-

Posts

5,520 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by rwiederrich

-

I’m out of state this weekend so very little to report. Maybe when I return tonight I’ll do a bit of work. Rob

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

Oh…..I’ll tell ya if you are becoming a rivet counter. This is my second Glory build and I started it with the intention of seeking aid from other sets of eyeballs. You’re all 😊 Rob

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

I really felt I was going to change it originally. Your input was the “stuff” needed. Thanks for keeping me true to her Glory……… Rob

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

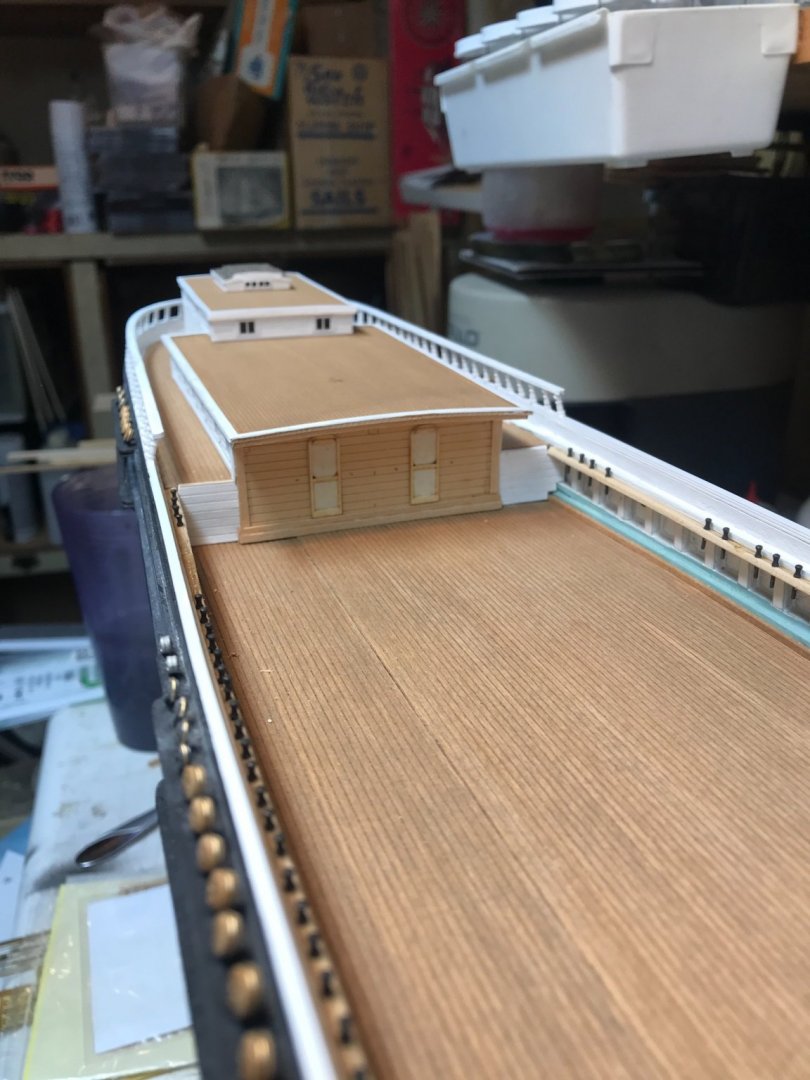

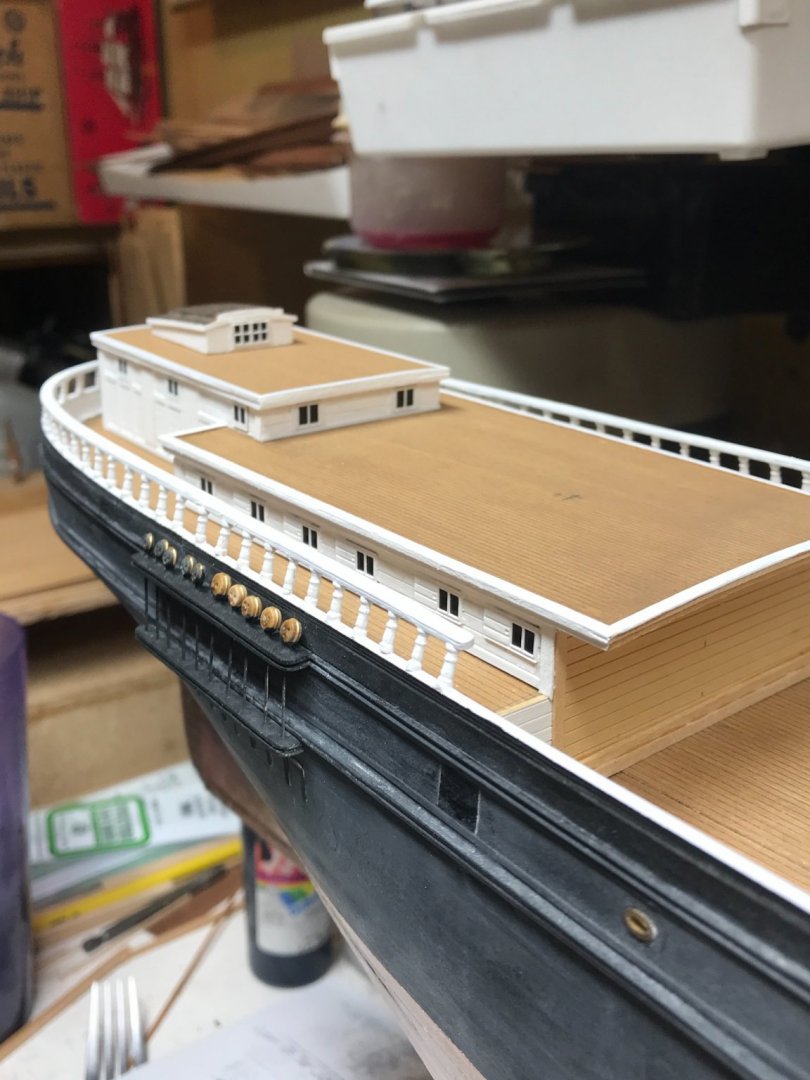

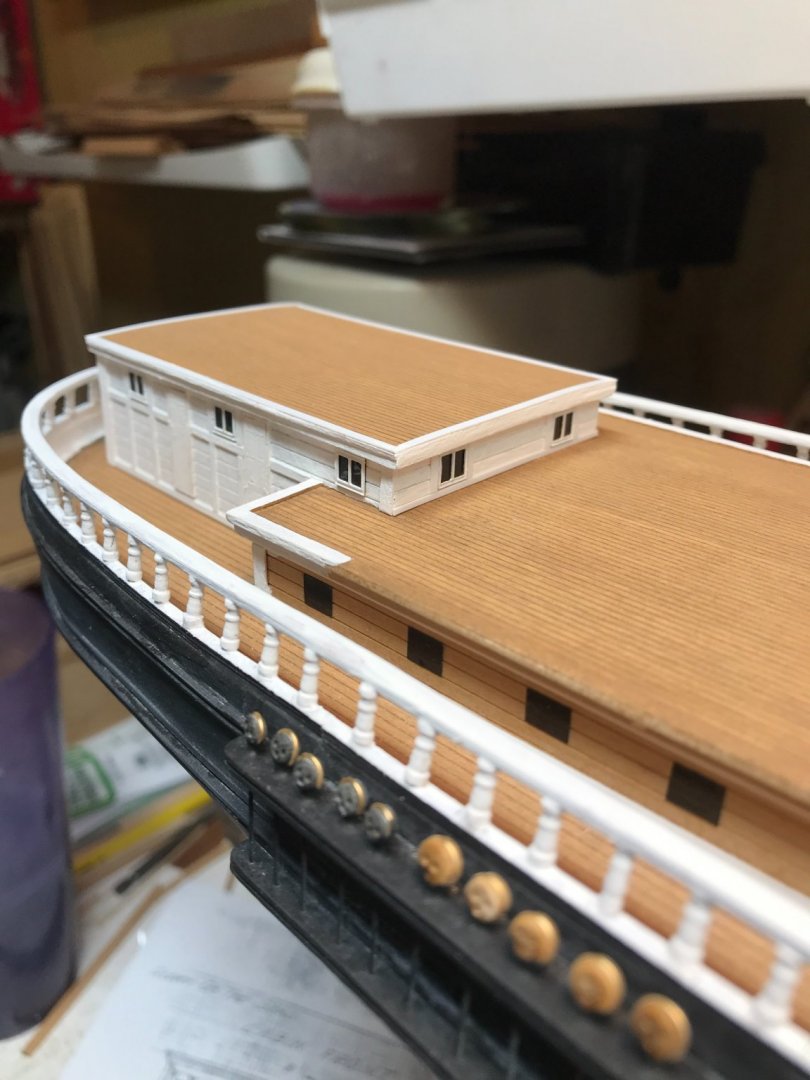

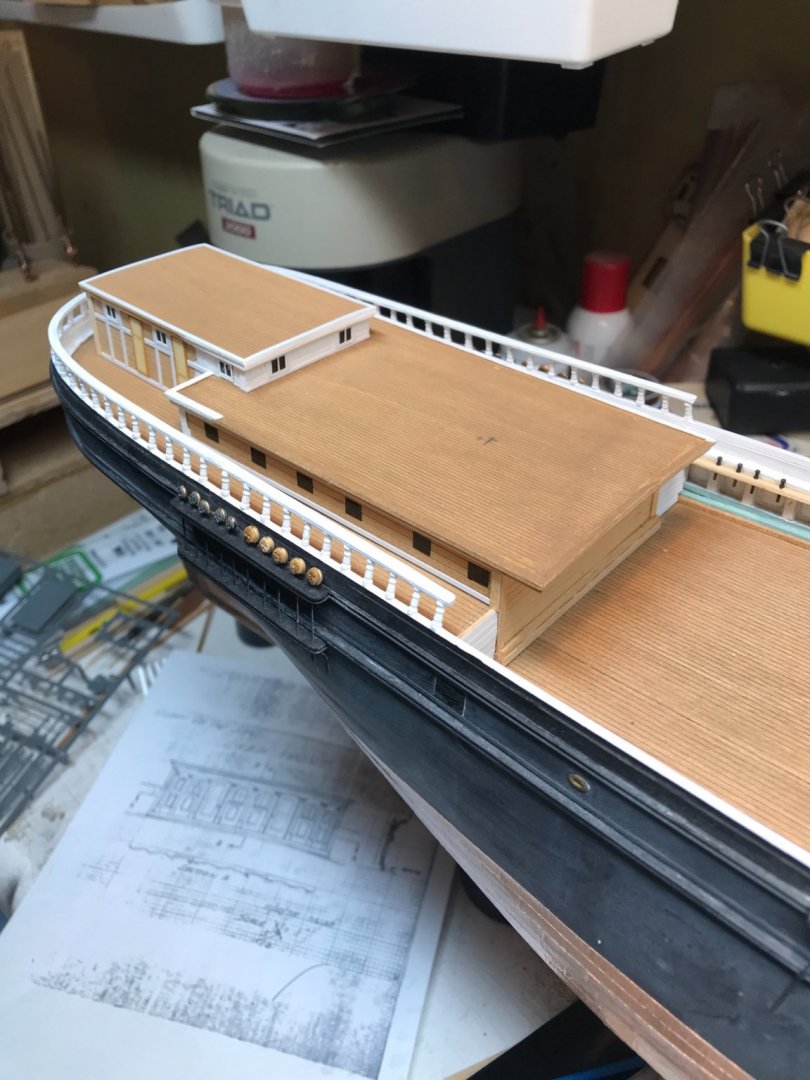

I remade the helm vent cupola. I began on the front. I’m making the windows off model and setting up the pillar caps. Rob

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

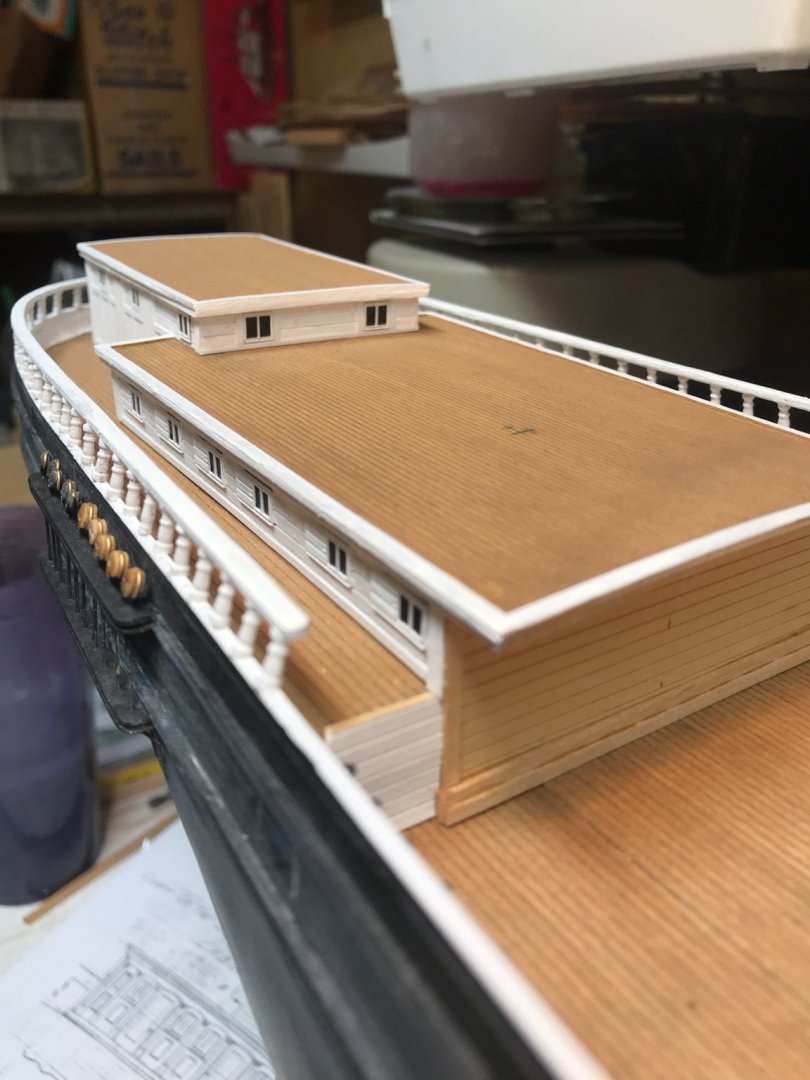

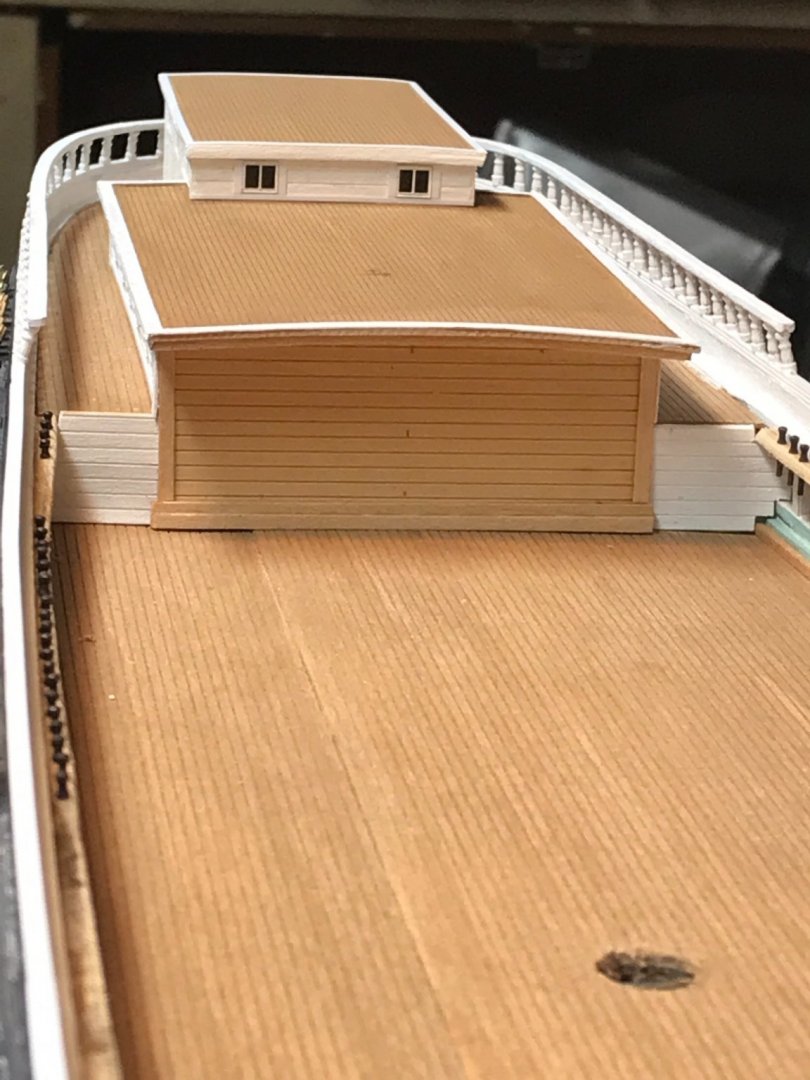

Rich...I knew when I posted these images....I would receive the critiques describing the exact issue you brought up. I knew it when I finished making it, it was too tall in the front. That is why I didn't glue it down to the helm roof yet.😎 Knowing full well I would need to remove material and redo the window/vent opening. I wanted to see if I could slip it past...since very few folks are truly aware of these details. This cupula is pretty small....an inch by 3/4 ish. The louvers on the aft end were a bear to make and I will NOT be remaking those. I made the window the size I did, by using material I already had on hand(I see it was too large)...not really knowing what the door or access really looks like. So a window is just as viable as any other covering for that open space. However, with that said, I might make the mod a louvered door instead...since nobody probably looked out through it anyway. You got me...but I knew it was coming. Rob

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

Thanks Vlad. Yes the scale is pretty small...but I can and do make mistakes...and correcting them seams to be a daily even for me now. but that is the process if I want to be as accurate as I can make her. Rob

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

Thanks Rich. I appreciate the confidence. Im doing the best I can and sadly I make lots of mistakes in scale and recreation. But I’m betting Vlad and I are still closer to the original then any other historical model. Thanks to fine research by yourself and of course Mike. Rob

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

The front of the cabin will be last to do Rob

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

I have to say...my chick is tough...she just trudges along. Dental issues can bring the toughest herculean man to his knees. I hope your wife finds relief and a long term corrective plan. Short term if that is all that is available will do....I'm sure. The older we get the more stuff falls off or breaks.....sheesh..... Good thing I have an eternal security plan.... I finished up and delivered my wife's Unilateral RPD and now I can focus on Glory for a bit...... Rob

-

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

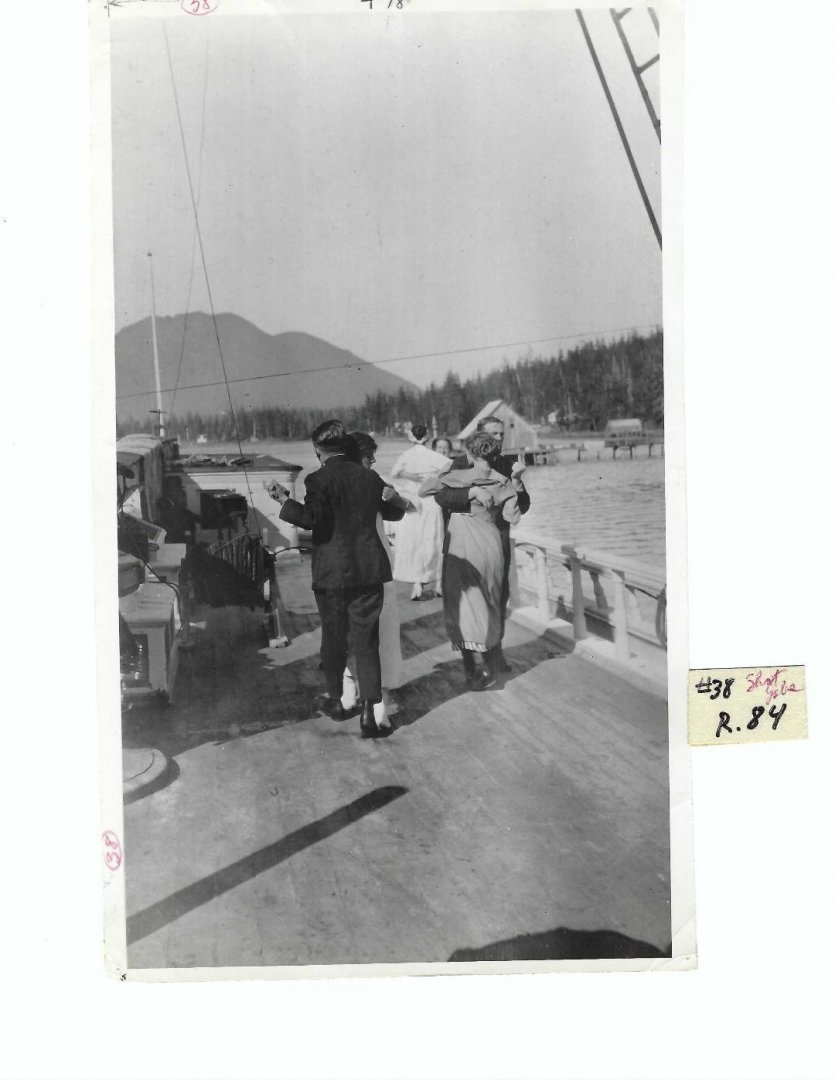

Upon further analysis....I think I am seeing a ghost, or a phantom image. this image from Mike surely shows that a man is freely standing/sitting behind the aft skylight. Rob

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

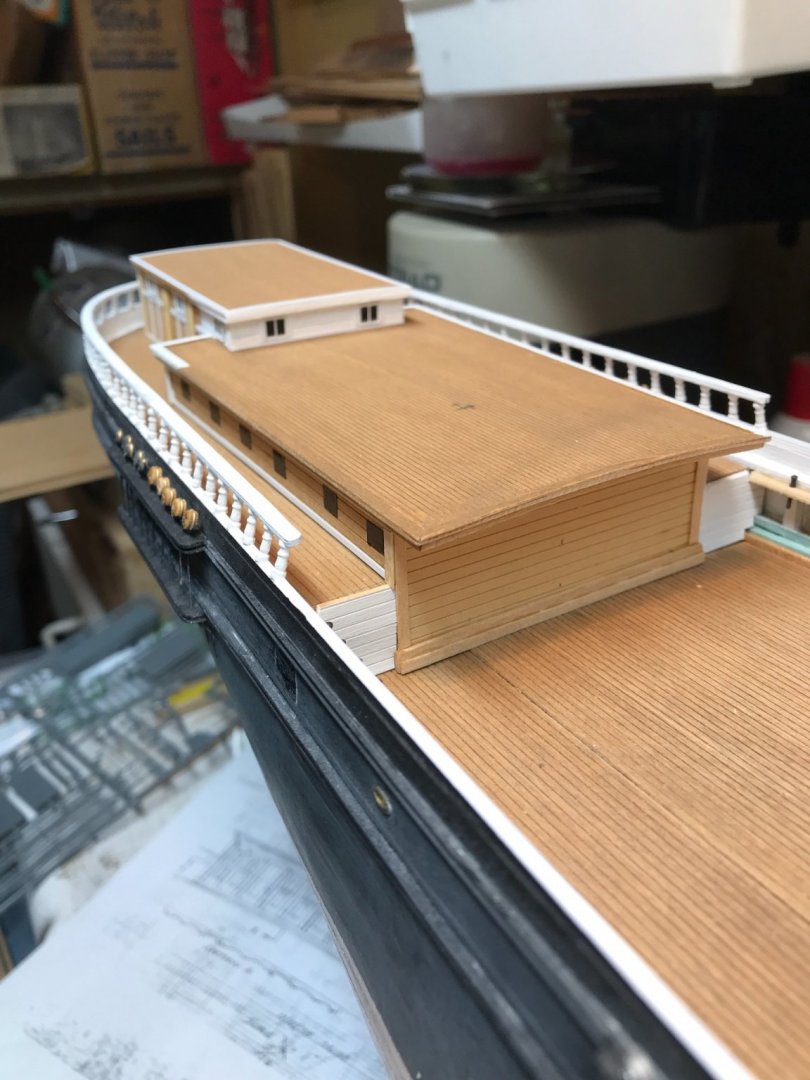

No...I don't think it is any part of the old entry into the aft parlor. The new construction is clean and architecturally rectangular. To leave a portion of the old makes no sense. It is either an extension of the aft skylight or a makeshift structure added by the canary mod crew. Maybe Mike might have more *Hidden* images of this area. If I can't figure it out or justify it...I'm leaving it off. Rob

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

Mike emailed me these yesterday. This is the best picture of the aft skylights I have seen and if you review other images, you will se a structure between the aft skylight and the wheelhouse extension. Rob

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

Rich, As I investigate further, it appears the structure atop the helm is indeed a vent cupula. As I've shown in photos the aft end tapers and the aft wall is louvered. The image here shows clearly that there is built into the front a window, or louvered hatch that opens. Opened during mild hot weather for good breezy ventilation and to be closed when bad weather is afoot. Being louvered you still get ample air movement, without water entry. A curtain is present in the forward window, surely demonstrating that the forward portion of the addition is considered an access way to the lower salon regularly traveled by passengers...hence the second door forward on the cabin, separating the working helm from the trimmed and dressed passageway. Rob

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.