-

Posts

618 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Vane

-

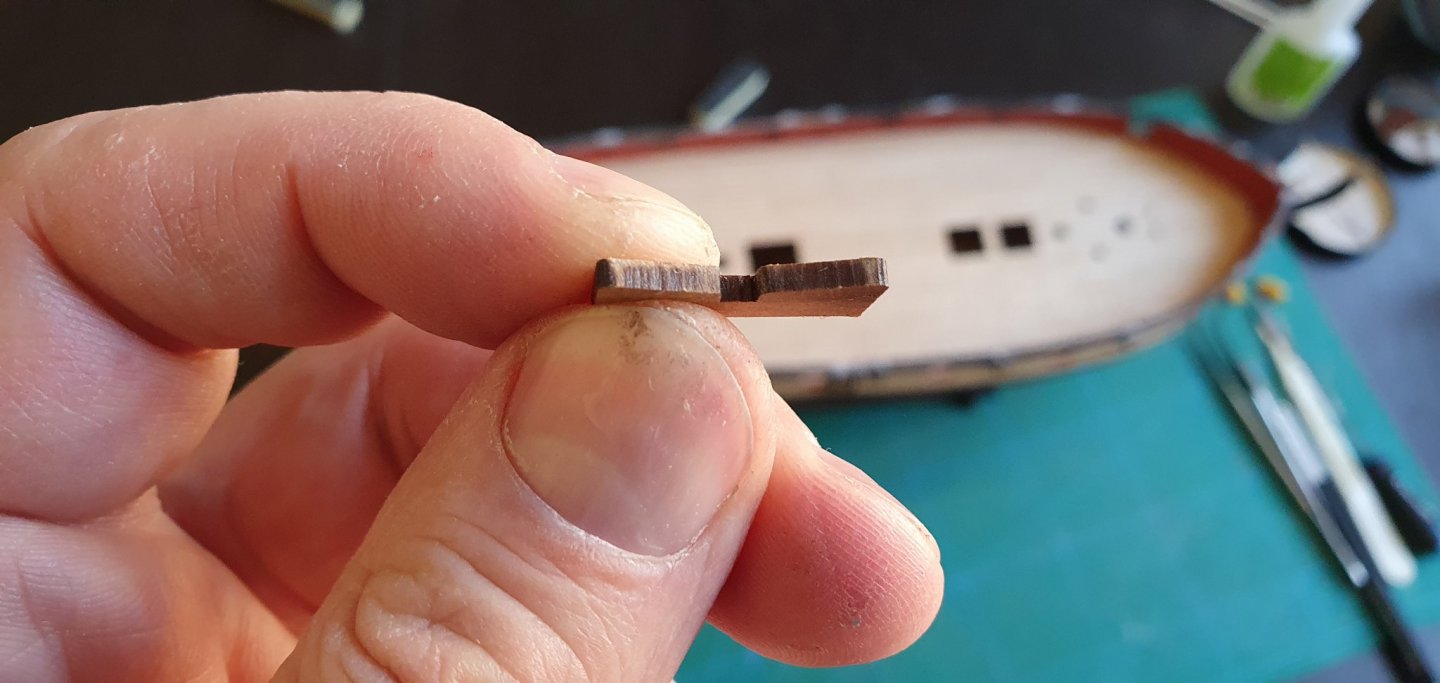

I had similar experience here. I focused too much on the gunswivel holders than the rail. But getting the rail right is more important. The first piece was also abit too short for me and i had to add some extra mtrl in the gap.

- 725 replies

-

- vanguard models

- speedy

-

(and 1 more)

Tagged with:

-

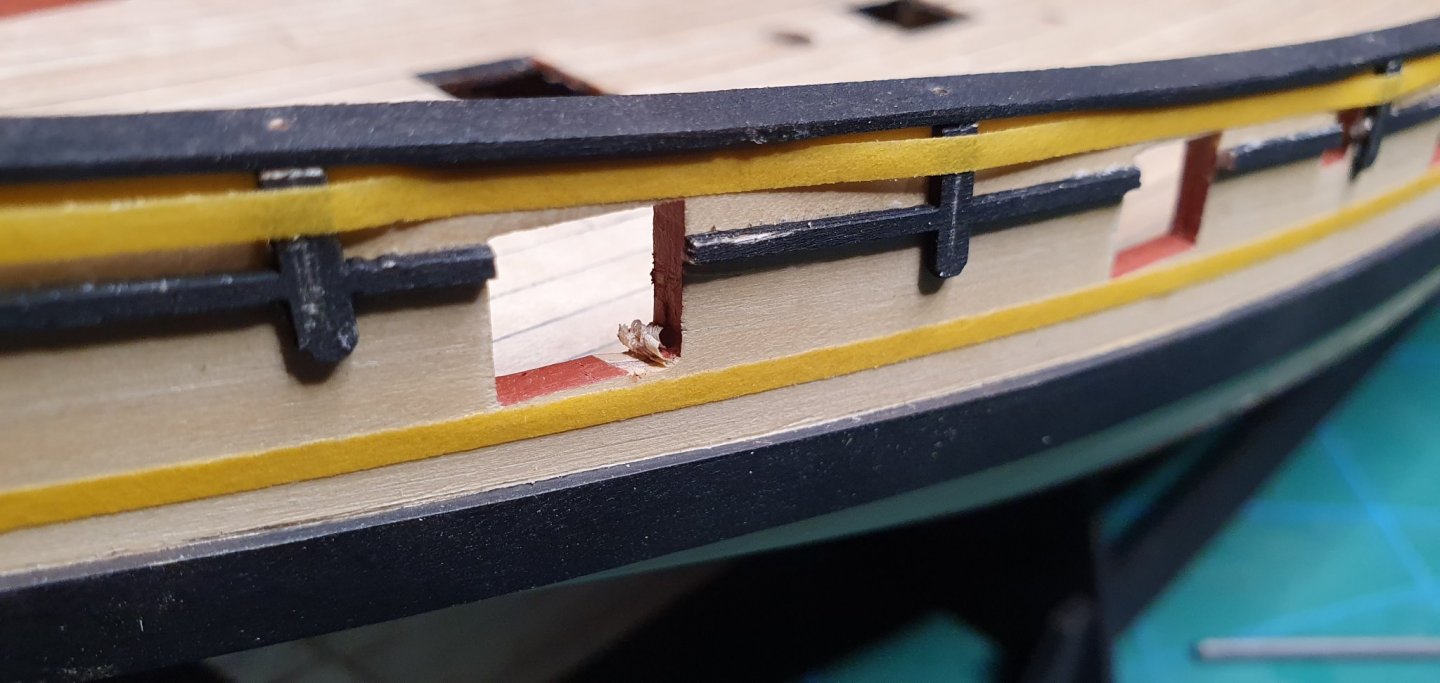

The stern is actually a section that i would like to see more photos in the manual. I have just finished mine and it was a little more tricky to do than the rest of the model.

- 725 replies

-

- vanguard models

- speedy

-

(and 1 more)

Tagged with:

-

The manual to Speedy is super. So far I have basically not looked at all at the plans which I think will first be needed when i start with the masts. The manual is also much more easy to have at the workbench without taking up too much space. Sometimes I have done things in a slightly different order but most of it has worked out well for me. The only thing I am missing is more close up photos of the stern.

-

Ah ok that explains it. So if basically the name tag is the difference, why not just release this kit a 3rd version Speedy and present it as "Speedy/Flirt" kit and let the builder have both options? Similar to the HMS Vanguard. This is very common strategy when it comes to plastic models where there often are slight variations included in the kit.

- 109 replies

-

- Vanguard Models

- Flirt

-

(and 1 more)

Tagged with:

-

Great to see this build. I do understand that the kit itself will have some design changes in materials etc compared to Speedy. However, what are the differences between the actual two sisterships?

- 109 replies

-

- Vanguard Models

- Flirt

-

(and 1 more)

Tagged with:

-

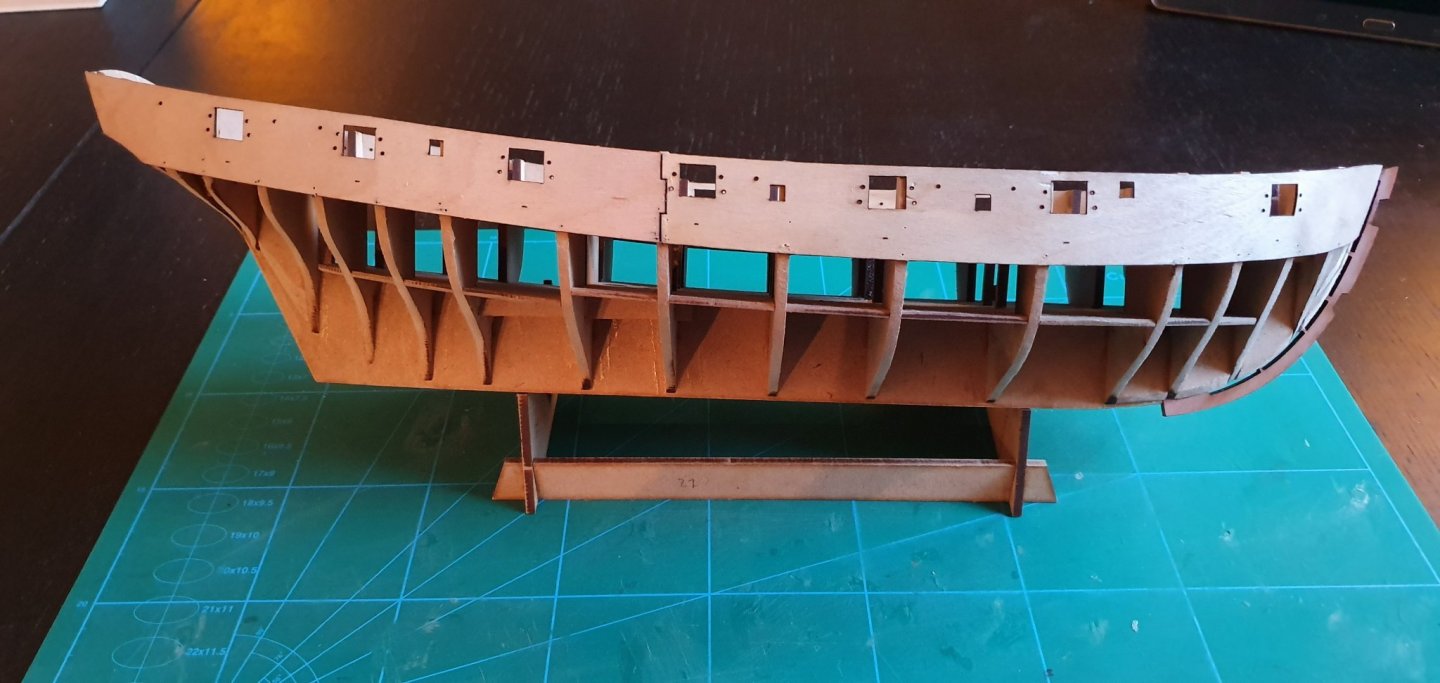

Congrats to your new kit, looks great! Regarding your new in house laser cutting capabilities. Do you think the quality of the cuts are even better now when you can finetune everything yourself instead of sending wood to the lasercutter company? I just noticed that the cuts on the new deck for Speedy looks better than the original where the laser tended to leave a very small burnmark in some corners. And also, I find the other pieces (MDF, Cherry) is very precily cut, but the "burnt edges" has a slightly "wavy pattern" which you sometimes needs to sand down.

-

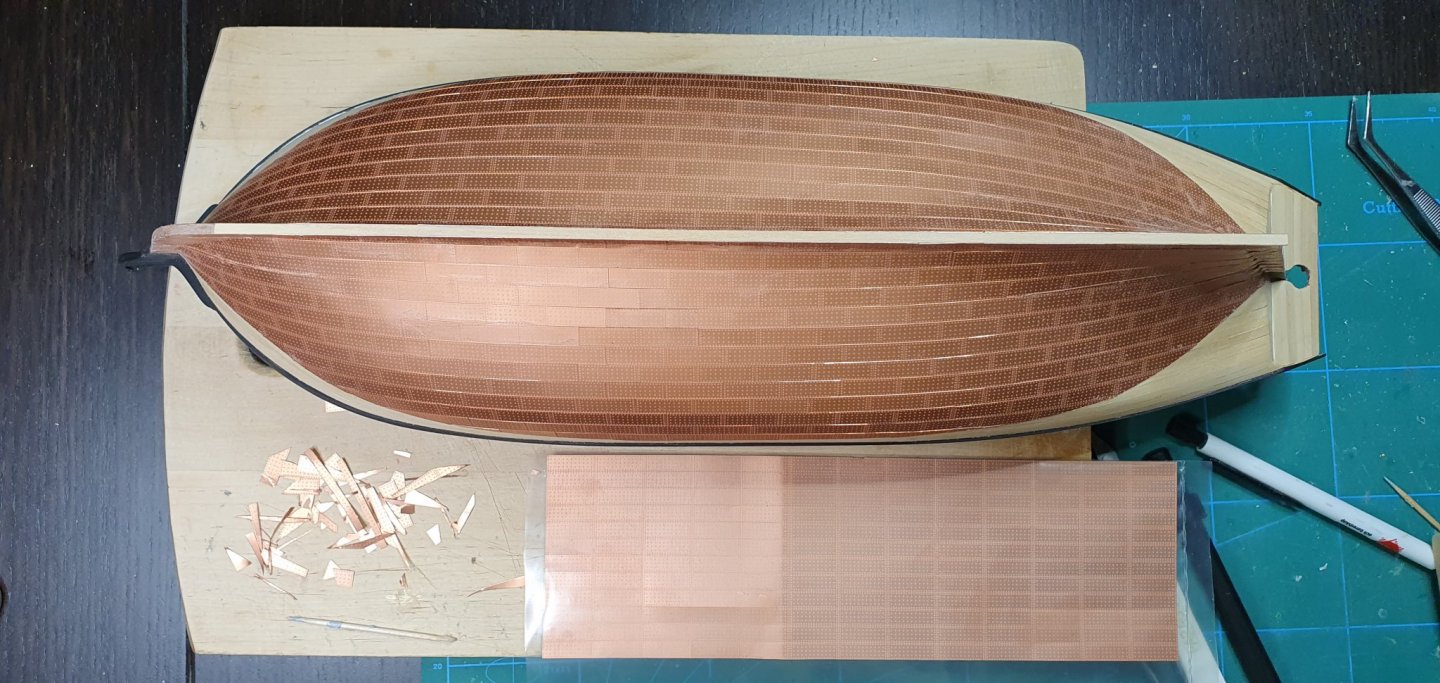

I did a few mistakes with my coppering but i am overall happy with the result. Its the 2nd ship i do this on so i am still learning but now i feel comfortable for the next time (Diana). The kit included two sheets of copper and its plenty of metal over. These sheets are way better than the Caldercraft version so i might have to upgrade for my future builds....

-

Waterlines are tricky and nice tip with the laser. I try to look at the marked waterline from various angles when i correct it. Taking photos also helps since then it becomes even more visual when its not completely straight. Regarding CA i have just discovered a New method that solves alot of problems. Scraping... on boxwood you dont need to be that carefull actually. Just scrape away a couple of microns and everything looks brand New. 🙂

- 725 replies

-

- vanguard models

- speedy

-

(and 1 more)

Tagged with:

-

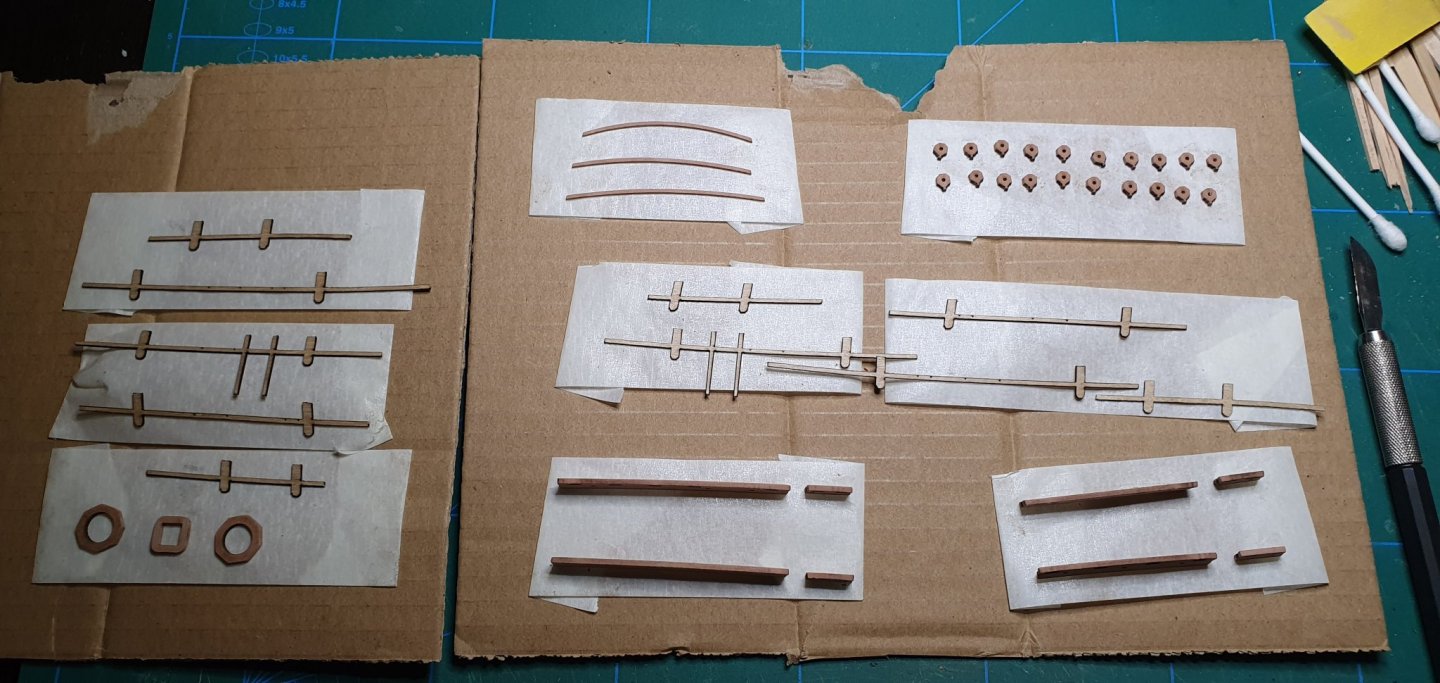

Preparing some of the details for airbrushing. Its feels great to finally start moving on from the hullbuilding stage. Thats basically all I been doing since I started this hobby again. The last year has been productive and i built 3 hulls.. this one and Snake and Granado. Hopefully i can complete a ship before the end of this year and not starting on new kits 😛

-

I agree, its abit of a challange and you can use various strategies on how to fit square pieces on a round hull. Vanguards copper is ok to work with at least.

- 725 replies

-

- vanguard models

- speedy

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.