-

Posts

371 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Paddy

-

Absolutely beautiful work Rusty and thanks for the detail about your work as you progress.

- 332 replies

-

- Triton

- cross-section

-

(and 1 more)

Tagged with:

-

Hello Pete and Larry, Thanks very much for that gents. When I attempt the four for the Triton I’ll just pretend that they were booty from four different foreign foundrys. Looking at a printout of my Keel Parts Templates page and laying a straight edge on the Keelson there is a slight curve to it. Is this correct or has my printer run amuck? Cheers

-

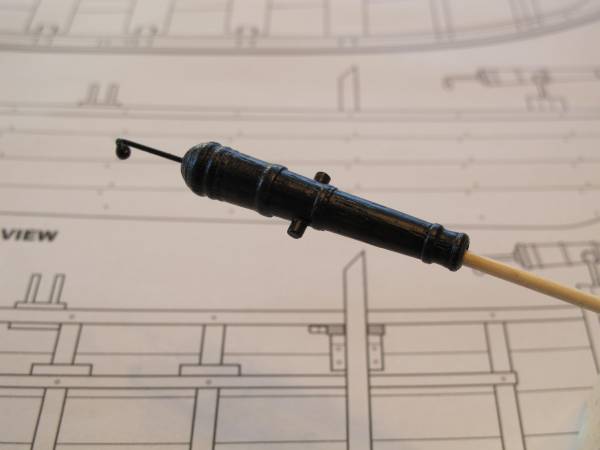

Hi Grant, I have decided I’m going to turn the cannons. So, I thank you for the encouragement. As soon as I known their dimensions I’ll order enough blocks of Gaboon Ebony to do the turnings. The more I think about it the more I look forward to it. I’ve been working on a swivel gun on the lathe for another project and feel I’m beginning to make some progress; the lathe is a new acquisition. The first photo is my second attempt and the cannon is turned in walnut then stained with a black Sharpie marker. The second photo is of the cannon in the lathe now and it’s being turned in Gaboon Ebony. Fingers crossed that it comes to a fair completion. BTW, the measurement is from the second reinforcement ring to the left to the start of the barrel muzzle on the right which is approximately 18 mm. Have been working on the gantry system building board but maybe finished with it this weekend and can get back to finishing the cannon plus get started on the keel part of the Triton CS project. Thanks again. I’m really looking forward to the start and joining all of you. Cheers, Paddy

-

Joss: Thanks for the reply. Turning one in wood may be doable, but turning four that are duplicates now there’s the rub. rocker: Thanks for the welcome and I look forward to being part of the group. Pete: Thank you too for the welcome. I agree that turning the cannons ourselves would be fun to try and I’ll sure give at least one a go and see how it turns out. You may know that I’m now working an ebony swivel gun in the lathe now for the Batteau. I’ve temporarily stopped for now while I get the gantry system up and usable. Russ: Thanks. So nine pounders they are. With Joss and Pete’s encouragement I may give them a try on the lathe. Getting four close enough may get me wrapped around the axle, but if I do one I’ll then have to try at least another. Thanks again gents for your input.

-

Though I have not started the Triton’s keel I decided it would be alright if I started my build log. I have questions that come to mind that I would like to post to begin preparing for the steps forthcoming. The only thing that I known at this point is the False Keel will be milled out of African Blackwood and cutting its length long enough to screw mount* to my gantry building board as bbrockel mentioned in his log. I’m still thinking about the wood I should use for the Keel and Keelson. One of the questions that I have concerns the cannons that will be used in the cross section. If I can count from photos I’ve seen in other logs it looks to be four but what is the caliber? Looking forward to joining you all and getting the keel step completed so I can take the next step and request access to the rest of the drawings. This is going to be a fun project! * Board drilled and tapped for 2-56 machine screw. My gantry type building board is made of MDF and is not quite complete but I'm getting closer.

-

Hi Pete, Just spent the time going thru your log and want to thank you for the detail you're posting. You all have injected me with the bug to do the Triton Cross Section as my first build when I get the gantry building board finished, except I can start on the introduction page of the keel before that and get a log going. Then, on to the next step. Thanks also for starting the pinned threads on the "Timber List" and "Frame Construction" BTW, you do very nice work.

-

Long9Ron: Thanks again for your help tonight. I will spend more time in your thread but what I've seen so far the cross section is looking great. I also see there are many good suggestions from those following along. I'm working on a gantry building board and hopefully it will be ready to put to work before to long. The Triton Cross Section is beginning to look like a good candidate to run the first shake down with. Cheers

-

Cross-section by russ - FINISHED - 1/48 scale

Paddy replied to russ's topic in - Build logs for subjects built 1751 - 1800

Thanks Long9Ron, I appreciate it.- 69 replies

-

- frigate

- cross-section

-

(and 1 more)

Tagged with:

-

Cross-section by russ - FINISHED - 1/48 scale

Paddy replied to russ's topic in - Build logs for subjects built 1751 - 1800

This looks like a great project Russ. I'm a beginner at model ship building but scratch building and a cross section like yours is what interests me the most. Would you please tell me how I may get the plans for the Triton Cross Section? Regards, Paddy- 69 replies

-

- frigate

- cross-section

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.