-

Posts

450 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Brucealanevans

-

ALERT Lesson learned: stain first, THEN place the monofilament pieces. I thought I was very careful with the glue but still ended up with many halos after first staining. Had to spend time touching up with matching paint. Thank heavens this is a slapdash beat up looking ship and end result was ok. Will give stain a sanding when dry, then wipe on a light final coat as I did with the inside.

- 67 replies

-

- philadelphia

- model shipways

-

(and 1 more)

Tagged with:

-

Not my original idea. Chuck showed this on his barge prototype. Unfortunately here I had over 700 to do on the outside (many fewer inside. Just finished this morning. Did a google for black monofilament line and picked one supposedly 0.4mm diameter and used #76 drill bit. I think it came from Japan.

- 67 replies

-

- philadelphia

- model shipways

-

(and 1 more)

Tagged with:

-

It's a fun kit because of the scale, although a bit of a monster for the same reason. I have an almost neurotic love of small detail and I think this kit is going to take me down that rabbit hole! have fun. Thanks all for the "likes"

- 67 replies

-

- philadelphia

- model shipways

-

(and 1 more)

Tagged with:

-

Prior to staining the exterior, I've been working on placing the nails for the exterior planking. These were iron and clearly visible, as on the modern reconstruction. Drilled all the holes with a pin vise, slightly widening the entrance with a sharp awl. Placed short pieces of black mono-filament held with the needle nose pliers (tweezers don't work due to twisting or "snapping away" of the line piece) illustrated after dipping the end in a drop of CA. Then cut each nearly flush with the flush cutter illustrated. The second picture shows a row of holes, a row filled with the mono-filament pieces, and a row after clipping. After some sanding with the grain of the planks the look is pretty good (last picture). They will be somewhat less prominent after staining of the exterior.

- 67 replies

-

- philadelphia

- model shipways

-

(and 1 more)

Tagged with:

-

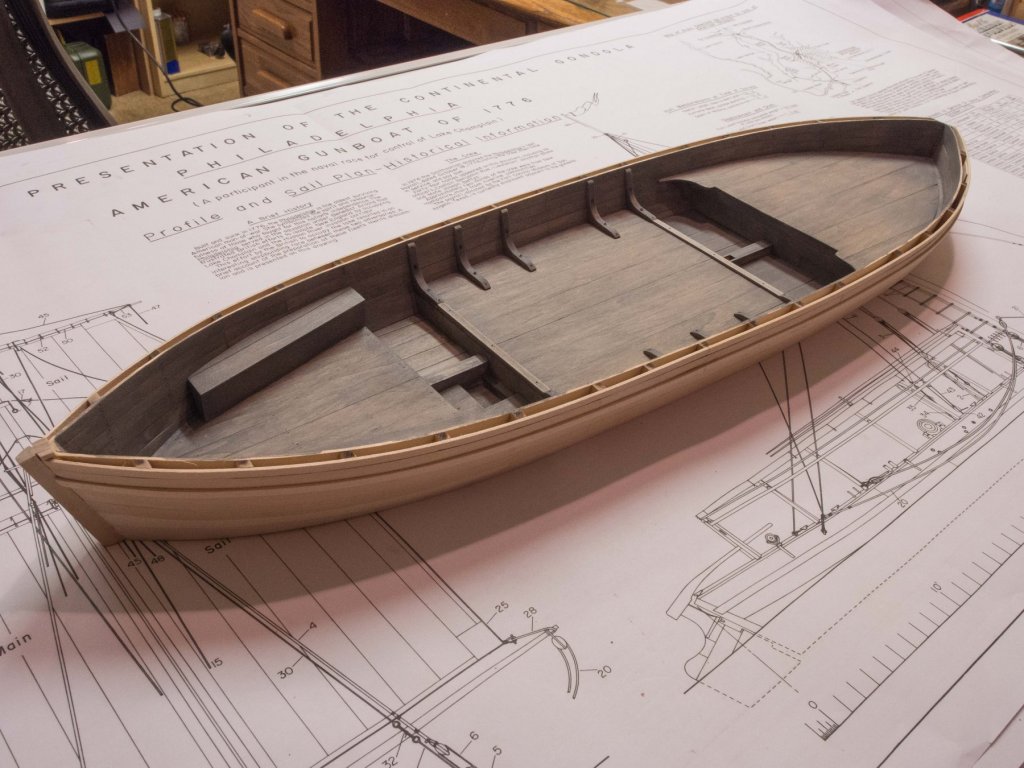

Added "nails" for the ceiling and decks with mono-filament line dipped in a touch of CA, inserted into pre-drilled holes, then clipped with a flush-cutter. Stained the interior. To get the used-up look sanded the central "traffic" areas after the first coat of Minwax stain dried and applied another light coat. Put in the knees and coaming with nails and bolts simulated. For the bolts cut out small circles with a punch from a card colored with magic marker, punched a small hole in the center with an awl, and slipped over a protruding piece of mono-filament line, glued down, and clipped the protruding line. Now on the the repetitive job of nails for the exterior planking.

- 67 replies

-

- philadelphia

- model shipways

-

(and 1 more)

Tagged with:

-

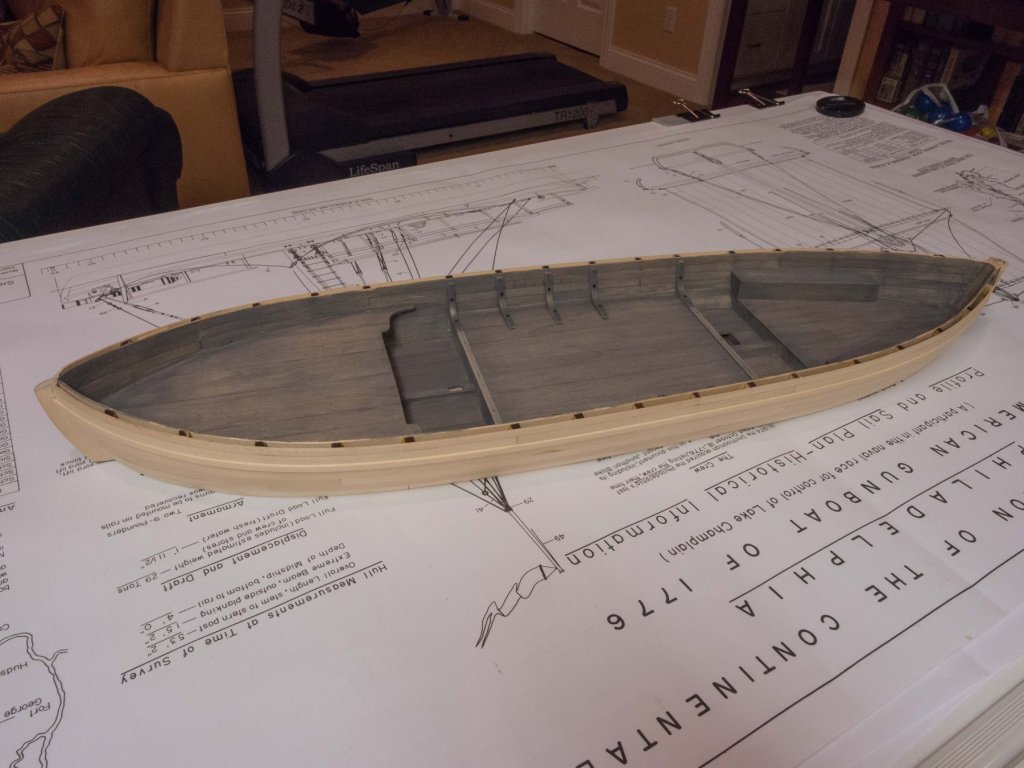

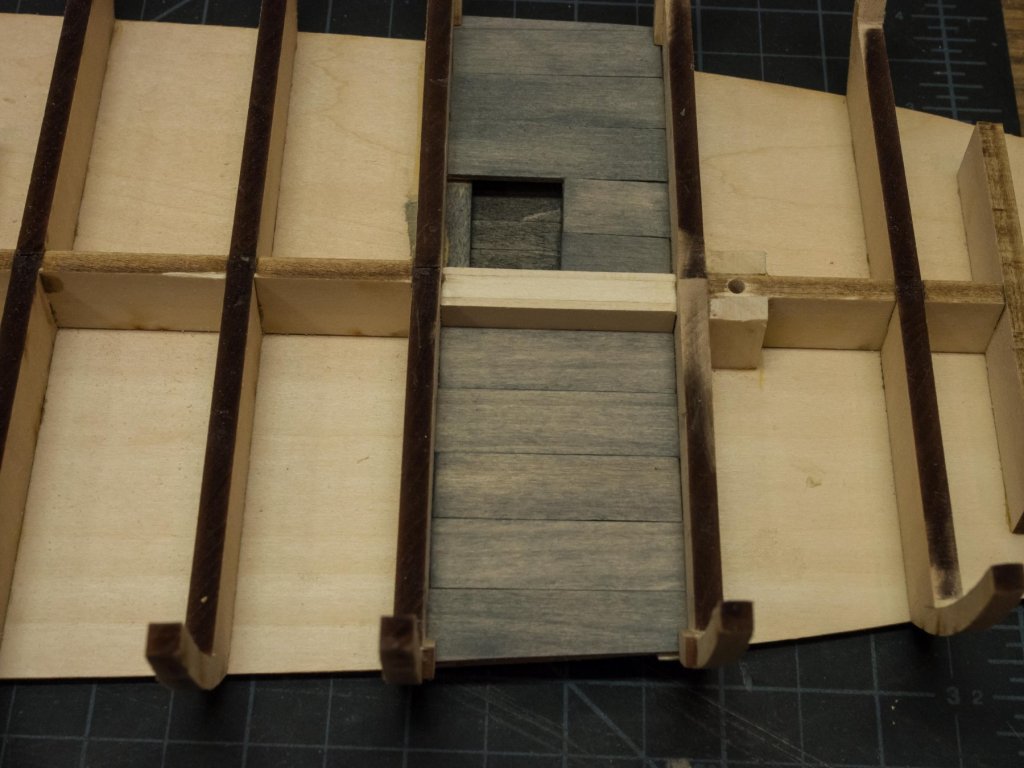

Finished the ceiling planking. Had a look at the Smithsonian plans which arrived afterwards, tho, and the interior planking was wider than the 1/4" (6 scale inches) the kit uses. Oh well. Put the decks in - I cut the deck pieces into individual planks as I didn't like the scribed planking which ended up really highlighting the midline join between the port and starboard pieces. The cuts "lost" enough of the total width that I had to add a small piece to either side to make up the difference. Suggested by the Ships in Scale series. Also some fiddling due to the "drift" of the false keel amidships (see posts above). All in all tho I'm pleased with how it looks at the moment. Before I stain the interior I'm going to simulate the decking nails (they were iron nails, not trenails) with holes/black mono-filament line. Since I want to give those a light sanding I have to do it before I put the stain on. I reinforced the place where the hausepipe hole goes through the exterior planking since those planks were not edge-glued. That's visible between the exterior planks and the ceiling near the bow in the pictures. The arms chests are just placed on the deck in these pictures. I'll not glue those or the knees in until I've done the staining. I'll stain those pieces individually prior to gluing them in. Having a lot of fun with the Smithsonian plans (I'd better since getting them was a real splurge) - a real wealth of detail for fitting this boat out. Interestingly, also shows fascines - bundles of small diameter wood - hanging above the bulwarks to give sailors some additional protection. I'll have to decide if I'm going to include those.

- 67 replies

-

- philadelphia

- model shipways

-

(and 1 more)

Tagged with:

-

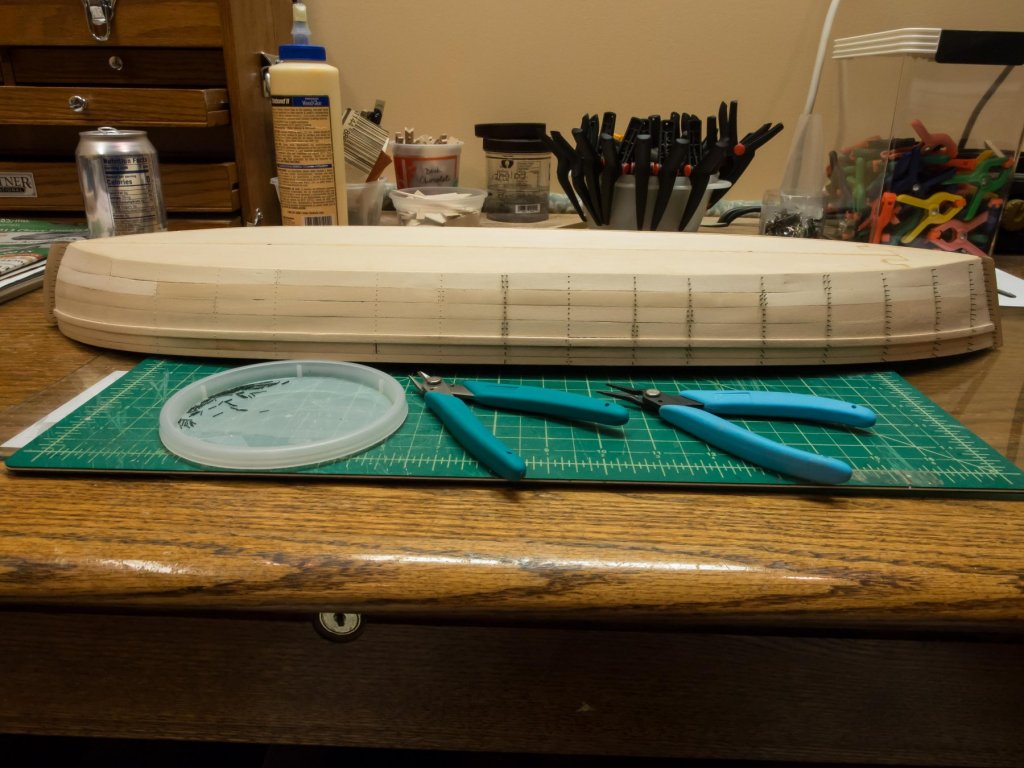

Finished the exterior planking and gave it a first sanding. Next is the ceiling interior planking. Here are some photos of current status, placed on the unfinished stand.

- 67 replies

-

- philadelphia

- model shipways

-

(and 1 more)

Tagged with:

-

Good work Elijah! I have the bottom strake to go before I finish the exterior planking. So much 3-4 day travel over the last few (and next) weeks that it's hard to forge ahead. Are you planning on adding the nails to the exterior in some fashion? The photos seem to show nails rather than wooden pegs. Fresh water boat maybe? Bruce

- 228 replies

-

- gunboat

- model shipways

-

(and 1 more)

Tagged with:

-

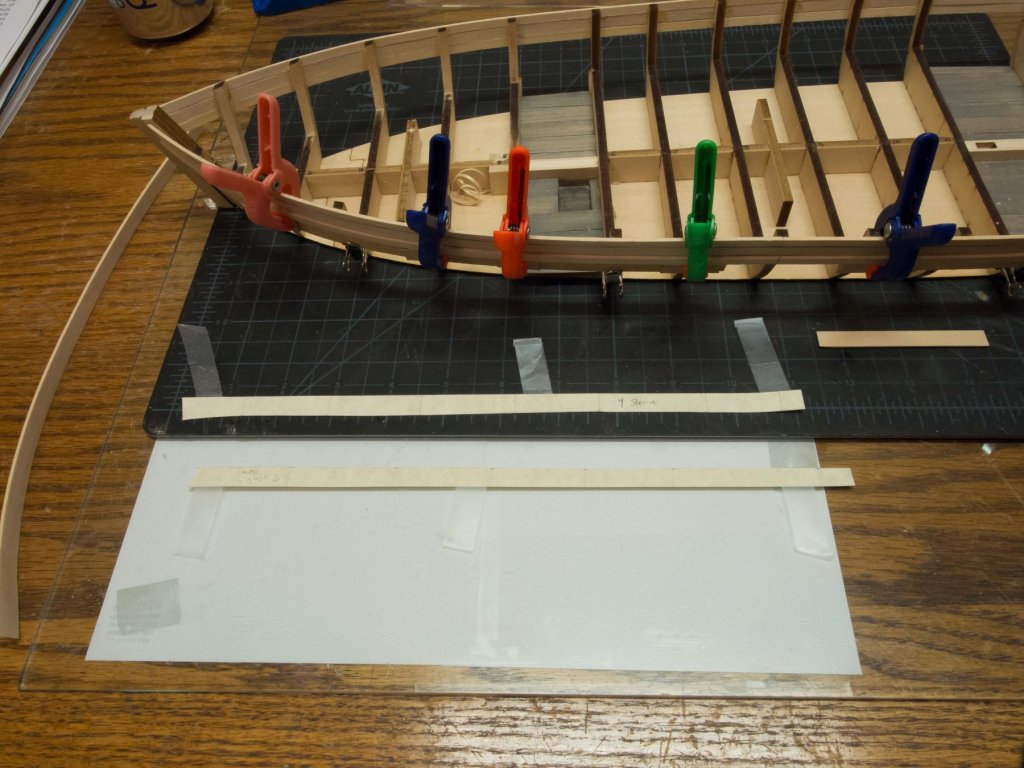

I thought I'd share the procedure that seems to work for me for spiling planks for this build, where the planks, due to the scale and the construction of the boat, are quite wide. I fit a template made from card stock to the upper plank and then mark the laser tick for the bottom of the new plank at each bulkhead on the template. After drawing a smooth line with the help of ships curves through those points, I cut out the template and double check its fit. I tape the template over an appropriate width plank and trace the edges, then cut outside the line with a knife and smoothly sand down until the line is just obliterated. I'm soaking the plank and giving it the approximate curve passing it over the plank bender pictured so that it follows the curve of the boat quite closely, then clamp and let it dry. Once dry, some final fitting and sanding, knock off the upper inner edge with a sanding stick, and apply #2 pencil to one edge for the visible caulk. At that point the plank follows the ship and bulkheads quite closely so the clamping is mainly to make sure it's firmly against the plank above throughout its run. Looks like I can do one strake (3 planks) each morning, and take a bit of time in the afternoon when its good and dry to glue it in place and clamp it so that I'm ready for another the next day. At this rate (4 strakes each side below the wale) I should have the outside planked in a week or two.

- 67 replies

-

- philadelphia

- model shipways

-

(and 1 more)

Tagged with:

-

Started in on the "easy" part of the planking - the first 3 strakes that are constant width. Instructions state aligning with the tops of the frames, but at the bow that seems off and the profile plans show an angled taper on the very end of the plank to meet the angle on the bow-piece. Also if aligned to the top the spacing is off according to the template for the bow strake widths. So I elevated the top of the first strake at the bow and will sand the taper on them as shown on the profile plans. Now the bottom of the 3 constant width strakes line up perfectly with the hood template at the bow. You can see this at the far right of the pictures below. As I prepared to add the wale (which is considerably thicker) I also felt it should stand proud of the adjacent planks by half its width, including, I think, at the bow and stern. So I'm carving the ends to have 1/2 the width fit into the rabbet and the other half lie flush against the side of the bow piece rather than sanding the whole width down to a wedge to fit into the rabbet. Not sure how authentic that is, but I like the look (potentially). While waiting for the glue to set I got to work on a display base. The model is wide, and I also wanted to display a period map of Lake Champlain. Consequently I needed 12" in width and lacking full size tools to deal with a plank of nice wood of that width, I decided to take the coward's way out and use a laminated piece of MDF meant as a bookshelf. To elevate the model making clear it's a flat boat and not a waterline model I got a couple of unfinished wood candlesticks and drilled a 1/8" hole through them with matching holes in the base and the ship into the false keel. When inverted, the broad end gives good support to the boat. I'll glue the other end and the 1/8" dowels to the base, and the model slips nicely onto the protruding dowels with the broad end of the candlestick pedestals giving good support without gluing. I'll stain the pedestals with the grey stain I'm using for the interior, which also goes well with the base laminate. The space to the right of the map is where the nameplate will go. The case I'll be using is wide enough to accommodation the base with the off-center mounting of the ship while still allowing the ship itself to be in or near the middle of the case so that the 14-15" width of the lower yard will still fit well within the case. The admiral has informed me that this ship will be living downstairs across the room from the shipyard in the "TV" half of the basement room (area visible in part in the pictures below) because there's no more room on the main level. My next builds better not need huge tall cases - thinking Echo cross section and Confederacy Admiralty model (both on the shelf). Admiral may be taking a job that will require 50 business days of travel a year attending national and international conferences with "spouse expected to accompany" so my retirement shipyard hours may be somewhat limited if she gets the position. I'm quite certain they're thinking of "wives" since few surgeons of her seniority are women, but what they'll get on their entertainment activities for the spouses while the "guys" are meeting is a rumpled and occasionally grumpy old guy who is not interested in shopping, fashion, etc. Ha! Anyway, my projects on the shelf (plus Chuck's barge when it comes out!) will likely take me to or beyond the end of my fine motor skills.

- 67 replies

-

- philadelphia

- model shipways

-

(and 1 more)

Tagged with:

-

Glued everything down. I put in lateral supports in two sites along the false keel and drilled vertical holes for later mounting. I have a print of a period map of Lake Champlain that I want to work into the base if I can. Floor boards in the cockpits added as well as a few support pieces for the ceiling planks in the cockpits. I'm going to go weathered/grunge look with this build. Chose a grey stain for the inside and stained the cockpit floorboards before installing them. I have made the bailing well grungier as you can see in the second picture. I did put some very thin planks at the bottom of the bailing well to represent the bottom planking that doesn't exist in this model. The exterior will have a different stain. Now I should be ready to start the planking. I got two books on the Philadelphia from Amazon yesterday with a lot of pictures of the raised ship and the reconstruction. A lot of ideas for super-detailing this build which should be fun at this scale. The exterior planks were nailed and the pattern was not the perfectly aligned and symmetric pattern OCD model builders strive for. I'll probably use black mono-filament glued in pre-drilled holes to represent the nail heads. It's worth remembering that these were hurried purpose-built ships and fit and finish were not high on the priority list. I'm also interviewing crew members - likely will use one or two on the ship, including a commander.

- 67 replies

-

- philadelphia

- model shipways

-

(and 1 more)

Tagged with:

-

Well, I got tired waiting for the replacement piece to arrive, so I worked on the keel, stem, and bowpiece I removed from the incompletely lasered sheet and managed to bring them up to useable form. I still need the replacement piece for a number of other parts, some quite small, that were very poorly laser cut. But I won't need them for a while. Keel was straight, and putting the bow and stem pieces on straightforward, as were constructing the bow and stem rabbets with shaped and glued on pieces as shown below. I cemented the floor, and glued the keel to it. Oh, Oh! Although the keel was dead-flat, and I carefully aligned the bow and stern to the midline, I didn't realize that in adjusting those two spots, the drag on the middle of the keel from the glue kept it from perfectly following the adjustments. When I test fit the bulkheads, which need to meet the upper edge of the floor exactly, it became clear that although perfect at the bow and stern, the keel "bulged" to port by up to 1/16" midships. I contemplated the old alcohol reversal (on the keel, not me) but such an extensive area was involved I decided against. This meant that most of the bulkheads had to be adjusted (sand one half, shim the other) to bring each bulkhead on port and starboard exactly to the upper edge of the floor (picture below). A lot of extra work because I didn't either draw a line off center to align the keel with or check the port/starboard measurement before the glue set and the assembly was nudge-able. That's assuming few adjustments would have been required. At least now I know the alignment with the floor is perfect throughout. Oh well, it's all good now. Outer and inner faring of the bulkheads was done off the ship following the engraved line outboard and paralleling that inboard, which made the use of a small hand belt sander fixed in a vise possible and a relatively quick job resulted. I got facile with that tool making the Morgan's 7 whaleboats from lifts. Tomorrow I'll glue them on using the small machinist right-angles visible in the picture, and sand the edge of the floor to match the vertical curve of the bulkheads. The extra work should make the planking a lot easier!

- 67 replies

-

- philadelphia

- model shipways

-

(and 1 more)

Tagged with:

-

Yeah I have Chuck's pinnace on the shelf with some boxwood strips. Not sure when I'm going to get to that!😀

- 67 replies

-

- philadelphia

- model shipways

-

(and 1 more)

Tagged with:

-

Kind of a bummer... sat down to get started with the first pieces - keel, stem, and stern piece - and found the thickset wasn't laser cut all the way thru and cutting the complicated notches with a knife resulted in unsatisfactory accuracy and snapped bits along the grain. Checked the other thicksets (all ok) and contacted Model Expo thru their website to request a replacement. Oh well, enforced holiday in the shipyard while I wait. If I had some materials I've ordered I'd use the time to build the brick stove but they're not here yet either. I'll work on other projects for a while. Jim, as usually happens after asking for help I found some figures from Model Dockyard that should work with some creative painting. If they're good I may stick one on my Picket Boat #1. Update: While I was typing above got a response from John Garcia of Model Expo. Great customer service as always!

- 67 replies

-

- philadelphia

- model shipways

-

(and 1 more)

Tagged with:

-

I would love to add one 1/24 (1/2 scale or possibly G scale) figure to this ship to visually establish scale. I love the crewmen I added to the Morgan for that reason. A quick search didn't find much. Any suggestions for sources? I have searched the forums.

- 67 replies

-

- philadelphia

- model shipways

-

(and 1 more)

Tagged with:

-

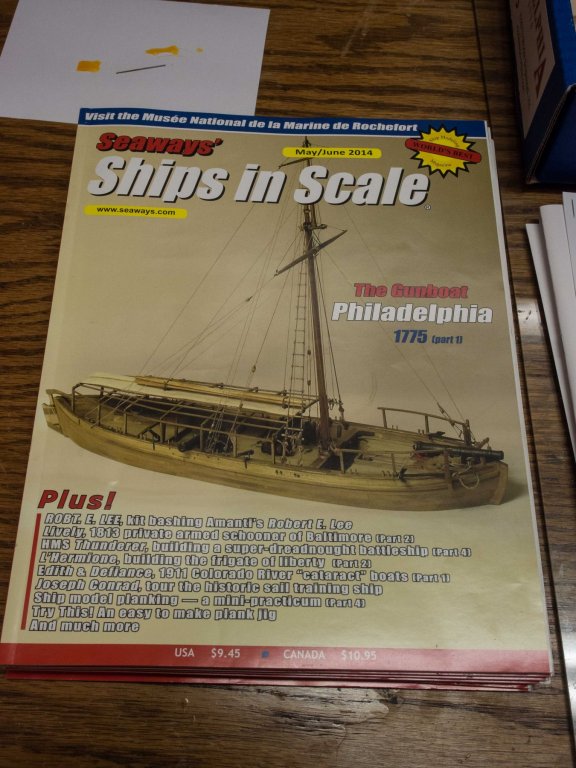

With the Charles W Morgan safely in her case awaiting only a brass engraved nameplate before moving upstairs, it's time to start a new project (projects?). Going to start with the gunboat Philadelphia which I've had on the shelf for some time. I need a break from 1/64 fully rigged ship so the Granado will wait for this project to be completed. [note: Granado will wait a while longer] I'm looking forward to (super)detailing a 1/24 build with minimal straight-forward rigging (at least compared to the Morgan). I've ordered replacement blocks and line from Chuck, and gathered materials including the 6 part series on this build from Ships in Scale. I'm not detailing in photos the box contents as they have been covered in a current build log and several fairly recent finished ones. Will start construction next week. I've been at loose ends in the mornings as that has been my shipyard time through the (long) end of the Morgan build. There is a nice case awaiting this rather wide model (nearly 14 inches) that I had bought years ago for a Victory model I bought but did not build. As my house started to fill with MY completed models I decided to give that ship away to a friend who had admired it. I was tired of explaining to people that I had built the New Bedford Whaleboat, Picket Boat #1, and now the Charles W Morgan but NOT that one. At the same time (now that I'm fully retired) I'm going to practice Byrnes saw, scroll saw, and mill skills to begin the Echo cross section on some ordered boxwood before I break into the wood included in the Admiralty Models package. These are things I've not done so need the practice for this entry into the shallow end of the scratch build pool.

- 67 replies

-

- philadelphia

- model shipways

-

(and 1 more)

Tagged with:

-

Thanks Joe Granado will be next after Philadelphia. I need a break from fully rigged ship and would enjoy a large scale build as a change of pace. The Echo x-section will be a simultaneous side project going forward. Now that I'm retired I have more time.

- 245 replies

-

- model shipways

- Finished

-

(and 1 more)

Tagged with:

-

Build log tagged as finished, and some photos of the model uploaded to the gallery. Thanks to all. I'm going to build the gunboat Philadelphia next for a change of pace, expecting NOT to take anywhere near as long as the Morgan did. Replacement rope and blocks ordered. While doing that I'm going to spend some time practicing wood/mill skills for the Echo x-section.

- 245 replies

-

- model shipways

- Finished

-

(and 1 more)

Tagged with:

-

I finished the Morgan today! Put up the last two whaleboats, added some rope coils to the cleated lift lines, and did a small bit of touch up painting. It really is a very busy model, and especially so with any added detailing. I'll take comprehensive pictures once I set up some good lighting and a backdrop and post them in the gallery. Now I need to decide on the next project, with the following on my shelf: Confederacy, Gunboat Philadelphia, Mortar Vessel Granado, Echo X-section, and English Pinnace (oof - how did I collect this much stuff while building the Morgan?) I have an empty full size case since I gave away a Victory model I bought but did not build into which the Morgan will go so the case I got for the Morgan is empty. Which argues for the Granado or Philadelphia, but the x-section is muttering to me from its shelf. I'll just bask in finishedness for a bit and decide later.

- 245 replies

-

- model shipways

- Finished

-

(and 1 more)

Tagged with:

-

Thanks All. I like them. Mounted 3 on the Morgan today. The other 2 go on tomorrow and the build will be finished.

- 245 replies

-

- model shipways

- Finished

-

(and 1 more)

Tagged with:

-

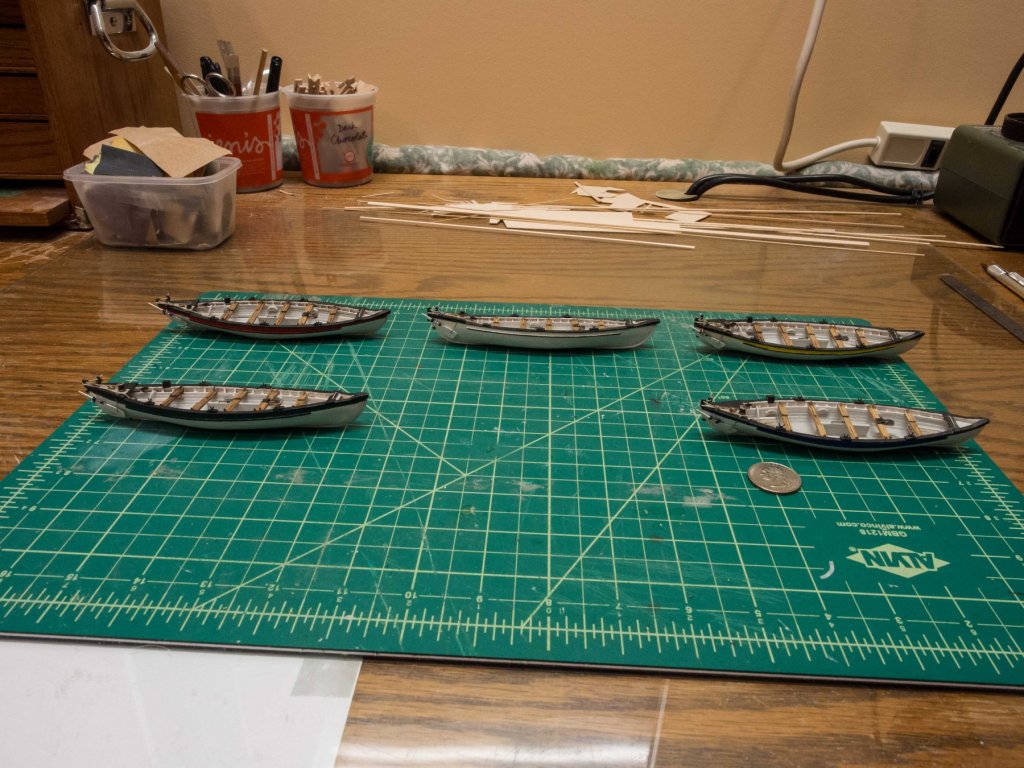

Big moment. The whaleboats are finished with the content they will have when mounted - oars, spars/sail wrap, and paddles. Next is to retrieve the Morgan from her case in the living room and mount the boats, hopefully without snapping a davit for the umpteenth time. So close to done now I can taste it, but will have to wait as we have a week in Napa coming up. Thanks to all for the comments and likes on the boats. The effort to have the details match the work on the mother ship was really worth it, and was quite fun once the hull carving was completed. My advice to all Morgan builders - use work on the whaleboats as a break from the main construction so that only the fun stuff remains at the end.

- 245 replies

-

- model shipways

- Finished

-

(and 1 more)

Tagged with:

-

There is a heck of a lot of scratch work involved in the Morgan build. I've learned a lot in the 3+ years I've been working on it. The best decision was to fabricate the rendering furnace from individual "bricks". There's a PDF around the site somewhere with useful instructions. Took a while but the appearance is really worth it. Working on oars now - drawing 1/32 square boxwood strips through Modelworks drawplate down to scale width. Works a treat. I can even create the handle on these little tiny dowels by carefully working the end for 1/8 inch into 4-5 smaller yet drawplate holes.

- 245 replies

-

- model shipways

- Finished

-

(and 1 more)

Tagged with:

-

Whaleboats are done. I've had to stop myself from adding a few more details that don't really add anything to the visual impact of these, and I'm declaring victory! I've put the boats aside to begin working on oars, probably paddle sets, and the spars/sail bundles. I haven't put the eyes for hanging on yet, as I want to make certain the lines hang straight down from the davits, so will customize them for each specific boat's place. It looks like there may be a few mm variability. Final boat photos below (25 cent piece for scale)

- 245 replies

-

- model shipways

- Finished

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.