-

Posts

5,504 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by rwiederrich

-

Thanks Ed...yes I read that reference on sheer poles myself. I have a reference somewhere else that makes additional mentioning of sheer poles for shroud twisting and distancing control/prevention. I'll have to find the reference for tarring the lanyards. Superb work. Rob

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

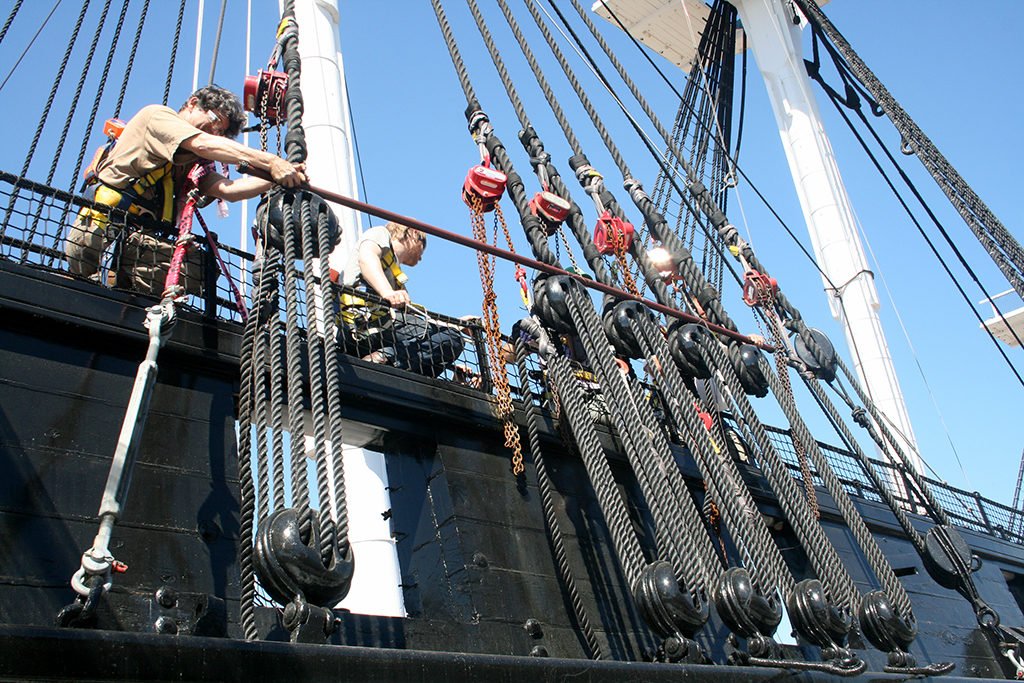

Ed...here is an image of re-rigging the Connie...note: the tackle cinching up the lanyard(as you mention earlier). One thing I want to point out is why so many folks model lanyards with tan line....Yes it was considered running rigging in a sense but it was also standing and needed weather treatment. I have read where it was coated(as all standing rigging was ) in a thinned tar for protection. They are replicating that here on the new Connie rigging......so then why not replicate the same practice on modeling the same? Just wondering. Rob(Avid follower)

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Interesting read. I gather from all this that in practice a left or right handed twisted shroud coupled with in in or out layed rope with left or right drawn lanyards could cause the shroud entire to twist..making the lanyards roll back over themselves...in essence twisting the entire arrangement. I've seen it happen on models...so it is not unreasonable to imagine it happening in practice. Acute observations. Rob

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Are you saying your grating is an incorrect representation? I would think you would want ventilation from the space below and if the grating was not present the air from below would be trapped under the awning. Just a guess though. Rob

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

And I completely agree with Jack who whole heartedly agrees with Allen. Rob

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Wonderful work as usual Ed. I don't know, it must be me,(This is NOT a criticism), but I never use a jig to hold the deadeyes or use wire to establish equal distance for my lanyards. I simply eyeball them...and I'm pretty darn close every time. I'm also guessing they(riggers) never used a jig on the real ships...and I'm also confident, keeping the deadeyes precisely the same height wasn't a major esthetic requirement. The seizing was used for synching up the tension of the shroud and they all stretched at different rates. Irregularities were expected if not common....slight irregularities make the rigging more real-world credible...IMHO On the other hand........a symmetrically rigged ship..is a smart ship. Not to mention it probably makes for a simpler install for some. Sorry for the rant. Impeccable build. Rob

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Canvas covers a world of details one can avoid messing with....plus the boats were probably canvassed to protect interior supplies and gear. Can't wait. Rob

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Fantastic metal working Keith....I really appreciate that kind of attention to detail...and you do it so effortlessly. Rob

-

Good night nurse! Magnificent work and splendid craftsmanship. Your technique is outstanding and you have perfected your method, evidenced by your clean work. I applaud you. Rob

- 487 replies

-

- ship of the line

- 80 guns

-

(and 1 more)

Tagged with:

-

Patrick....will you be modeling the lobster tail dinner served on the main dinning table? And glasses full of wine? Rob(Do you wear magnifying glasses when you work?)

-

Nils..have you decided on the manner you will attack the boats and davits? Vacuum-form or plug? Rob

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

First liner to sport 4 funnels...and you made her come to life....luv it. Rob

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Pandora by marsalv - FINISHED - 1:52

rwiederrich replied to marsalv's topic in - Build logs for subjects built 1751 - 1800

Magnificent build! I love the clean precise lines and manner you are working to. Rob -

MONTAÑES by Amalio

rwiederrich replied to Amalio's topic in - Build logs for subjects built 1751 - 1800

Magnificent! What a quality build. Rob -

Fantastic work...coupled with insight and precision. The thought that went into the fabrication of the tooling let alone the final structure is nothing short of impeccable. Am I mistaken or did you say GAW, that this *version* is for testing procedure and is not the actual model? Rob

- 281 replies

-

- falls of clyde

- tanker

-

(and 2 more)

Tagged with:

-

When I took this class...I had no idea of the extent of the education I was going to receive. Beyond impressed...... Rob

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Ed...was the parceling a form of weather proofing the seized shroud head loops? I like your representation. Fantastic attention to detail. Rob

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Wonderful construction...and smooth lines. Rob

- 287 replies

-

- michelangelo

- ocean liner

-

(and 1 more)

Tagged with:

-

Fantastic work Tom...love your Connie build......The rigging is the best and I'm really looking forward to your work. Rob

- 1,348 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

Good night nurse! Patrick... Well done and all that detail in shucha small exploded version. Great concept...fine execution. Adding the furnishings will be something entirely. Rob

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.