-

Posts

975 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by iMustBeCrazy

-

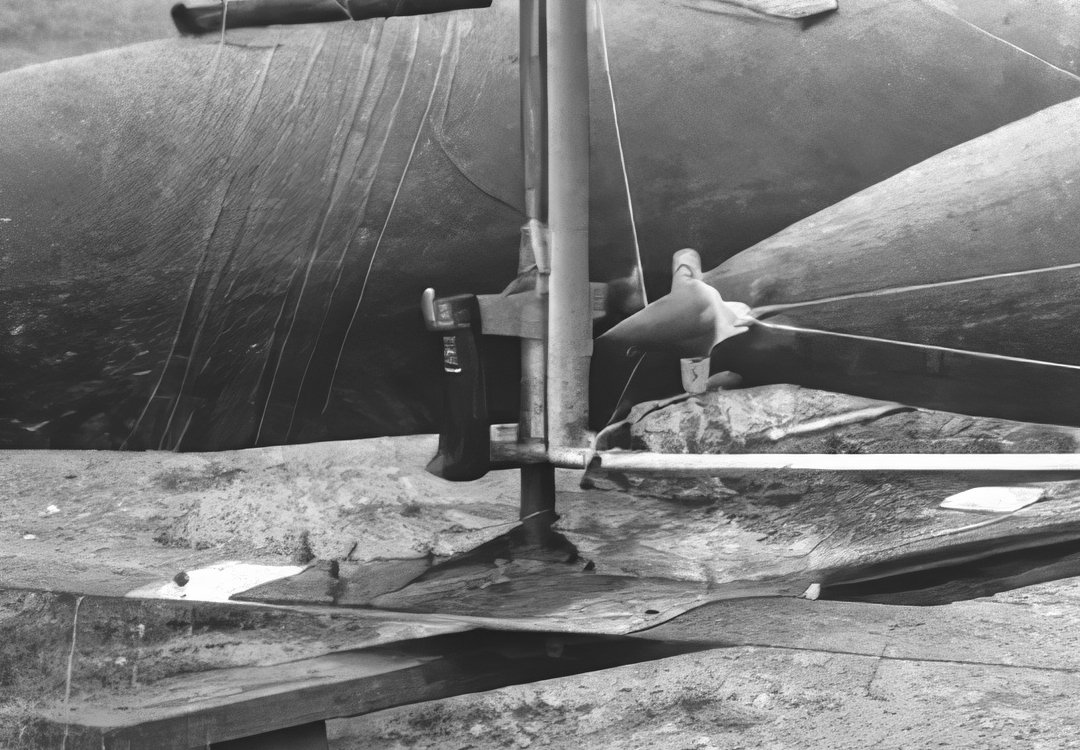

I think it's fine, it looks like the pointy bit is a metal cap with flanges for the wires. Overall I think your model looks a little too good, better than the original.

- 288 replies

-

- Santos Dumont No. 18

- hydroplane

-

(and 1 more)

Tagged with:

-

And Make your own, the skills needed for model making and tool making are the same. See posts 261 through 271 in Tims 'Speedy' thread https://modelshipworld.com/topic/34769-hm-cutter-speedy-1828-by-oakheart-from-plans-drawn-by-bill-shoulders-in-1972/page/9/ You can make yours longer so you can set a stop for longer deck planks. For getting things square, the corners (and sides) of (factory cut) MDF sheets are square and the sides are straight ( you might be able to get some scraps from a cabinet maker) as are the corners of copy paper, both can be used as squares. By gluing sandpaper to the (factory cut) side of a piece of MDF you can sand things to 90°

-

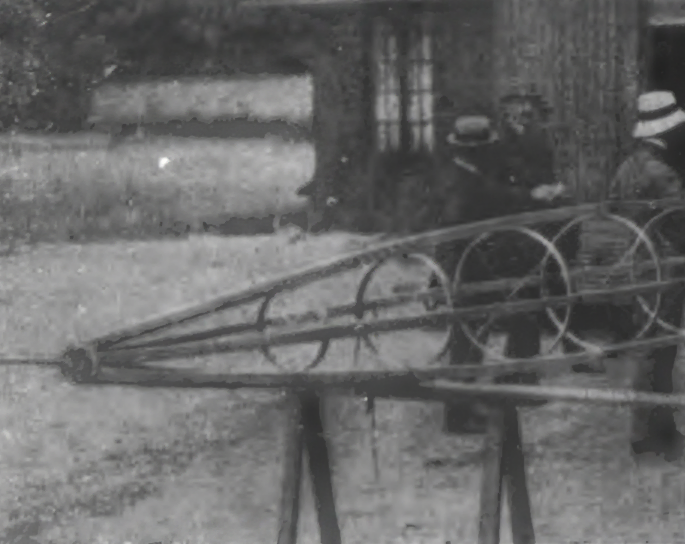

I suspect all the wires came off a roll of bicycle spoke wire, the hoops were essentially wooden bicycle rims and the tubing was bicycle frame tubing either flattened at the ends or rolled into an oval for streamlining.

- 288 replies

-

- Santos Dumont No. 18

- hydroplane

-

(and 1 more)

Tagged with:

-

Another enlargement: Santos_Dumont_N-18g.zip It looks like the front foil (and I think the back) had suspension:

- 288 replies

-

- Santos Dumont No. 18

- hydroplane

-

(and 1 more)

Tagged with:

-

This enlargement might help. SD 18-cleargc.zip

- 288 replies

-

- Santos Dumont No. 18

- hydroplane

-

(and 1 more)

Tagged with:

-

- 288 replies

-

- Santos Dumont No. 18

- hydroplane

-

(and 1 more)

Tagged with:

-

I'm extremely organised (HAH, heehee, hah heehee, mmmph. giggle, giggle) mine are carefully filed dumped in a folder labelled 'Endurance'. No problem, luckily I like puzzles.

- 206 replies

-

- Endurance

- Shackleton

-

(and 2 more)

Tagged with:

-

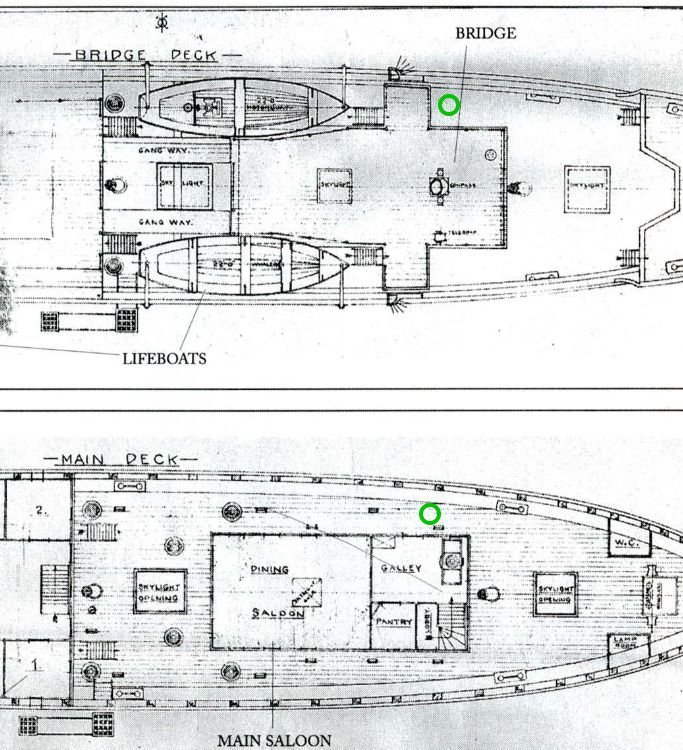

https://digitaltmuseum.no/011024193055/modell-av-fartoy This model looks like it got it right to me except they were later put over/outside the railing.

- 206 replies

-

- Endurance

- Shackleton

-

(and 2 more)

Tagged with:

-

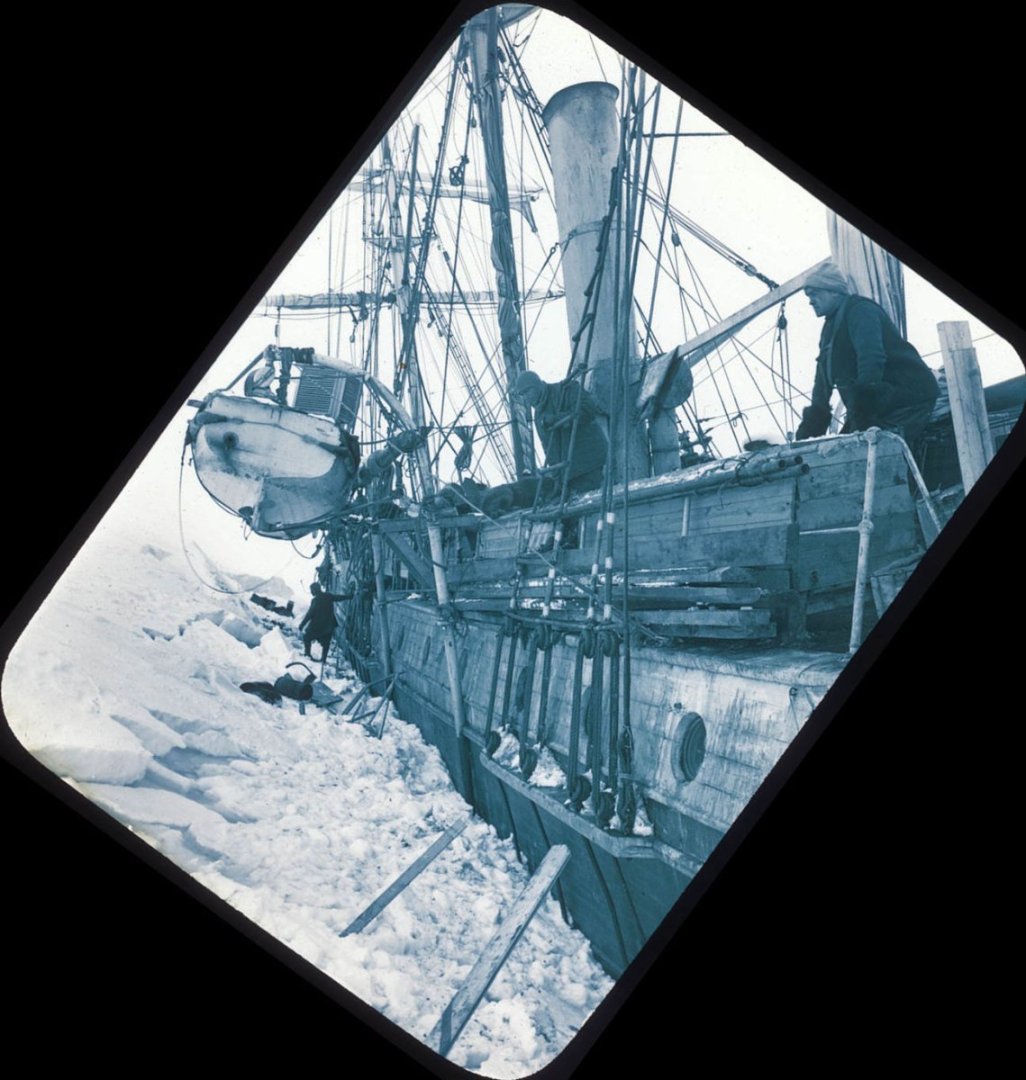

I thought they might be for a while but the davits are just in the wrong place and moving them would have been very difficult. Anyway, this shot shows the aft starboard guy just wraps over the rail and attaches somewhere down the side of the cabin ??? Not a stanchion, not the davit. The forward one I think does the same but attaches to the chain plate. Maybe. I would say further forward, starboard side of the forward binnacle? Crane jib? But yes. Edit: This shot shows no sign of them running down the side so I guess they go to the top of the side of the cabin.

- 206 replies

-

- Endurance

- Shackleton

-

(and 2 more)

Tagged with:

-

Tom, it looks like after the kennels were fitted the guys were attached to the top of stanchions so as to clear the kennels.

- 206 replies

-

- Endurance

- Shackleton

-

(and 2 more)

Tagged with:

-

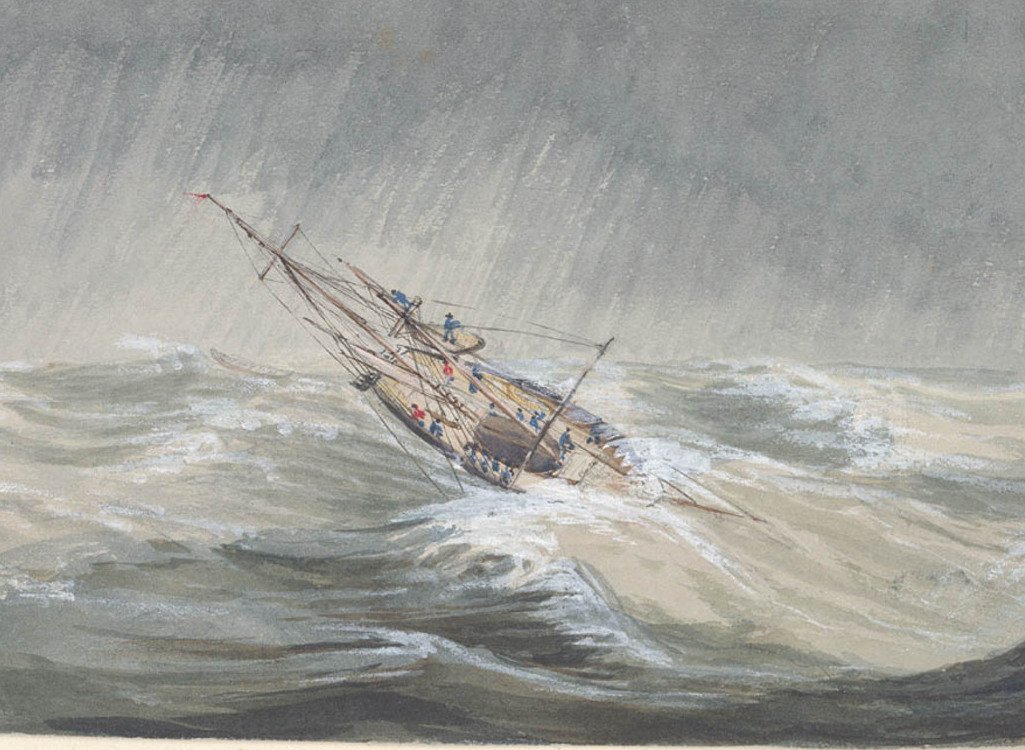

The Roaring Forties was only the start, you could try your luck further south in the Raging Fifties or even the Screaming Sixties. Along the edge of the Roaring Forties was pretty much the standard route. Fortunately for those aboard Lapwing she turned north to Adelaide long before reaching King Island or Victoria's south coast. The Loch Ard is well remembered, the gorge she foundered off is name after her (it's the one with the big car park).

-

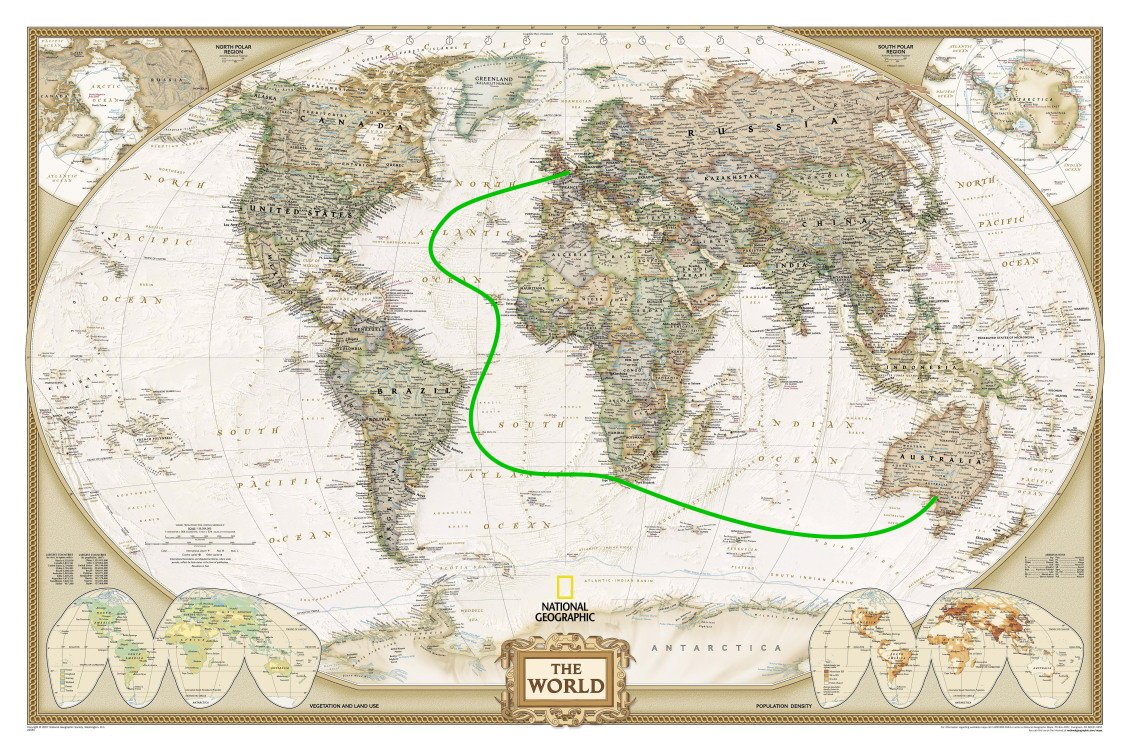

They finished up with only one paying passenger plus the owners family (wife and two daughters) and two servants (this is from newspaper articles and the servants may actually have been the daughters). They were heading out for the Gold Rush so possibly had a full (free?) crew. I don't actually have any info from my Great grandfather but again from newspaper reports (passing ships took mail and messages and reported sightings, whoever reached port first let them know who was coming and vaguely when to expect them) it was London to Cape Verde then probably Cape Town via the Brazilian coast, then on to Adelaide or Adelaide direct (I think Cape Town). Roughly 14,500 nautical miles in a boat that fits comfortably in my cousins front yard ( a 1 acre block, ~100' wide). No idea but probably. Supposedly Bramble just going in to Brisbane:

-

Yes it's an exciting image, probably more so for me as I can (and did this morning) visualise my Great grandfather on board. I don't remember why I thought she was the 1778 Kite, perhaps I mixed up dates in my head, but that extra row of planking above the gun ports makes her more likely to be post the very early 1800s. Given the painting is dates ca1850 it is possible the artist as a boy knew Lapwings sister and remembered her fondly. There are discrepancies, the companionway faces aft and the wc and pantry are missing but she carries the right number of guns (well gun ports, she probably didn't carry a full compliment of guns) in the right places. He may have used Lapwing as a model as she was still around at the time of the painting but made changes based on boyhood memories, who knows. Looking at the painting itself, she's running downwind with both the main and square sail set, that would be wrong, she would be unbalanced with the main trying to turn her to port. Look at the helmsman, he's heaving on the tiller trying to keep her on course. The artist understands, this is a chase, every fraction of a knot counts. As you said, an exciting picture. So, yes this could be Lapwings sister, Speedys aunt.

-

Tim, don't forget the pumps. I had a little play with ideas when you first posted your little cutters little cutter. I came up with ZAZ6347 (Vigilant) which has light pencil lines representing boats each side of the main hatch. Now Vigilant was a little larger making this more practical but I drew 18' (port) and 16' (stb) cutters on Lapwing:

-

As they decked over the bridge deck openings the four forward ladders became redundant. It would appear one was cut down and used to get over the top of the kennels, another had a couple of upper treads removed and used port side aft probably because the amount of stores along the centreline prevented previous access from the starboard ladder unless you went all the way up to the mainmast and back. Just a guess.

- 206 replies

-

- Endurance

- Shackleton

-

(and 2 more)

Tagged with:

-

Ship Ribbing with CAD?

iMustBeCrazy replied to Sanjith_D's topic in CAD and 3D Modelling/Drafting Plans with Software

Well, you can follow my bumbling path through the links in my sig with the Lapwing drawings and build (to date) but I seriously suggest you start with something simpler than a Frigate, say a dinghy, skiff, dory etc. in 1:24 or 1:16 Meanwhile look for Frigate drawings you like in the best quality you can find, perhaps the Enterprize class, many nice big drawings: https://commons.wikimedia.org/w/index.php?search=rmg+enterprize&title=Special:MediaSearch&go=Go&type=image&fileres=>1000 https://commons.wikimedia.org/w/index.php?search=rmg+rose+plan+-chart+-painting&title=Special:MediaSearch&go=Go&type=image&fileres=>1000 -

Mike, I've always seen the dog kennels as recycled packing crates, pretty rough and ready. Built in sections of 3 and 4 dogs, sometimes the gap between two sections is roofed over for an extra dog. Probably 1/2 inch planks roughly sawn to length, butt jointed (I think that shingled look is just warped planks). Those forward seem rougher than the rest, possibly they used the best material aft? The 'Bovril' shot probably the best guide to their construction.

-

It is indeed. Dan, here's a few more clues: https://www.arbeitskreis-historischer-schiffbau.de/mitglieder/modelle/roemerschiff-victoria/ https://roemerschiffe.de/victoria/ Looking at the last shot I see the midships moulds look to be arcs and the other moulds use the same arc rotated. Taking the above and adding it to This: Gives: Certainly not 100% right but perhaps 90%? It doesn't include the bow or stern either.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.