-

Posts

6,728 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Keith Black

-

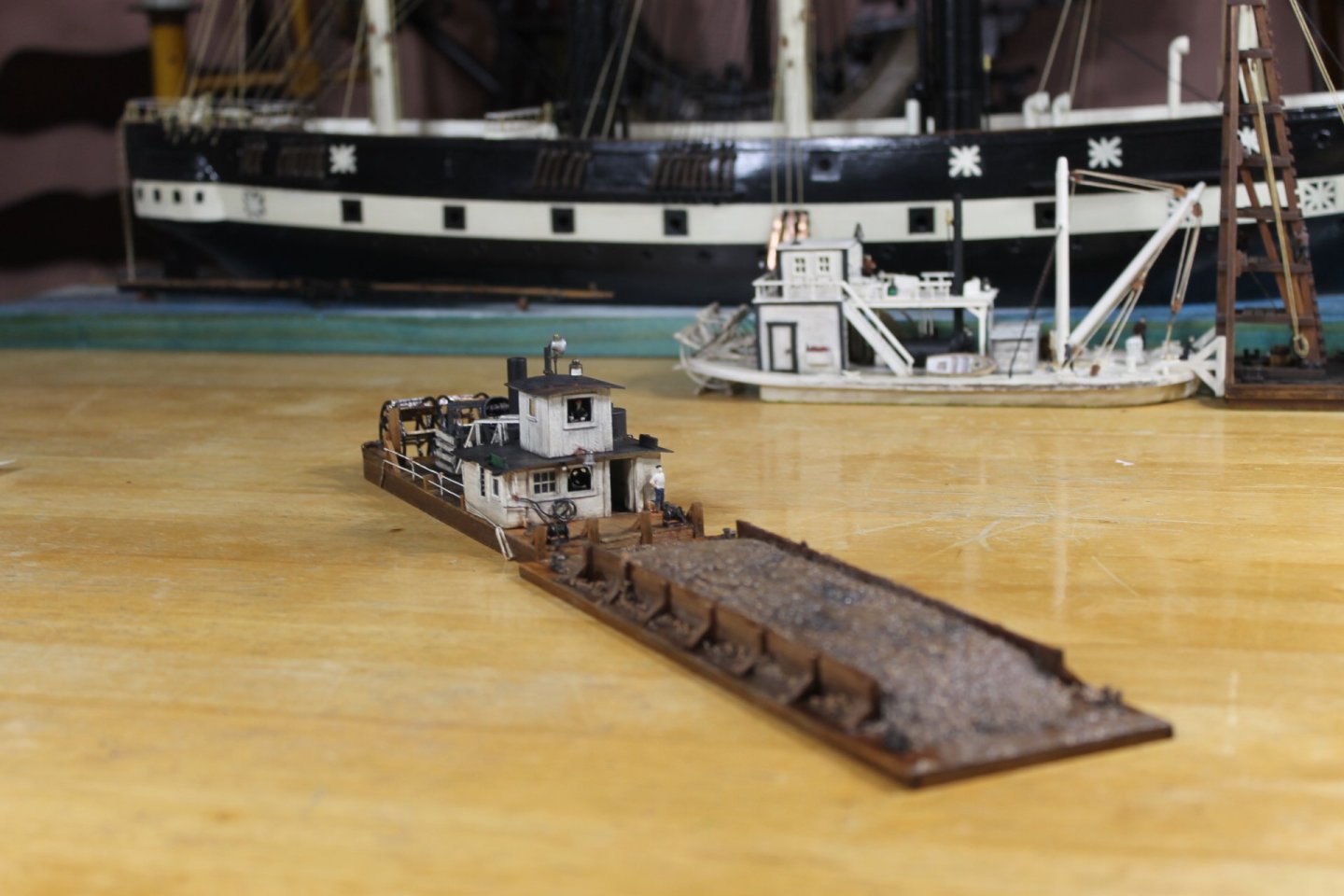

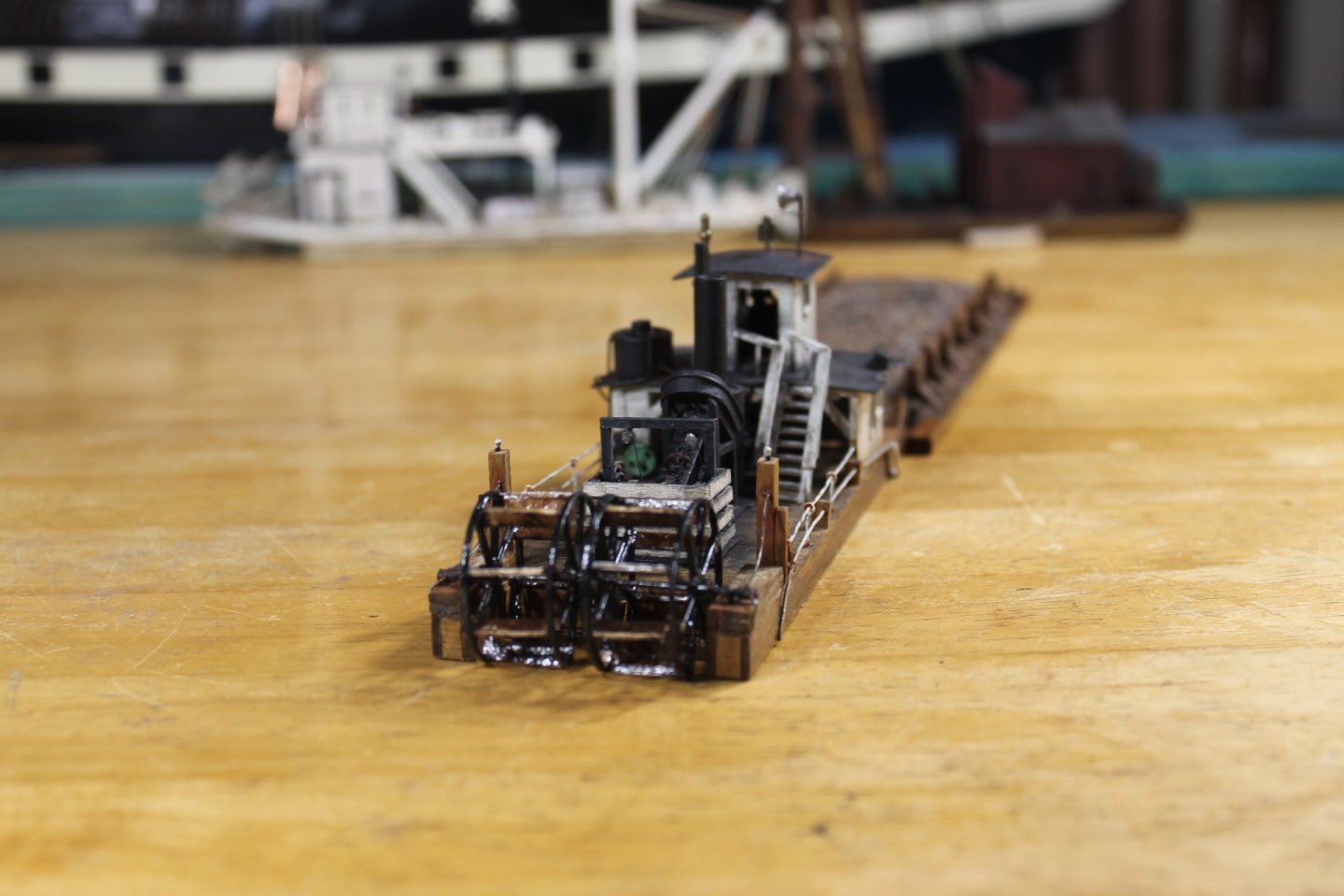

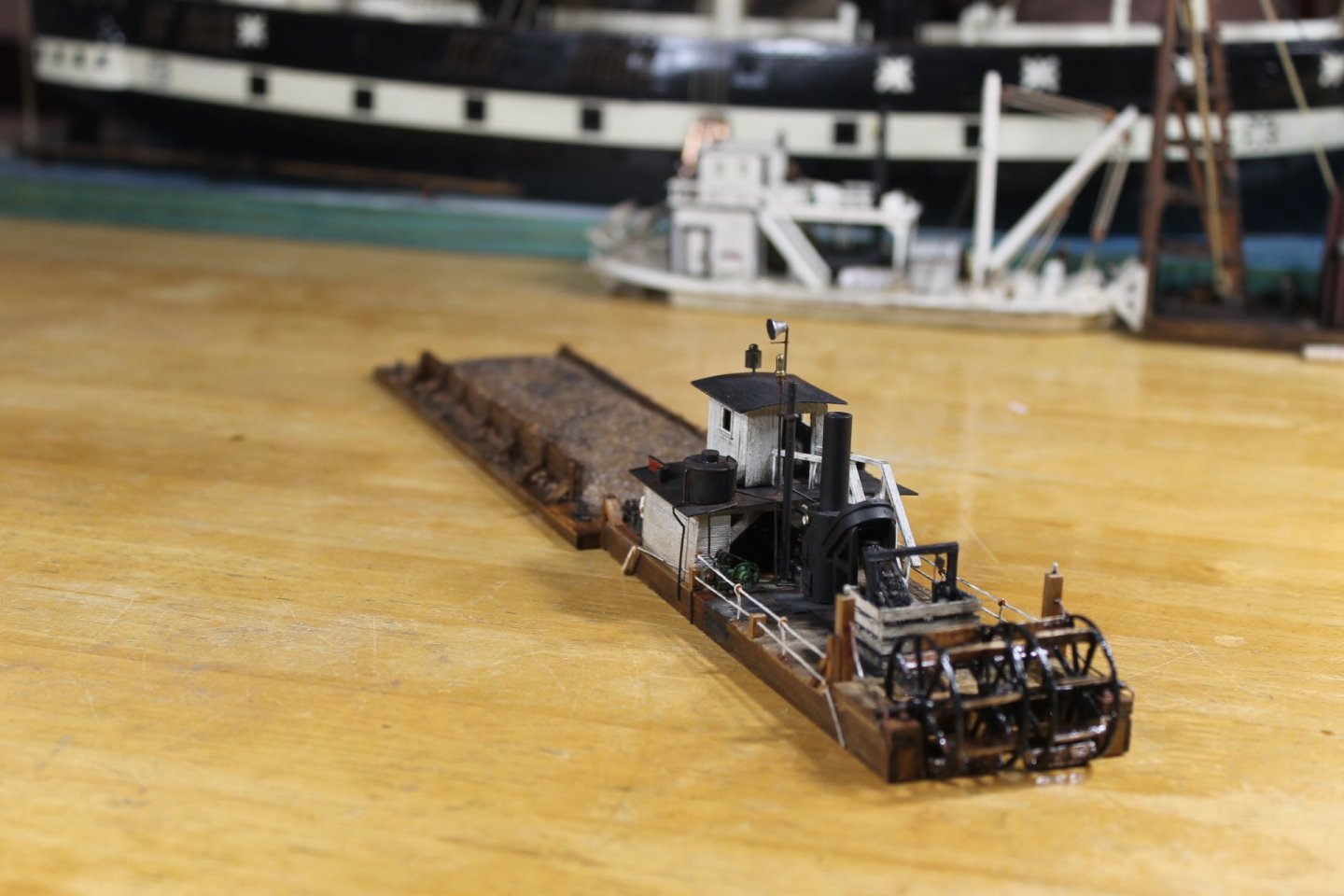

To all of you who have supported me during this build with your comments and likes, thank you. I have enjoyed each of you being part of the journey. TA DA! Tis done. I fought trying to get the color of the dredge material to what I thought it should look like. Eric, you know the Susquehanna better than most, I hope I'm close because it's too late now. It's crazy in that the colors change depending on the light, in fact you see evidence of that in the photos, one to another. I tried making the material at the ends and outside of the side wall look like drying sand while keeping the center of the load looking wetter. I made the barge floating lower due to load and the fact that it's a soggy ole barge, And so this journey ends, I hope you were able to find a smile along the way. Keith ps. I mentioned displaying Lula and the pile driver with the Susquehanna River sternwheeler and barge. Here are a couple of photos showing my thoughts. on that. Note the color of the material in these two photos.

- 457 replies

-

- sternwheeler

- Hard Coal Navy

-

(and 1 more)

Tagged with:

-

You be makin' the penguins proud with them ratlines, Bob. 👍

- 261 replies

-

- Victory Models

- Pegasus

-

(and 3 more)

Tagged with:

-

Congratulations on completing the Oryol, Phil. She turned out looking amazing.

- 288 replies

-

- Card

- Pre-Dreadnought

-

(and 3 more)

Tagged with:

-

News and photos at six! Ken, thank you for sharing. Thank you for posting, Julie.

- 457 replies

-

- sternwheeler

- Hard Coal Navy

-

(and 1 more)

Tagged with:

-

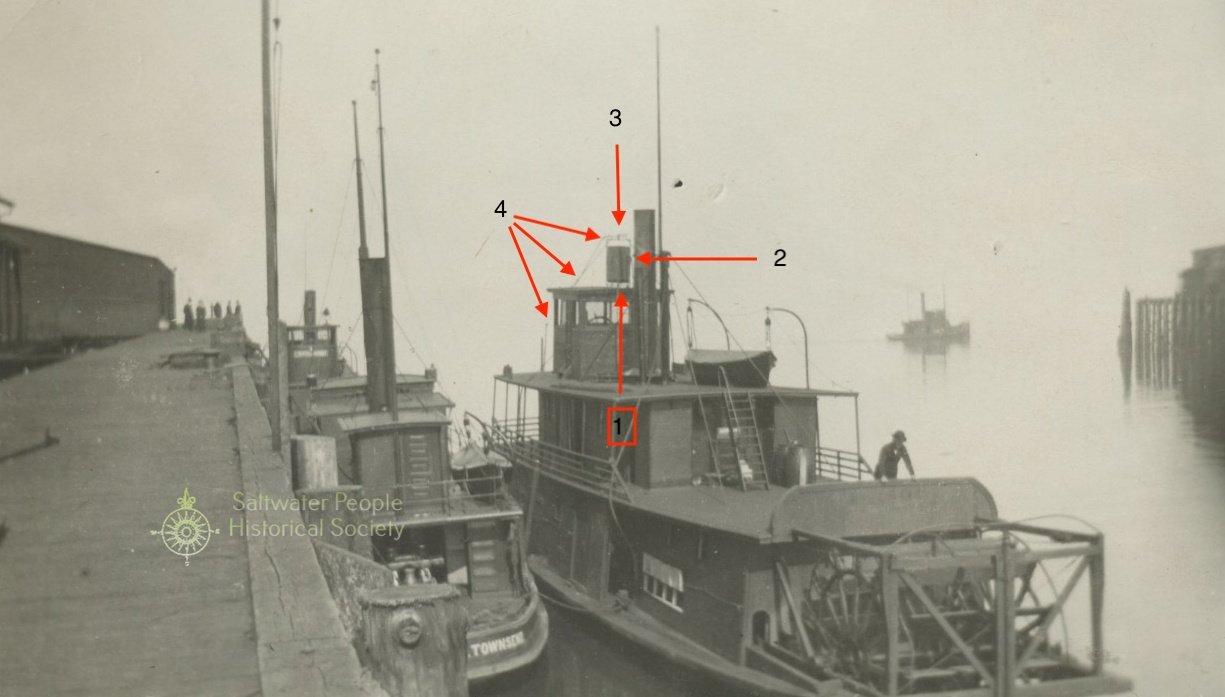

Ken, I think the legs would be too wobbly (1) and short on head room (3) plus the pilothouse its self is three decks high. Eberhard, awfully small for a water tank and the spindly legs wouldn't support a lot of weight. Pat, I think you're spot on. I believe it's a cool safe, cold safe, cold box, food box, or whatever you want to call that item. I've always referred to them as a cold box and will do so henceforth. Ken, Eberhard, and Pat, thank you so very much for posting. The reasons why I think this is a cold box... Item 1. Thin legs that support the cold box elevated off the pilothouse roof for air circulation. Item 2. I think that is a latch. Item 3. Appears to be a nozzle. I think this is for occasionally spraying water into the cold box to help keep food items cool. Item 4. Water pipe leading to the item 3 nozzle coming from the boiler deck, the same deck the galley is located on. The cook would have been the one in charge of controlling when and how much water was applied to the cold box.

-

Congratulations on getting the Revenge into the bottle, Glen. She's a real corker that one, fantastic execution. 👍

- 156 replies

-

- Queen Annes Revenge

- bottle

-

(and 1 more)

Tagged with:

-

Adrian, welcome to MSW. Glad to have you aboard.

-

Hello from the Finger Lakes Region of NY state!

Keith Black replied to Rinekar's topic in New member Introductions

Rinekar, welcome to MSW. All the best building the Adder, glad to have you aboard. -

Good looking busy work while waiting for the hull to dry, James. Regarding rigging line..... cotton line stinks, it's fuzzy and its life expectancy is very limited. A lot of builders (including museums when doing rigging restoration work) are using polyester thread. It's almost 100% fuzz free and it has a much much longer shelf life than cotton. I use Gutermann as do many others. You get a couple of kits under your belt and you'll start wondering why your paying high kit prices and scraping 50% of it.

- 75 replies

-

James, I'm unfamiliar with Varathane Polyurethane, I have only ever used Minwax Polyurethane. Once upon a time I did the same thing as yourself and tried wiping down with paint thinner and made a dog's lunch of the whole thing, In the end I still had to wait till the poly dried where I could then sand down and start over. Lesson learned......set it aside and wait till it dries. Find something to work on while you twiddle your fingers.

-

Sounds a bit sketchy to me, Patrick. It seems counterintuitive that you'd be able to apply pressure and drill a straight hole? A pin vise is an inexpensive tool designed for the sole purpose of drilling holes.

- 75 replies

-

You're more than welcome, James. The double ended pin vise is the best option, IMHO. They allow one to get closer if necessary. And yes, it definitely would have made it a lot easier. When drilling holes for nails you can drill a undersize hole, tap in the nail hoping pressure will keep the nail in place. Personally I like to drill slightly oversize, easily insert the nail with a bit of CA (super glue) on the shake to keep it in place. This is because wood dries out and shrinks and the nail could come loose. Using CA kinda insures the nail won't come out.

- 75 replies

-

James, if you have a pin vise you could drill holes where the nails would fit in neatly without hammering. If you don't have a pin vise it is a simple and relatively inexpensive tool that you should have, IMHO. The bottom link is for micro drill bits and included is a pin vise that is absolutely worthless but the drill bits are the ones I buy. https://www.amazon.com/Double-Detachable-Manual-Jewelry-Making/dp/B09NMGSR87/ref=sr_1_59?dib=eyJ2IjoiMSJ9.B22oabypIjH-iebkMfnzPJKL4a1vE532JIJK1jDQB5W2gooxlhfqH39wWAFNZeHkDeShVtejK1vwPqY57H38qn_-yZZTC4QhcHhvfAZ4zAOzZv61P6Hcp3o4WCbd77iPoYIju3j-aZe_R0-s-APT7HCH3_N5M8lGOFEn5ZNRe45zAkjM4VZQPcu7qaGB3-C1iuHI9fPgHLqlyNVNxHBKtBVJDokCexG8CAF4lcGnqKBrcJjFjEVSrGxuVGQXzZgLZHuJPmgdpY_og7DxQXAvar1YjQ8TRZOH9BrsKgr3wUo.vmcSnzUjNyKB76jttn8ZuITxbXpEFAo07LgWqqSykCA&dib_tag=se&hvadid=693388925260&hvdev=c&hvexpln=67&hvlocphy=9052573&hvnetw=g&hvocijid=12088025368565546822--&hvqmt=e&hvrand=12088025368565546822&hvtargid=kwd-436988750327&hydadcr=7499_13183988&keywords=pin+vise+amazon&mcid=6b07454c0cae36ef8775ed1eb0e4fe65&qid=1761378944&sr=8-59 https://www.amazon.com/Carburetor-Numbered-Jewelers-Mini-Pin-Plastic/dp/B0FKN8X949/ref=sr_1_13?crid=15GZPT3FXGCRK&dib=eyJ2IjoiMSJ9.tfi-QX1AoFqRxotiH0RCBQhs9jLI2An9Vwl8Tur4mOTurcnktlFWze0azTOjpCwiQmCXb-hR3HmCE0edGKX-mq8cxP-VMsBXMidh7pC76e1ZqVh8AArbYYk38se2VN868mxo8hv_pP2tV5fJmcjm0Q9wOOFRDYJZVudpnf76899vBqRCezuUeYw4qgs2CMl0z6Bc_Q2rz0HIpvv3pUq_1f1wuC2NEjPoAV-B4UhliMY.zW-Dt9aNDPFb74AtTli_s66MTrMCStxaT7gPjp36RcI&dib_tag=se&keywords=micro+drill+bits&qid=1761379202&sprefix=micro+drill+bits%2Caps%2C108&sr=8-13

- 75 replies

-

- 156 replies

-

- Queen Annes Revenge

- bottle

-

(and 1 more)

Tagged with:

-

Great planking job for the fist go, James. She's looking right smart.

- 75 replies

-

Thank you, Keith. I can't wait till the material dries where I can start playing with pastels and poly. Thank you, Eberhard. Ken threw that "culm" fastball right past me as well, I had to Google that unfamiliar word for the meaning. Thank you again, Ken.

- 457 replies

-

- sternwheeler

- Hard Coal Navy

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.