-

Posts

5,539 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by RGL

-

Allegedly Trumpeter are going to make one as it’s in their upcoming projects in their catalog it they have a habit of falling through. I’ve seen the resin one and it’s a tad expensive.

-

No#1 son will be Rowing all winter and #2 will be playing rugby, plus the Rugby World Cup will be on. We have a new dog on order as well so life is busy. I really want to build the CV1 Langley that Trumpeter has promised but not yet released. Maybe next year.

-

Vendetta was UK then went to Oz. France and Italy have some nice ships too. The Russian aircraft carrier would be a great build and now China is in the game too.

-

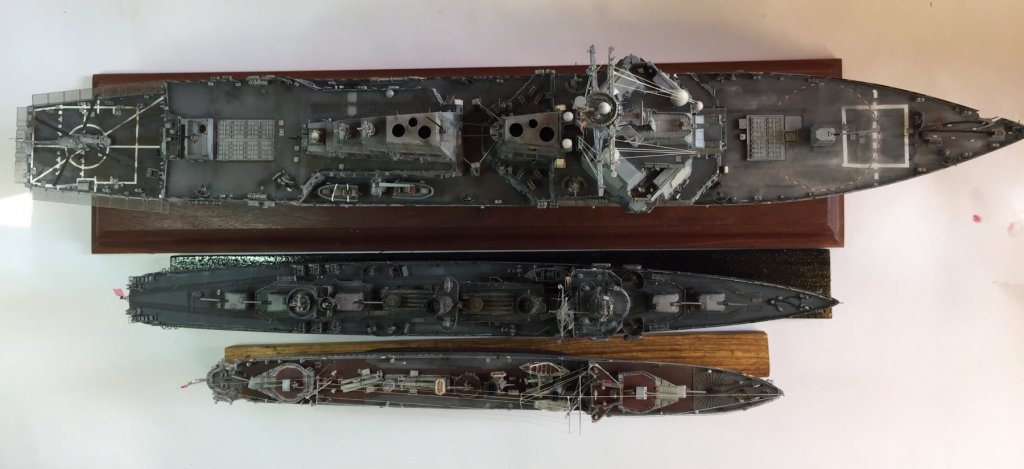

You’ll all be happy to know I have purchased the next kit, plus aftermarket and done the research. I like to do only three of each nation; so far Russia Varyag 1 Varyag 2 Germany SMS Emden SMS Seydlitz Britain HMS/HMAS Vendetta HMS King George v Japan IJN Ise IJN Isuzu IJN Yamato USA USS Spruance USS Fletcher so, that leaves a choice of Germany, USA or UK.

-

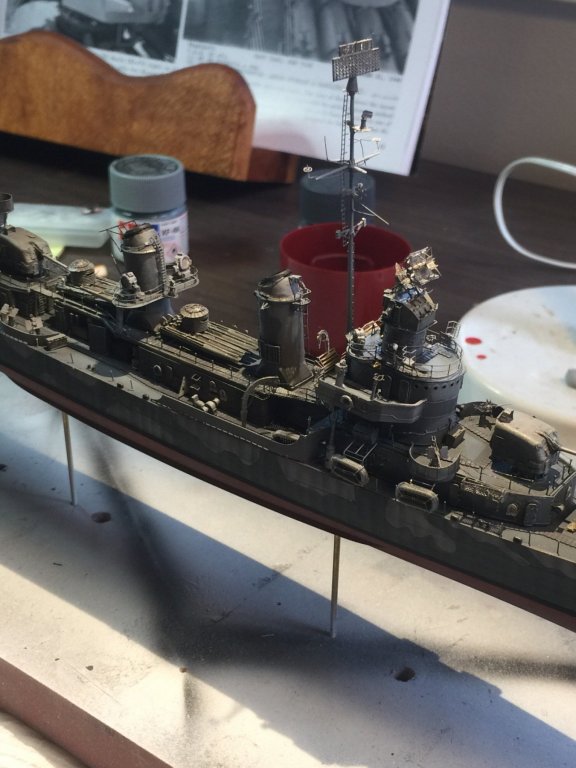

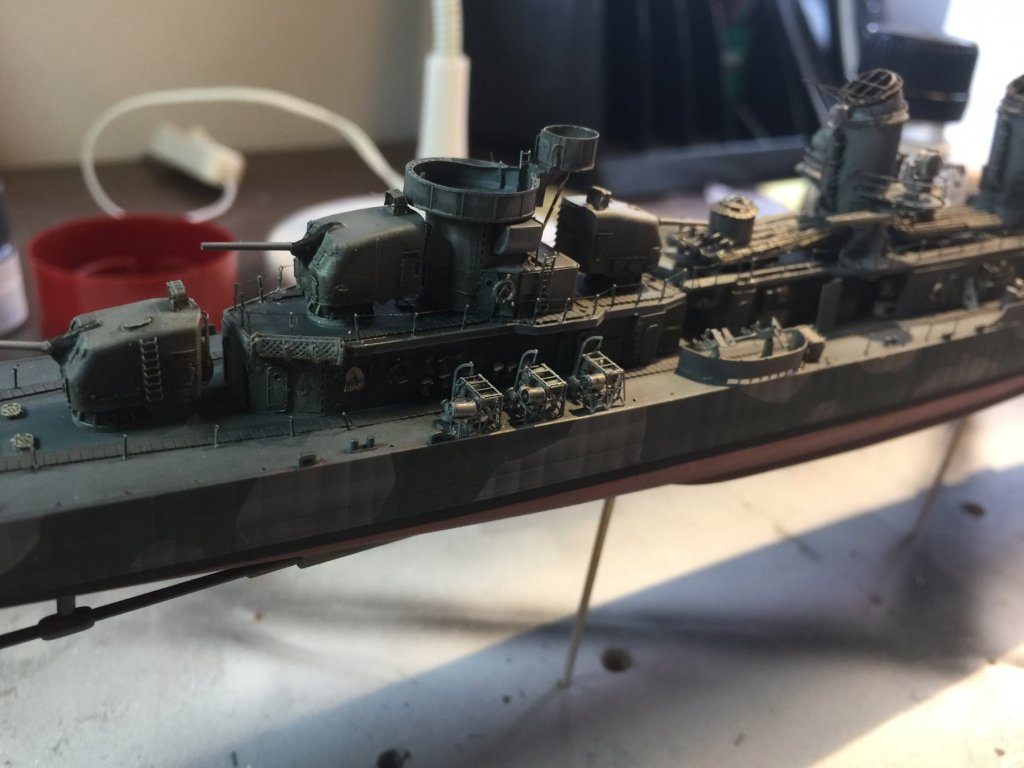

Last AA gun arrived. Very nice and easier than the 5 star offerings. The netting comes with the upgrade. As this is a 1942 build there is nowhere near the amount of AA Guns that came in later variants or upgrades.

-

Light rust on the hull plus some salt. No more than that for this build. I just need the borfors to arrive. Went to a lumberyard and bought some off cuts for a base.

-

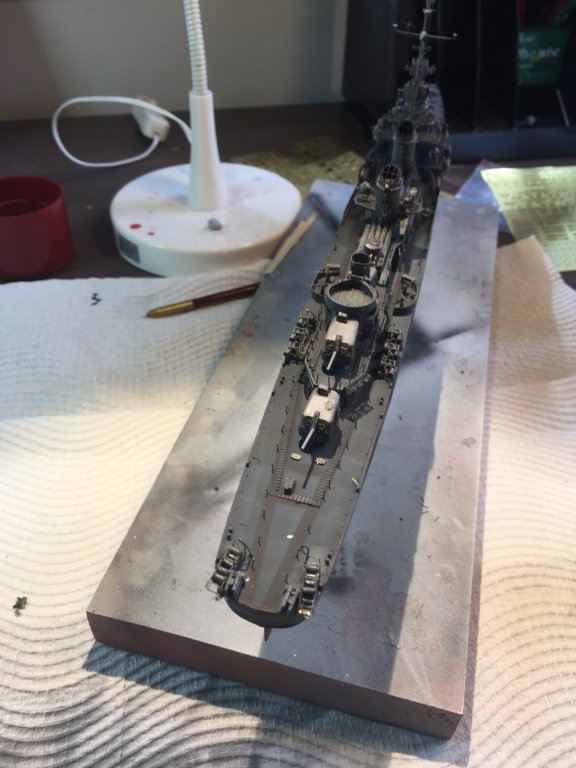

I think it’s lighting OC, this is such a dull paint job, I’ll do a better job on the final shots I promise. I kinda lost interest in this one about half way through as it’s a lot of plod. I’ll enjoy this build a lot more when I get to a bit of weathering.

-

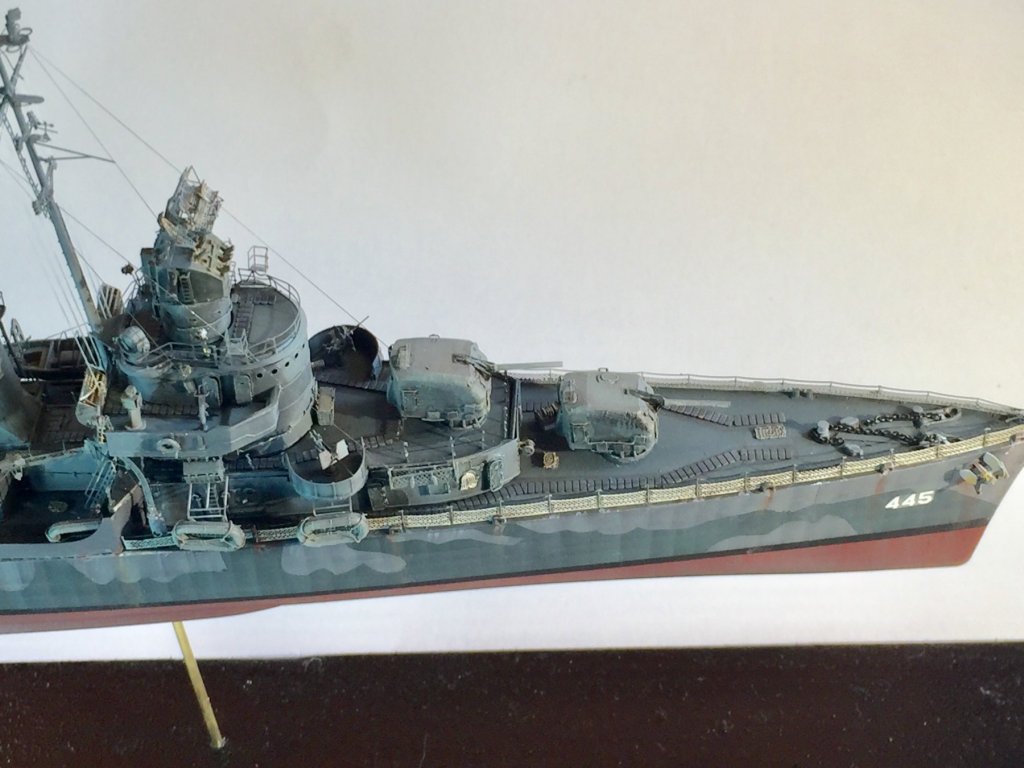

All the little bits thrown on, lots of touch ups to go, railings, and ship’s boats plus the last guns. Bit of rigging to go.

-

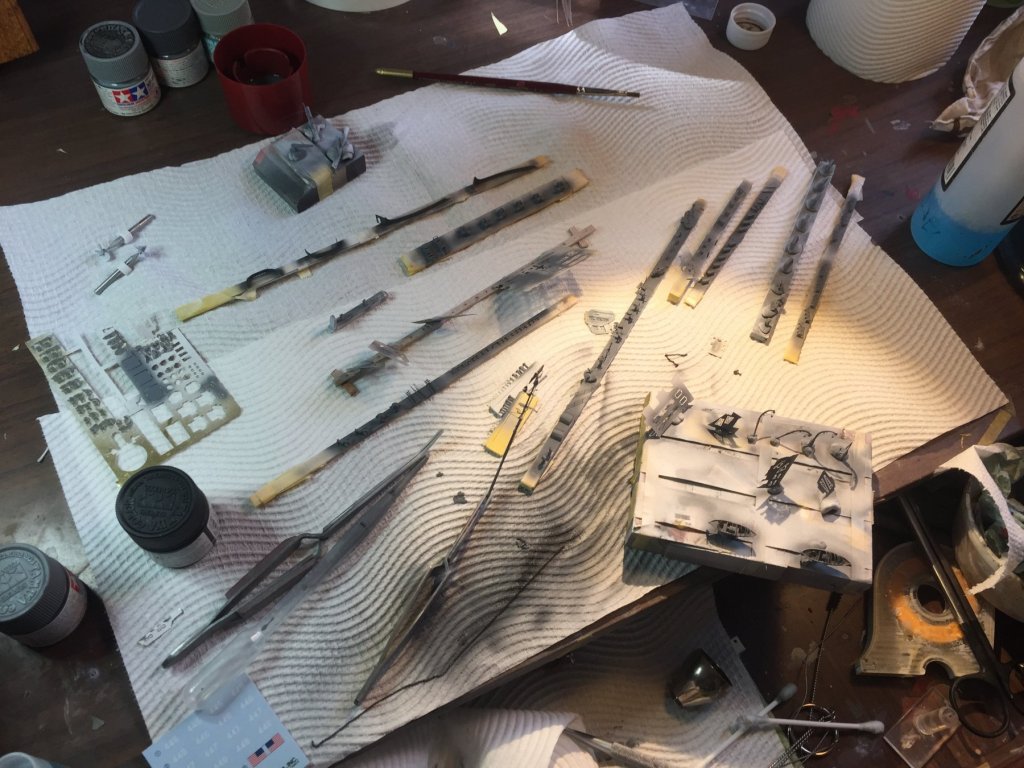

Decals are tomorrows job, I’ll just give them a matte coat prior to weathering. I’ve been quiet as all these tiny pieces have just taken forever to collate, plus work, dayshift and dropping #1 son off at rowing at 0545 every other morning. Wife, #2 son and dog off to the beach for the end of Autumn and Easter so I’m at home alone to finish this off.

-

So, about 5 days of throwing everything left to go onto the ship together, primer coat then a grey coat. Tomorrow I’ll place the 445 decals on, then commence throwing everything on board. Should come together quickly now I expect. I completely stuffed the borfors and had to order another one.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.