-

Posts

5,539 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by RGL

-

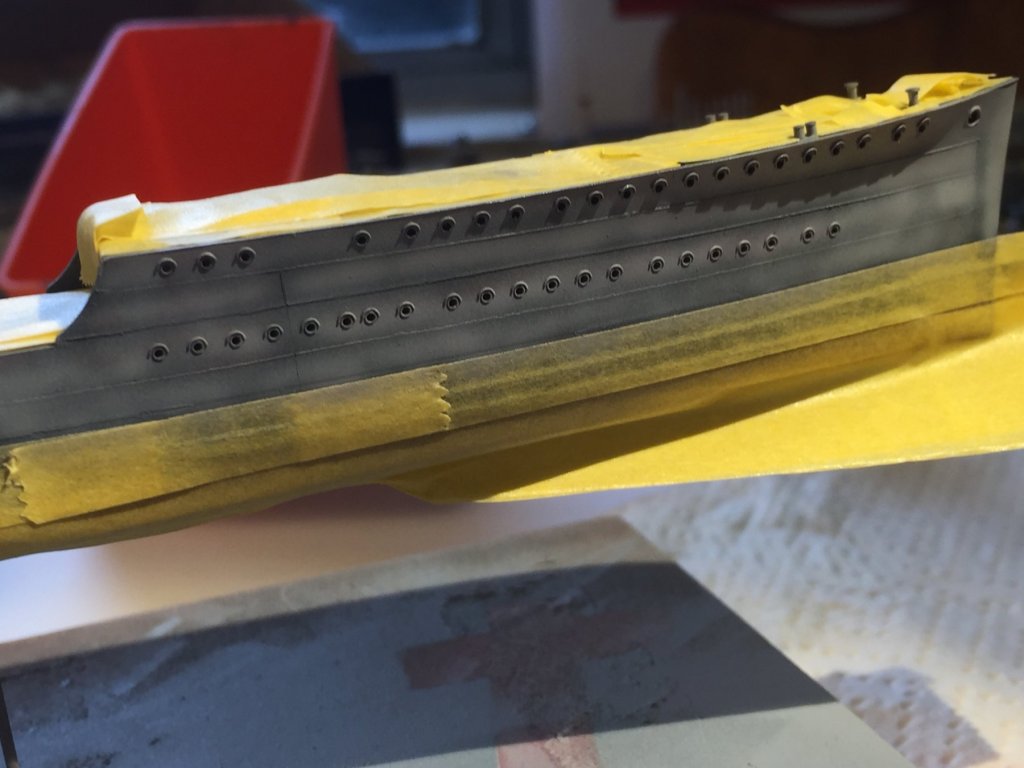

Hull grunge. I used diluted light grey to dull down the red hull, then diluted black to blend that in, then some green for alge and finally some more light grey to put a tide mark on the boot strap using a piece of paper as a mask. Not overly noticeable but it makes it all less shiny.

- 1,090 replies

-

- showcase models

- vendetta

-

(and 2 more)

Tagged with:

-

It just completely clogs my H&S airbrush regardless of thinning. Tamiya and Gunze are just soo much easier. Hull numbers and depth markers added.

- 1,090 replies

-

- showcase models

- vendetta

-

(and 2 more)

Tagged with:

-

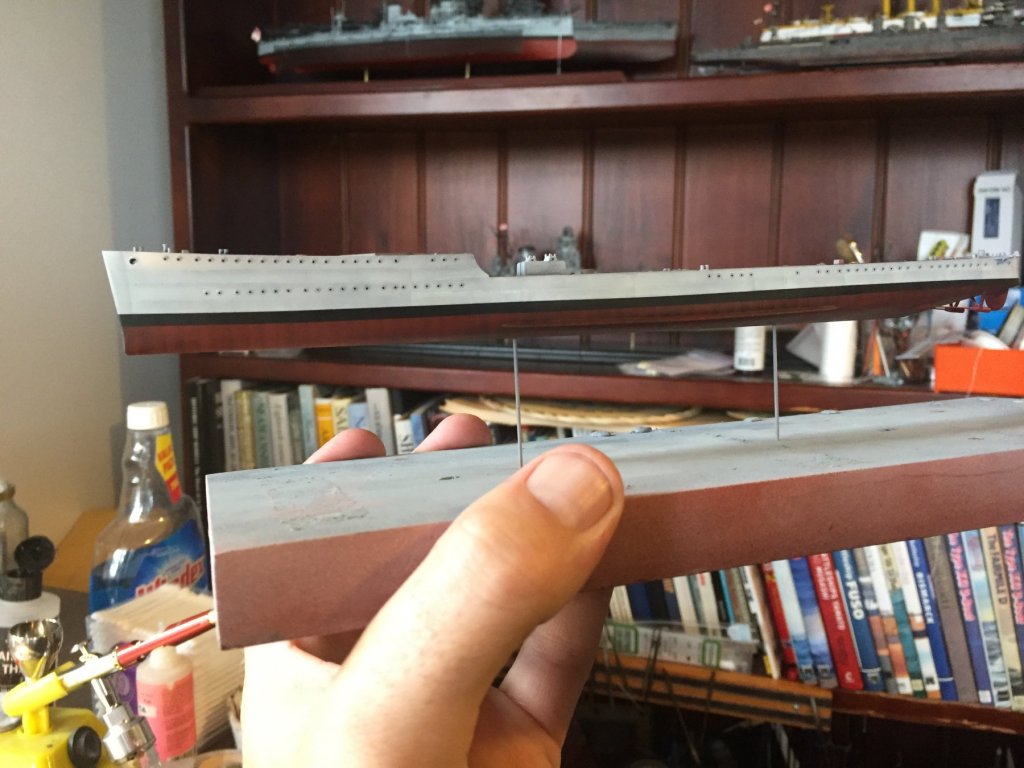

Light hull grey from Gunze, I won’t use Vajello as it does not like me.

- 1,090 replies

-

- showcase models

- vendetta

-

(and 2 more)

Tagged with:

-

Well done Cog, you’re flying ahead of me.

- 1,090 replies

-

- showcase models

- vendetta

-

(and 2 more)

Tagged with:

-

- 1,090 replies

-

- showcase models

- vendetta

-

(and 2 more)

Tagged with:

-

- 1,090 replies

-

- showcase models

- vendetta

-

(and 2 more)

Tagged with:

-

- 1,090 replies

-

- showcase models

- vendetta

-

(and 2 more)

Tagged with:

-

You just know there are perfect photos or models sitting in a Mess or RSL somewhere and the diggers are too old to care about the Internet

- 1,090 replies

-

- showcase models

- vendetta

-

(and 2 more)

Tagged with:

-

- 1,090 replies

-

- showcase models

- vendetta

-

(and 2 more)

Tagged with:

-

by 1944 the search light tower was replaced by radar which just looks like a large barrel. It’s referenced in one of the AWM photos. Vossy, you may be able to source some other photos being ex RAN. I’d love to build her in the final configuration but not without a decent set of images. The AWM ones are too distant

- 1,090 replies

-

- showcase models

- vendetta

-

(and 2 more)

Tagged with:

-

Vossy it’s because I’ve been at work all weekend and can’t get on the tools. I’m at a stage where I need a few hours on the airbrush and I just can’t do it after work as the 445am starts are a killer. We’ll get there.

- 1,090 replies

-

- showcase models

- vendetta

-

(and 2 more)

Tagged with:

-

So he should have invaded? I could have been born in a French penal colony not a British one!

- 1,090 replies

-

- showcase models

- vendetta

-

(and 2 more)

Tagged with:

-

There are lots of masts everywhere on the original photo so it probably is a parking lot.

- 1,090 replies

-

- showcase models

- vendetta

-

(and 2 more)

Tagged with:

-

This is a capture image I found in the imperial War Museum. Note the funnels are covered and there are boats on the deck. I suspect this is post WW1 but a nice image to show how grungy the hull was.

- 1,090 replies

-

- showcase models

- vendetta

-

(and 2 more)

Tagged with:

-

And the Molongolo river gets worse when the neighbouring Megopolis of Queanbeyan’s sewerage overflows into it.

- 1,090 replies

-

- showcase models

- vendetta

-

(and 2 more)

Tagged with:

-

little camera in my car records where I’ve been usually

- 1,090 replies

-

- showcase models

- vendetta

-

(and 2 more)

Tagged with:

-

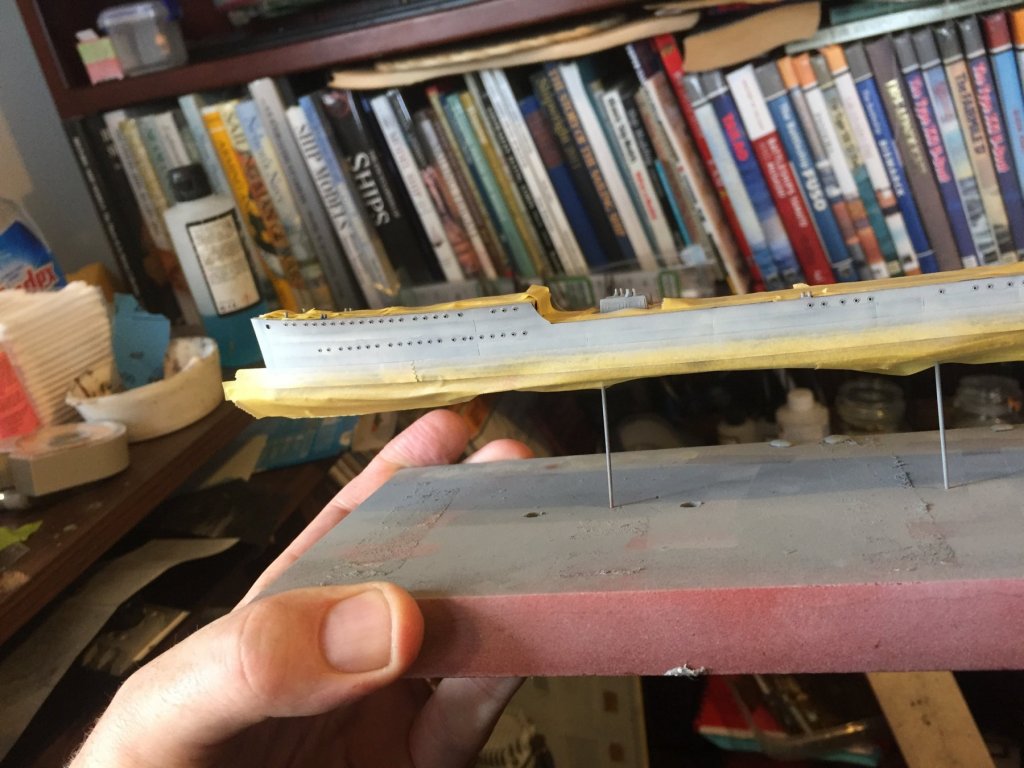

Took the photo whilst at work. Had an appointment with someone nearby and thought I’d take a photo. I have to do some masking yey before the next lot of painting. Wed\Thurs is my weekend this week.

- 1,090 replies

-

- showcase models

- vendetta

-

(and 2 more)

Tagged with:

-

- 1,090 replies

-

- showcase models

- vendetta

-

(and 2 more)

Tagged with:

-

We mummy’s boys are used to the blood running to our heads.

- 1,090 replies

-

- showcase models

- vendetta

-

(and 2 more)

Tagged with:

-

Morning from Oz. Too early for rum (though it is mother’s milk), I was once asked by a chap from Africa why Aussies only speak one language, I told him because we and the kiwis are the only ones down here. You notice Cog learnt to speak English from a pirate, which is very impressive as I thought it would be Vikings up that ways.

- 1,090 replies

-

- showcase models

- vendetta

-

(and 2 more)

Tagged with:

-

I’m loving the water, it’s very much done everywhere now and you’ve got it right.

- 378 replies

-

- java

- pacific crossroads

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.