-

Posts

312 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by KrisWood

-

-

I’d like to work with wood. I just couldn't cut anything accurately to save my life. I'll save up for a mill and focus on design and assembling the parts. First though is figuring out which software to use. I tried Delftship and got as far as setting up one reference image. So far its interface is completely alien to me but I'll keep at it for a bit and see what I can come up with.

- mtaylor and thibaultron

-

2

2

-

The problems with my build were not with Rhino itself, except that it isn't free and I don't have access to it anymore.

My problems were mainly with lacking the skill and depth perception to make the parts by hand.

Once I'm up and running again, the goal will be to make files suitable for CNC mill or laser cutting so that once I can afford one, or find somewhere that can make the parts, I can use them to get all the parts cut out.

- thibaultron and mtaylor

-

2

2

-

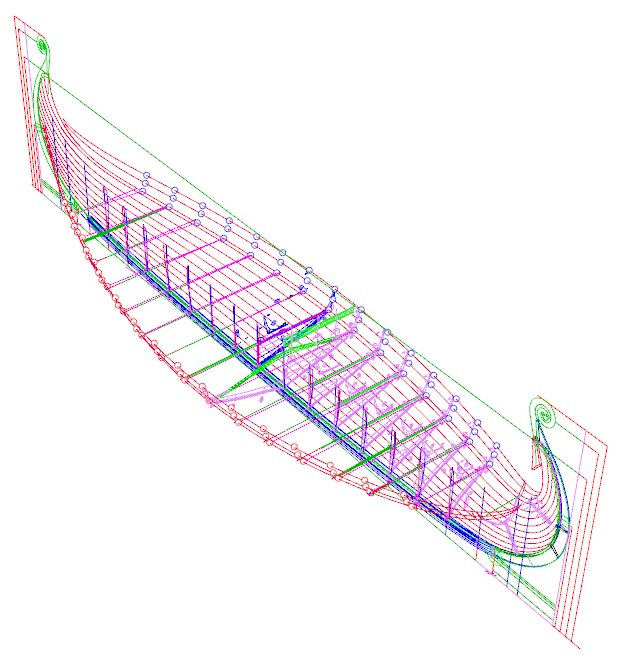

Hi all! Some of you may already be familiar with my much troubled scratch build of the Oseberg Ship (working from these plans). With my wood tools indefinitely in storage and without a license for Rhino at the moment, I'm on the lookout for free alternatives. The end goal will be to have the parts milled from the 3D files at some point in the future.

This begets three questions:

1. What is the best free hull / part modeling software available.

2. Can this software model clinker hulls?

3. Can this software import Rhino files?

Currently at the top of my shortlist is Delftship, which can certainly model hulls, though I don't know about parts or clinker planking. I'm having a hell of a time just getting acclimatized to the interface at the moment.

Next up I'll try Fusion 360, which looks more familiar given I started in 3dsmax and Autocad many years ago, but still foreign to my more recent Rhino experience.

I'd love any suggestions.

- mtaylor and thibaultron

-

2

2

-

-

-

Hi Petr! I'm revising my Oseberg project to mirror your Gokstad project. Are you still around? I could use some pointers.

-

What software did you use to draw/print your parts?Sorry, it's been a while, I forgot you're using Rhino - Could you please describe your technique for building up layers to scale thickness?

Thanks!

Kris

-

-

Hi all, it's been a while. Within days of my last message here, my house was flooded (aka destroyed) when an upstairs toilet malfunctioned overnight and continually filled the downstairs ceiling with water. My possessions have been in storage ever since and my project has been on hold.

Since then, I've also lost access to Rhino 3D so I can no longer use the files I had been working with, so I can't even work on the digital version. Alas.

Also, even if I could make use of my files, since all my money is going into the house repairs, I can no longer afford the CNC mill I was going to get to continue the project in wood, so meh, I'm all out of luck.

Meanwhile I dreamed last night about picking up the project again and it was fun so I'm thinking about, how can I do this in a way that makes sense with the tools I have available....

- A computer

- A MASSIVE amount of reference materials and research

- I can probably afford to work in card and have plenty of knowhow to make that work if I can learn just a few things...

What I need:

- Free software that can draw/print scale plans on card

- Help figuring out how to build up layers of card to scale thickness

Now to get started!

- GrandpaPhil, ccoyle, mtaylor and 1 other

-

4

4

-

While I have the utmost respect for those who can actually make use of hand tools, I'm afraid I have never managed to gain any skill with them. My lack of depth perception is the main impediment. I have the worst aim with cutting tools, and have a very hard time telling the difference between two similar sides of an object or whether one plank is larger than another or slightly off in any given dimension unless the planks from each side are exactly lined up on top each other.

I am meanwhile highly skilled with computers, so I'd rather let the computer handle the accuracy and only assemble the parts by hand.

- mtaylor and Louie da fly

-

2

2

-

2 hours ago, mtaylor said:

Have you considered getting one with the larger table but not the CNC? Many places will sell the CNC as an upgrade to a non CNC machine.

I hadn't considered it but really I'm not that handy. I'm a software guy, not hardware. The assembly of the premade CNC will be challenging enough as it is. 🙂

- thibaultron, Canute and mtaylor

-

3

3

-

...or I could just do my model at a smaller scale...

Edit: ok I did some more research and the 4030 without the extension will be plenty for now.

First, my rounding was wrong before. I was covering from metric to inches and back again and made rounding errors each time.

The longest part of the model is the fore segment of the keel which is exactly 15m at 1:1 or 600mm at my current 1:25 scale.

Even with the extension this would mean using the entire length of the workspace or going diagonal.

However, I looked up how to carve pieces longer than the workspace and it turns out to be relatively simple. It's just a matter of breaking the drawing into multiple sections, and including locator holes for the mounting screws with each cut. After the first cut, slide the workpiece to the next set of holes and run the next drawing which includes the locator holes for the following cut. Each overlaps a little.

I think this will work!

- Gregory, thibaultron, mtaylor and 1 other

-

4

4

-

I’ve looked up the Sainsmart 4030 with 6060 extension, and the 6060 table which is sold separately. It's a bit out of my price range at the moment, coming to a total of $1477.

I wonder if I could get by with just the 4030 for now and do half of my keel at a time. I think I'd just have to be very careful about aligning the work piece. Hmm.....

- mtaylor and thibaultron

-

2

2

-

24 inches is just a bit over 600mm, but fits well within the diagonal of 600mm square, which comes to just under 850mm.

Now I know my dimensions, I just have to find the best quality for the price.

- Canute, mtaylor and thibaultron

-

3

3

-

To follow up on that last post, the largest part of my model at 1:25 is the fore keel segment at approximately 23 inches long.

- Canute, thibaultron and mtaylor

-

3

3

-

Thank you everyone for the replies. I had looked at some of these before but am having a really hard time telling the difference between the real ones and the knock-offs online.

I’m looking to stay in the $400 to $1100 range so that limits my options a bit. So far the largest one even close to that price range seems to be the Bob’s CNC machines. Has anyone tried these before or have any idea how they compare to the competition?

- thibaultron, mtaylor and Canute

-

3

3

-

Hi all!

I'm looking into CNC machines and am having a hard time figuring out what to get.

Preferably something that can handle up to 24 inch pieces, or I'm going to have to shrink the scale of my 1:25 Oseberg.

I don't think I need more than a 3 axis machine because all parts can be milled in two dimensions plus depth.

What brands are good?

Thanks!

Kris

-

Looking great! She reminds me a lot of La Diligente.

-

-

-

I've been pondering how to save my project so that I can actually build it in wood. I'm coming up rather stumped. I have three options...

1. Save up and buy a CNC mill to cut out the parts, then learn how to use it

2. Find someone who lives near me so has such a machine and ask them to cut the parts out for me

3. Learn how to use hand tools correctly, and do it the old fashioned way...

Well, one of those is certainly the least expensive, especially considering I've already bought tons of hand tools for this project.

It all comes down to the keel, really. If I can learn to carve the keel correctly, I can learn to do the rest.

So my question for all of you is, how would you carve this keel in one piece? What tools would you use? How would you keep all the angles and curves accurate?

Most important is that the rabbet must be the exact angle as in the plans, and must flow smoothly into the T shape of the middle of the keel at the correct angle or the garboard strake will be out of alignment which will throw the whole hull out of whack.

- mtaylor and GrandpaPhil

-

2

2

-

12 hours ago, AnobiumPunctatum said:

I know, but one step after the other. Before I start with Rhino, I will prcatice with my new toy. For the first steps I use my old 2D CAD.

Cool! What will you build first? I'd love to follow your build log if you have one.

-

32 minutes ago, AnobiumPunctatum said:

I've done the step in the other direction. I own since a fey days a cnc-mill and now I am saving my money for Rhino.

Is it possible that the three views are not really perpendicular to each other?

I know the same form my 2D works. The point on the drawings are the same but not the 2D representation of the lines. There are always small differences. It's a problem with using splines.

Hi Christian,

This is very possible. I think it's more that the original drawing was done in Rhino, then rendered to PDF as a raster image, then the pixels have been brought back into Rhino. Thus it's very difficult to tell exactly which pixel goes at exactly which point.

You can get a 90 day trial of Rhino for free from their website.

- mtaylor and AnobiumPunctatum

-

2

2

-

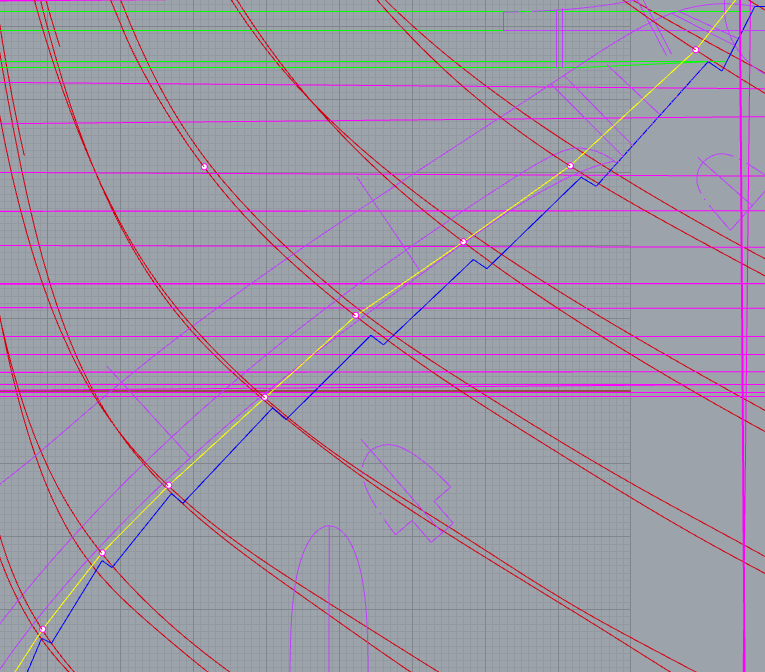

I hate to say it, but I think I must admit defeat on the Rhino front. I simply cannot get all three views to align with each other no matter what I do. If I draw a line in one view, it doesn't match the others.

To test this out I went back and re-drew just the garboard strake by extending the contact surface of the keel / rabbets. to the first line in each view. No two views lined up with each other.

Furthermore, after reading more of Ms Bischoff's report, I realize that there are only three dimensions that matter in the entire ship now that I have scaled plans for the planks. Those dimensions are the width of the keel, the width of the contact surface with the garboard strake, and the thickness of the planks. All other dimensions can be derived from these because the hull is built keel, then strakes, then frames.

Unfortunately I lack the woodworking skills to fashion the keel, so even through I have drawn it accurately in Rhino, I cannot make it in wood until I can save up for a CNC mill.

One day...

-

I've got a problem. My hand drawn lines for the ship are out of alignment. I'm not sure when it happened or how, but for some reason the plans themselves don't seem to agree with each other even within two views of the same plan...

So frustrating...

In short, I successfully plotted my projection surfaces by the numbers and projected my frames onto them at the correct angles! Then I realized, the surfaces were too small. I did some troubleshooting and found that my hand drawn top view is too narrow by a few centimeters, despite the fact that all my reference image views are the same scale! I have no idea where I went wrong here.

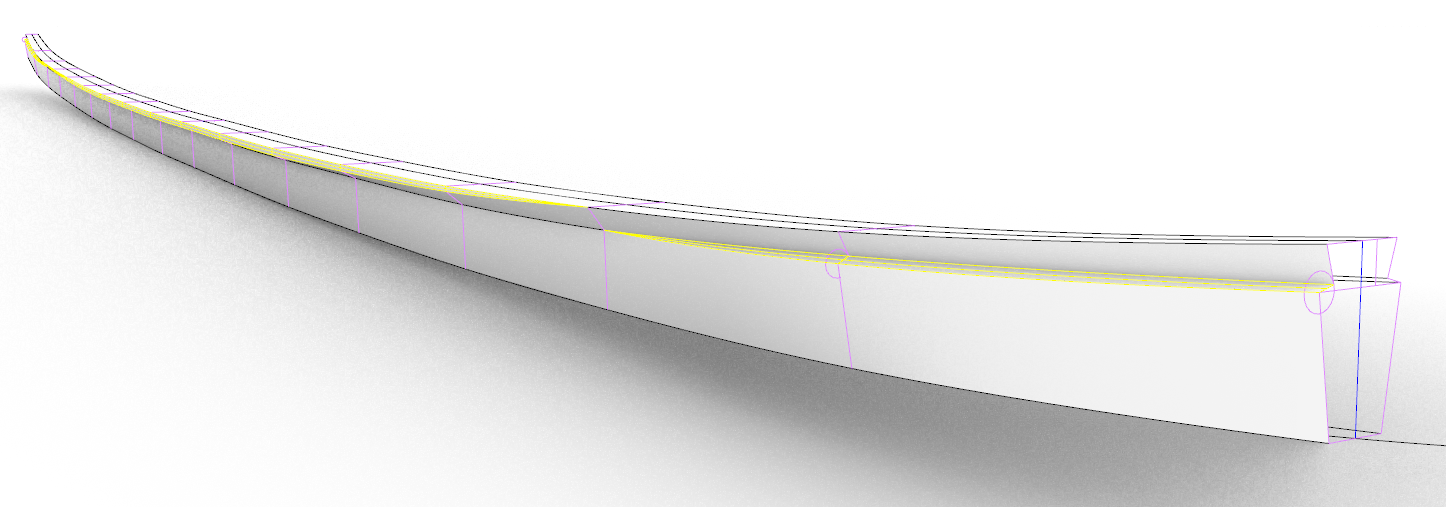

In the attached image the yellow line is plotted with math calculating the angle at which the inclined frame intersects the top inner edge of each plank of the hull.

The blue line is hand drawn and represents where the front view says those points should be.

Can anyone PLEASE give me some tips on correctly setting up references images in Rhino so that they're all the correct scale? These are all based on raster reference images that include multiple points with scales written.

Thanks,

Kris

Edit: Well, I figured out my problem. I've been drawing all my curves as projections from two curves, mostly top view and side view.

The ship exists in three dimensional space so Rhino projects the two views as if they were distributed evenly across the entire length of the space. In reality there is a third front/rear view which would inform where on the other two curves each point should fall, but I don't see a way to create curves from three views...

- Louie da fly, mtaylor and bigpetr

-

2

2

-

1

1

-

- mtaylor, GrandpaPhil, bigpetr and 1 other

-

4

4

Oseberg Ship by KrisWood - 1:25 - Vibeke Bischoff Plans

in - Subjects built Up to and including 1500 AD

Posted

You may have just corrupted me completely. 😆

Now to reduce my scale and figure out what software to use...