-

Posts

5,504 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by rwiederrich

-

I can't say much, but Steve is dealing with his mothers failing health and has taken time off from his modeling sites for a time. He also recently moved. Rob

- 453 replies

-

- thermopylae

- sergal

-

(and 1 more)

Tagged with:

-

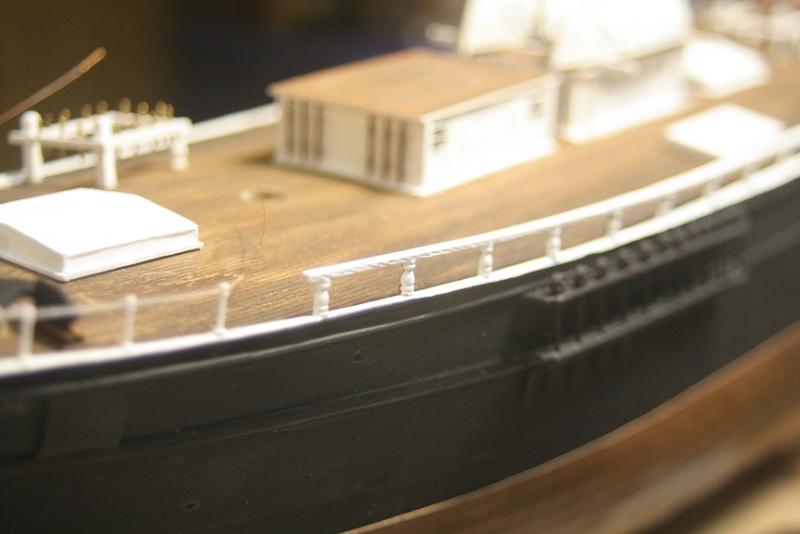

I used wood turned stanchions from Cast Your Anchor and strip mahogany for the rail. Rob

- 1,208 replies

-

- great republic

- clipper

-

(and 1 more)

Tagged with:

-

I tried steaming...and I think I am going to laminate several extremely thin sections together to form the bend of the fantail rail. Rob

- 1,208 replies

-

- great republic

- clipper

-

(and 1 more)

Tagged with:

-

Thanks Russ...I try. I wish my attention to detail was as good as some.....However the designer gave me lots to work with......(ie Donald McKay) Rob

- 1,208 replies

-

- great republic

- clipper

-

(and 1 more)

Tagged with:

-

- 1,208 replies

-

- great republic

- clipper

-

(and 1 more)

Tagged with:

-

- 1,208 replies

-

- great republic

- clipper

-

(and 1 more)

Tagged with:

-

Steve is an email friend of mine and we converse as often as we can...he does a great job and is a great mentor. Good call to post his google site. Rob

- 453 replies

-

- thermopylae

- sergal

-

(and 1 more)

Tagged with:

-

Thanks Patrick and Nils. I'm under the impression that a unique stand/display under your model accentuates the model....elevating it beyond a more traditional display. This is of course my opinion. Again..thanks for the fine comments..and likes. Rob

- 1,208 replies

-

- great republic

- clipper

-

(and 1 more)

Tagged with:

-

- 1,208 replies

-

- great republic

- clipper

-

(and 1 more)

Tagged with:

-

Glad to see you back at it...... Fine beginning. Rob

- 453 replies

-

- thermopylae

- sergal

-

(and 1 more)

Tagged with:

-

Thanks Popeye. I wanted something magnificent..unusual, a stand that projected the model and made a statement in presentation. It is well balanced as is quite stable. It will receive another coat of tongue oil before I am finished. Now that the cable/chain rail is installed, I can focus on the turned stanchion rail that will complete the railing project. Rob

- 1,208 replies

-

- great republic

- clipper

-

(and 1 more)

Tagged with:

-

- 1,208 replies

-

- great republic

- clipper

-

(and 1 more)

Tagged with:

-

I placed the model in its permanent place on the hutch to see what it will look like......Lots of room for it. Rob

- 1,208 replies

-

- great republic

- clipper

-

(and 1 more)

Tagged with:

-

I call it *Hyper detailing*...where you go beyond typical and you attempt to include details found on the prototype..regardless how insignificant. Rigging can be a storehouse of detail...when done in scale. Good luck. Rob

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

- 1,208 replies

-

- great republic

- clipper

-

(and 1 more)

Tagged with:

-

Thank everyone for their comments and likes....I appreciate that very much. I began working on the forward railing with wire/chain rail and stanchions. No pix yet..but I'll get to it..... Rob

- 1,208 replies

-

- great republic

- clipper

-

(and 1 more)

Tagged with:

-

Nah..Popeye...I used boats from two sources. All my Cutty boats have been used on the Donald McKay and the Glory. I picked up many scale boats from a fellow in town who sold all his collection of models and moved to Reno...Good for me. Not sure where he collected them...some are from several Constitution and other sailing ships. I do have a single CS long boat..but it is too large for the scale I'm in. I have dozens of white metal boats.....I might make the two whale boats that will be swung from the davits. Thanks for your comment. Rob

- 1,208 replies

-

- great republic

- clipper

-

(and 1 more)

Tagged with:

-

- 1,208 replies

-

- great republic

- clipper

-

(and 1 more)

Tagged with:

-

- 1,208 replies

-

- great republic

- clipper

-

(and 1 more)

Tagged with:

-

Thanks Patrick..you are so right. I love historical nautical items(Actually, that is all I collect). Rob

- 1,208 replies

-

- great republic

- clipper

-

(and 1 more)

Tagged with:

-

What a wonderful holiday Christmas season...I hope and pray all my friends here had a great time with family and friends. I was up to a bit of creativeness apart from my GR build. For Christmas a cousin gave me a brass porthole with the glass intact that came from a 45ft sailboat he purchased in Japan 40 years ago. the boat has been destroyed since then, but he retained 7 of the portholes..one of which he gave me. So I dusted it off and retained the old chipped paint and oxidized brass and I then added a clock to it and placed it above the whaling section of my nautical den. What a perfect addition to my nautical collection. Here's a couple images for your enjoyment. I'm in the process of fabricating the 6 crab winches and aft sky light........ Rob

- 1,208 replies

-

- great republic

- clipper

-

(and 1 more)

Tagged with:

-

W2YSM..(ie).. Picard.. I'm very pleased with the results. If my hands and eyes were 20 years younger...I may have taken another route. That route surely would have included re-engineering something to create the panels..that's for sure. I tend to settle for things..then I did years ago. One thing remains....I try to inject something ingenious(jab at humour), that makes the build easier to complete. I truly appreciate the many likes and fine comments. Rob

- 1,208 replies

-

- great republic

- clipper

-

(and 1 more)

Tagged with:

-

Beautiful Nils....coming down the final stretch...looks like. Rob

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Thanks for the holiday salutations.....Popeye. Wishing the best for you and yours this Christmas season as well. I keep a varied size of mesh screen on hand for such an occasion. It has many applications in the modeling world. I'll utilize anything in the building of my clippers. Rob

- 1,208 replies

-

- great republic

- clipper

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.