-

Posts

6,725 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Keith Black

-

What a pleasant surprise to see a update on the Tiger, Siggi. I hope your renewed work on the Tiger is as enjoyable for you as it is for us.

-

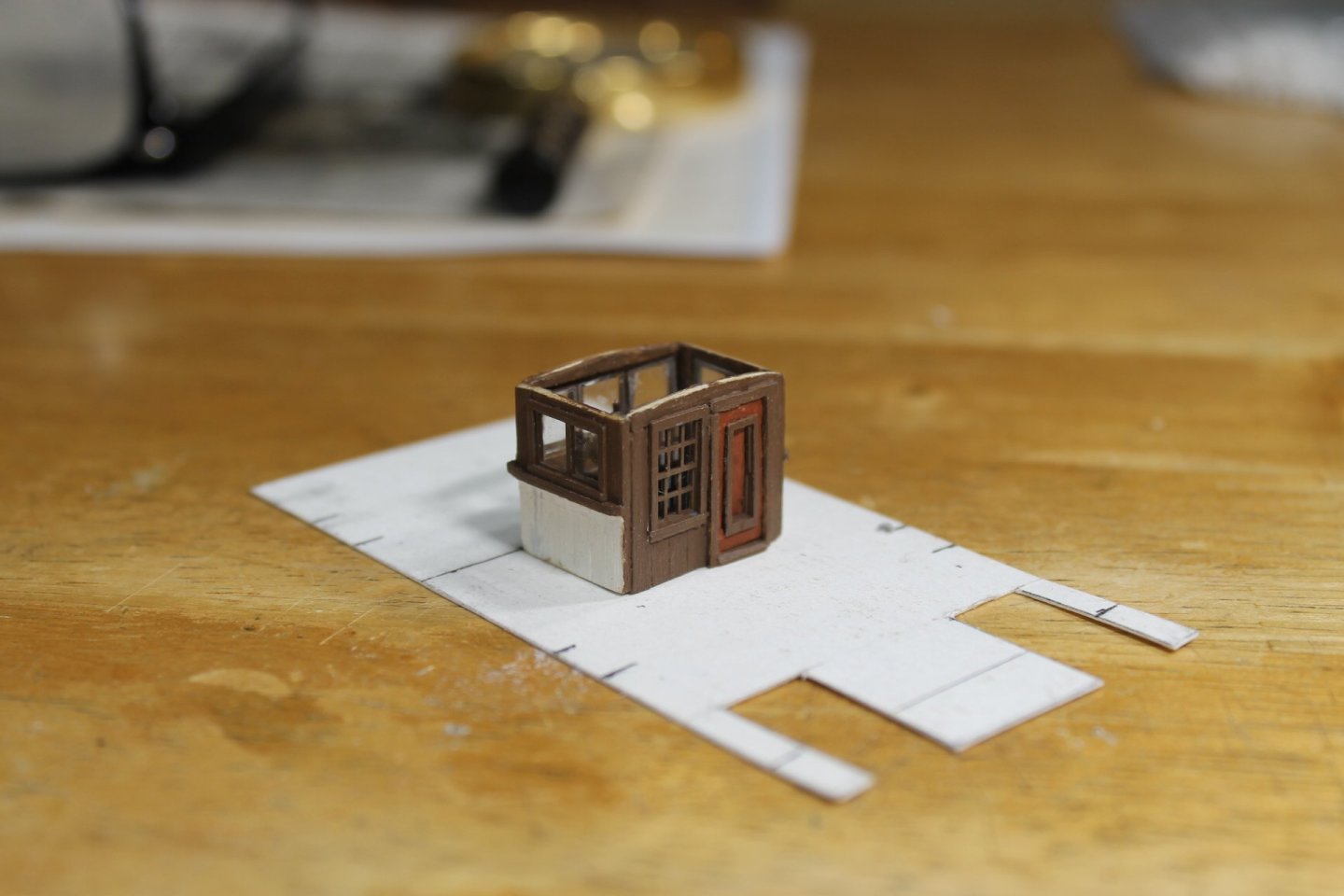

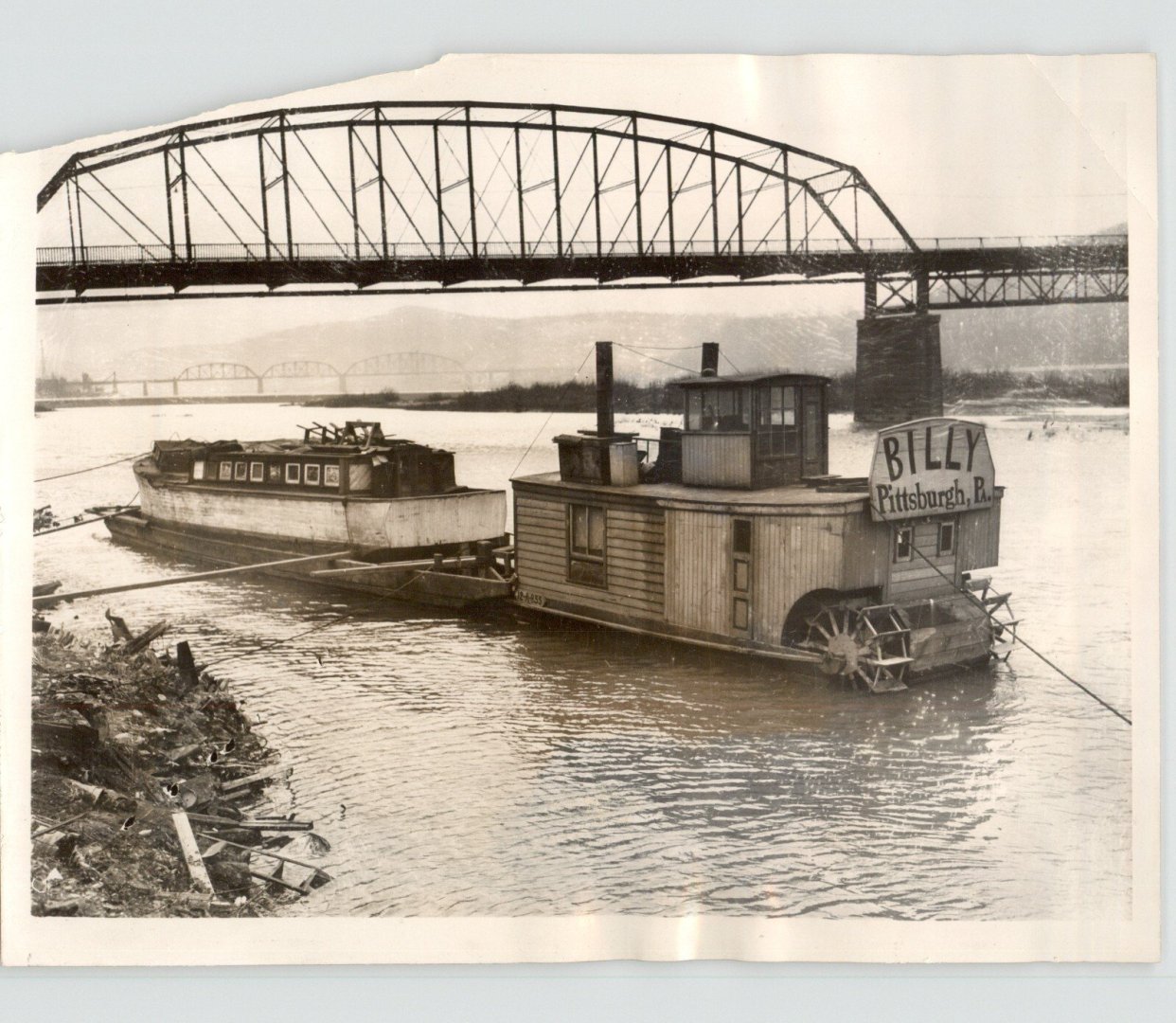

Thank you for the likes and your comments. I'm almost done with the pilothouse. All that remains is the roof and the mystery object on top. On the inside I added the ship's wheel, my signature control arm, and a spittoon. Sorry, Bob, no whisky barrel. The windows are glazed and the floor I almost forgot is in. Which left the door. Looking at the press photo the PH door is the most elaborate piece of woodwork on Billy. It's pretty danged fancy for a sternwheeler especially Billy. I'm sure it was from one of the buildings Engel salvaged to build Billy. It had fancy trim, panel, and appears to have bene painted/stained two different colors. The doors in my other builds have been simple utilitarian and left open where one could see inside. I choose to keep the door closed as it is in the photo. I used one of my spare windows for the trim by removing stiles and rails and narrowing to fit the door. I painted it in two colors and the jury is out. After living with this a couple of hours I think it would look better if was just the single brown color. What the door in the photo lacked was a doorknob which I thought strange but then I realized. this is Billy. Thank you for your support and for following along. Keith

-

Bruce, should you come up dry at Michaels......... https://www.ebay.com/itm/204584823974

-

Bogdan, I forgot to mention the supplier Cornwall Model Boats (link provided below) they have a great selection of models and fittings. I believe they have a 50 pound min and shipping cost are okay. They provide two types of shipping, Royal Mail for 17+ pounds and UPS Express for 27+ pounds. Up till my last order I have always chosen Royal Mail but it took 10 days plus for my orders to reach me here in the States. This time I paid the extra 10 pounds and choose UPS Express and my order arrived 3 days after the order was placed. Incredible! Please take note, I have no financial incentive in mentioning them. https://www.cornwallmodelboats.co.uk/?gad_source=1&gad_campaignid=20303646385&gbraid=0AAAAADCl8FfzKOMKjRE2G3kHWu5506oGp&gclid=EAIaIQobChMIusbg3o_tkAMV40l_AB26iR6EEAAYASAAEgK7APD_BwE

-

Wow, congratulations, Glen! That's long over due in my opinion. I do hope they won't mind if you do a build log?

- 156 replies

-

- Queen Annes Revenge

- bottle

-

(and 1 more)

Tagged with:

-

There is nothing wrong with your model, Bogdan. Beautiful work thus far and I look forward to following along till its completion. During the course of our builds everyone of us is forced to make compromises due to the lack of preferred material or our lack of skills to perform a given task and there is absolutely nothing wrong with that. We are after all, only human. I am glad that you chose to start a build log, 👍 Keith

-

Bogdan. welcome to MSW. Glad to have you aboard. Myself and others have taken to modeling common everyday work boats from 1750 to present. There are a vast array of nondescript but worthy subjects to model that require little rigging whose beauty is found in the quirkiness of their design. Keith

-

Thank you for posting the video, Eric. I wish it was early summer and I was riding that ferry! I had a question regarding what that was aft of the wheels. I thought it was a monkey rudder but the video confirmed, it's a bit strange in comparison to others but none the less it is a monkey rudder.

- 457 replies

-

- sternwheeler

- Hard Coal Navy

-

(and 1 more)

Tagged with:

-

The latest to begin the Model Shipways 3 kit set

Keith Black replied to Taken Aback's topic in New member Introductions

Brian, welcome to MSW. Glad to have you aboard. -

James, very impressive work considering that this is your first.The hull with it's deck furniture look very nice. 👍

- 75 replies

-

Getting Started: From Dollhouses to the USS Constitution

Keith Black replied to Jasennord's topic in New member Introductions

Jasen, welcome to MSW. Wising you all the best with your modeling journey, glad to have you aboard. -

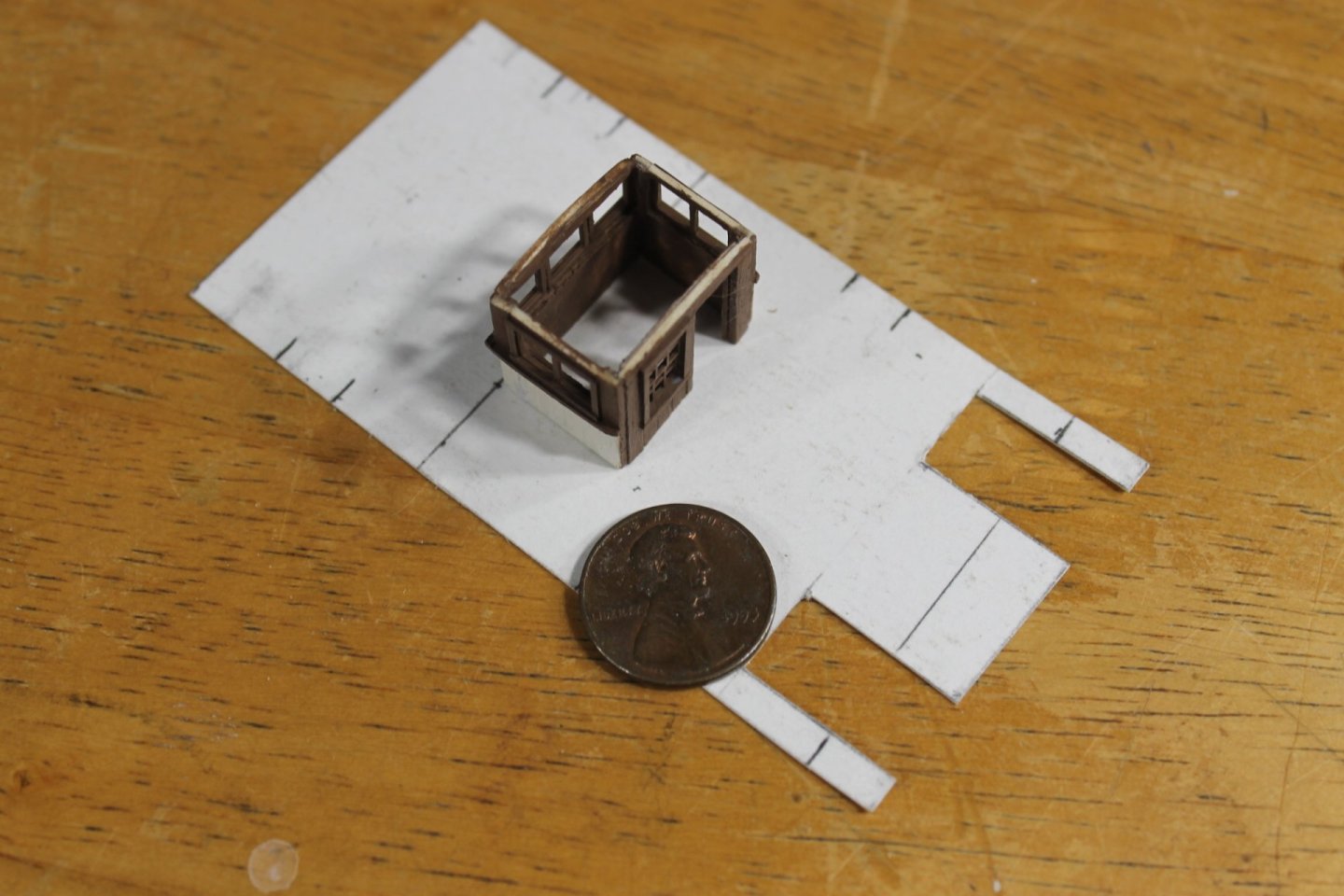

Thank you, mcb. Yes, Billy has a lot of colors (Rainbow Billy ) including some raw wood at the stern between the wheels. Thank you, John. Yes, I think I was able to capture the look of the PH pretty accurately. Hopefully I'll be able to say that when finished with Billy. Thank you, James. Me and you both! Thank you, Geordie. Tichy Train Group windows are the best (IMHO) and they have a great selection. The coin is a US Penny and has a 0,70 inch diameter.

-

Thank you, mcb. I enjoyed having you along for the journey.

- 457 replies

-

- sternwheeler

- Hard Coal Navy

-

(and 1 more)

Tagged with:

-

I have missed building. I know that research and kicking ideas back and forth with you guys is the necessary first step but when I find a subject that grabs me I wanna jump right into building it. I think what I like best is building a thing in my head. Figuring out the sequential order/steps necessary to reach a successful conclusion. It's figuring out the puzzle that keeps me coming back again and again. Well, Billy is off and running! I've got the four walls of the pilothouse made, windows (from Tichy Train Group) installed, and the first bit of paint applied. I wish I could have made the PH two feet (0.20) longer but I was restricted by the size of the windows and trying to replicate the photo. I originally thought Billy was 40 feet in length but after placing the PH on my deck card I've adjusted Billy's length to 35 feet meaning when completed Billy will only be 3.5 inches long. As I said, Billy is going to be the Matchbox of sternwheelers. To complete the PH I still have to add the window glazing, make the door, add the roof, and make that round air vent or fire alarm bell that sits of top. I couldn't use stain as it wouldn't have covered the windows so I used craft acrylic paint. I'm not necessarily in love with this brown color, maybe it'll grow on me? Thank you to everyone for the likes and for helping get Billy off the ground. Your support and following along mean the world to me. Keith

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.