-

Posts

975 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by iMustBeCrazy

-

It's wood and you're only really worried about the outside surface, it's repairable. Carve out the areas in purple until almost the depth of your planking, select wood with matching grain and glue in (clamp with your thumb if you have to), sand lightly. Remove the plank from the stern post and do it all in one piece (edge glue 2 or more pieces to make a broad plank if you have to). I think it will look better if the grain runs parallel to the aft edge but choose what pleases you.

-

I think the big issue here is Chinese piracy, if these plans were easily available I have little doubt they would be cloned. That said, there is more than enough information in the instructions to build the model. Add in the numerous build logs and have at it.

-

-

Flotherwoode seems to be fake wood grain. Queen Elizabeth employed Leonard Fryer to decorate the long gallery at Oatlands with a woodgrain pattern in 1598. He primed the panelling with white lead paint and then painted imitation "flotherwoode", with gold and silver highlights on the mouldings, with arabesque patterns and paintwork of "markatree", perhaps resembling marquetry. So, ornate paintwork seems to be the theme.

-

Again, I think there were more exceptions than rules: https://www.rmg.co.uk/collections/objects/rmgc-object-535332

-

Which is a copy of HIL210 from the RMG. This is a drawing by a shipbuilder not the Admiralty which might explain some differences.

-

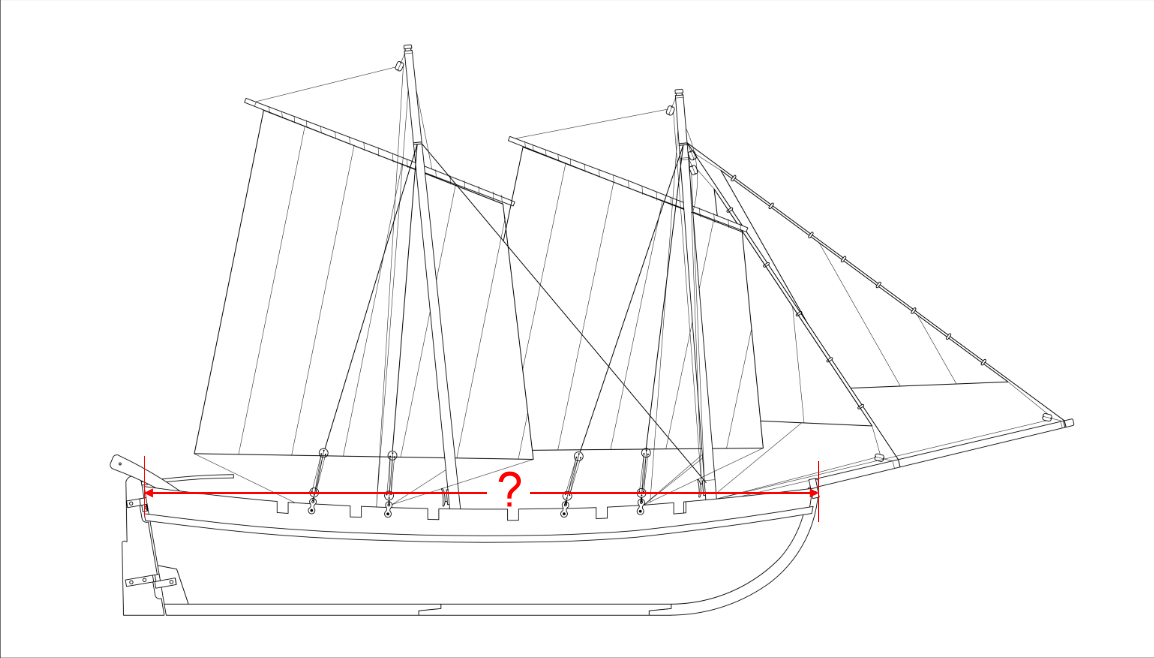

I have been trying to work out what size boat this model depicts, could you do one measurement for me? Thanks,

- 24 replies

-

- OcCre

- bounty launch

-

(and 1 more)

Tagged with:

-

I would think so, but I also think it's a boat built for a specific task rather than modifications. It's too nice a drawing. The bow roller looks like a normal anchor handling roller, the stern roller 'feels' like it serves the same purpose but the drawing provides no details. It's possible not impossible that these could be used together to carry a cannon slung under the hull. Combine that with four swivel guns and we may have something fit to support a landing somewhere. Not impossible but...........fantasy perhaps? Yes, but it's backwards. I don't think so but it's a better guess than any I can propose at this time.

-

Well, they might reach the water when fully loaded Hmm, I thought I did a similar cheat on my 16ft cutter but now I'm not sure. I think I dislike oars.

-

G'day Allan. This drawing contains a few enigmas doesn't it? 'A' and it's mate/s in the bow look like sockets to me, the top section being drawn in black ink suggests they are near or on the gunwale, either for an awning stanchion or a small swivel gun. THIS would fit nicely. 'B' No idea at the moment but the red ink suggests it's near the centre line. 'C' (just in front of the mast) You didn't ask but it's probably a 'horse' for the jib sheet, Maybe? It would have been nice if the showed A, B and C on both drawings. Other interesting things: Double lifting eyes fore and aft, rollers fore and aft, cant frames fore and aft.

-

Looks great! I really like the colour choices. I think you and I suffer from the same issue, the desire to make a wooden hull hewn with hand tools look like fibreglass popped from a mould. At least it's single banked, only six to make.

-

And so we come to a rather delicate subject, one not much talked about in polite society since the advent of indoor plumbing. The backside! So she has an issue with her backside It seems to be a genetic flaw common to her sisters but never discussed. Her transom is wrong! It's wrong and it can't work. It will have to be bodged, fettling isn't enough

-

Tough question. Expensive-ish. Very fine grain, often highly figured ,sometimes dead straight (like mine), growth rate can be < 1mm per year, often half that. Very long lived. Can no longer be felled, only salvaged. Very smooth finish, polishes to a high sheen without any need for oils or varnishes. Fades to a soft buttery yellow. https://www.australianwoodwork.com.au/blogs/news/what-is-so-special-about-huon-pine https://www.tasmanianspecialtimbers.com.au/special-huon-pine-slabs-for-sale/

-

Welcome Rob, there are two other build logs here for the early version and they both started very slowly. The instructions are pretty poor if you're trying to do a serious build but we'll get there somehow. As mentioned earlier I do intend to fit the bulwarks prior to finishing the first planking as I'm not an octopus. I'll also fit the keel before starting the second planking so that it all 'blends' nicely.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.