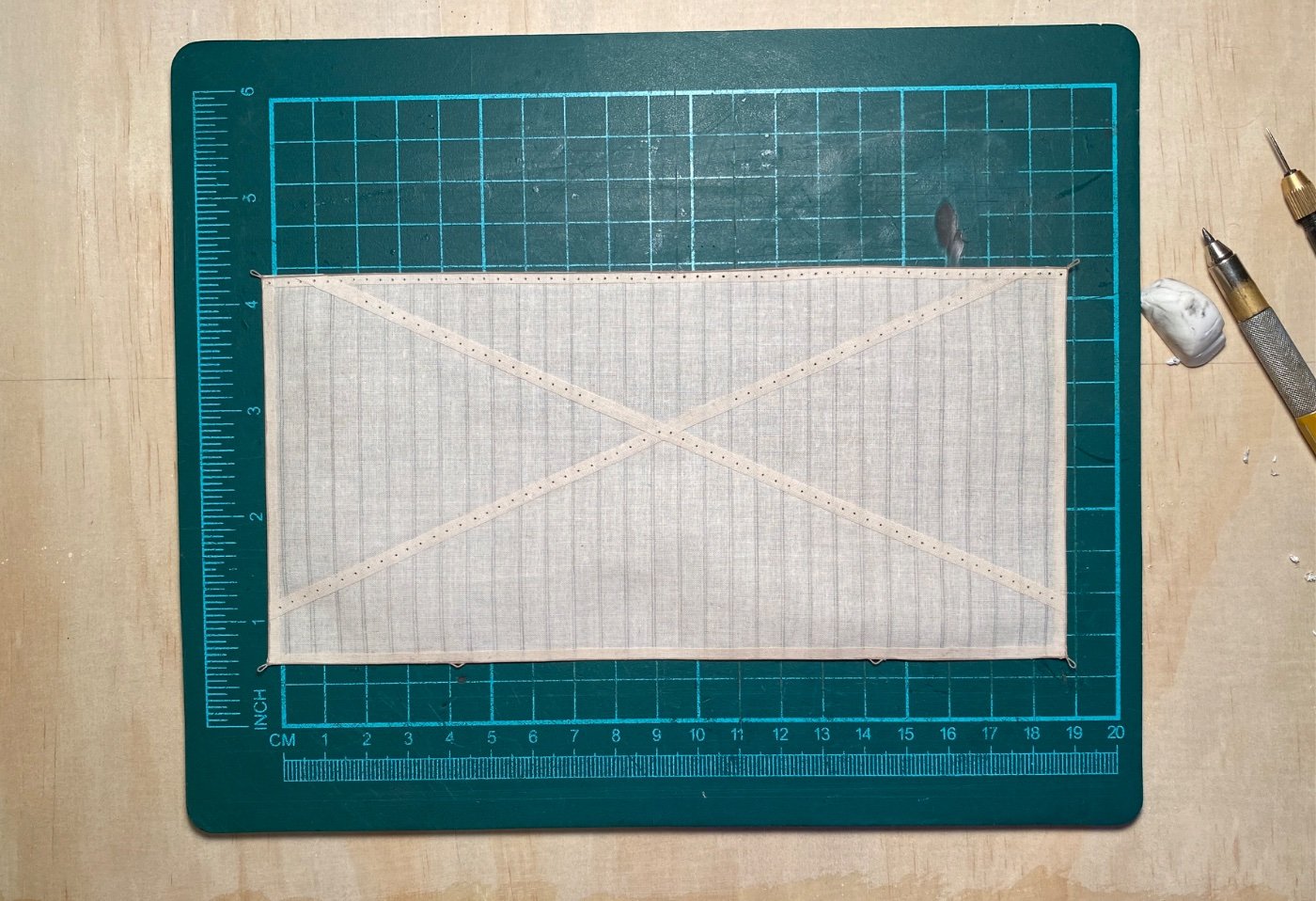

Finding a silkspan is not a problem. I got as much of it as I wanted here: https://sigmfg.com/products/sig-silkspan-tissue I just want to warn you that from my own experience I tried making the sail from it and abandoned the idea later. Silkspan is way too brittle and impossible to repair. I spent a week working on one sail and got it torn off in a second. Since then I abandoned the idea of silkspan. I work with very light batiste. You can look at my endeavors here. First picture of broken silkspan sail. Next is from thin fabric. Scale is 1:90

-

Y.T. reacted to a post in a topic:

Sail feedback request, Mondfeld method

Y.T. reacted to a post in a topic:

Sail feedback request, Mondfeld method

-

Y.T. reacted to a post in a topic:

Sail feedback request, Mondfeld method

Y.T. reacted to a post in a topic:

Sail feedback request, Mondfeld method

-

Ryland Craze reacted to a post in a topic:

Wood Plank Benders - Rounding

Ryland Craze reacted to a post in a topic:

Wood Plank Benders - Rounding

-

MintGum reacted to a post in a topic:

Wood Plank Benders - Rounding

MintGum reacted to a post in a topic:

Wood Plank Benders - Rounding

-

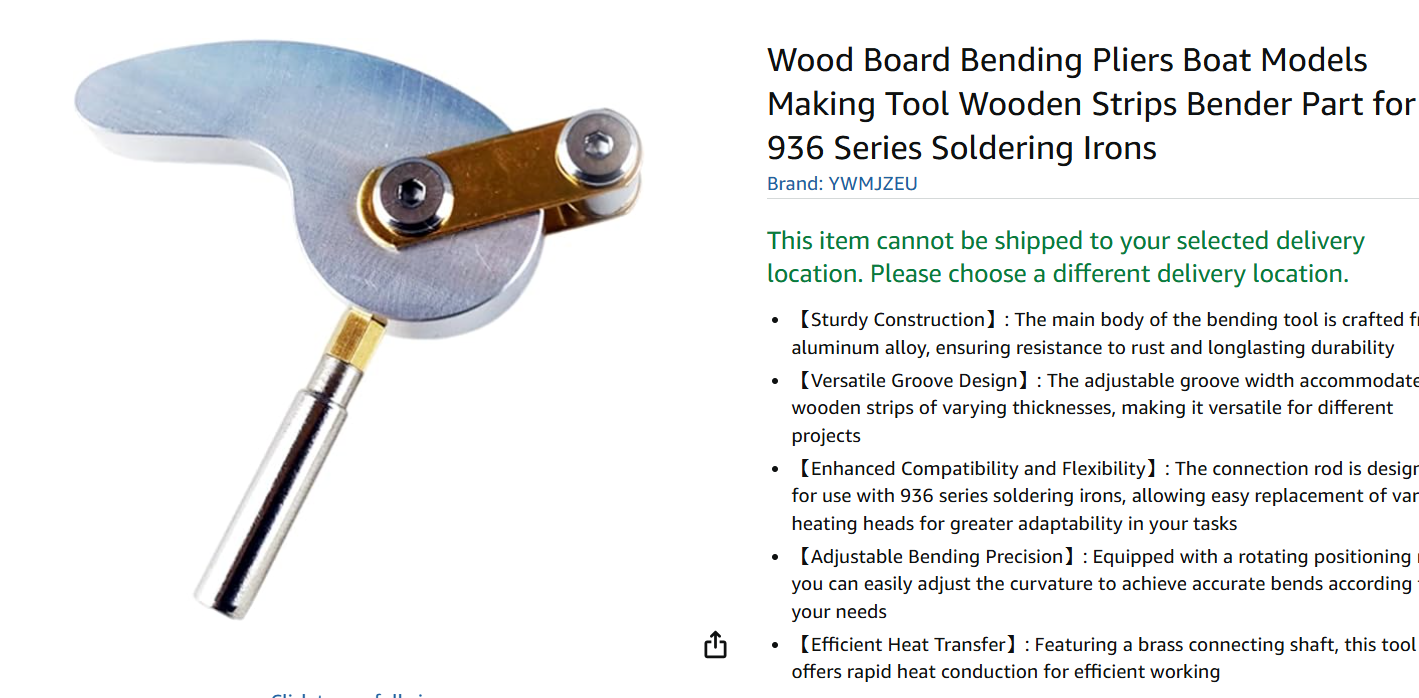

Wood Plank Benders - Rounding

Y.T. replied to MintGum's topic in Modeling tools and Workshop Equipment

I have been through this.the 220 V device will provide you not enough power to bend any planks. currently I am using Weller’s 110 V soldering iron 80 W power and the head from AeroPiccola plank bender which fits right into it. -

Y.T. reacted to a post in a topic:

Innocraftsman Mill

Y.T. reacted to a post in a topic:

Innocraftsman Mill

-

hollowneck reacted to a post in a topic:

Cutters, Choppers, Guillotines, Slicers

hollowneck reacted to a post in a topic:

Cutters, Choppers, Guillotines, Slicers

-

Canute reacted to a post in a topic:

Innocraftsman Mill

Canute reacted to a post in a topic:

Innocraftsman Mill

-

Wood Plank Benders - Rounding

Y.T. replied to MintGum's topic in Modeling tools and Workshop Equipment

If this one is still available from anywhere it is the only one worth considering. I have original Aeropiccola like this. To my opinion all the rest are not good. -

Y.T. reacted to a post in a topic:

Oops -- Repairing broken bowsprit on Cutty Sark

Y.T. reacted to a post in a topic:

Oops -- Repairing broken bowsprit on Cutty Sark

-

Cutters, Choppers, Guillotines, Slicers

Y.T. replied to MintGum's topic in Modeling tools and Workshop Equipment

-

I use this disk sander for years and am very pleased with it. It is four times cheaper than Proxxon and does same job. https://www.amazon.ca/Vibration-Free-Bench-Disc-Sander/dp/B07SFZGHVQ/ref=asc_df_B07SFZGHVQ?mcid=939201fb73b2384da47191e8a4656ceb&tag=googleshopc0c-20&linkCode=df0&hvadid=706725384462&hvpos=&hvnetw=g&hvrand=16140153878231337219&hvpone=&hvptwo=&hvqmt=&hvdev=c&hvdvcmdl=&hvlocint=&hvlocphy=9189954&hvtargid=pla-2245741550629&psc=1&hvocijid=16140153878231337219-B07SFZGHVQ-&hvexpln=0&gad_source=1

-

Disk sander is more important for wood ship modelling. I have no doubts. Table saw is complimentary especially if you are not going to manufacture your own wood planks from scratch.

-

Y.T. reacted to a post in a topic:

1:48 La Renommée 1744 - CAF Model

Y.T. reacted to a post in a topic:

1:48 La Renommée 1744 - CAF Model

-

I am going to stick to a brass tube. This is a sample 1 mm OD. I knock it with a center punch so it is easy to be wrapped with a rope. Not wiggling out.

-

Y.T. reacted to a post in a topic:

Simple, low cost, small thimbles

Y.T. reacted to a post in a topic:

Simple, low cost, small thimbles

-

Tired hearing of "pirating". Proof of pirating must be presented before accusing. In general this issue is the matter for legal courts. Has little to do with consumers.

-

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.