-

Posts

920 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by drobinson02199

-

Hans: Another "fix" I might suggest is to not replace the beams on frames 4, 5 and 9 until after the Deck A planking is done and sanded. Would make the sanding just a bit easier, but not a big issue. I am loving this kit so far. 😁

- 136 replies

-

- kolderstok

- batavia

-

(and 1 more)

Tagged with:

-

I've planked the lower deck, and fashioned and installed a hatch that will be visible from decks above. The sharp-eyed among you will notice that I forgot to plank one small section between the right upper frames -- but I've checked the drawings and it will be completely enclosed, so I'm not going to fix it. Speaking of drawings, I also noticed that I need to add a second layer of planking in the center area moving forward from the main hatch. I'll do that and varnish it on the next varnish round. What this made me realize is that I have to study the plans and drawings much more carefully, as there is info on them that isn't referenced in the manual. There are also some sequence issues to catch -- for example, reading ahead I've noticed that there is a knighthead attached to this deck aft of the main mast. It would be very difficult to install once the deck above is installed, but the deck installation comes much earlier in the manual then the place where the knighthead is mentioned. So i'll fashion and install it now before that deck goes on. So more reading forward, and more studying the plans. Regards, David

- 136 replies

-

- kolderstok

- batavia

-

(and 1 more)

Tagged with:

-

I have mounted the lower deck (see below), and I have a building note. The sternmost deck won't fit unless you cut it. I cut it in the wrong place on the starboard side, so had to make a second cut, and then replicated that cut on the port side. It's all planked over, so no problem, but it took me a while to figure out why I couldn't get that deck to fit in one piece. Regards, David

- 136 replies

-

- kolderstok

- batavia

-

(and 1 more)

Tagged with:

-

The starboard gunports are now done and mounted. I'm going to run an extra bead of glue around them to be sure they are really fixed on so that they won't pop off when they are sanded down to flush with the frames. Now on to the port side. Regards, David

- 136 replies

-

- kolderstok

- batavia

-

(and 1 more)

Tagged with:

-

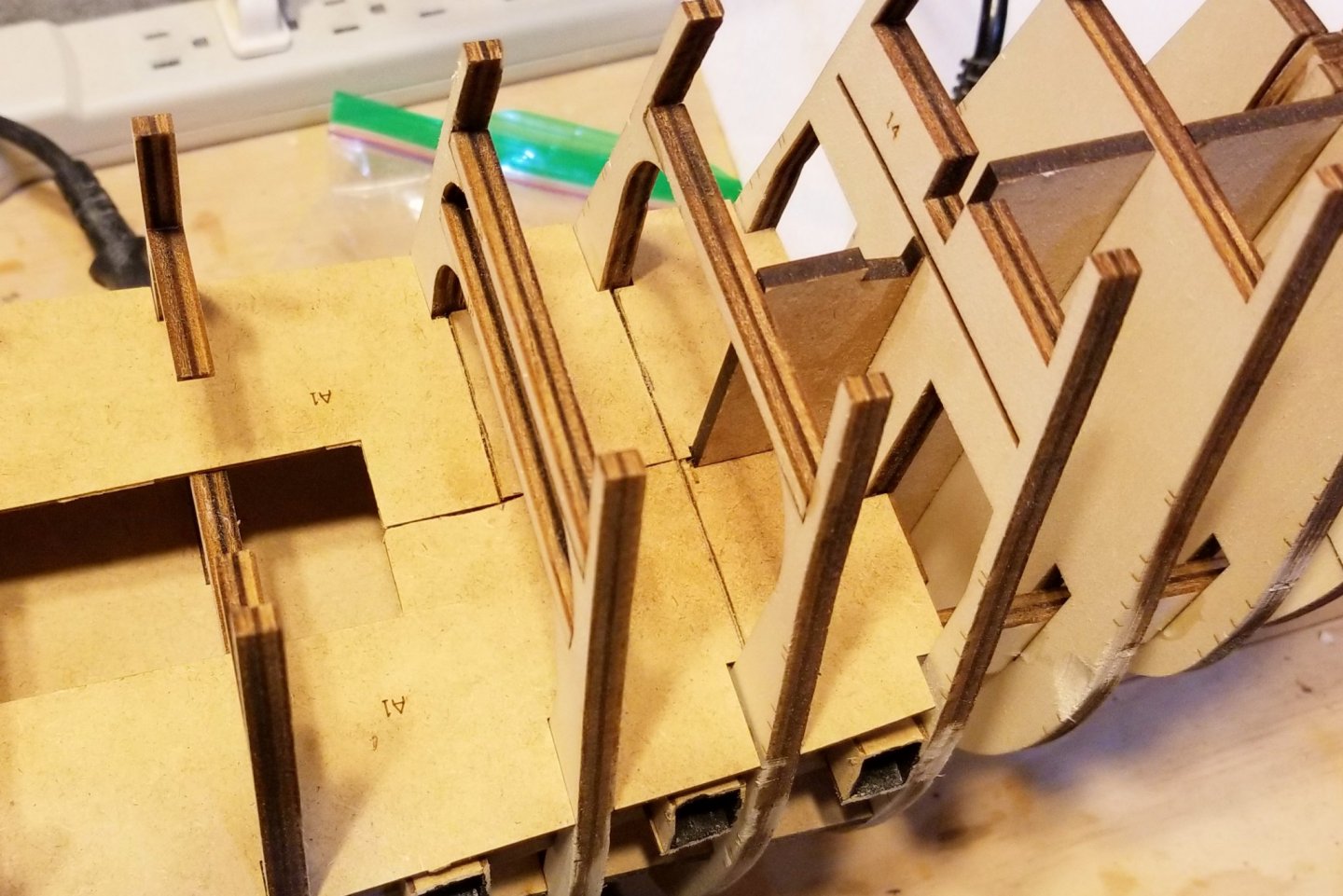

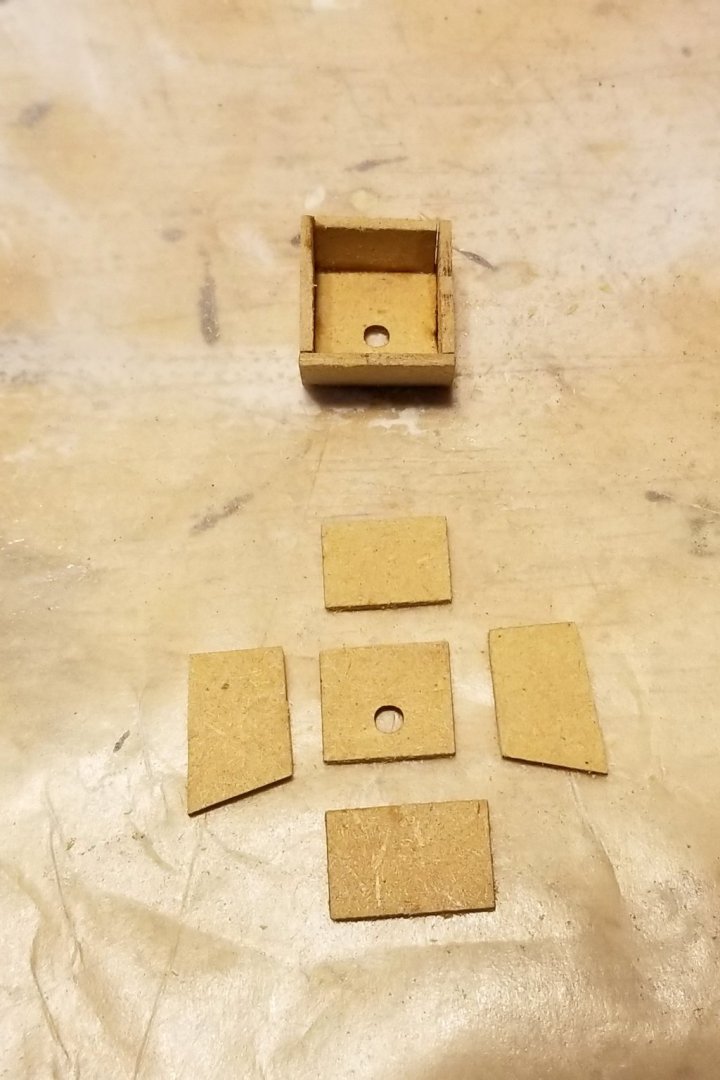

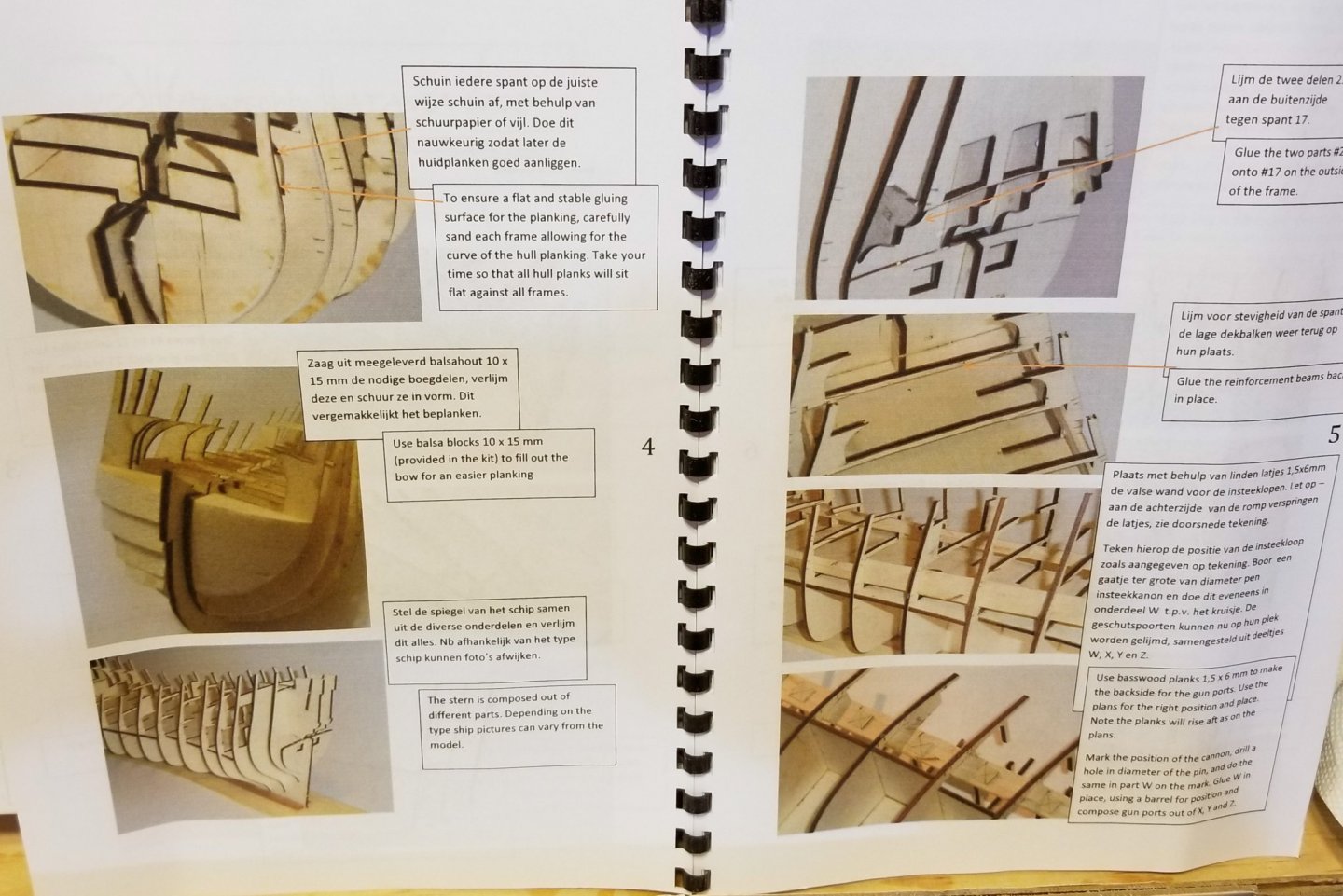

I have begun work on the gun ports. They are mounted on three slats you can see in the second picture. The manual suggests mounting the rear of the gun port (the piece with the hole) on the slat first, and then building the gun port around that. I felt it would be easier for me to build them off the ship and then mount them, as you can see in the first picture. Third picture shows two mounted gun ports. The cannons have a shaft extending from the back of the cannon that fit into the hole. There are no gun carriages, as they would be below decks and not visible. By the way, Hans provided me with an all walnut hull planking option, which I like better than a painted hull, so there is no basswood hull planking in the kit -- that's why you see the slats made from walnut. Regards, David

- 136 replies

-

- kolderstok

- batavia

-

(and 1 more)

Tagged with:

-

Charles: The five parts on the right are part of the lower yard attachments. They attach to the yards (5 of them) through the center hole, and the two holes on the "wings" are for a pin that goes through a brass part attached to the mast to create a swivel. There are drawings of this somewhere on the mast or yard plans. I had a very difficult time attaching those to the yards without them coming loose, and finally resorted to lashing them to the yards, and gluing the lashings, which worked well. I think there's an entry about that somewhere in my build log. The other parts I'm not sure of, but they look like they might possibly be part of the two deck winches. Have you built those yet? If the parts on the left are hollow inside, then I think they are the ends of a winch axle made from a dowel that fits into the hollows. I call these "winches" but the manual may have a different name for them -- but there are two on deck, one in front of the fore mast and one in front of the main mast. They have a lot of brass parts. The center parts might also be part of those winch assemblies, or they could be the body of small cranked winches that mount on the side of the channels. Hope this is helpful. Regards, David

- 133 replies

-

- cutty sark

- mantua

-

(and 3 more)

Tagged with:

-

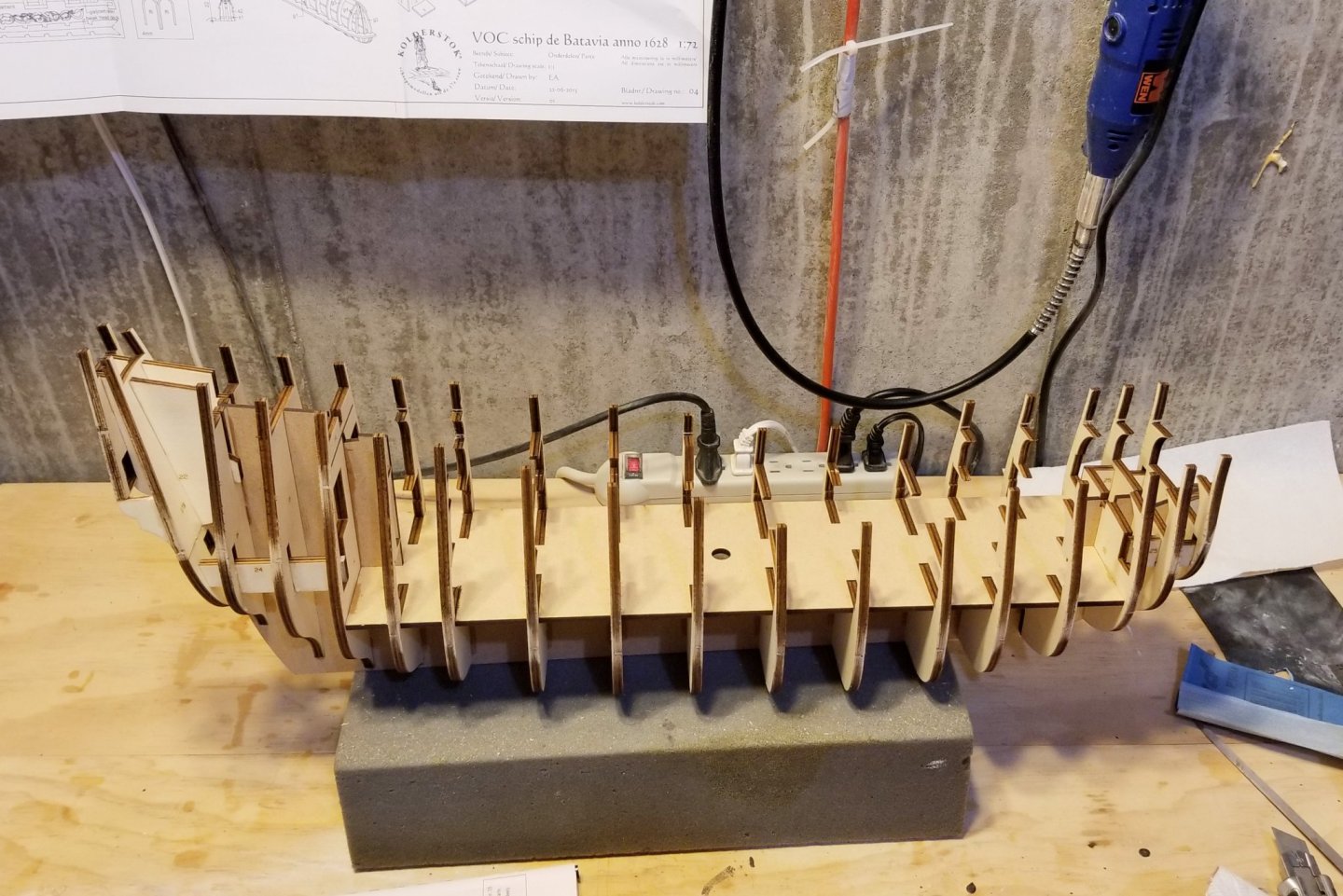

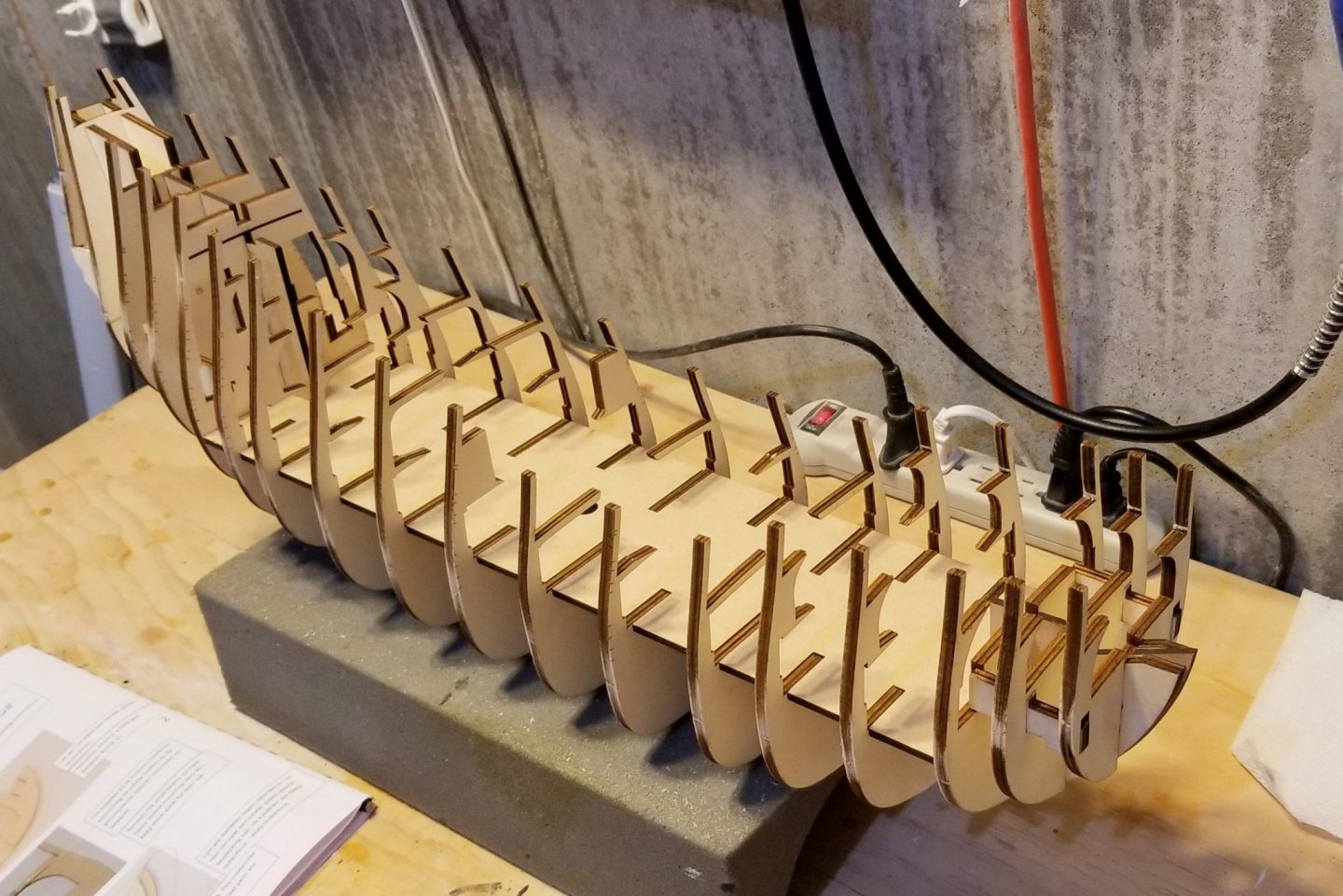

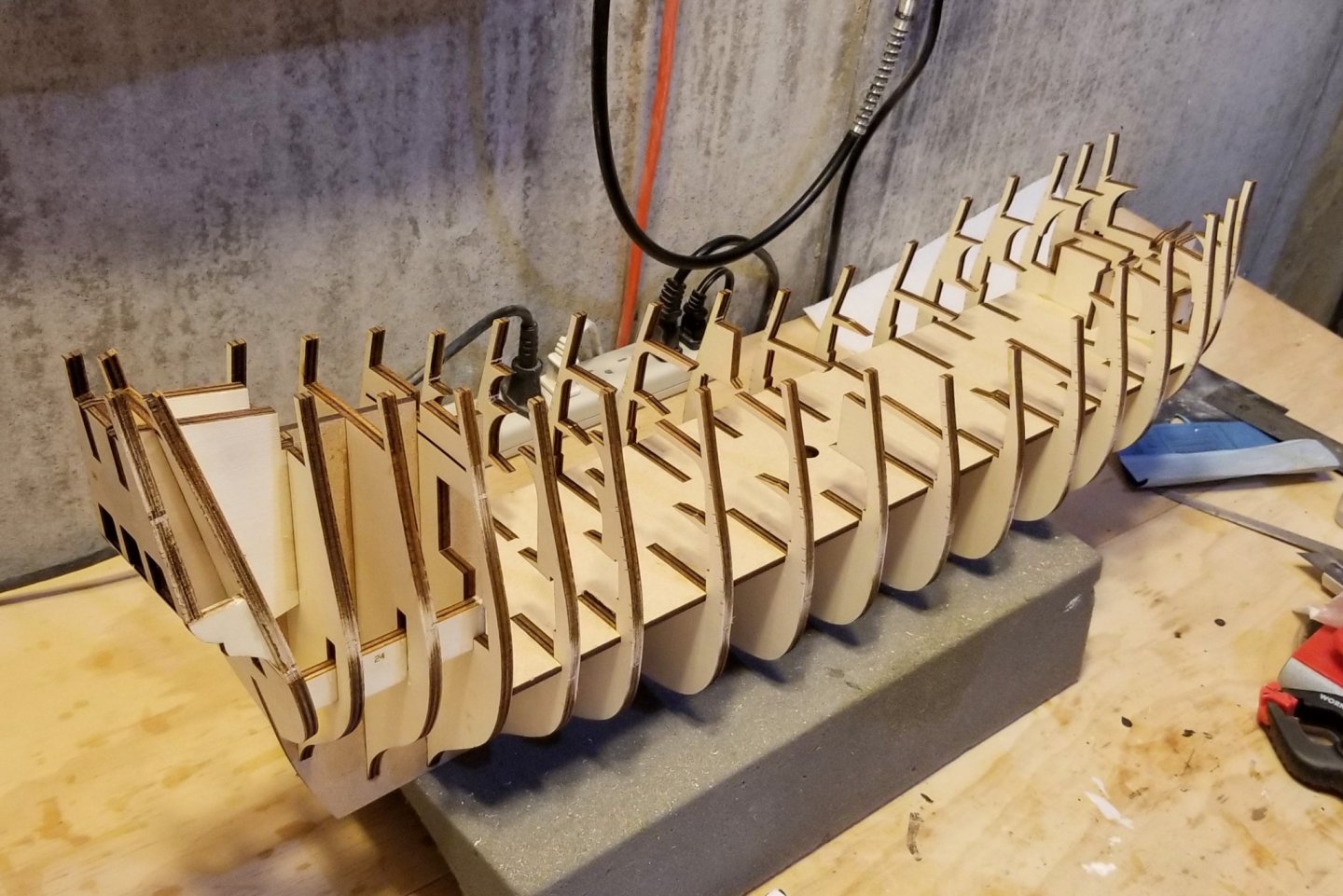

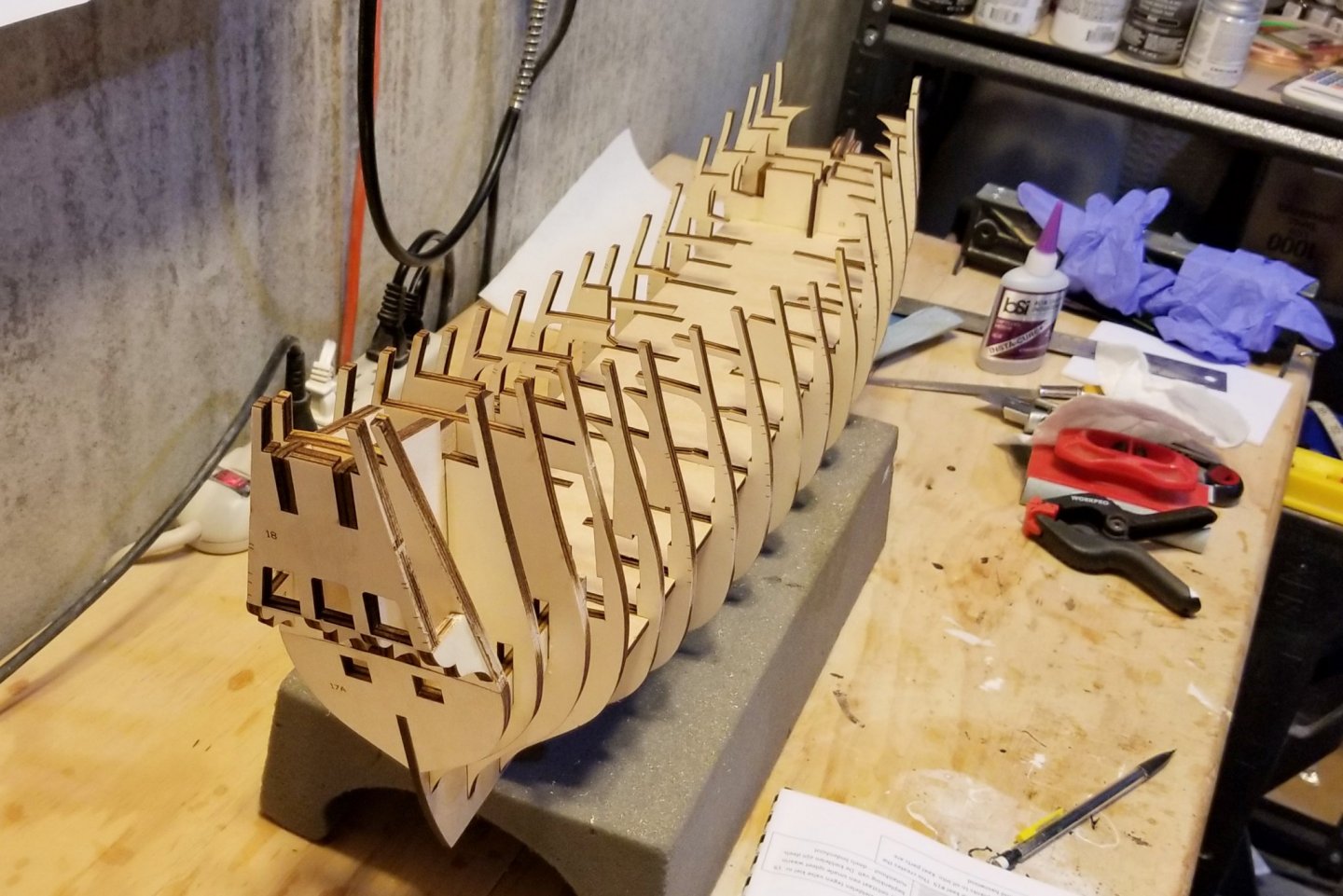

Chris: It's a single-plank ship, so lots of bulkheads is a good thing. Regards, David

- 136 replies

-

- kolderstok

- batavia

-

(and 1 more)

Tagged with:

-

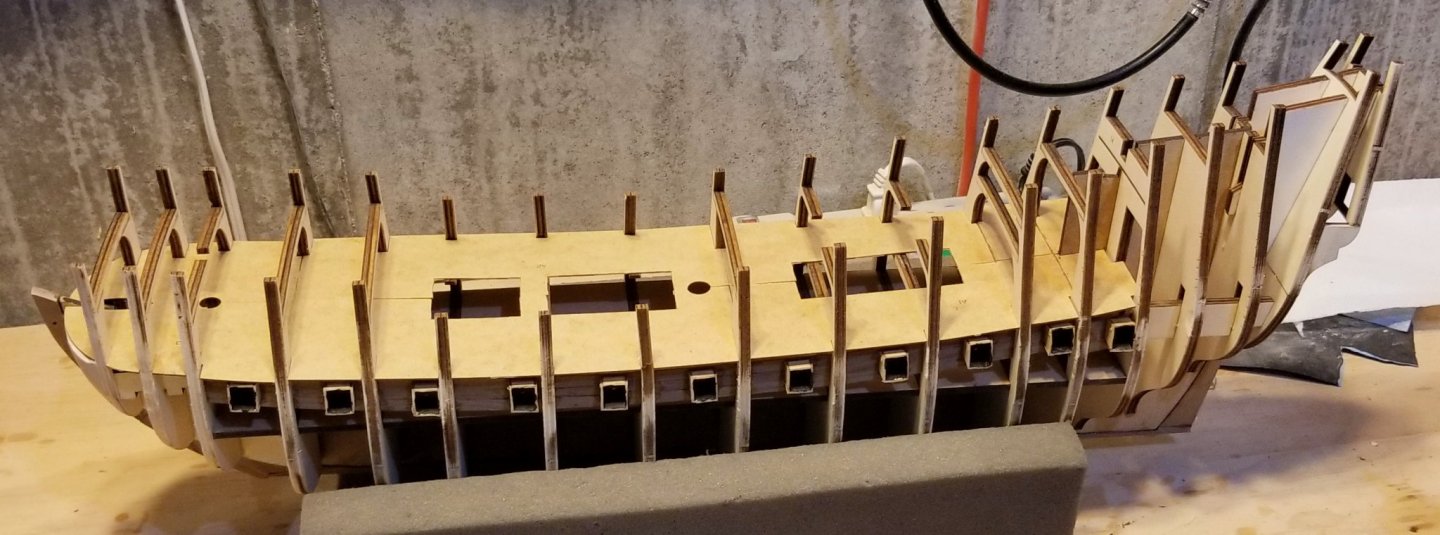

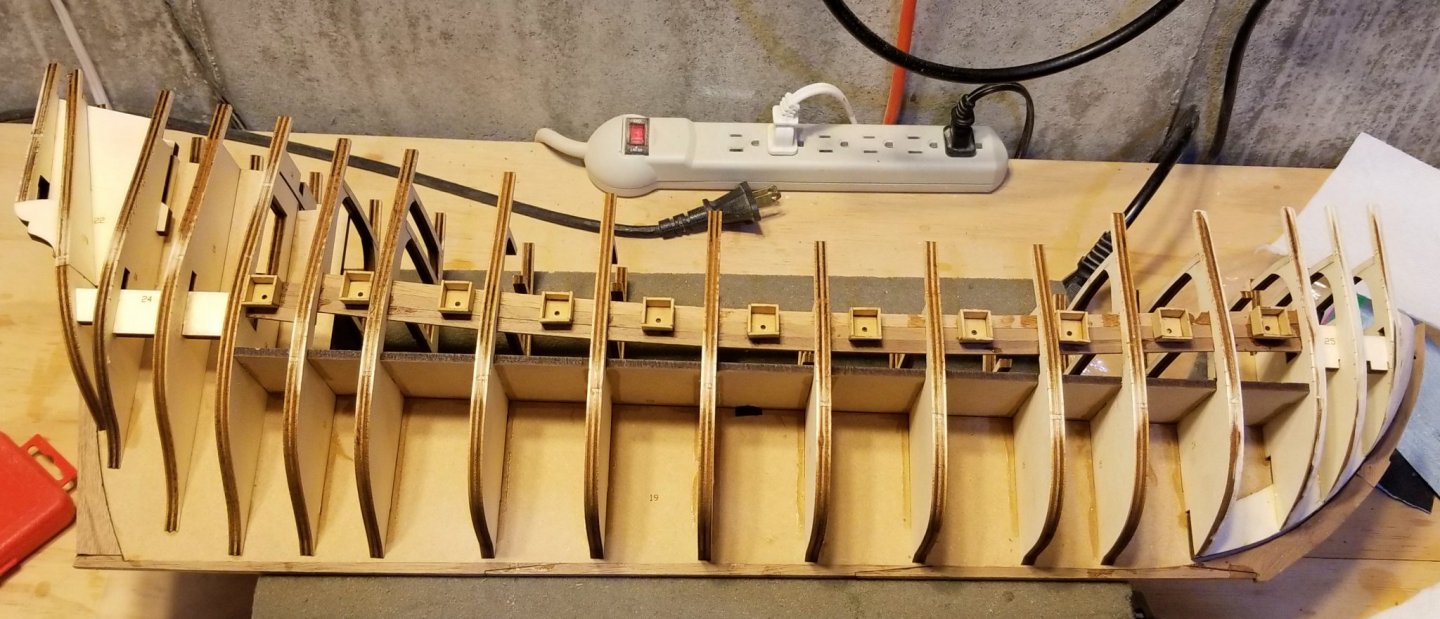

The basic hull structure is complete, although I still need to do: keel parts, sanding frames, balsa blocks, and reinforcing rib replacement. I built this by dry-fitting everything you see in the pictures before gluing anything, which was important as there were a couple of tight deck slots that needed to be opened, and the alignment of the stern parts depends on having them all installed. Then I glued from the front back, using CA gel along the joints. Regards, David

- 136 replies

-

- kolderstok

- batavia

-

(and 1 more)

Tagged with:

-

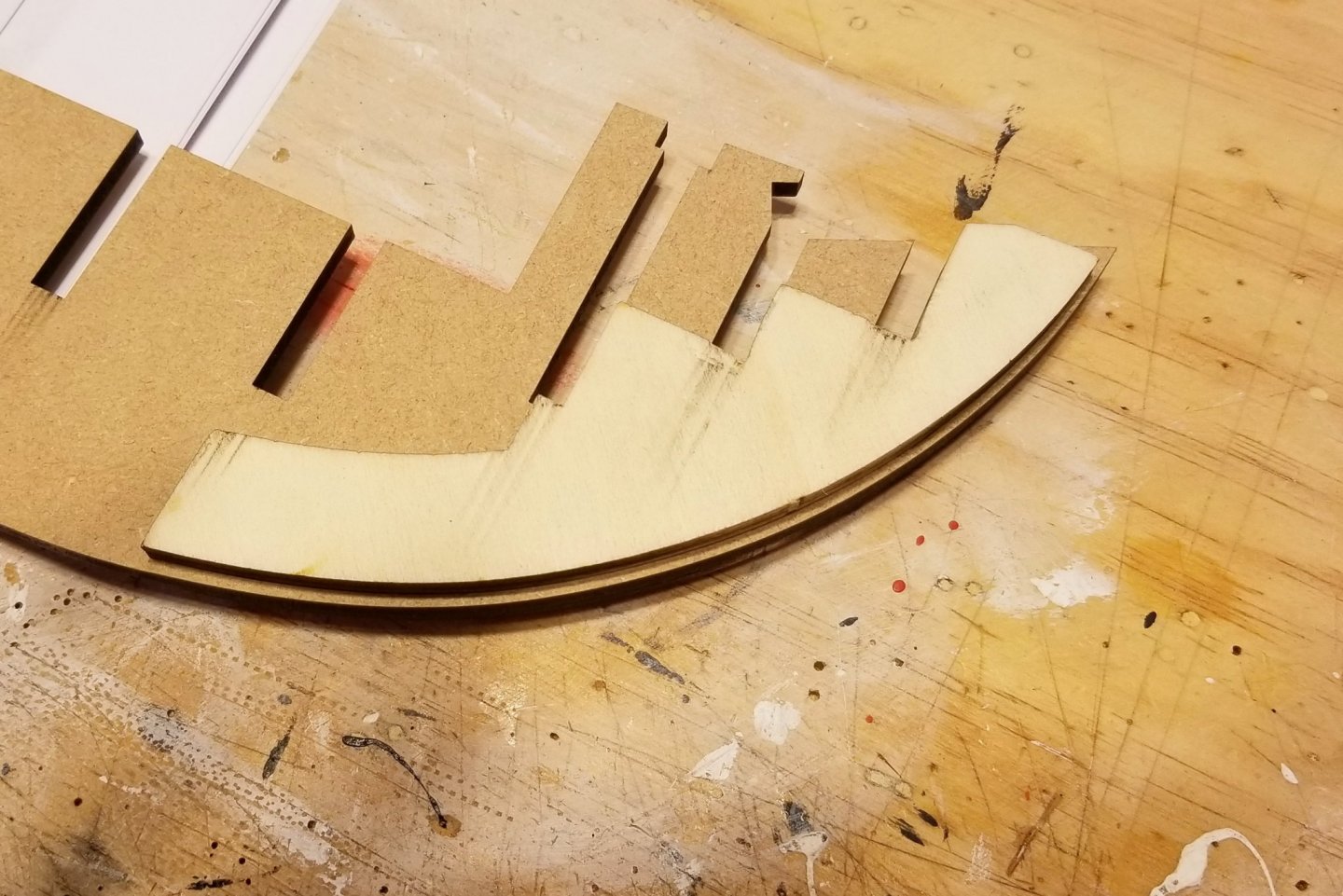

The first step is to add two pieces to the keel at the bow, and the alignment of those is very tricky. It wasn't until after I had mounted them that I looked ahead and realized that there needed to be a constant gap of 1.5-2.0mm where the bow curves. This is to provide a slot for the frames once a slightly wider keel piece is installed. On the starboard one (Bow Piece 1), I got the gap right (more or less by accident) but had to do some filing to get the slots perfectly aligned, although I thought I had accomplished that when I mounted it. Then on the port one (Bow Piece 2), I got the slots aligned but the gap along the curve disappears at the top. So after studying the fit of the slightly wider keel pieces, I sanded and filed it down to create the right gap (Bow Piece 3). I mention all this because that sanding/filing operation has to be done, if needed, before the frames are mounted. I have also started dry-fitting the frames and they are made of very nice plywood, and fit perfectly. Regards, David

- 136 replies

-

- kolderstok

- batavia

-

(and 1 more)

Tagged with:

-

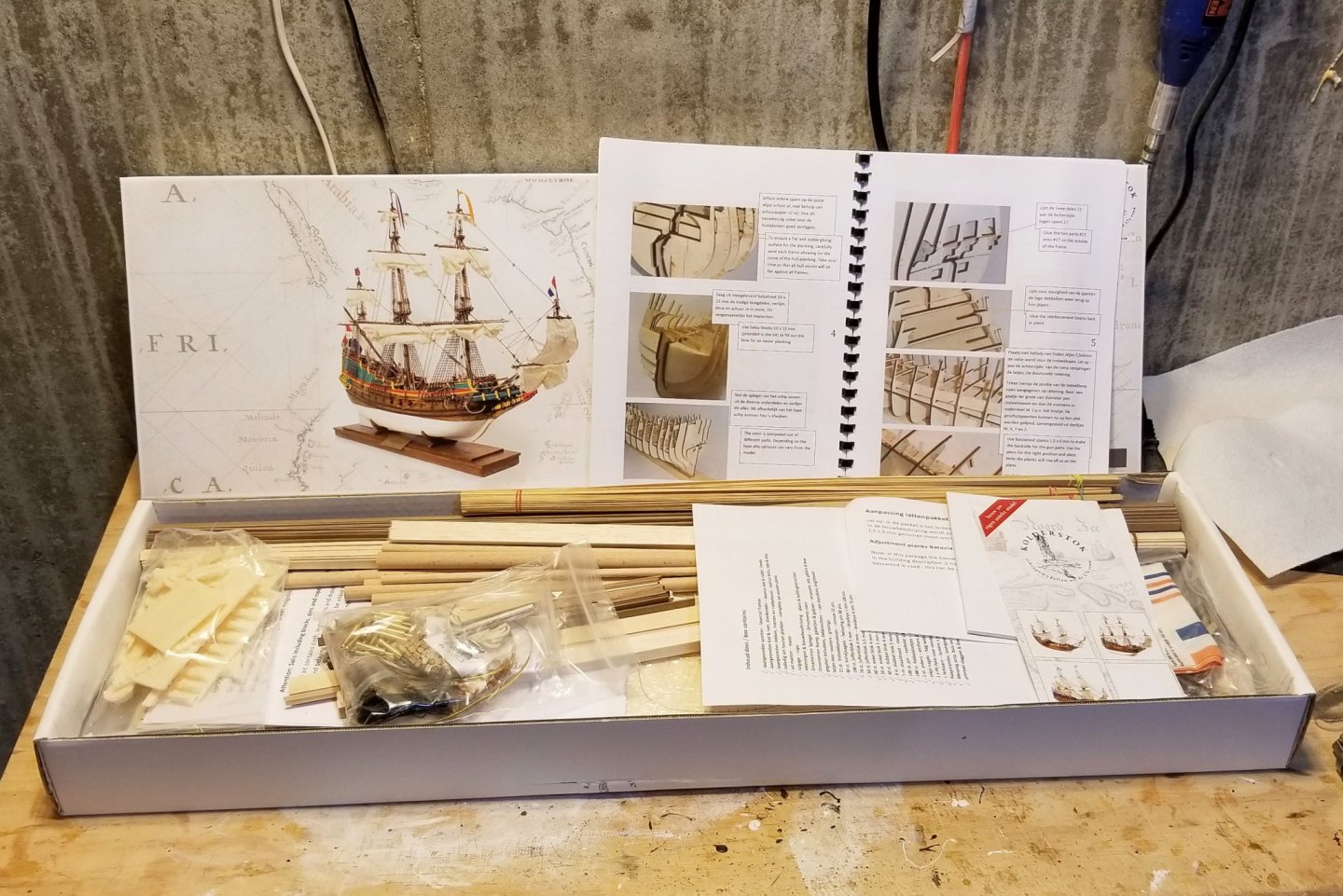

I'm going to start on the Batavia by Kolderstok. I was attracted to this model because of the colors (see Pic #1), and also because I wanted to try out a Kolderstok model. What's in the box: Laser cut boards Lots of wood Parts Instruction manual and plan sheets Note the manual -- I really like manuals with accompanying pictures. There's also an interesting parts bag with white resin-like parts. I haven't seen this before. Either it's injection molded, or possibly done on a 3D printer, which would be a first for me. I ordered this model directly from Kolderstok (http://www.kolderstok-models.com/index.en.html), and I want to particularly commend the wonderful pre-sale service I received from Hans van Nieuwkoop. I had outstanding communication from him via email, and he offered me several different customization options, one of which (an all-walnut second-planking) I took, because I like the look of all-wood hulls vs. painted hulls. Really excellent service and professional shipping. So here we go on another one. I haven't seen any logs on Batavia, so I hope this one contributes. Regards, David

- 136 replies

-

- kolderstok

- batavia

-

(and 1 more)

Tagged with:

-

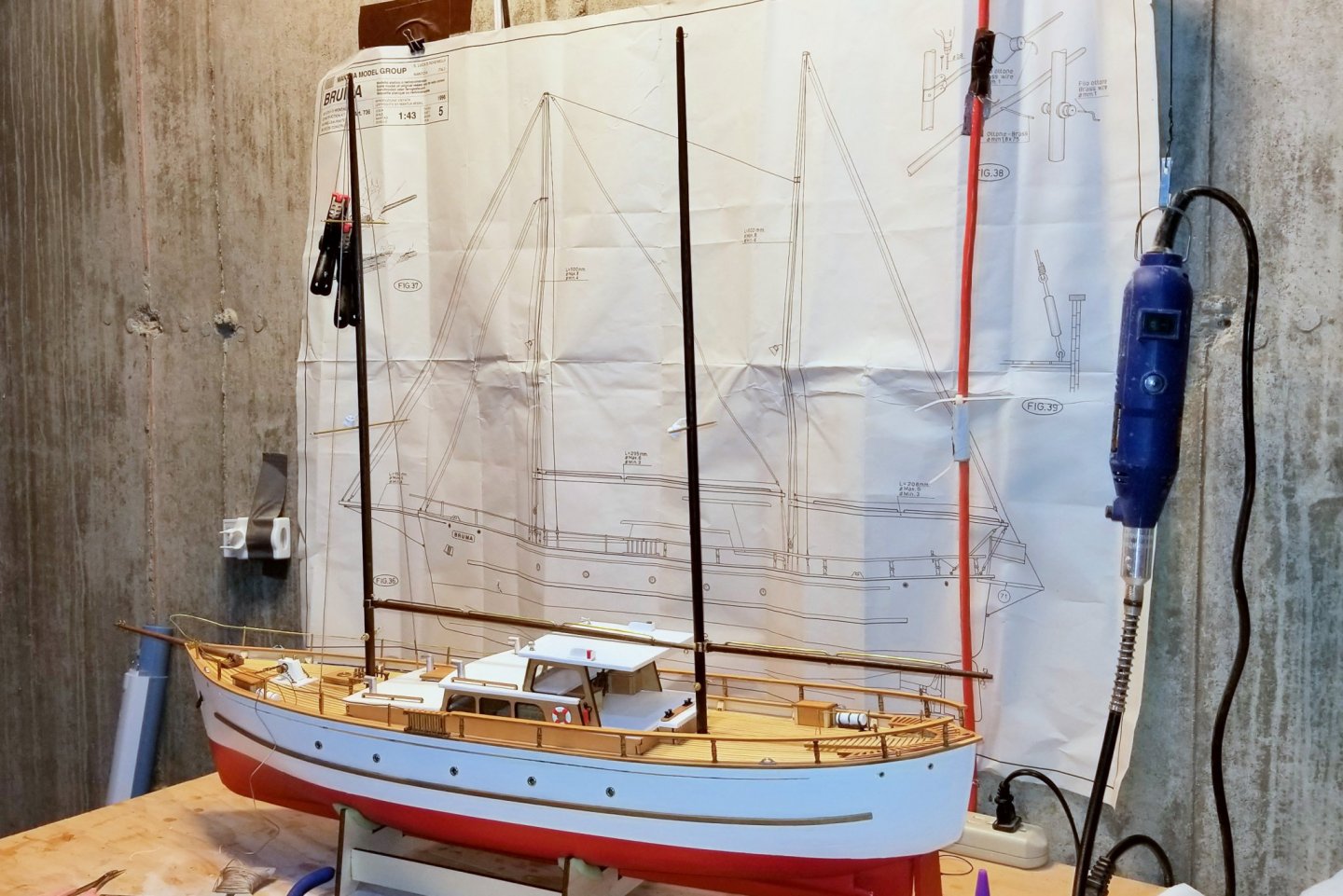

Rick: Here's the quotation from Mantua's writeup on the boat: "This is a lovely scale reproduction of an ocean going fishing boat, converted into a pleasure yacht" Regards, David

-

The Bruma is complete. I've posted a set of completion photos in the kit-built ship gallery. This was a relatively easy kit, which was my intention after building the Cutty Sark and laying all of those copper plates! A few comments on the kit: A number of missing small parts, none of them fatal. I was able to go to my spare wood/parts store and improvise. There is one rigging diagram, and while the rigging isn't complex, the diagram is very hard to read. You need to pull all the photos you can find from the internet and use them as a reference to be sure what goes where. Regards, David

-

Masts, booms and bowsprit are shaped and mounted, and I'm now starting on the rigging. One of the detail drawings indicates that brass winches were supplied, but I can't find them anywhere, so I made them from my spare parts stock using deadeyes, filled with wood filler and painted gold, some brass parts that I think were supposed to be deck buckets, and wire. Regards, David

-

All of the deck detail is now complete. Pictures show bow area with capstan, life preserver containers, small tables, hatch covers, ladder, boarding walkway and stern seat. That's it for the hull -- now on to the masts and rigging. Regards, David

-

Back to work on the Bruma after a couple of weeks in Florida. Finished the cabin exterior details including handrails, vents, horn and light, and fire extinguishers and life rings. Tricky paint work on the extinguishers. Regards, David

-

John -- Yes, it does angle back just a bit. Just the way it came out when I drilled the hole for the mounting. Regards, David

-

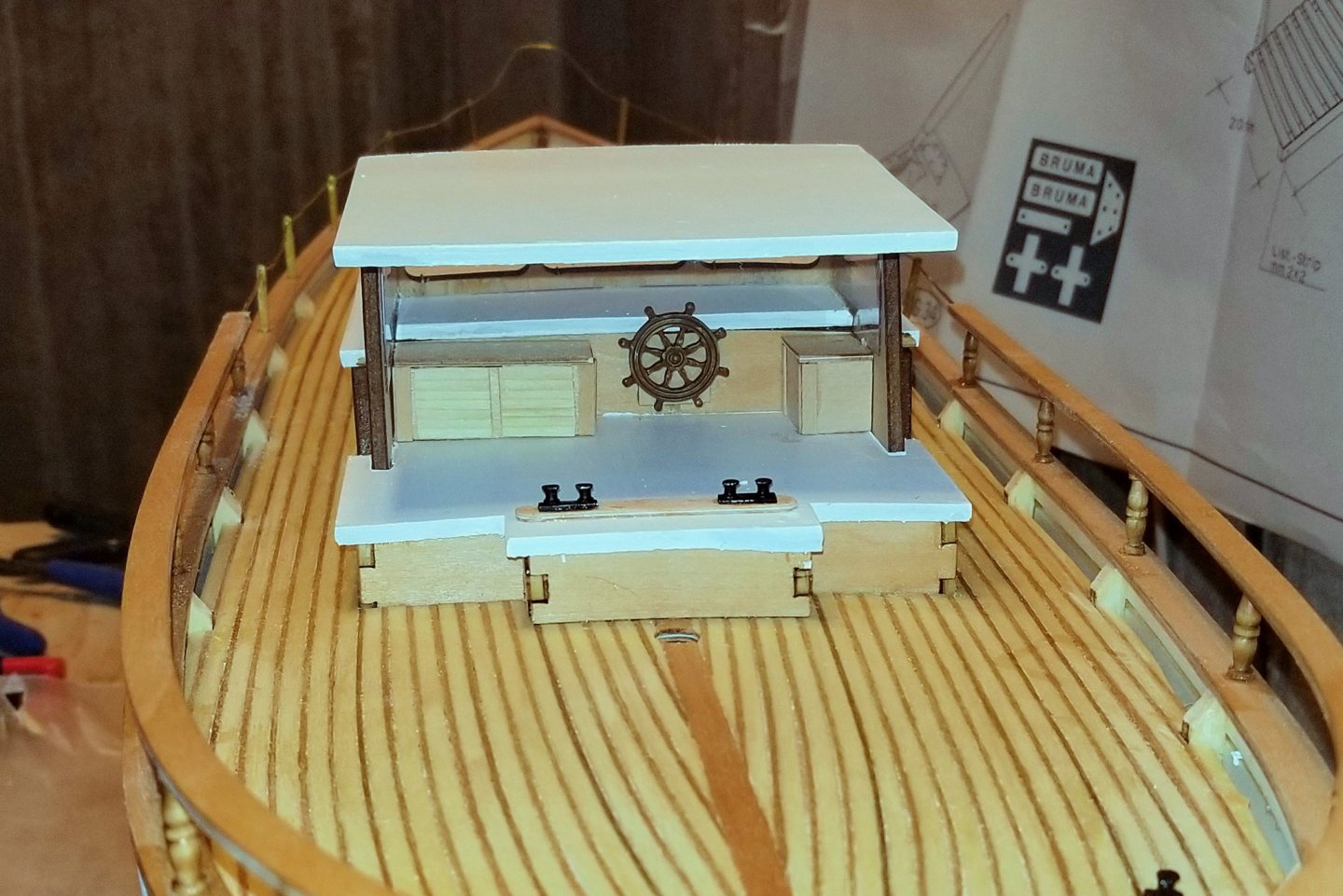

Assembled and mounted the cabin structure. Building this takes some forward planning, to get the subassemblies right and square, and then paint and assemble things in a workable order. The instruction sequence isn't the best. Regards, David

-

Bob: It works better than a brush to get a really smooth surface, but the main way I avoided lap marks is to use 5 coats. That's what it took to get a uniform color. The paint was just a good quality hardware store flat acrylic interior paint. Regards, David

-

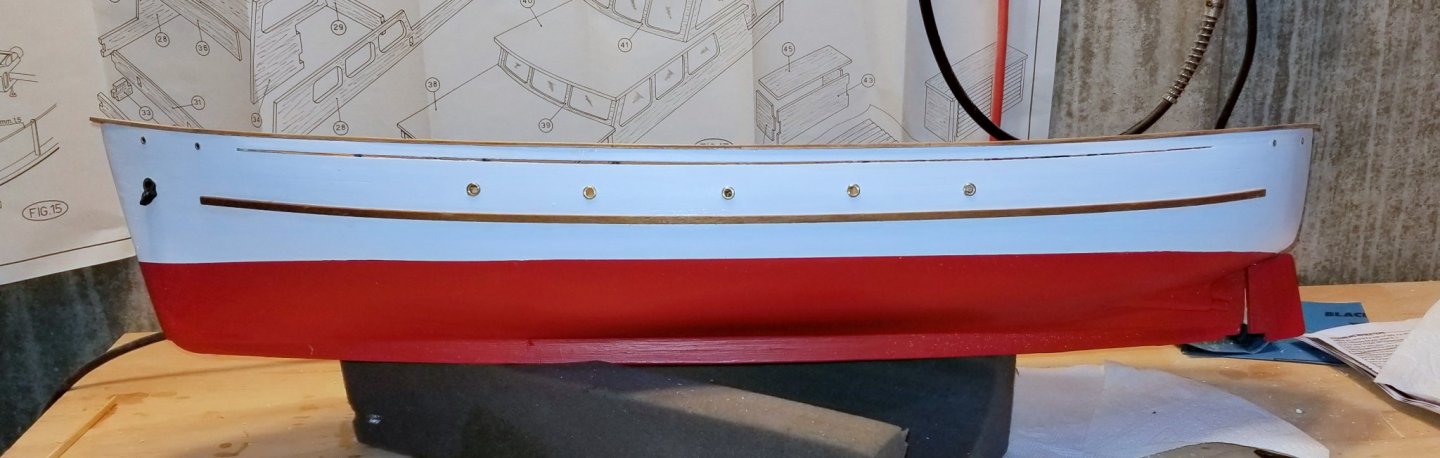

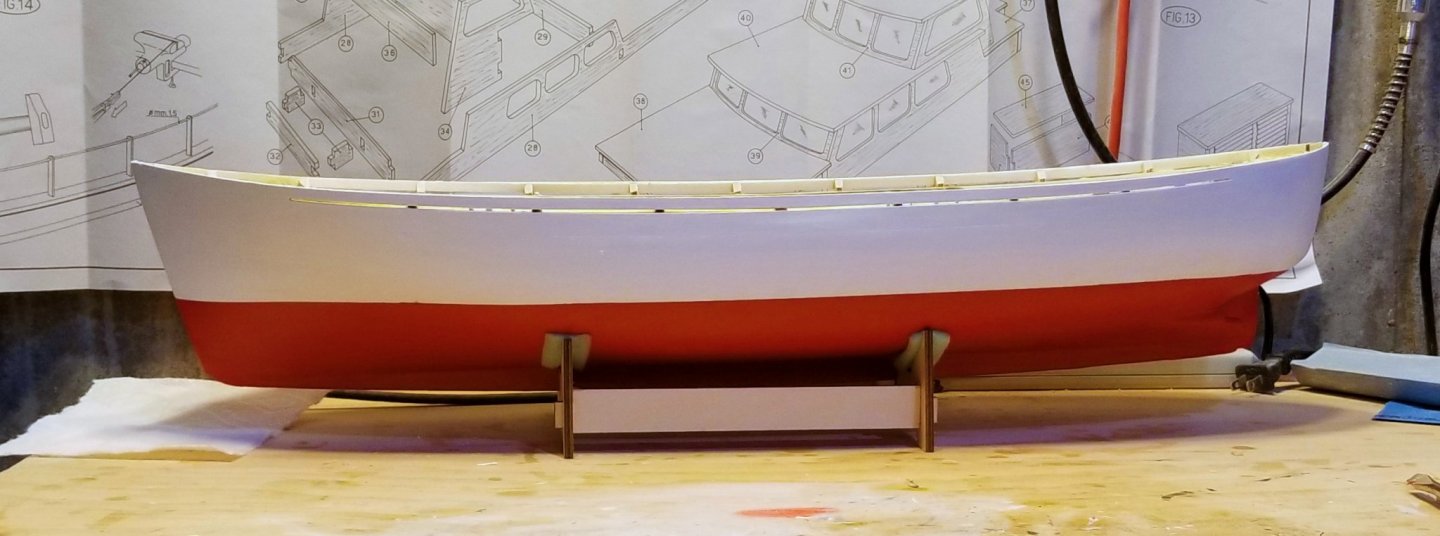

I've painted the hull. Two boats ago, I got fed up with spray paint because of the unavoidable mess it makes in my workroom (spray particles out from the spray area and onto the floor), and problems with tracking it out of there and into the house. Can spray outside in summer, but not in winter (which is much of the time here in Boston. So this is brushed on with a foam brush and 5 coats of white and 5 coats of red. Looks good up close, and no mess! Regards, David

-

Started on the propeller shaft housings. I've done one. Here are pictures of the unfinished one, and the one I've done. Regards, David

-

I've now finished the second planking -- the picture here shows it sanded with a coat of varnish. Next step is to build the fairings over the propeller shafts, which are made of wood strips. Then some painting. Regards, David

-

Cornish: I'm now building the Bruma from Mantua. Here's the log. https://modelshipworld.com/topic/22550-bruma-by-drobinson02199-mantuapanart-scale-143/?tab=comments#comment-670233 Regards, David

- 133 replies

-

- cutty sark

- mantua

-

(and 3 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.