-

Posts

371 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Paddy

-

Thanks Bob. The actual size and not scale size was what I was referring too. I should have been more specific in the question. Again, fine work. I had the Lilliputians treenail folks at work again yesterday as I waited for some glue to dry. They’re learning more about trennals production as we go along.

-

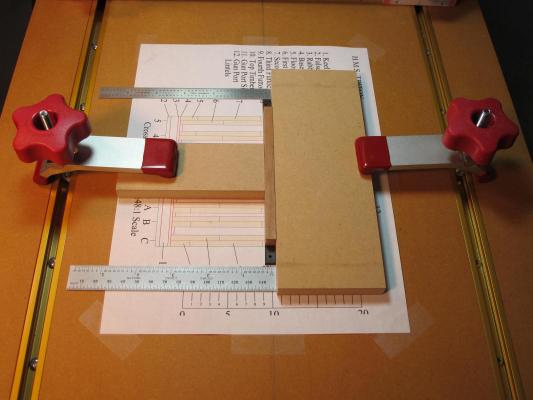

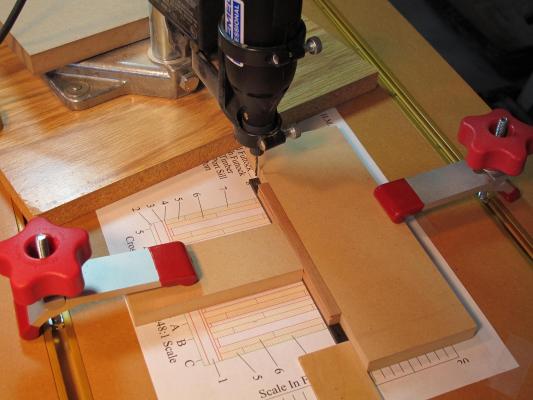

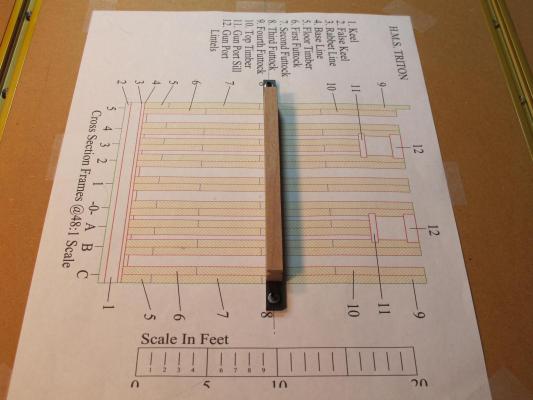

Spent my time in the shop today setting up the gantry building board preparing for the mounting of the frames to the keel. In the mean time I can use the GBB for dry fitting the frames to insure the proper fit before the glue-up starts. Another is simply getting familiar with the board and learning to use its advantages. Setting up a temporary fence to keep the keel from moving while drilling the bores for the 2-56 tap. Clamped the Dremel tool to the GBB for drilling the bores. Taping and mounting the keel to the GBB. Dry fitting the “C” and “B” frame to the keel.

-

Grand work on the hatch coamings. I really like the look of the Redheart you used and just checked a dealer I frequent and they have some in stock. I feel another purchase for the dockyard coming on. More beautiful joinery!

- 332 replies

-

- Triton

- cross-section

-

(and 1 more)

Tagged with:

-

Having reached a goal with my anchor pool yesterday I ordered a Byrnes 4” Table Saw with some extras like Slitting Blades. Being just a wee bit excited about it I thought I would share my good fortune with the squadron. Looks like I plan on continuing with the ship building and especially scratch building for some time. You all have heard me say this before but I’m thoroughly enjoying this experience.

-

Started laying up the “B” frame futtocks today with some minor adjustments to the jig base but the biggest help was the purchase of some different “C” clamps to insure the stability of the jig frame as I work. I’ve started the process with the abaft futtocks turned up so that I can make sure that futtocks are in alignment and to make it easy to make adjustments before actually applying glue to the butt joints. I’ll let this dry overnight and then tomorrow I’ll flip the frame over, templates lines down, before laying up the forward futtocks. As Russ suggests when finally pulled from the jig you have templates on both sides of the frame to aid you in any cleanup you wish to do. Also gives you a guide for placing you treenail holes from both sides. Now, the rest of the squadron may have different approaches to their frame building sequences and this is just the way I seem to have settled in. That could well change for me by the next frame as these are the first frames I’ve ever built. P.S. Here’s the birthday ice-cream cake Annie surprised me with Saturday. Wish I could have shared it with the whole squadron.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.