-

Posts

7,406 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Mirabell61

-

Thanks for visiting my Little shipyard Greg, enjoy the further log parts if you like Nils

-

David, I asume you mean the Overall shiplength and not something else ha ? I measured 120 cm, and for a furcoat we`ll have an eye open when next fleamarket takes place. I bought her a VW beetle already, but she would`nt be happy with that model in 1:48 Thanks for your appreciative words Nils

-

Thanks for stopping Micheal, many of the Digit pics have been over 2 MB, so I had to reduce the size before posting, but you are right, I trust they still remain well representative for visual exploring... Cheers Nils

-

I love this Little boat of yours Peter, was thinking whilst the beginning of your log parts if These template-like parts could be magnified and used for putting a real one on keel Well done! Nils

- 109 replies

-

- zeeschouw

- billing boats

-

(and 1 more)

Tagged with:

-

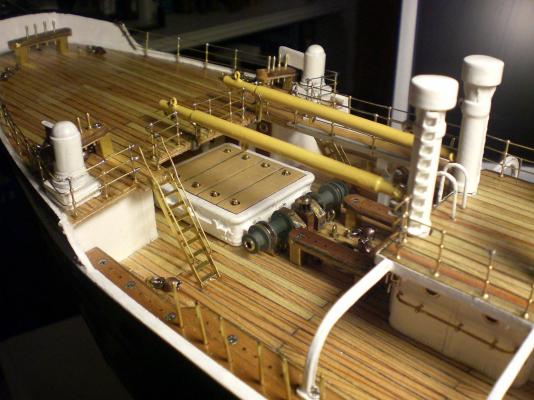

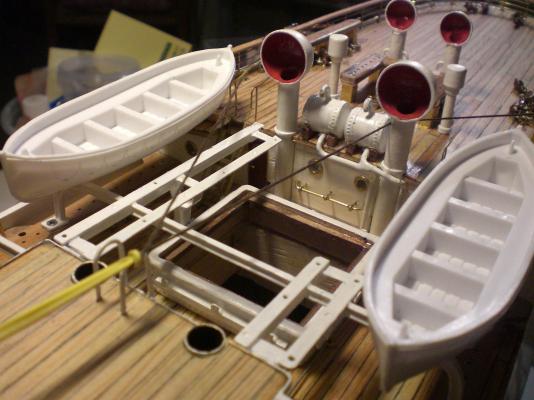

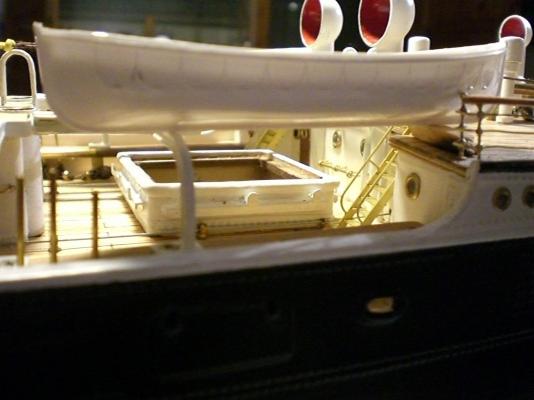

Build log part 27 overview aft welldeck checking with one of the 4 aft boat davits space positioning for wheel- and Chart-house as well as other deck housings on highdeck looking where to place lifevest Containment on aft boatstation spacing aft poopdeck housings the shipyard Management is quite happy with the progress so far again checking mast positions Forward welldeck Davits mounted port lavatory door on aft welldeck pig Kennels, port / starboard (for live pork) behind the forecastle bulkhead not fitted yet Build log part 28 to follow.... Nils

-

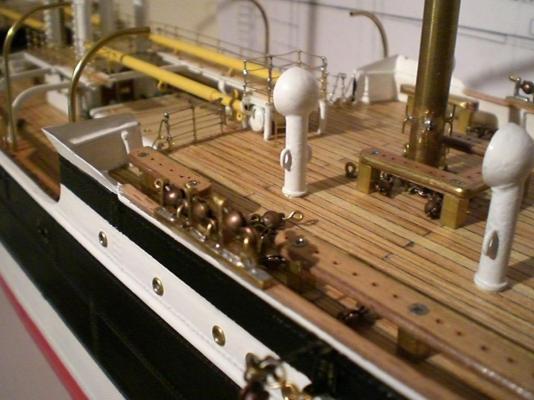

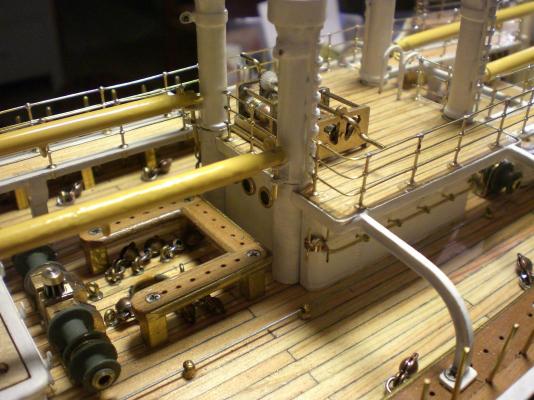

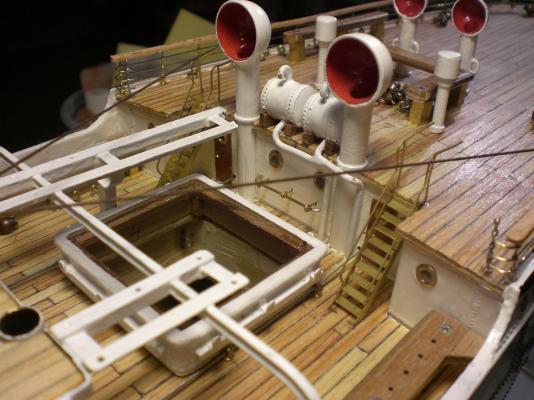

Build log part 26 railings fixed to boat stations, catwalks and deckhousing decks overview of aft welldeck area, cargo derricks attached utmost time for mounting blocks around the mast area (no good Access afterwards) portside boatstation railing on compasplatform and stairs attached to railing forecastle railing and stairs foreward welldeck port boatstation aft welldeck port boatstation everything has found its place Build log part 27 to follow.... Nils

-

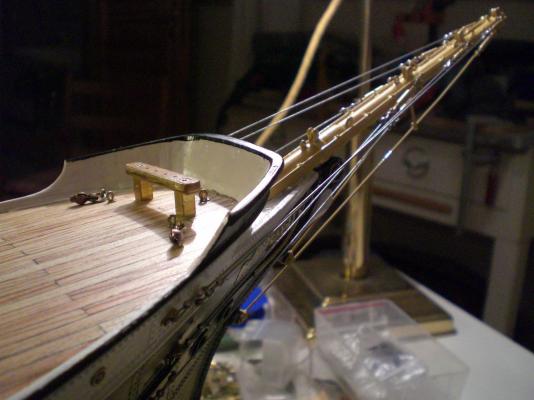

Build log part 25 poopdeck railing mounted, moved small vents away from the place where the brace winch goes to preliminary space check with the larger 2 ones of the 4 aft boats jib boom stays and bobstays attached Forward welldeck (primered) cargo derricks in Position check Stern view with poop railing forecastle railing not attached yet bow view at this stage Buildlog part 26 to follow.... Nils

-

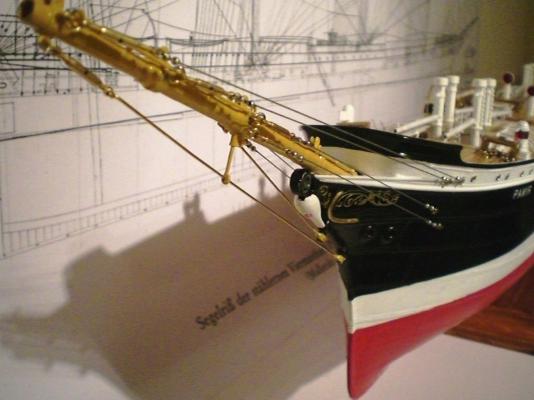

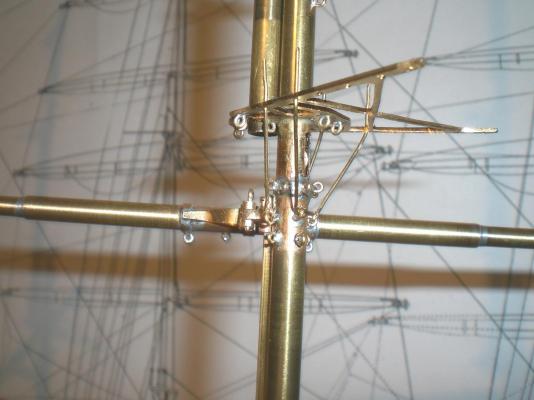

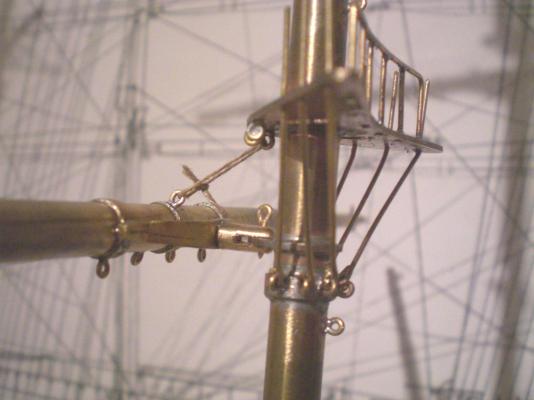

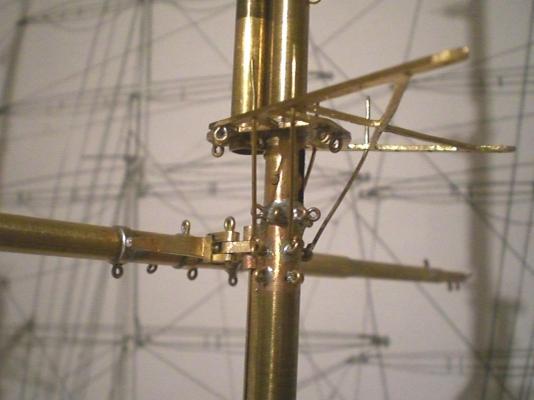

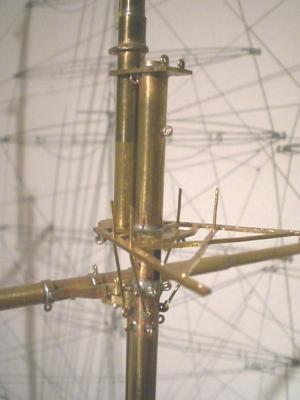

Build log part 24 cross checking mast angle, positions, hights, alignment masts go right through the decks into the "spine" above the keel, mentioned earlier in this build jib boom placed at an angle (horizontal of about 19° tripple block Arrangement for foremast brace Tackling, these two devices will be mounted to the highdeck bulwarks These two pics...., bracing tackle bumpkin for blocks and ropes for third mast bracing tack bracket for second mast mainsail bracing tackle bumpkin for blocks and ropes for third mast bracing tack bracket for second mast mainsail Build log part 25 to follow.... Nils

-

Ken my experience is : sand the planking to smooth and step free condition sweep off the dust with a brush thorrowly and also by using a clean Cloth apply 2 coats of nitro based clear Wood primer, (Nitro Einlassgrund)that drys within 3 minutes leaving a dull smooth shiny but dense Wood surface. No sanding afterwards !!! That is the best surface base for applying the tape Nils

-

Yes Lou, i use a White coloured resin based primer (otherwise no propper paint adhesion) Nils

-

Yes Crackers its going to be the complete sunday suit of sails, nice Little pic. you posted... Nils

-

Thank you Nenad, yes the MSW is a wonderfull game of give and take, I`m glad if I can help anybody Nils

-

Build log part 23 some more impressions on the mast work soldering the jackstays to the jib boom some paint to the masts and beginning with the upper shrouds some of the Yards tackled with blocks Yard rack and bearing device Build log part 24 to follow..... Nils

-

Crackers, in general all the "running rigging" was of flexible rope. The "static rigging" like shrouds, stays backstays, Yard lifts, footropes,jib boom stays, the short stopps from Yard nock to the first bracing block, etc. were of wire Nils

-

Harvey, thank you for your appreciative words... I have a whole Shelf full of Pamir related books but for that one I shall be on watchout, Thanks for you tip Nils

-

Daniel, the poncewheel is selfmade from an old toothwheel from a mantel-clockwork and the handle of an old Paintbrush. If you like, you can refer to my buildlogfor for my steamship Heinrich Kayser at the end of part 2 therein (Topic: scratch built models in Progress) Trust that helps along, otherwise feel free to come through again, I`ll be glad to help Nils

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.