-

Posts

225 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Hsae

-

Another option: https://ultimation.ca/products/slicer

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Glenn, you work is marvelous, as always. I have to ask: where did you get your “mini-me” from? Did they actually scan you, or how does it work? I hope you didn’t answers this question before, I didn’t see it …. Hermann

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Byrnes ropewalk https://www.byrnesmodelmachines.com/ropewalk5.html

-

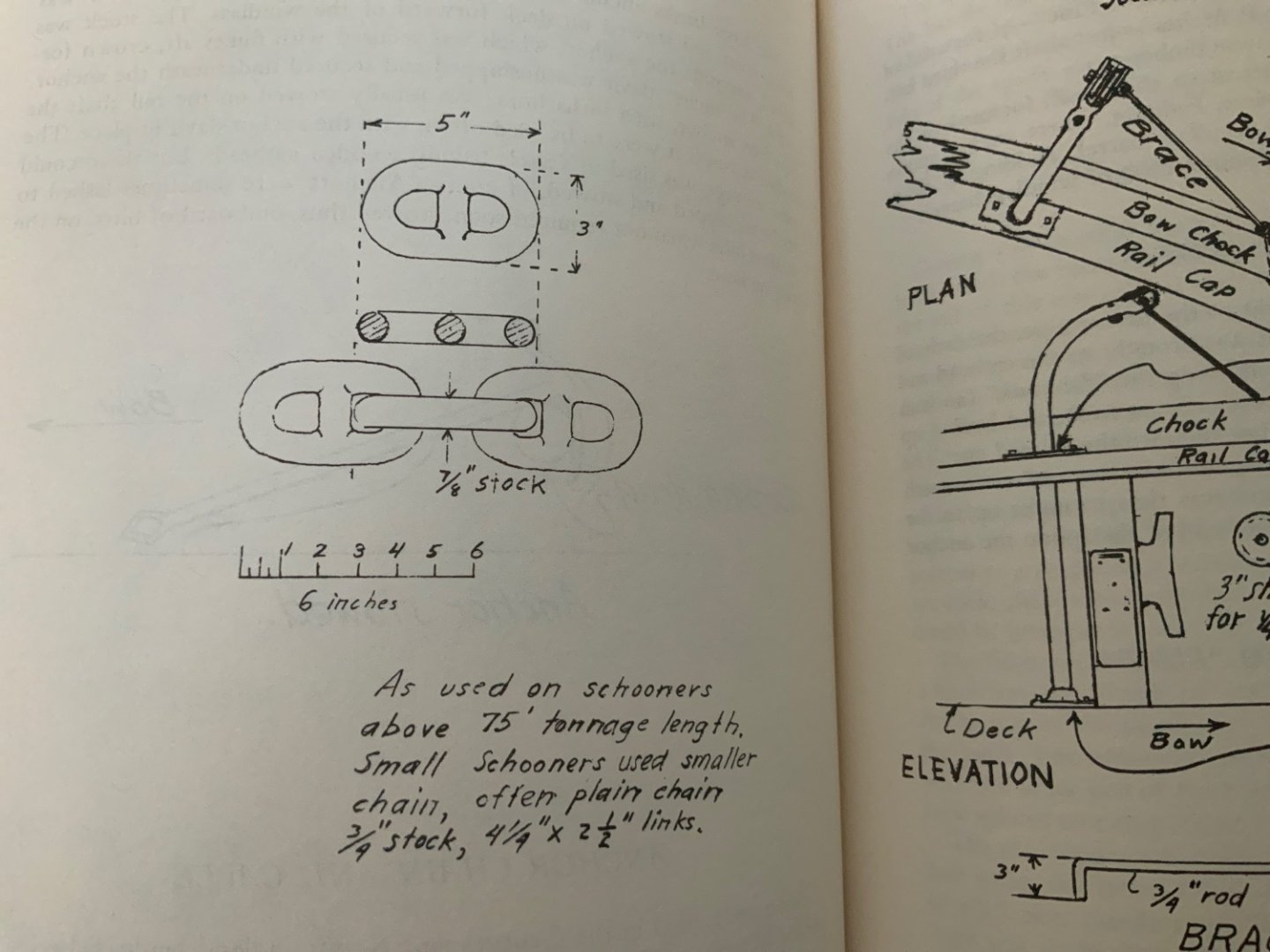

I am building a whaleboat from the late 1800. I was wondering which paint would be best for wood? So far I painted plastic models with acrylic or enamel with the brands you are easy getting, like Testors, Tamiya, Vallejo or AK. And if I had to paint some wood I used only Wipe-On Poly. But how do I paint a model, say from 1800 in the appropriate color? I don’t have experiences with the Model Shipways paint, or other paints which are made especially for wooden models, so they say. But it there really a difference compared to the more common brands, like I mentioned above? Since paint got quite expensive I don’t want to buy all kind of different brands. I would really appreciate any input. Thanks, Hermann

-

Also I would like to know what preperation ship modellers are using to brass or other metals prior to priming the surface before using an acrylic based paint.I always find that the paint is easily scraped off afterwards? I always prepare the brass with steel wool or #400 sand paper, after that I clean it with acetone, or alcohol. It is important that you don’t have any grease for instance from your fingers on the brass anymore. Hermann

-

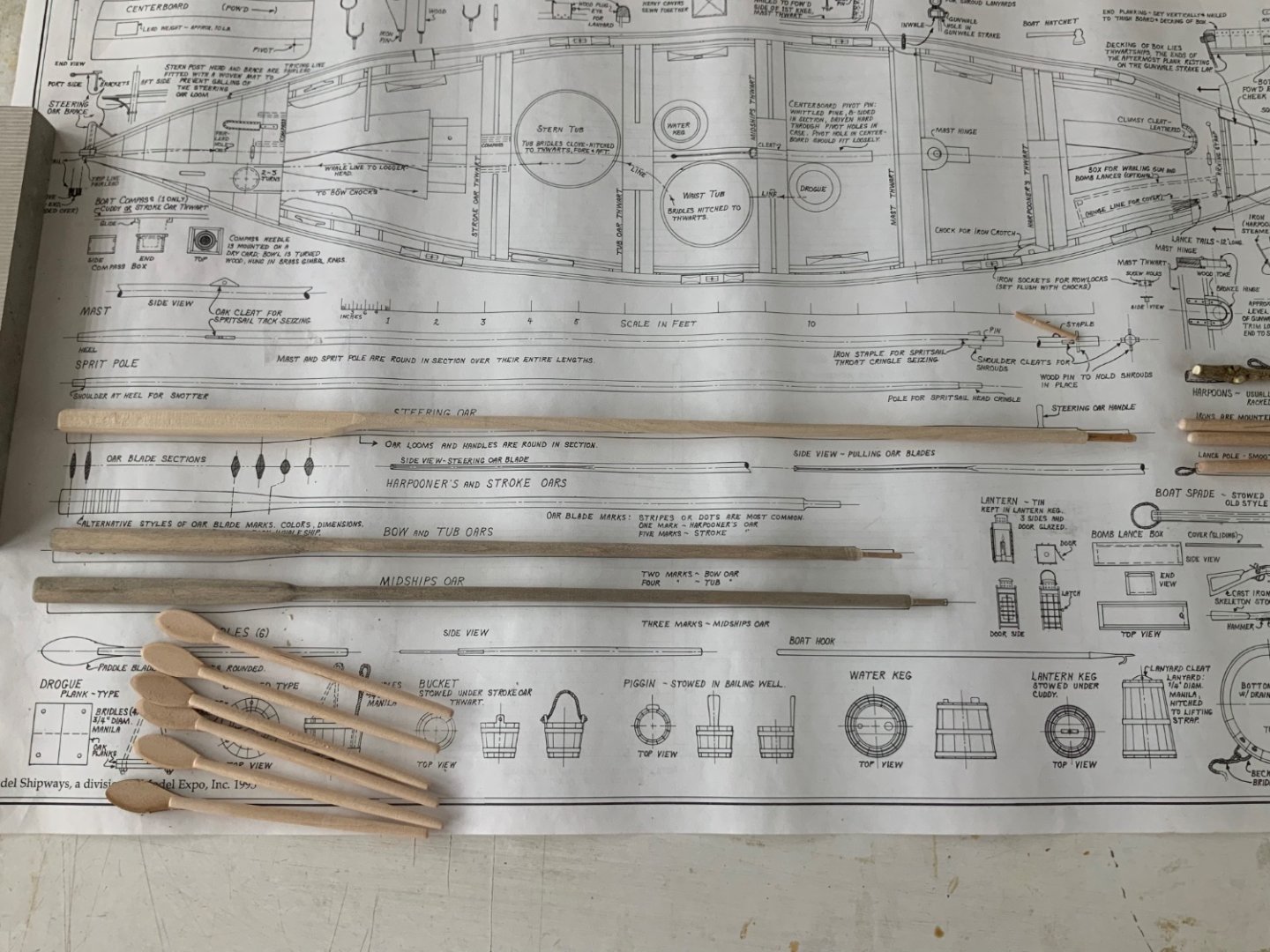

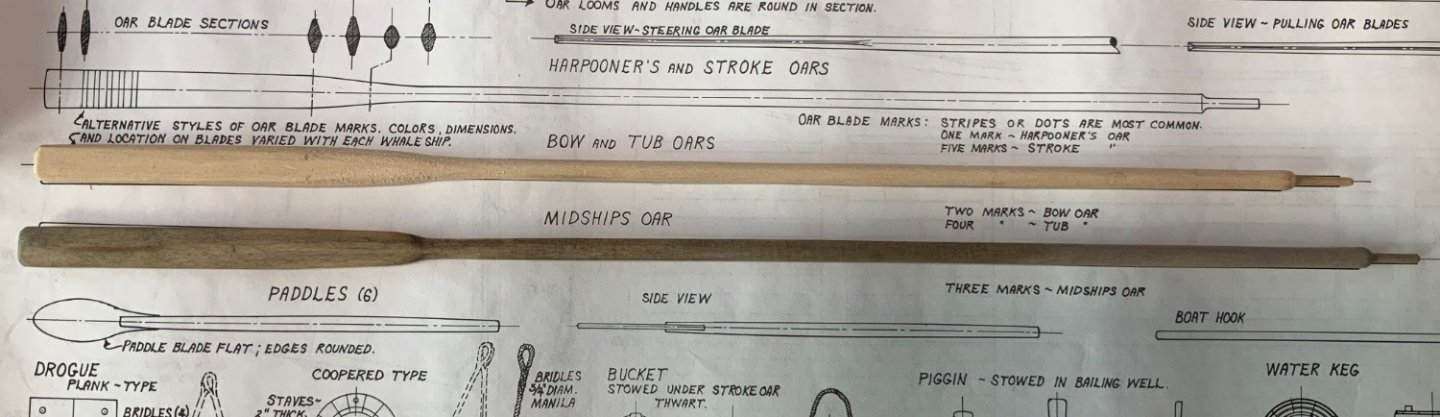

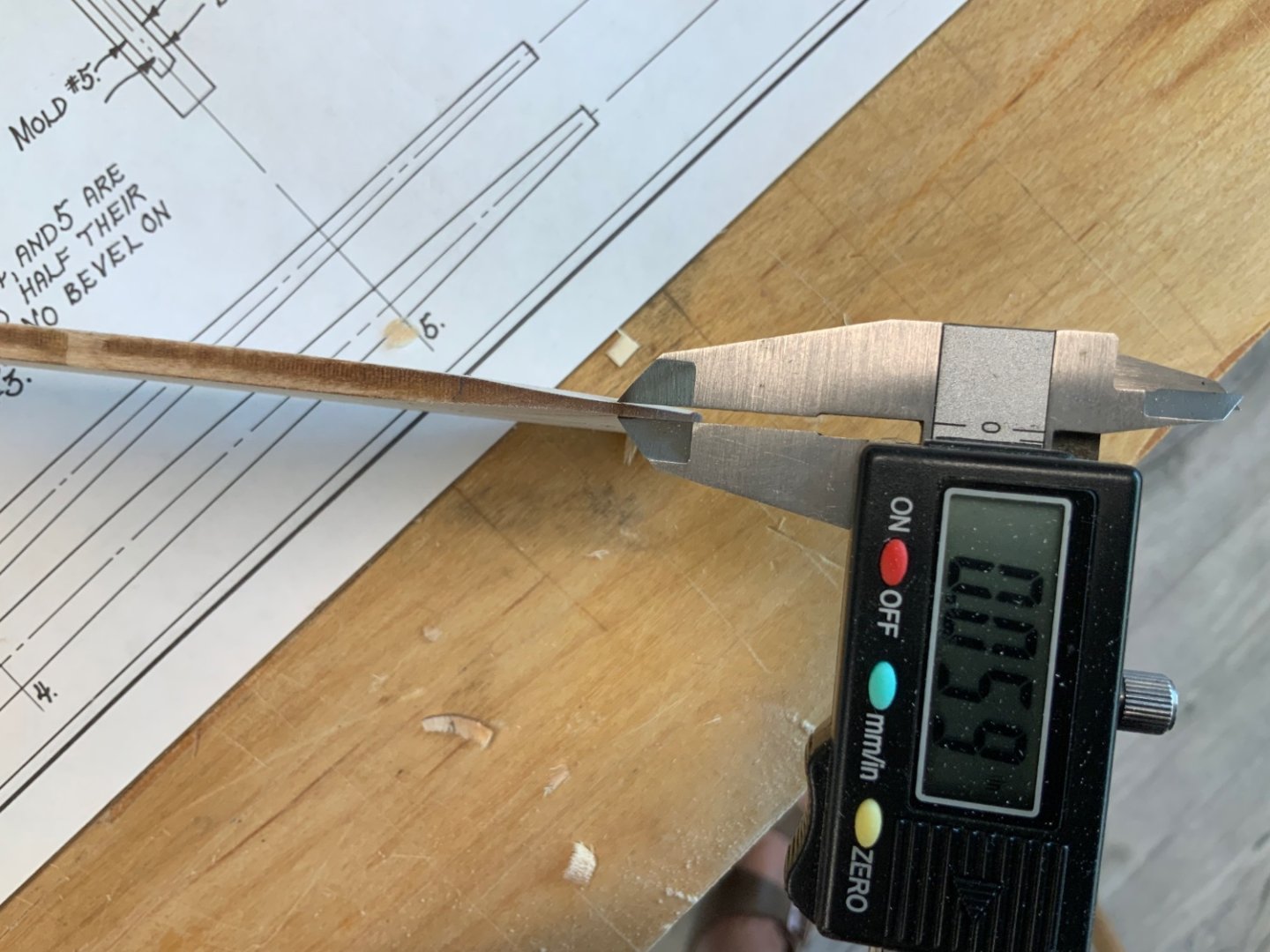

PJG, may I ask what kind of diameters you used for the whale line & rigging? I agree the supplied stuff is awful. Hermann

- 52 replies

-

- model shipways

- new bedford whaleboat

-

(and 1 more)

Tagged with:

-

Used Cameron Drill Press Opinions Requested

Hsae replied to James G's topic in Modeling tools and Workshop Equipment

My two cents … 1) it depends how well maintained the drill press was/is 2) I don’t think that age matters as long as the drill press wasn’t abused 3) well I guess you find out later. Unfortunately you can measure the concentricity on eBay. You have to trust the seller. 4) I guess that is with every machine you purchase a concern. Maybe you should buy some parts while they are available, like belts. On the other hand what kind of parts do you need with a drill press? I have a Proxxon for over 20 years now, without any issues. I am guessing you don’t use it every day anyway. On the other hand you get a set up like in the picture below for roughly $300 new. Which in my case was from the point of accuracy sufficient (for my needs). Hermann -

Good evening Lester,

I was browsing the thread from Roy (New Bedford Whaleboat) and you offered some photos from Whaleboats.

I am in the process of building the Whaleboat too. Would it be possible to get some photos?Thanks,

Hermann

-

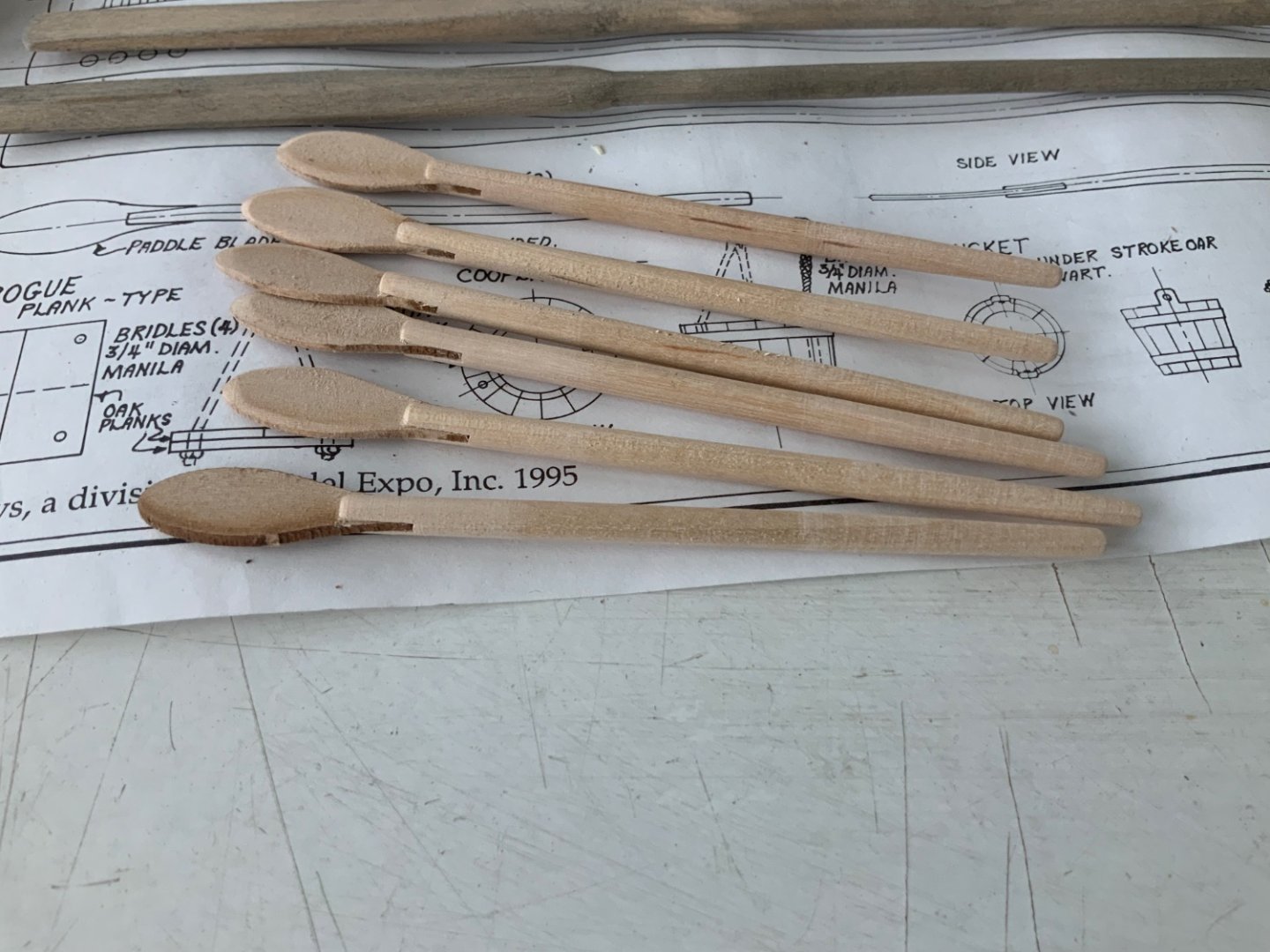

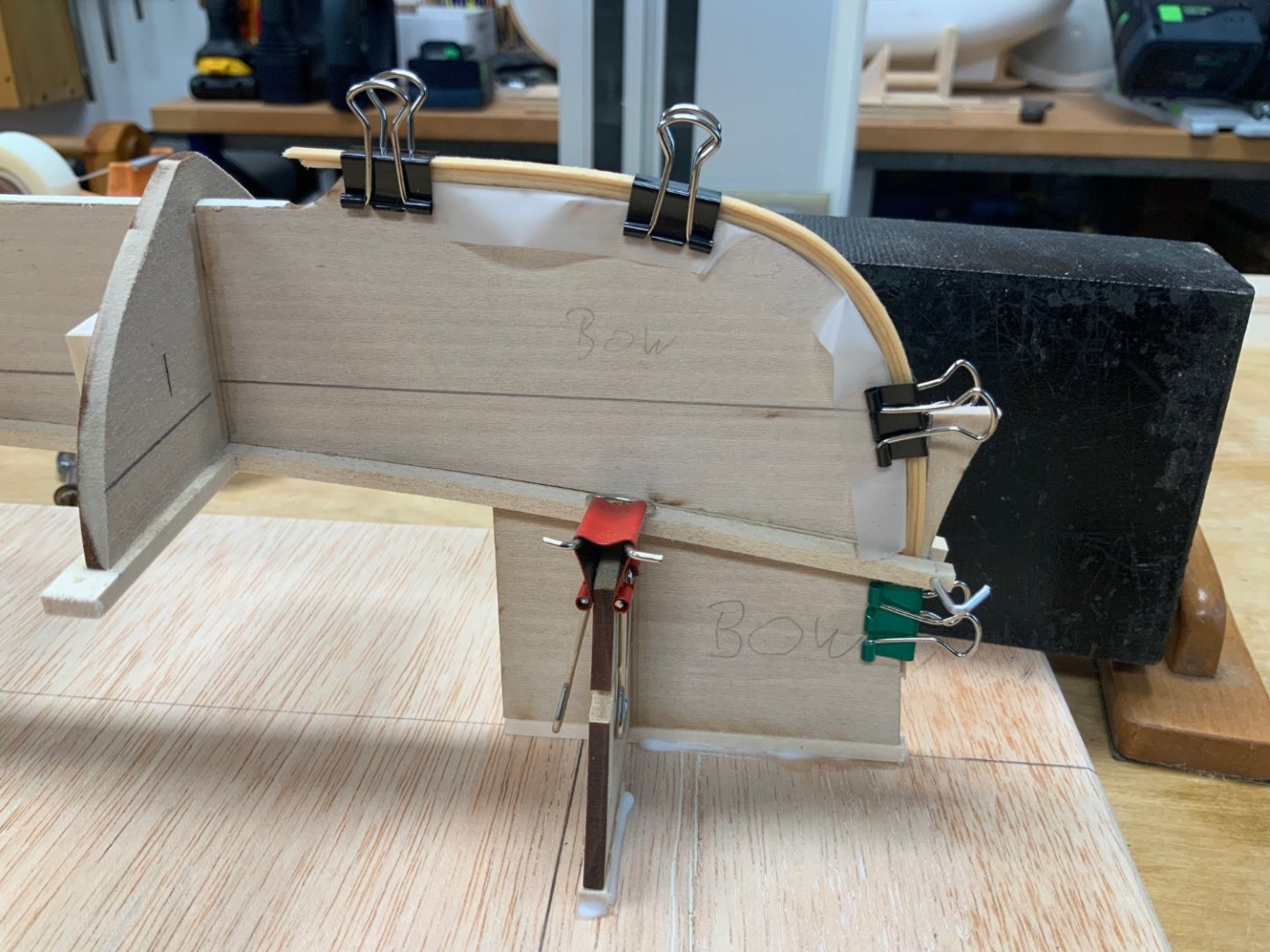

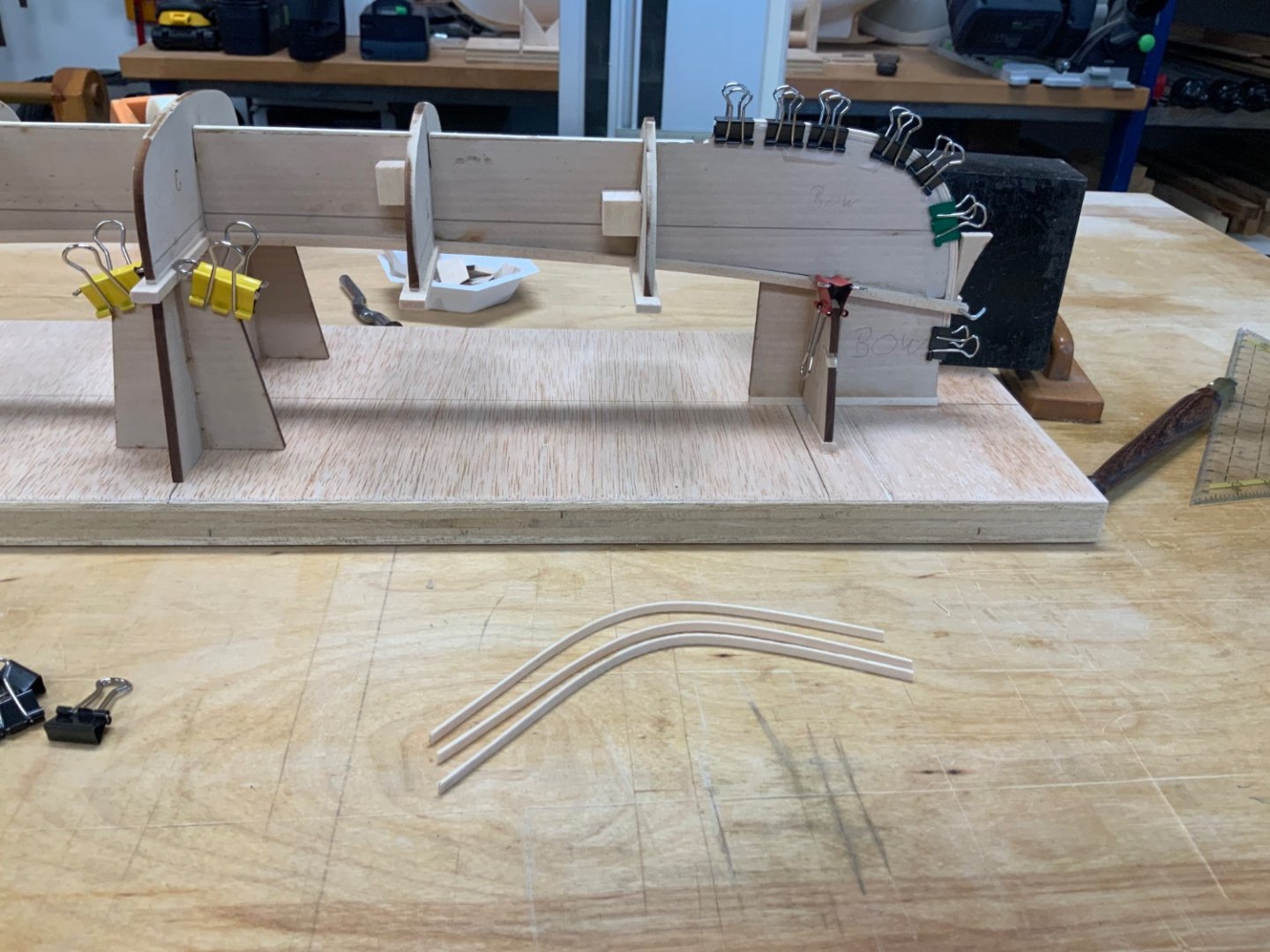

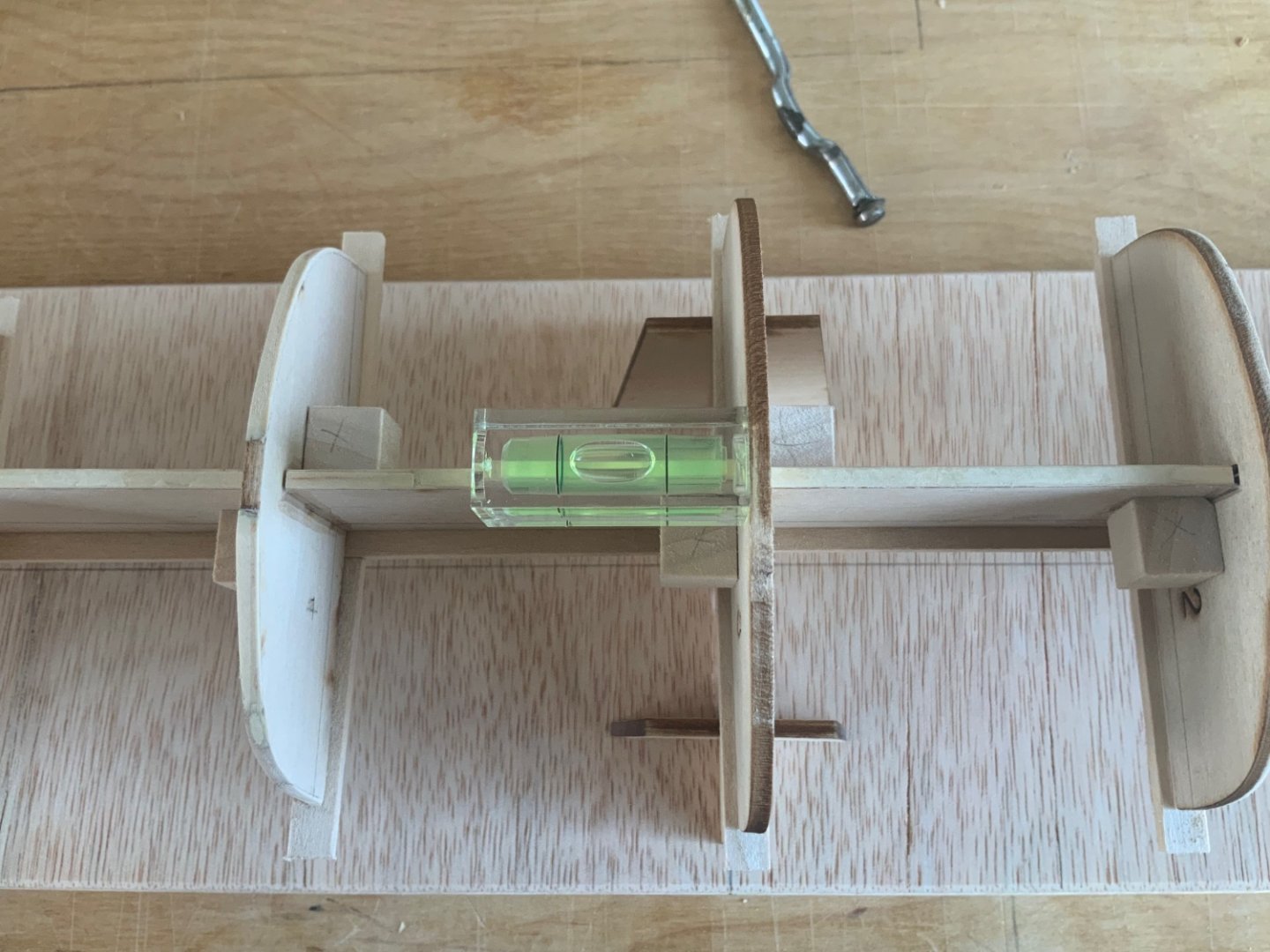

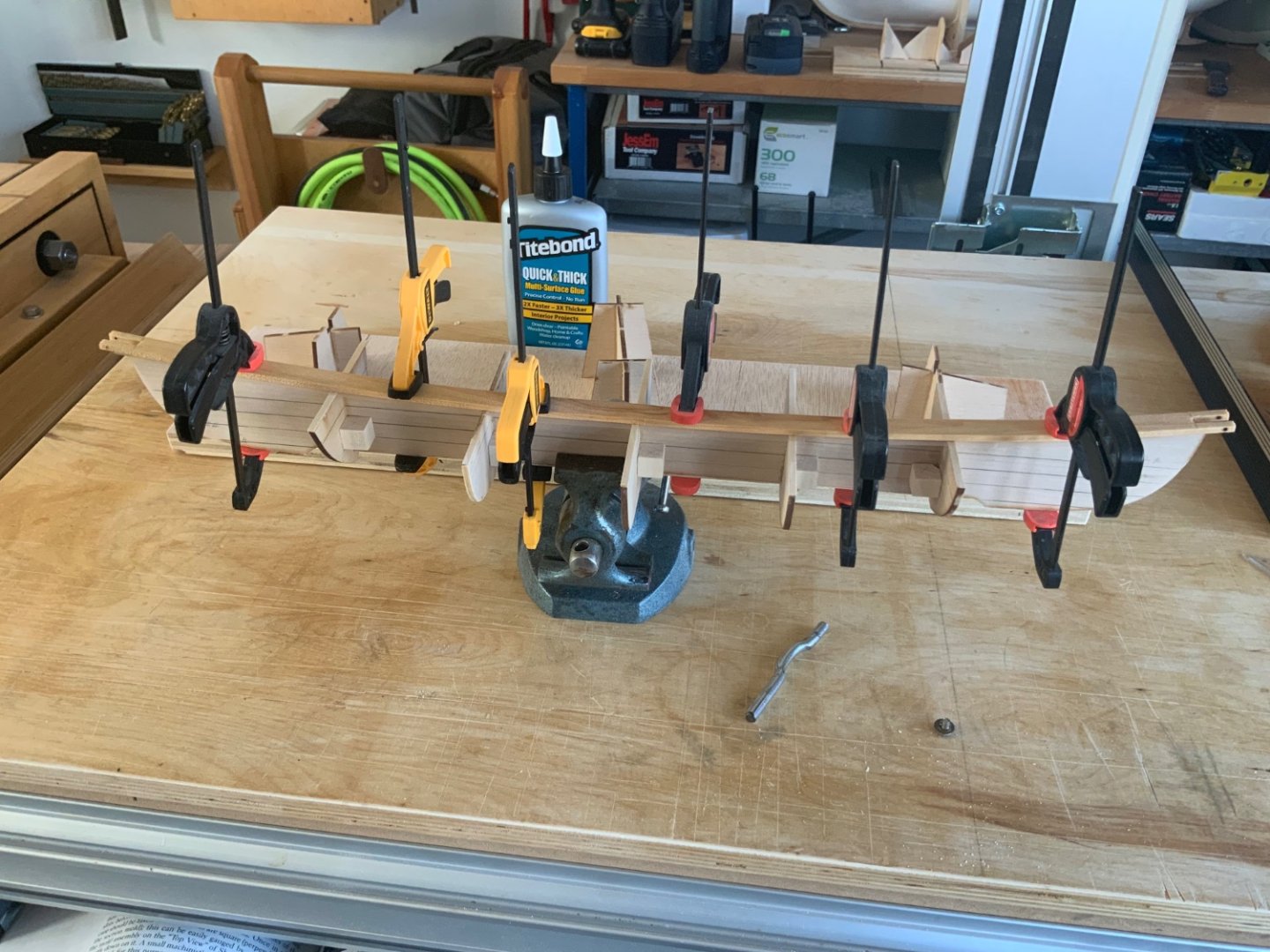

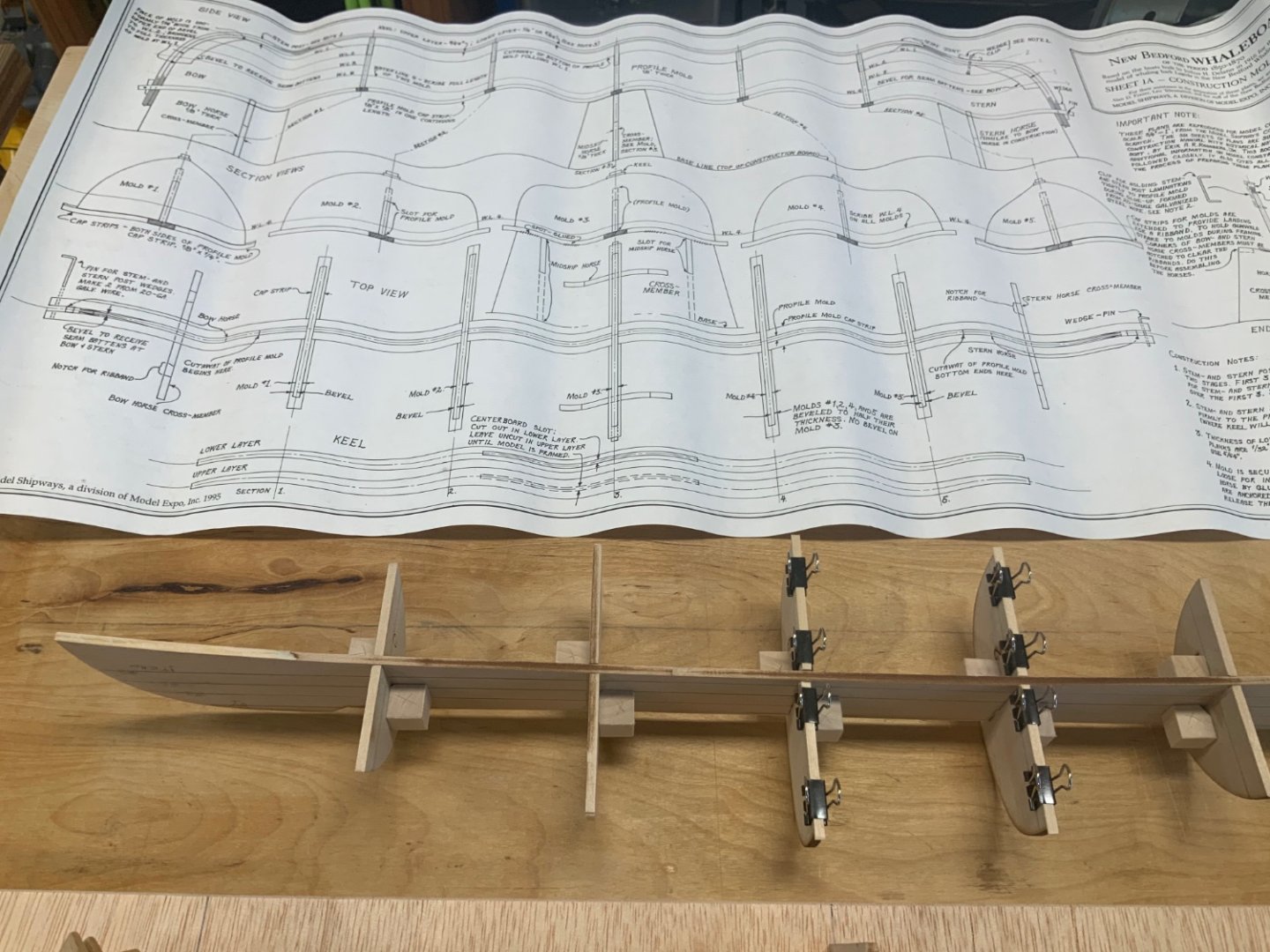

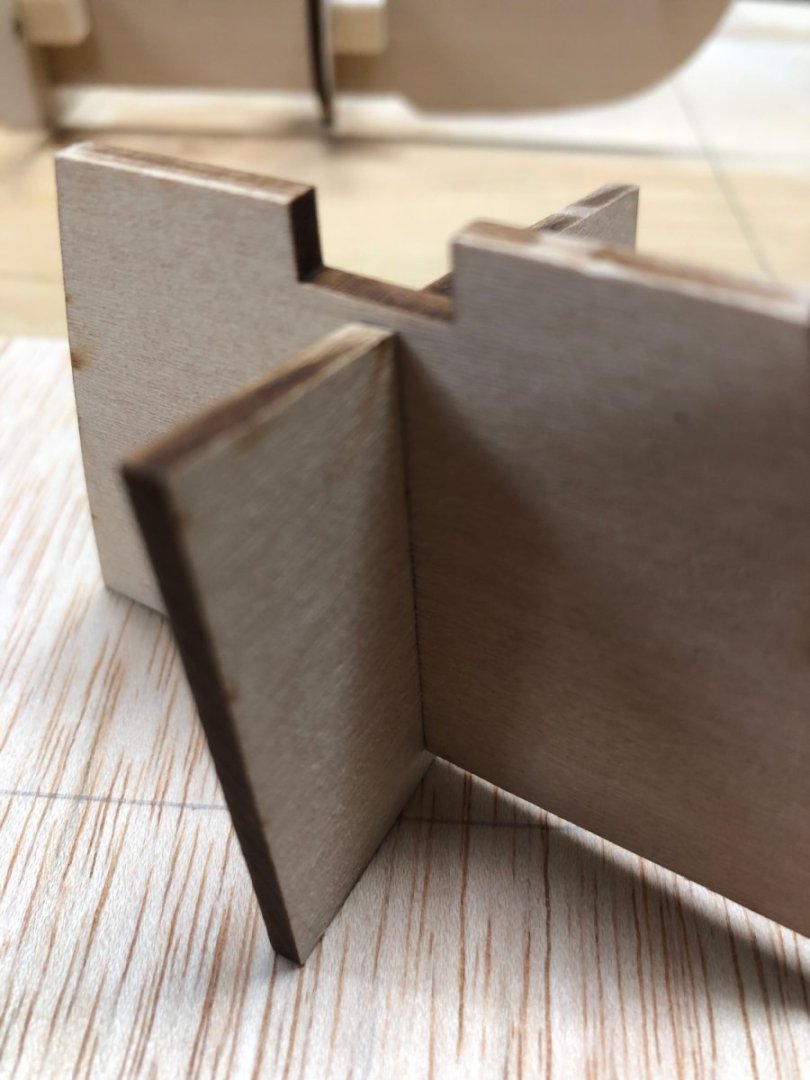

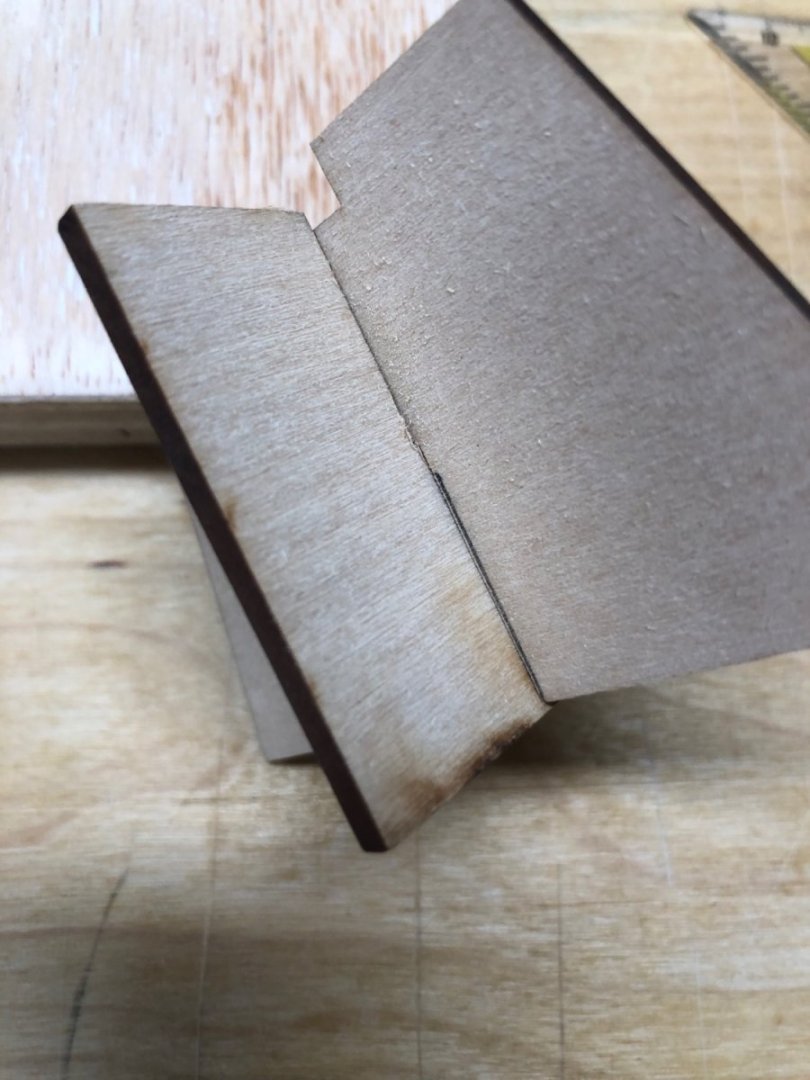

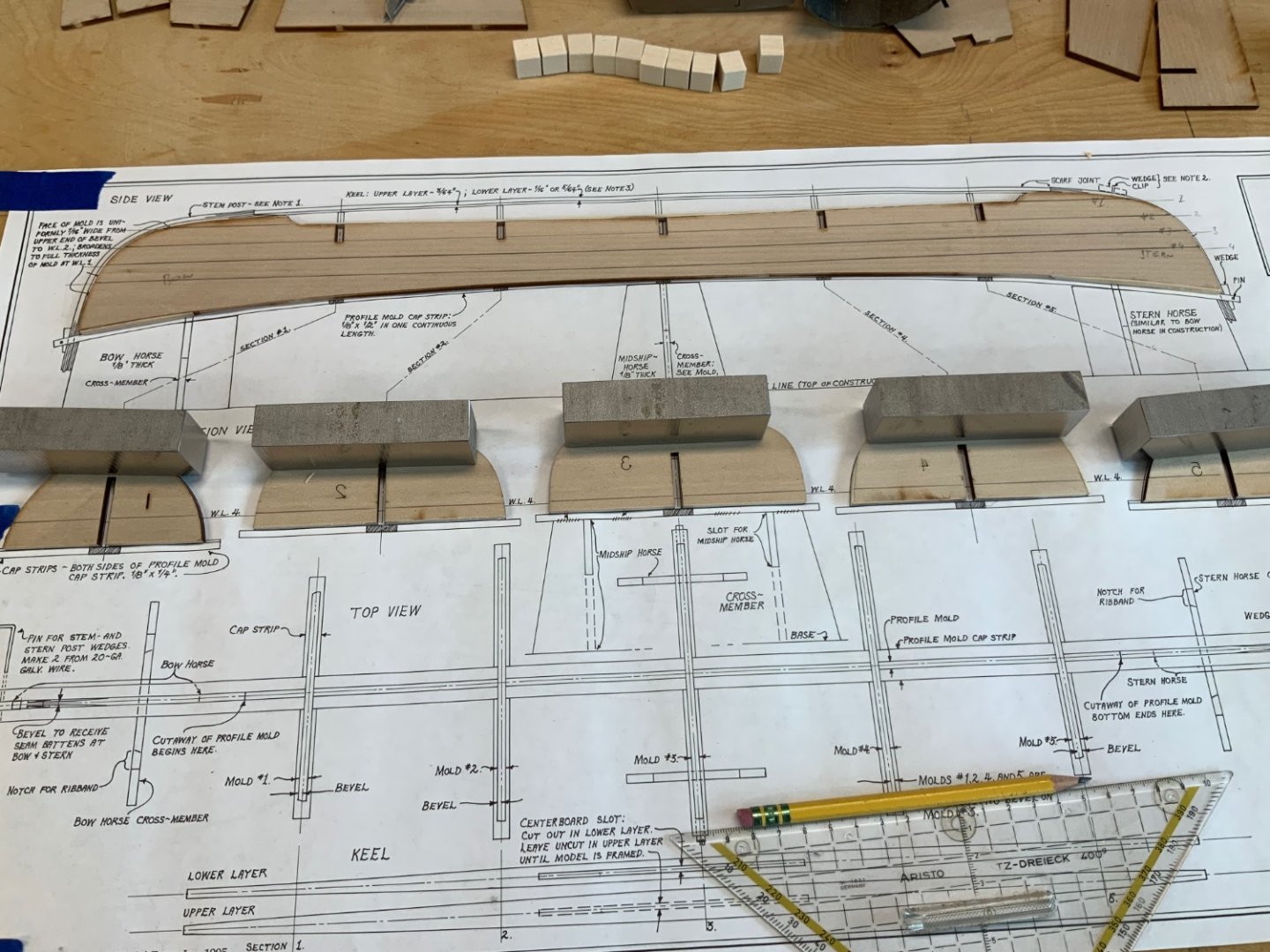

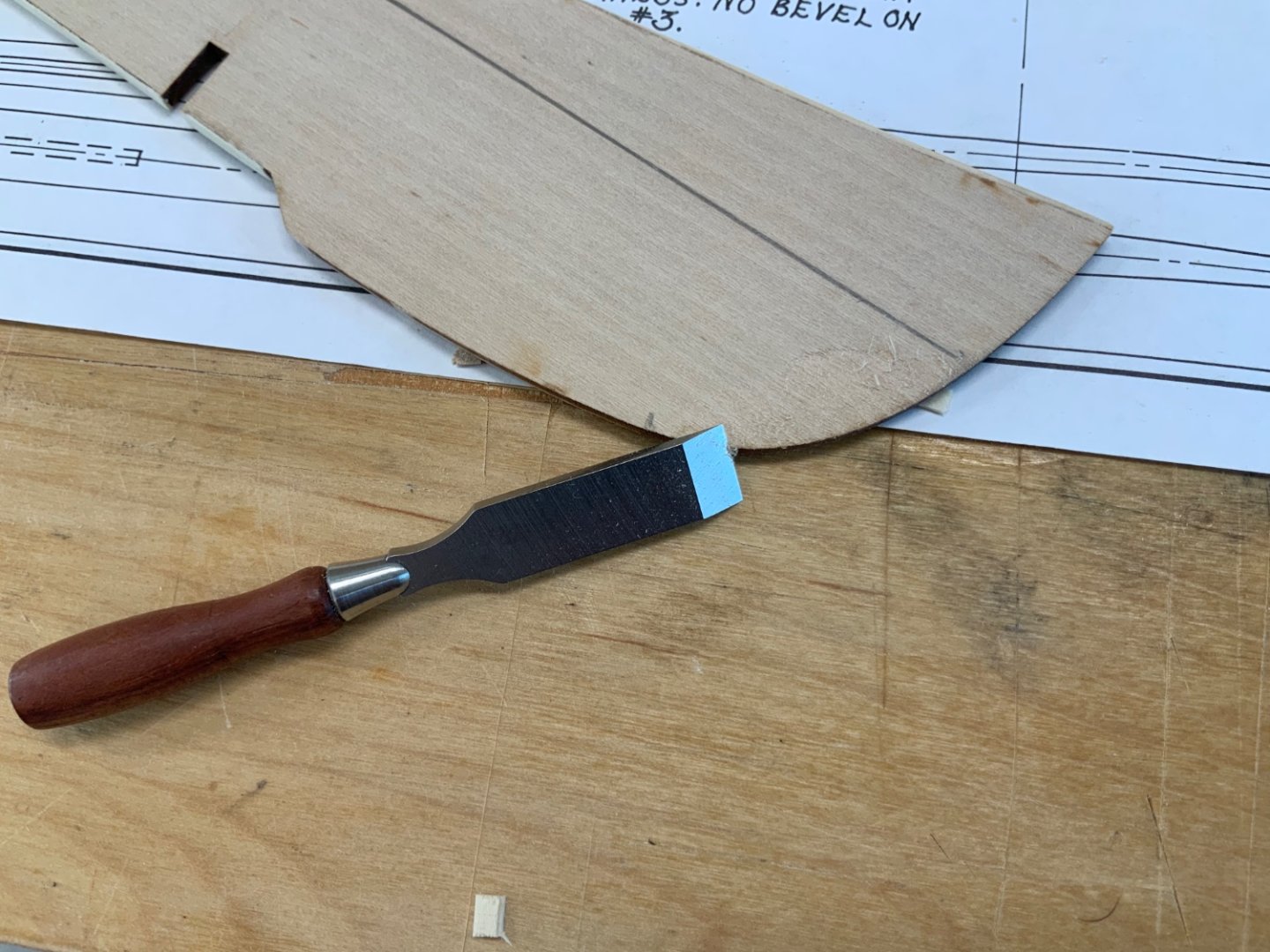

The big moment where I finally start building a boat, to attach the molds to the horses. And an even bigger surprise, it didn’t fit. In my infinite wisdom I glued the center horse already in place. With the result you see in the pictures. Maybe next time I should dry fit everything first, before I glue it together. Oh well … After adding some strips under the stern & bow horse, I was able to level the mold.

-

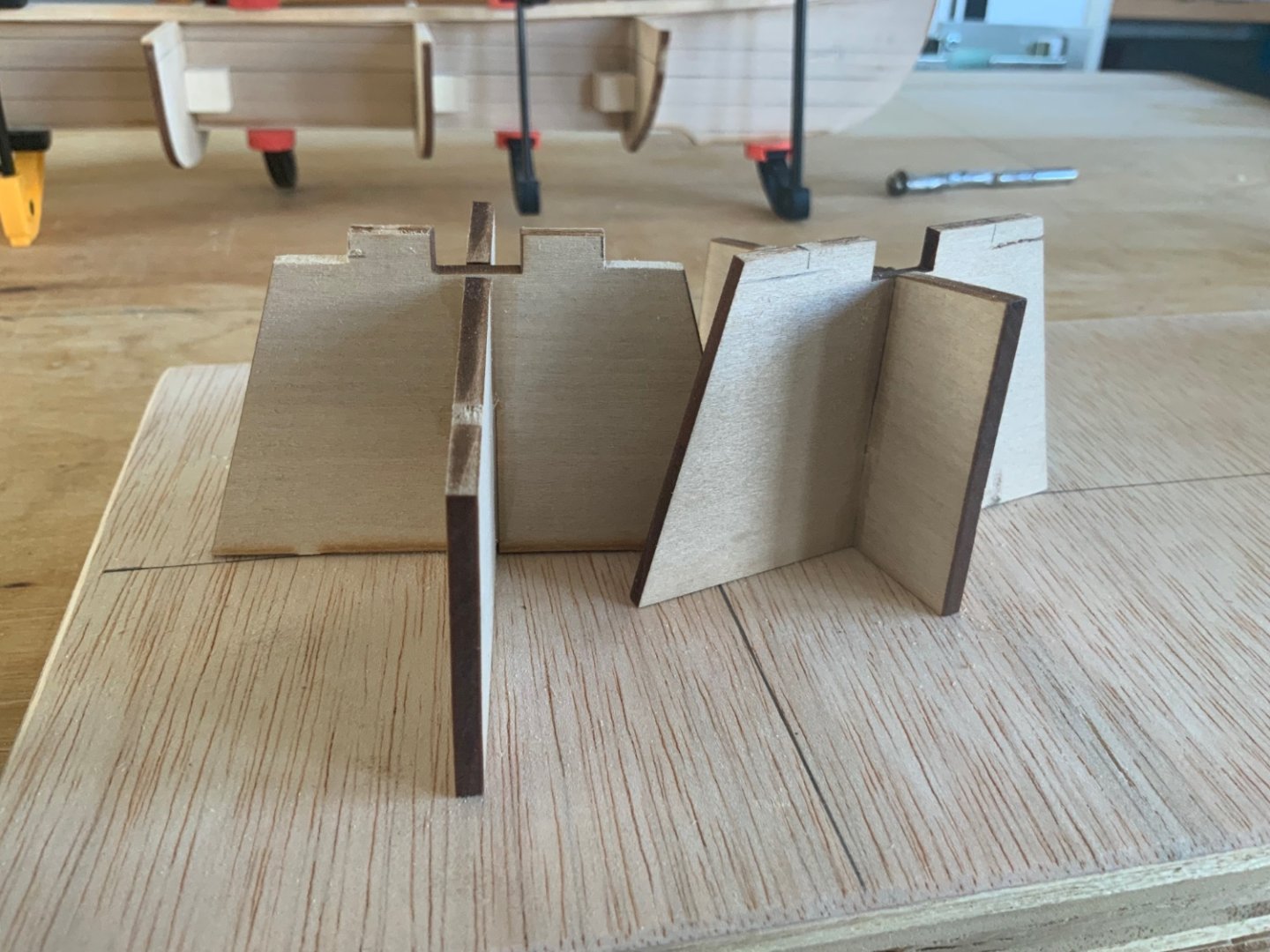

Thank you for the likes & comments That will be a long build, time wise, because I can only work on the model on weekends. Furthermore I had to build something for my cloth pin collection. I managed to get the hull molds and the horses done. I encountered more issues withe the “laser cut” parts than I had imagine. But nothing which couldn’t be fixed. It was just time consuming before you actually start building.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.