-

Posts

5,547 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by RGL

-

- 81 replies

-

- Micromaster

- Eduard

- (and 4 more)

-

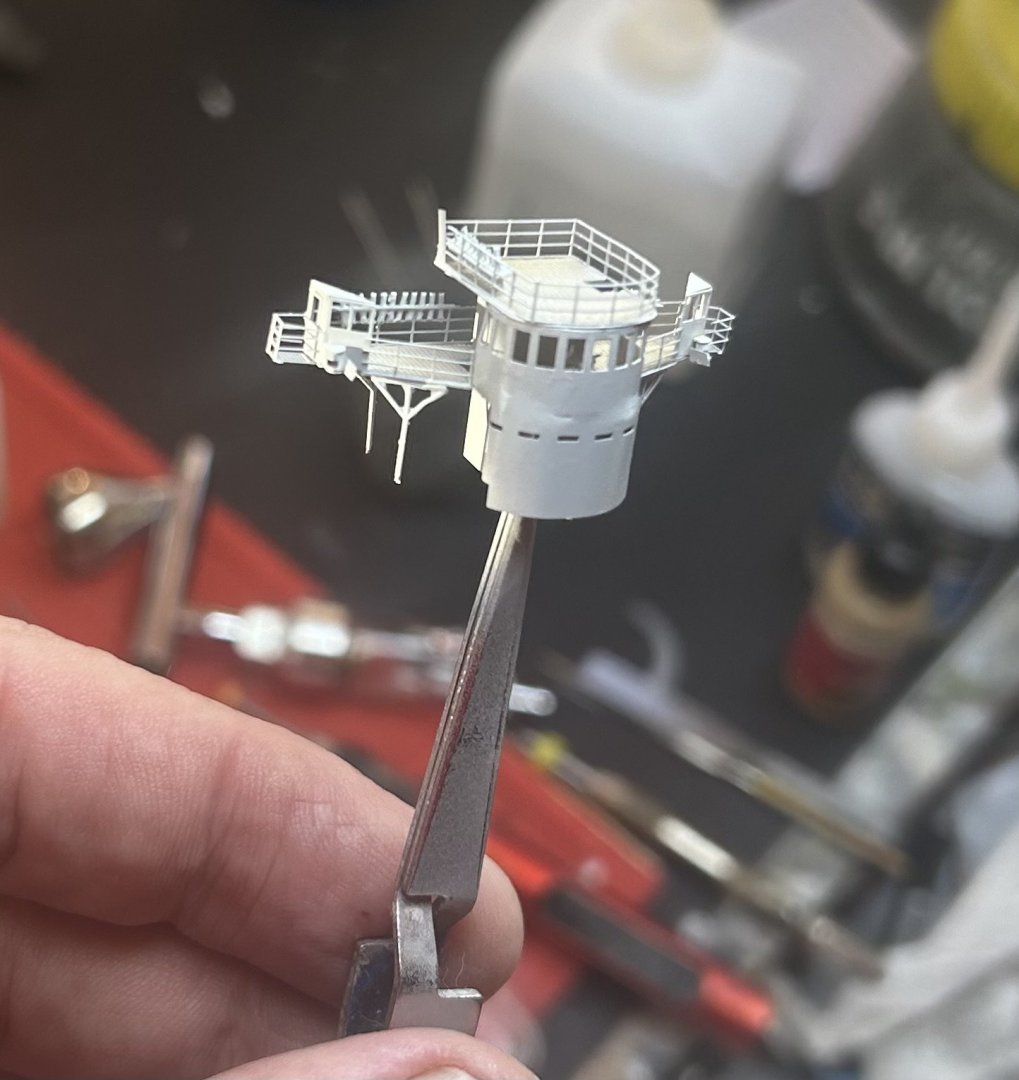

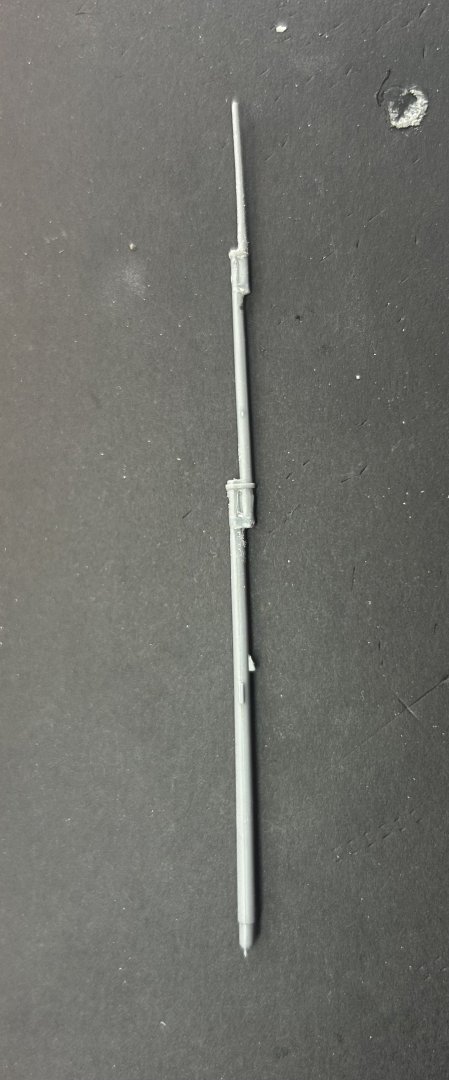

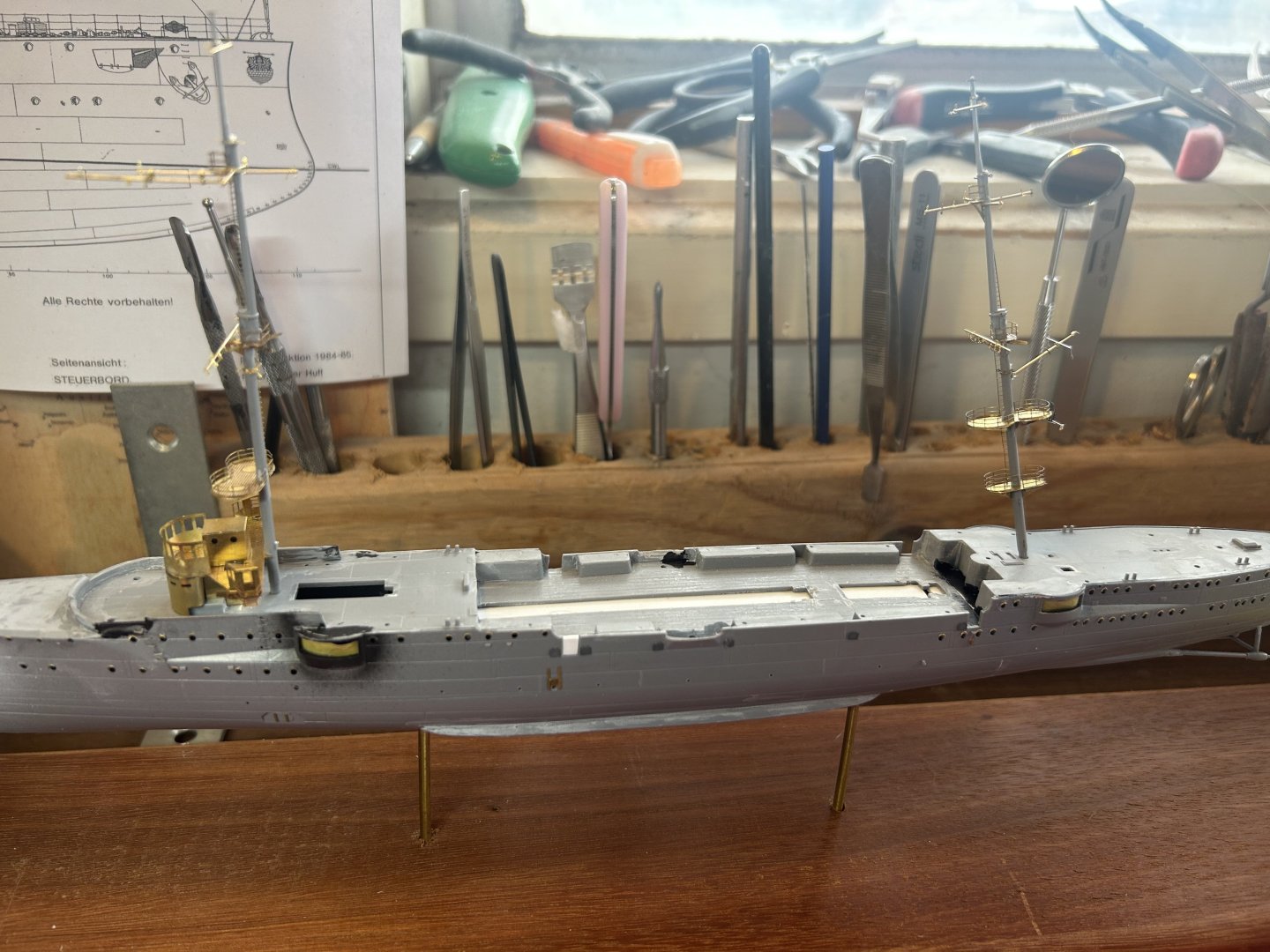

3D printed search lights, scratch built search light controllers, masts painted and navigation lights added to the tops

- 81 replies

-

- Micromaster

- Eduard

- (and 4 more)

-

- 81 replies

-

- Micromaster

- Eduard

- (and 4 more)

-

- 81 replies

-

- Micromaster

- Eduard

- (and 4 more)

-

Flying Sd.Kfz.222 by RGL - HobbyBoss - 1/35 - PLASTIC

RGL replied to RGL's topic in Non-ship/categorised builds

-

That’s coming up nicely, if I may make a suggestion, a few layers of close coat with some foam or spume layered between? Just use a rattle can

- 176 replies

-

- new orleans

- iron shipwrights

-

(and 2 more)

Tagged with:

-

- 233 replies

-

- 81 replies

-

- Micromaster

- Eduard

- (and 4 more)

-

- 81 replies

-

- Micromaster

- Eduard

- (and 4 more)

-

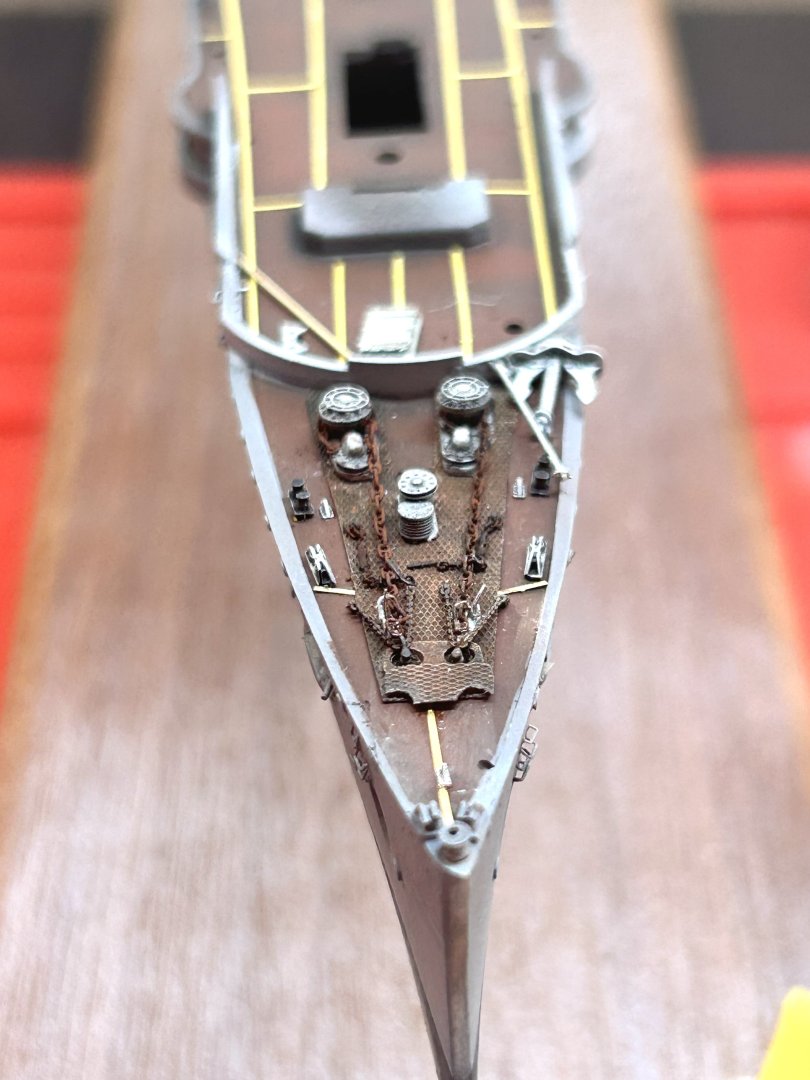

As you are aware, the brass is waaay to bright, so dulled down with some diluted green then a wash. Coaling scuttle’s added and a wash to dirty them up. By the time all the dockside dealings added this will just be background canvass.

- 81 replies

-

- Micromaster

- Eduard

- (and 4 more)

-

- 81 replies

-

- Micromaster

- Eduard

- (and 4 more)

-

- 81 replies

-

- Micromaster

- Eduard

- (and 4 more)

-

- 81 replies

-

- Micromaster

- Eduard

- (and 4 more)

-

- 81 replies

-

- Micromaster

- Eduard

- (and 4 more)

-

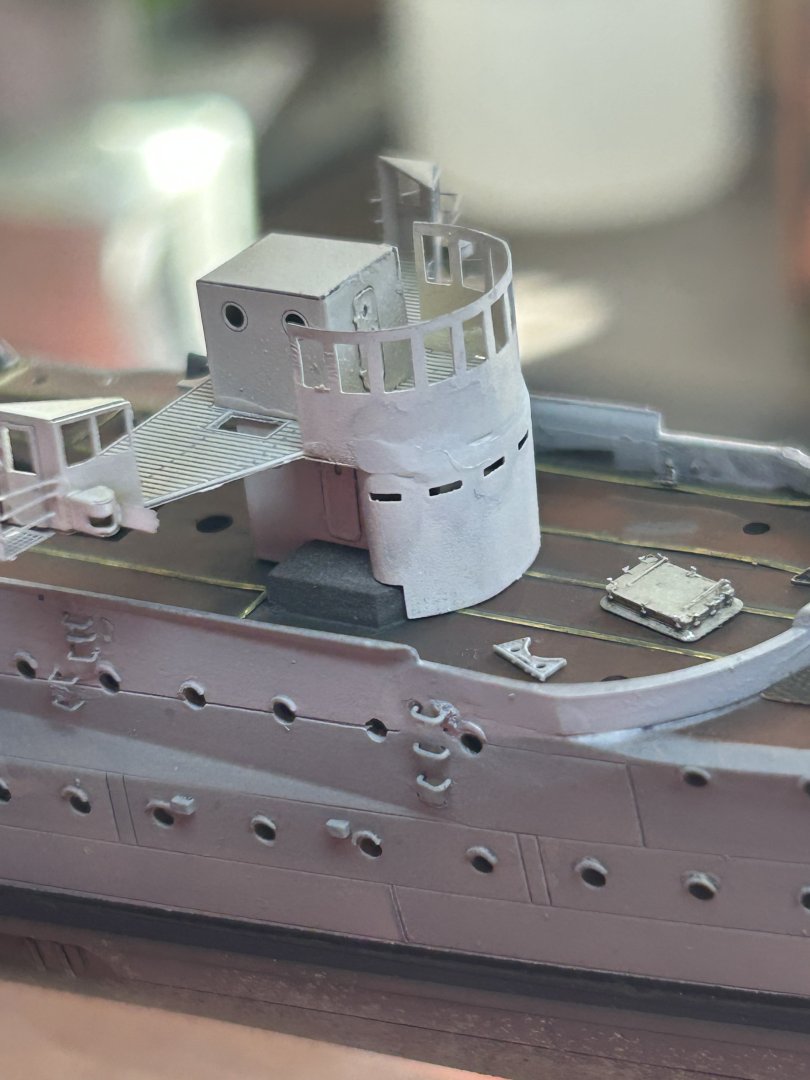

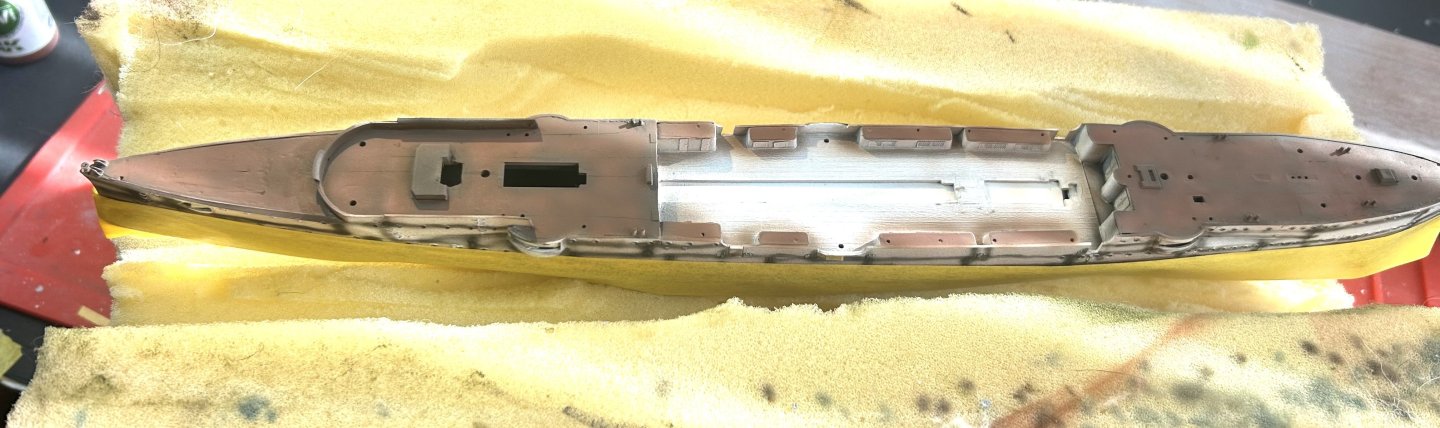

Wooden stick on deck. Sprayed with a tan to get rid of the pre chewed look. I’ll give it a clear coat so it can be weathered

- 81 replies

-

- Micromaster

- Eduard

- (and 4 more)

-

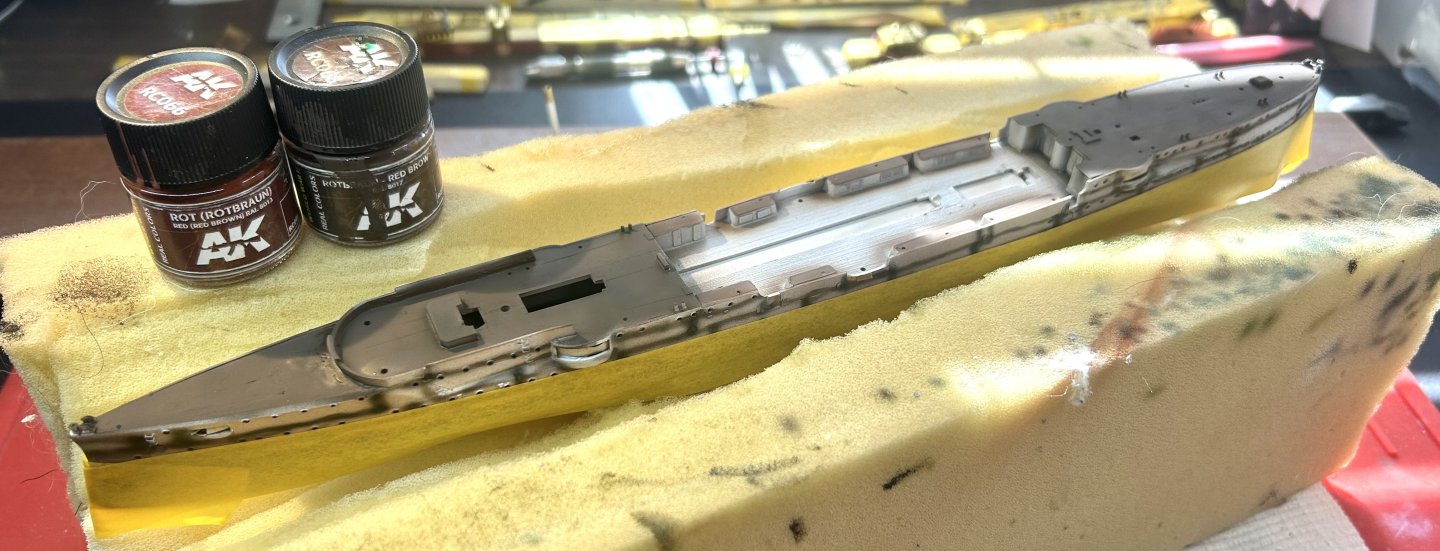

Emdens deck, two shades of brown; this was linoleum and I imagine it would get a bit of fade in the tropics. It comes up black in the old photos but would have been burnt. I’ve given it a clear coat and will mask it when dry. Next is to paint the hull before I can remove the mask and add the brass hold down strips

- 81 replies

-

- Micromaster

- Eduard

- (and 4 more)

-

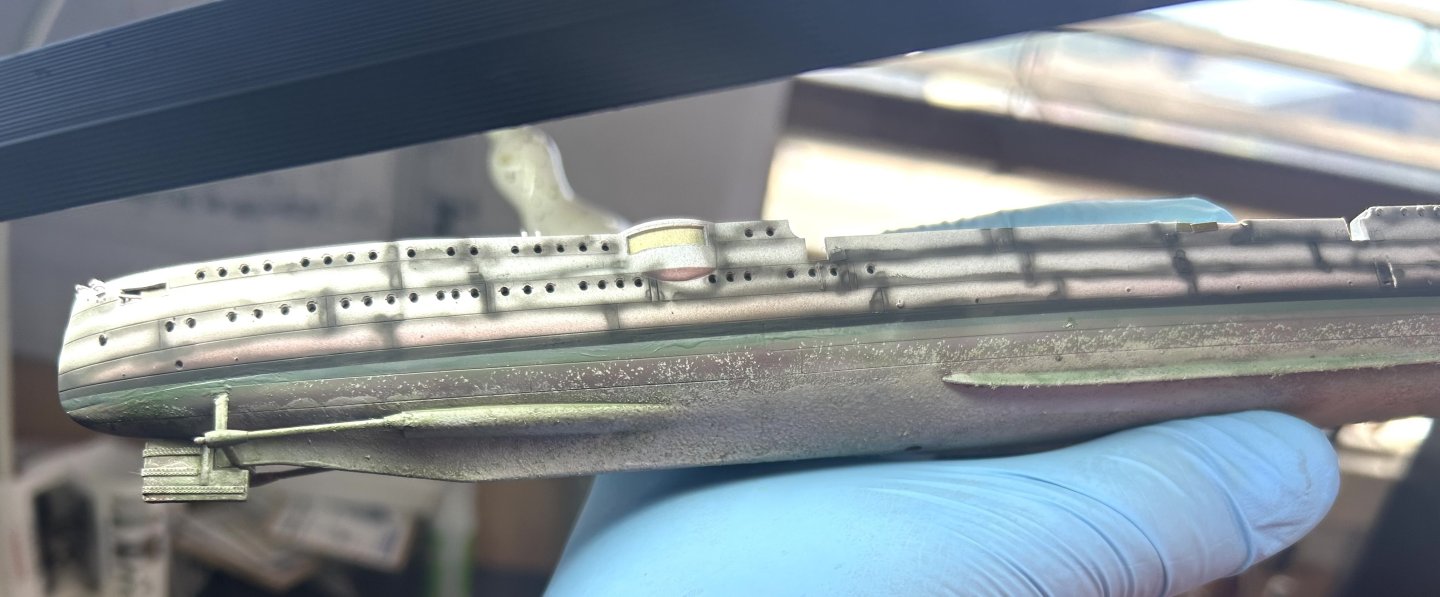

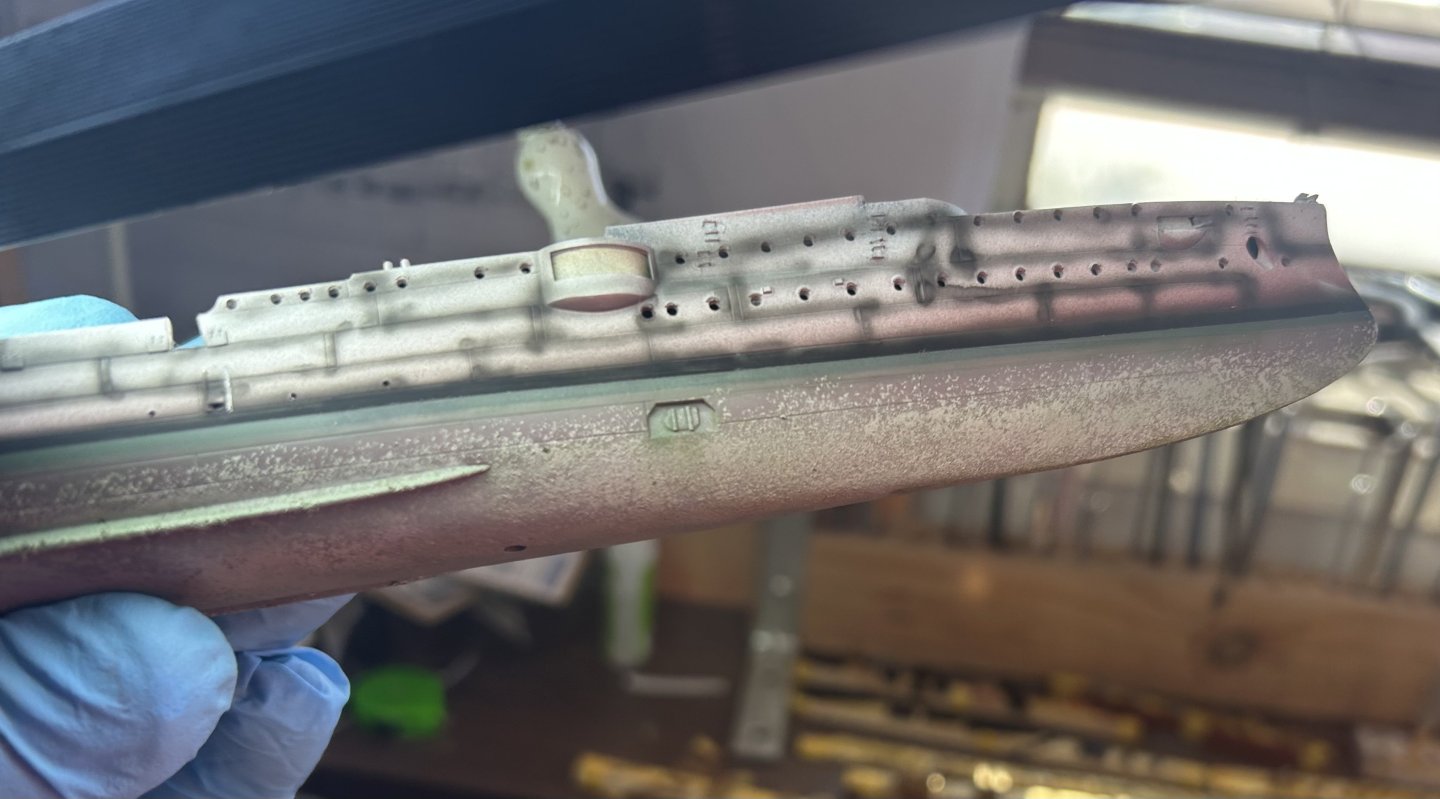

Continuing to work in the grunge, when upon close inspection I can see seam lines and putty. More sanding to do the patch work repairs and I’ll redo the boot strap and I want to make it a little more defined .

- 81 replies

-

- Micromaster

- Eduard

- (and 4 more)

-

Starting on the alge. Given the scale it is sponged on and tomorrow I’ll start on layering overspray of black, grey and green

- 81 replies

-

- Micromaster

- Eduard

- (and 4 more)

-

Starting in the lower hull, dark brown base, red overspray then pink fade. Next will be alge to a) cover up the sins and b) to make it look like a ship that travelled around the tropical South Pacific without frequent scrapes

- 81 replies

-

- Micromaster

- Eduard

- (and 4 more)

-

- 81 replies

-

- Micromaster

- Eduard

- (and 4 more)

-

- 81 replies

-

- Micromaster

- Eduard

- (and 4 more)

-

- 81 replies

-

- Micromaster

- Eduard

- (and 4 more)

-

So today we did fife rails. The kit provides 4, it needs 5, a bit more surgery required but I think once painted they will look better than the grey blobs

- 81 replies

-

- Micromaster

- Eduard

- (and 4 more)

-

- 81 replies

-

- Micromaster

- Eduard

- (and 4 more)

-

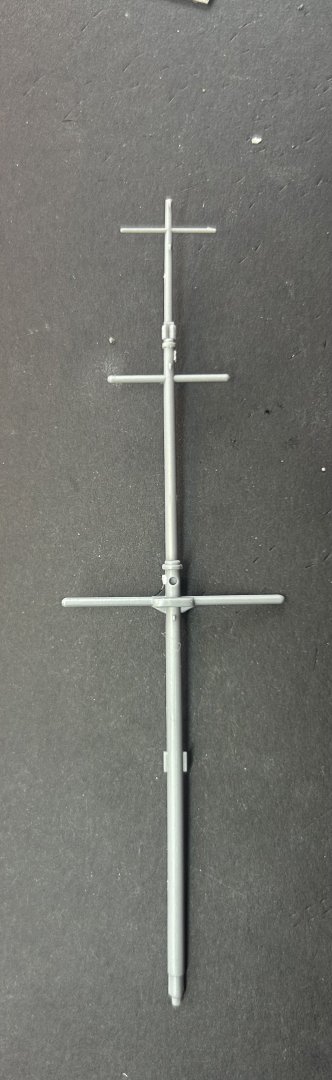

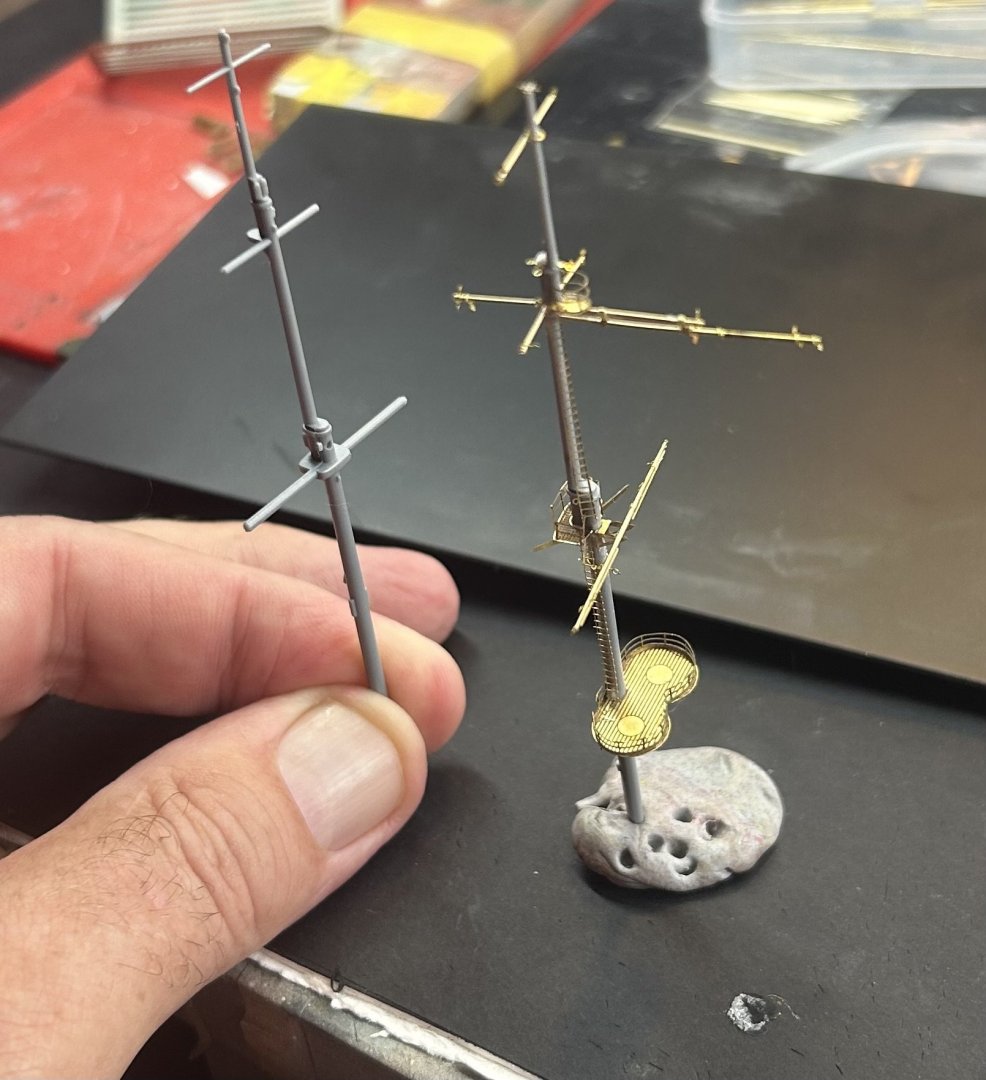

SMS Emden masts, 3 days and the formast is done, all the rigging points added sans navigation lights and search lights. For comparison the main mast !

- 81 replies

-

- Micromaster

- Eduard

- (and 4 more)

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.