-

Posts

438 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Steve 12345

-

Quick question hof looking back over the log in the pictures you supplied in page 1 I notice you fitted the handrails before the inner bulwark uprights did you find that made the process easier than fitting the uprights then trying to cut flush at correct angle

- 130 replies

-

- mare nostrum

- artesania latina

-

(and 1 more)

Tagged with:

-

back to my bounty Derek should have been on it at minute but love this little ship and was surprised it took over but at the end of the day its a hobby work on what you enjoy most that's why its a hobby

- 130 replies

-

- mare nostrum

- artesania latina

-

(and 1 more)

Tagged with:

-

I found with the spray laquer im using harry on the wheel house when I had to glue small parts on the roof with ca cause id already applied finish it left a small sort of clouded affect I was almost gonna rebuild but then I tried spraying a small amount into the spray can plastic lid and appling with a brush the clouded effect disappeared I feel that will work for using ca on the fish boxes however I do like your idea of pinning

- 130 replies

-

- mare nostrum

- artesania latina

-

(and 1 more)

Tagged with:

-

haven't started the fish box thingies yet harry key to them will be consistency that will be a good point for me to show how to use the proxon safely and efficiently not to show granny how to suck eggs but one follower has already purchased the proxen on my advice and I want to teach even a small table saw deserves respect I can show a few simple tips trust me this is because ive made all the mistakes on the full size

- 130 replies

-

- mare nostrum

- artesania latina

-

(and 1 more)

Tagged with:

-

needle threader is great little device ive always found with deadeyes and blocks the ca was best the needle threader normally only comes out when piercing thru shroud lines above deadeye with me anyhows

- 134 replies

-

- artesania latina

- mare nostrum

-

(and 1 more)

Tagged with:

-

Hi I didn't know the term for it either but what hof is suggesting is dip about 20mm of the line you want to thread in ca then if needs be you can slice the thread to a point to help thread it you will be cutting the stiffened line off afterwards ofcourse

- 134 replies

-

- artesania latina

- mare nostrum

-

(and 1 more)

Tagged with:

-

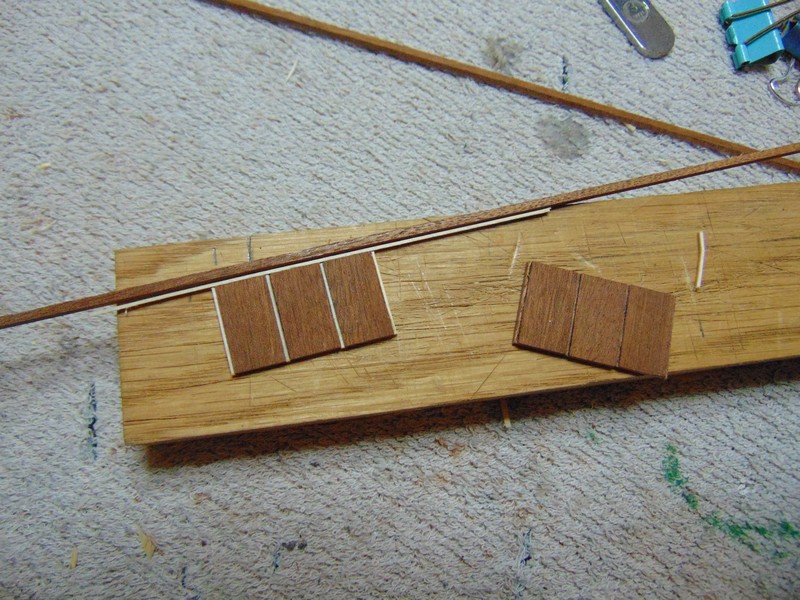

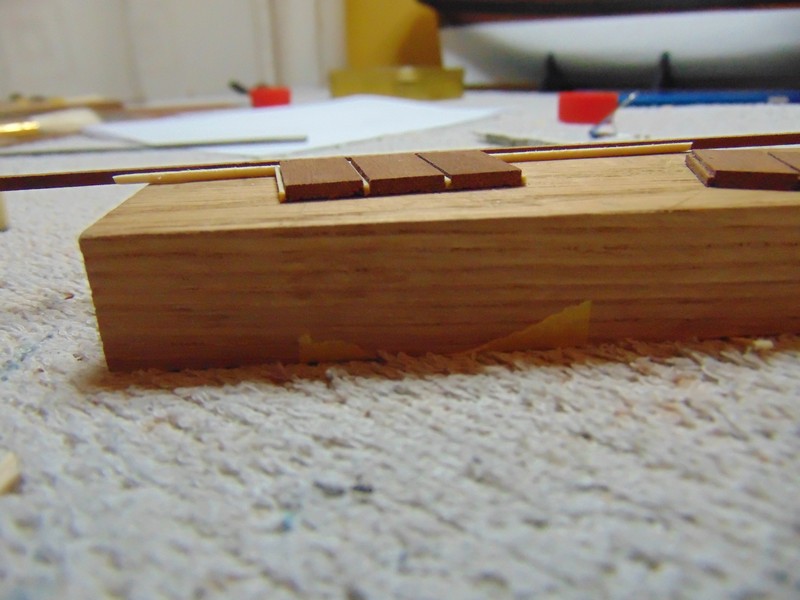

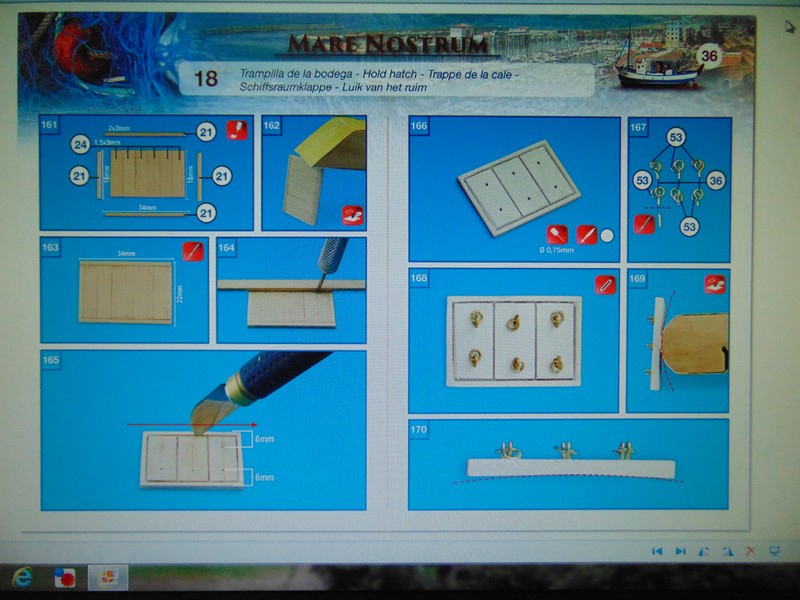

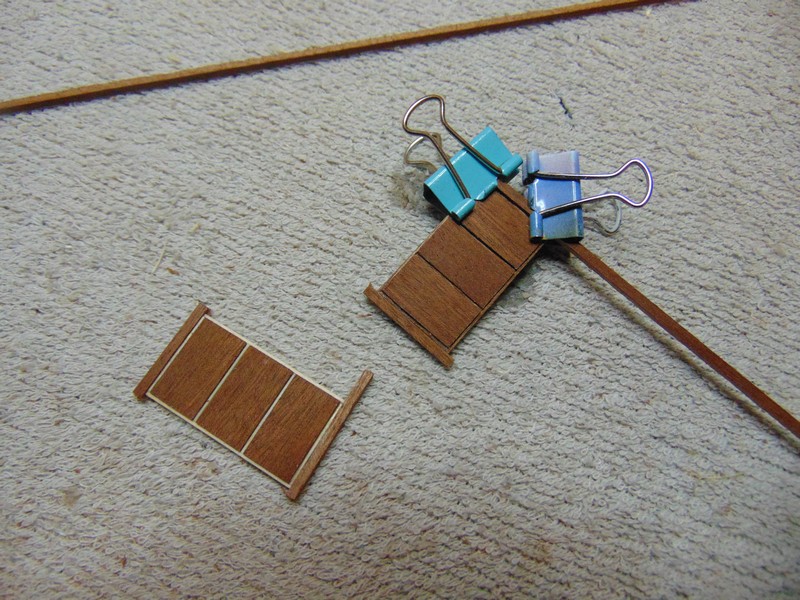

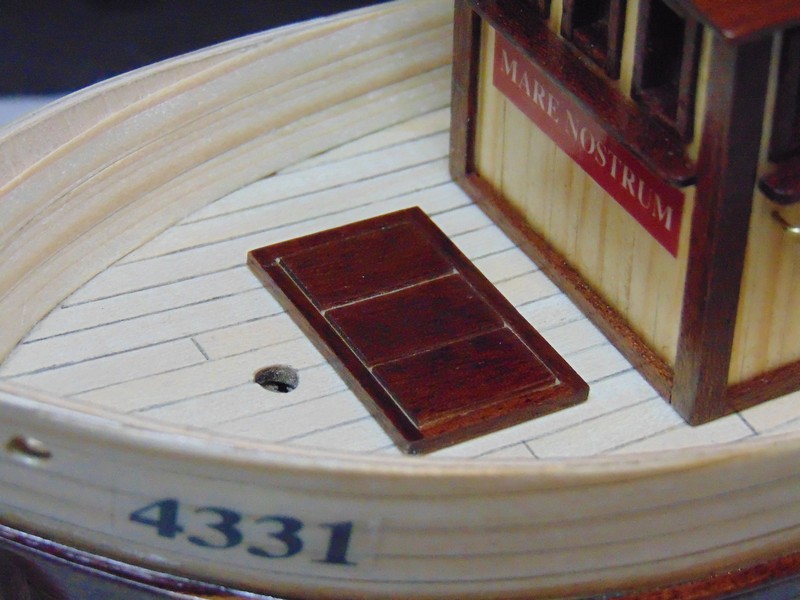

For the hatches in front of the wheel house the kit instructions where to glue up a rectangle from planks then scribe lines out to form the three different lids the following is how I decided to approach this instead. I made two one with all hardwood and one with contrasting woods keeping with my theme I think I like the mixed one better

- 130 replies

-

- mare nostrum

- artesania latina

-

(and 1 more)

Tagged with:

-

Be nice if you could raise and lower the blade on mine that way you could make ladder stringers I assume the bigger saw has the ability to raise and lower but is the blade still nice and thin

- 130 replies

-

- mare nostrum

- artesania latina

-

(and 1 more)

Tagged with:

-

Guaranteed or your money back hope proxon are watching this he he

- 130 replies

-

- mare nostrum

- artesania latina

-

(and 1 more)

Tagged with:

-

Thanks Harry that's why these things take so long you might as well be building the real thing Edit I also need to add a lot of what I've been able to do is down to the little proxon saw once again I highly recommend one of these

- 130 replies

-

- mare nostrum

- artesania latina

-

(and 1 more)

Tagged with:

-

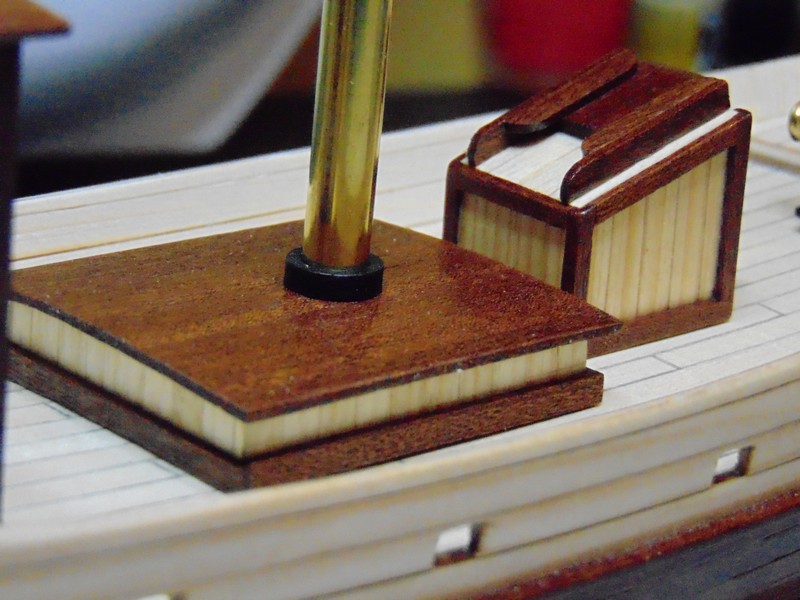

companionway cover I have gone with the softwood on the top and hardwood for door and runners I think this gives a bit more contrasting wood effect and lets the viewer see how the door operates

- 130 replies

-

- mare nostrum

- artesania latina

-

(and 1 more)

Tagged with:

-

Hi Brian thanks for the input think I will leave the doors closed or perhaps just a tiny bit ajar to show they are functional Just a reflection in the brass Steve

- 130 replies

-

- mare nostrum

- artesania latina

-

(and 1 more)

Tagged with:

-

think im gonna keep the campanion doors shut harry as this kit didn't provide the bunks ,im also not decided on the pale wood top of the companion entrance might plank it with the mahog whats your thoughts on that ? bearing in mind the doors and slide rails will be mahog thanks steve

- 130 replies

-

- mare nostrum

- artesania latina

-

(and 1 more)

Tagged with:

-

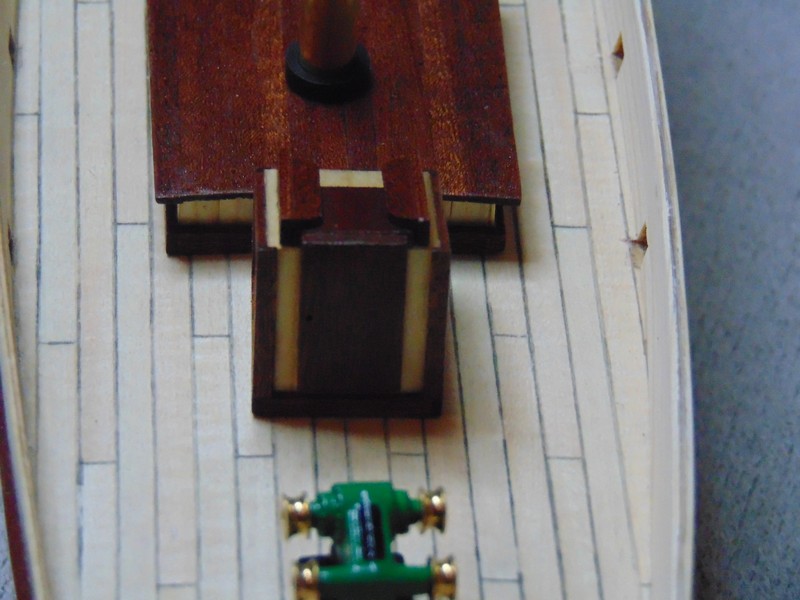

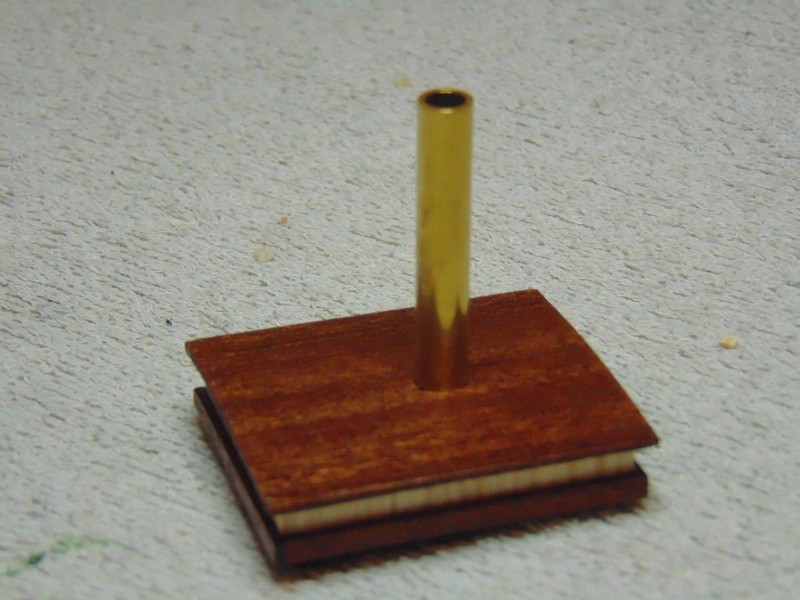

:piratebo5:hello all just a quick update this week I have scratch built the required handrails and started to plank the inner bulwarks I have also added some more detail to the wheelhouse and built the engine room cover regarding the engine room cover I tried several times to make the small ring that slides over the exaust pipe with no success that I was happy with I decided to go with the plywood kit provided piece and paint it black I haven't decided to use it or not yet ,it isn't hiding anything so is not required however I think a bit of colour added here and there adds a bit of flavour to the unpainted version and finely tried my hand at a bit of fine detail painting with the winch ,at the minute its a john deer winch but may change to a ford

- 130 replies

-

- mare nostrum

- artesania latina

-

(and 1 more)

Tagged with:

-

Sorry no bounty posts at the min what supposed to be a side build the mare nostrum has caught most of my attention at the minute I've tried to force myself to work on bounty however am enjoying the little ship so much you gotta ask yourself it's a hobby do what you makes you

- 291 replies

-

- bounty

- billing boats

-

(and 1 more)

Tagged with:

-

One example would be say you wanted to drill an 8mm hole into a 10 mm by 10 mm piece of wood almost impossible however dril that 8 mm hole into a 300mm *300mm piece then cut it down

- 130 replies

-

- mare nostrum

- artesania latina

-

(and 1 more)

Tagged with:

-

As I have mentioned in some of my other posts before .working with wood and scale modelling are worlds apart even with my experience of 18+ Years carpentry I find scale building challenging

- 130 replies

-

- mare nostrum

- artesania latina

-

(and 1 more)

Tagged with:

-

Figure I have aprox ten hrs work invested into that wheel house if I preseted that to an employer or customer after a days work figure they would tell me not to show up tomorrow. Thing is I could have built the real thing in that time

- 130 replies

-

- mare nostrum

- artesania latina

-

(and 1 more)

Tagged with:

-

Thank you harry never thought about the concept of Cornwall model boats not showing it online but there ability to source it is better than mine will give them a call Monday morning

- 130 replies

-

- mare nostrum

- artesania latina

-

(and 1 more)

Tagged with:

-

Regarding scratch building a painted version I have looked up al fittings on Cornwall model boats and al own website the box of fittings comes with many parts I could provide myself like the copper wire etc. But can't find where to purchase the winch or horn and lights etc any advice on where to find a fittings kit ?

- 130 replies

-

- mare nostrum

- artesania latina

-

(and 1 more)

Tagged with:

-

I really like the diorama idea harry ive seen couple of them in build logs and the engine idea sounds fantastic

- 130 replies

-

- mare nostrum

- artesania latina

-

(and 1 more)

Tagged with:

-

Hi Doug the kit only provided plywood for the cabin I added all the strips as for the finish its something ive used a lot on woodworking builds and wanted to try on a ship the mare nostrum seemed very fitting for the experiment. Its a bog standard trade clear laquer bought from a car autoparts store I can buy a 500ml spray can of the stuff for £2.20 its self levelling and has gap filling propertys also I can sand back to change or repair a piece and simply spray over again each new coat adheres to the previous its sprayed straight onto the bare wood with as many coats as required light sanding between. Also allow I haven't tried I suppose you could polish it with car wax

- 130 replies

-

- mare nostrum

- artesania latina

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.