king derelict

Members-

Posts

3,272 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by king derelict

-

Airplanes and Tanks in plastic by Jörgen

king derelict replied to Jörgen's topic in Non-ship/categorised builds

Beautiful weathering Alan -

Curtiss BF 2C-1 by CDW - FINISHED - Hasegawa - 1:32 scale

king derelict replied to CDW's topic in Non-ship/categorised builds

Beautiful model Craig. Excellent work Alan -

Vincent Black Shadow by CDW - Revell - 1:12 Scale

king derelict replied to CDW's topic in Non-ship/categorised builds

Thank you Craig. I'm doing well; just not getting enough time at the workbench. It would be nice if someone could turn the heat down a bit but from what I read there are areas much worse off. Just hoping this isn't the prelude to a nasty hurricane season. I'm enjoying this build a lot. The Black Shadow was a dream when i was at university. Never got beyond an AJS and a BSA Alan -

Thank you Ken Good to know that about the Yak kit. I got a bit carried away ordering from a Ukraine based seller on eBay. As usual I was attracted to the unusual. Excellent seller too. About ten days from Kiev to Florida. The Dora Wings kits look very nice. I haven't looked at the rest yet. I want to try a bare metal finish soon so this might be a good donor for a learning experience. Expectations dialled down on all fronts for this one. Alan

-

Vincent Black Shadow by CDW - Revell - 1:12 Scale

king derelict replied to CDW's topic in Non-ship/categorised builds

The spoked wheels are wonderful. A huge improvement Alan -

Hi OC I've had to spend too much time in the real world recently but its great to see the photos of your figures again. I really like the one of the Rifles streaming out of the gate. I can almost see movement there. I hope your dental issues were resolved and all is well with you. I seem to be seeing far too much of the medical profession at teh moment and its far from my favourite activity even if a lot of it is on behalf of someone else. Alan

-

This is looking real very nice. Your printed details are a lot tidier than mine. As regards the wooden decks at least for the Flowers it seems to be a case of some of them had wooden decks some of the time and the layout was variable too possibly depending on which shipyard built them so I expect you are probably correct in what you have done. Alan

-

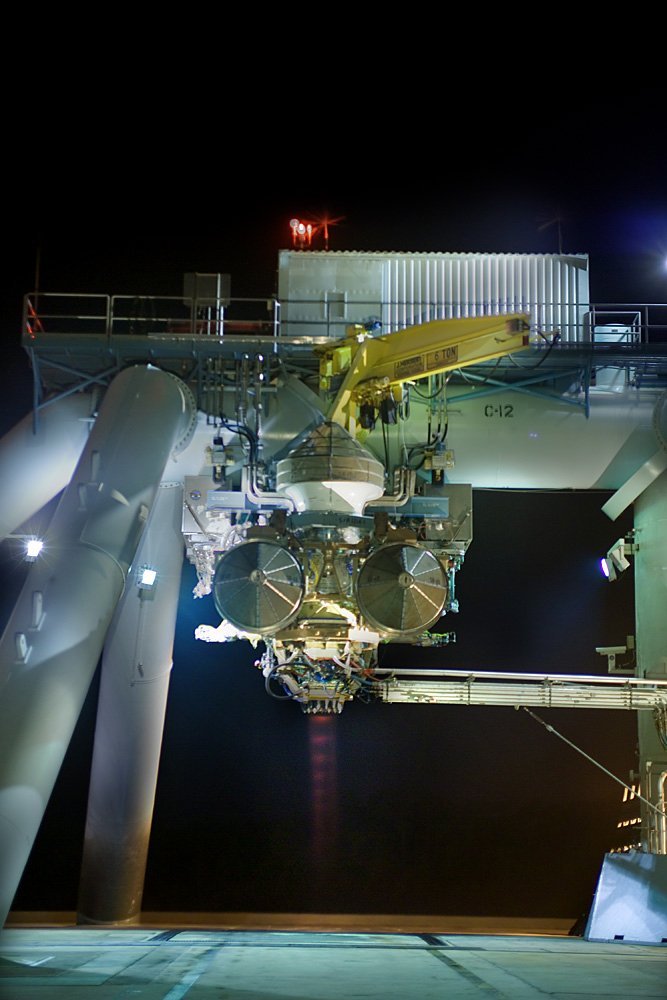

After a shamefully long absence I'm back and hoping to make regular appearances again. Work has been very intrusive and eaten up far too much modelling time. Helping a friend through surgery has used up what was left of my waking hours. Hopefully both are coming to a conclusion in a positive way shortly This is what I've been spending far too much time dealing with. This is the F-35B engine in Powered Lift mode; nozzle down and Liftfan engaged. Its not in afterburner but you can still see the shock diamonds from the exhaust. AB is not supposed to be engaged in Powered Lift but we have done it accidently and it really cooks the concrete The one slight benefit of all this work stuff is a bump in the piggy bank. Most is going off to pay for boring stuff like replacement water pipes in the house and repainting the exterior I have used the opportunity to add to the kits on the shelf (and in the cupboard and under the bed etc) I quite fancy another Wingnut Wings kit before they disappear forever but I'm not sure I am good enough to do them justice. I've also been looking for the Flyhawk Iron Duke ship model kit but the only place I can find it is Squadron and I seem to recall mixed reviews about them. Anyone got any recent experience since they absorbed Freetime. So back to the Castillo Loarre. I try to be a little done when I have an hour spare. Although the pace is glacial it actually lends itself to this sort of attention. The sessions are far too short to get fed up with endlessly shaping the bricks. The inside of the circular towers are really tedious to do and smoothing them out afterwards is a bit challenging, Thats where the deep sockets in the background come in. I have stuck sandpaper onto them and they fit onto the tower and can be rotated to clean up the interior walls. The short sessions are handy in another way. The work is all done reaching across the baseboard and the old back gets a bit cross about that after a while. The lack of time has meant my plan to complete the curtain walls before the hot weather arrived has failed but a desk fan on the workbench is keeping things tolerable in the garage. At least nothing is light enough to blow away on this project. So, this is where I am now Only 2 and a half towers left and enthusiasm is still there to make it to the end. Then I can switch to other bits of the model; the main building and the lighting. Sorry its been a while but thank you for stopping by. Alan

-

Hi Craig This is really shaping up to be a hot summer. Working out on the test stand is miserable especially when the sun has warmed up the metal surfaces. Thankfully most of the time I'm in the air conditioned control rooms which are cooled to the point of needing a fleece jacket at times. I'm hoping to be back on the site a bit more regularly now as testing slows down. Its been frustrating watching time drift away doing real world tasks. Thanks for the good wishes. Alan

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.