-

Posts

4,379 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Egilman

-

Nice looking machine.... Matches up with the lathe very well... And btw, most job shop horizontal mills have a 4' spindle height, because most jobs are mounted by hand, the saddle height is set by the height a couple of workers could lift the work... So, at 1/12th scale, it is right on the money... The sliding beam of a Cincinnati 2MH rises to upper chest height on me, and I'm 6' tall... I'll be here when you choose the next one.... (psst, a radial arm would be perfect) Beautiful work...

-

Renault RE20 Turbo by DocRob - FINISHED - Tamiya - 1/12

Egilman replied to DocRob's topic in Non-ship/categorised builds

That's what I'm hoping.... (it's the Trumpy 1/12th scale version) I did the Revell Monogram version when I was a kid and fell in love with it, it will be a nice fit with the Tyrrell P-34 in the same scale, fell in love with that blue and yellow paint job when I built it as a kid as well... -

Renault RE20 Turbo by DocRob - FINISHED - Tamiya - 1/12

Egilman replied to DocRob's topic in Non-ship/categorised builds

Thank you for the info on the fittings and tubes... I'll need some when I start my '66-'67 GT 40 MkII... Thank you very much... -

Very true my friend... (as far as the sideways images, if your working with windows it's easy to fix... Click on the pic in windows explorer, it will open in windows photo viewer, there is a button to turn the pic in the direction you need, then close it, it will save in the orientation you set for it, then upload it)

-

#8 goes straight down... That would be the front rank cylinder directly opposite the Propeller Governor Drive which is on top of the gear housing... Pratt Whitney R-1830-75 -98 Service Instructions.pdf P W R-1830 Twin Wasp Maintenance Manual.pdf Yes #1 would be the upward cylinder on the back rank...

-

Renault RE20 Turbo by DocRob - FINISHED - Tamiya - 1/12

Egilman replied to DocRob's topic in Non-ship/categorised builds

Necessity is the mother of invention, or, in this case, innovation... -

Hawker Typhoon 1b "Car Door" by AJohnson - Airfix - 1:24

Egilman replied to AJohnson's topic in Non-ship/categorised builds

A site that's been around since almost the beginning of the internet, it's real... It's just one of my resources for searching the net... like anything else sometimes it's a boon sometimes it's a bust... overall, it's a pretty good site if your looking for something specific... They have both editions of it, the first edition and the revised second edition... -

Hawker Typhoon 1b "Car Door" by AJohnson - Airfix - 1:24

Egilman replied to AJohnson's topic in Non-ship/categorised builds

I'm down brother, wouldn't miss this for the world... -

It was agreed early on in the war period that patent enforcement was suspended for the duration and anyone showing a need for the technology would be handed it... It was part of the original Anglo-American mutual support pact in place before lend lease..... It's partly the reason why the cavity magnetron was shipped to America from England in 1940... The public story was that they didn't want to lose it to the Germans if they lost the battle of Britain, the real story was that current US radars although good, (best in the world) were not good enough... The magnetron was sent to MIT to integrate it into what we had already developed.... Technology transfer in wartime is an absolute... There were no commercial secrets allowed to be held during the war...

-

yep, in it's most powerful incarnation it delivered 2500hp out of a 2100 lb mass... Roughly 1.2 hp per lb... which was above what was considered optimal in the aircraft industry for piston engines making it pound for pound as efficient as the P&W R2800 which was the first to deliver 1to1 hp to weight... the R2800 eventually delivered 2250 hp which put it in the same class... I would have loved to see the Sabre developed into it's maximum potential... Today it's all about fuel consumption efficiency when it come to ICE's, maximum HP is a thing of the past... In terms of relative efficiency hard to beat the Sabre or the R2800 as the kings of the hill for production engines, they were both phenomenal achievements of mechanical engineering... so we agree... {chuckle}

-

Oseberg ship burial replicas by Eindride

Egilman replied to Eindride's topic in Completed non-ship models

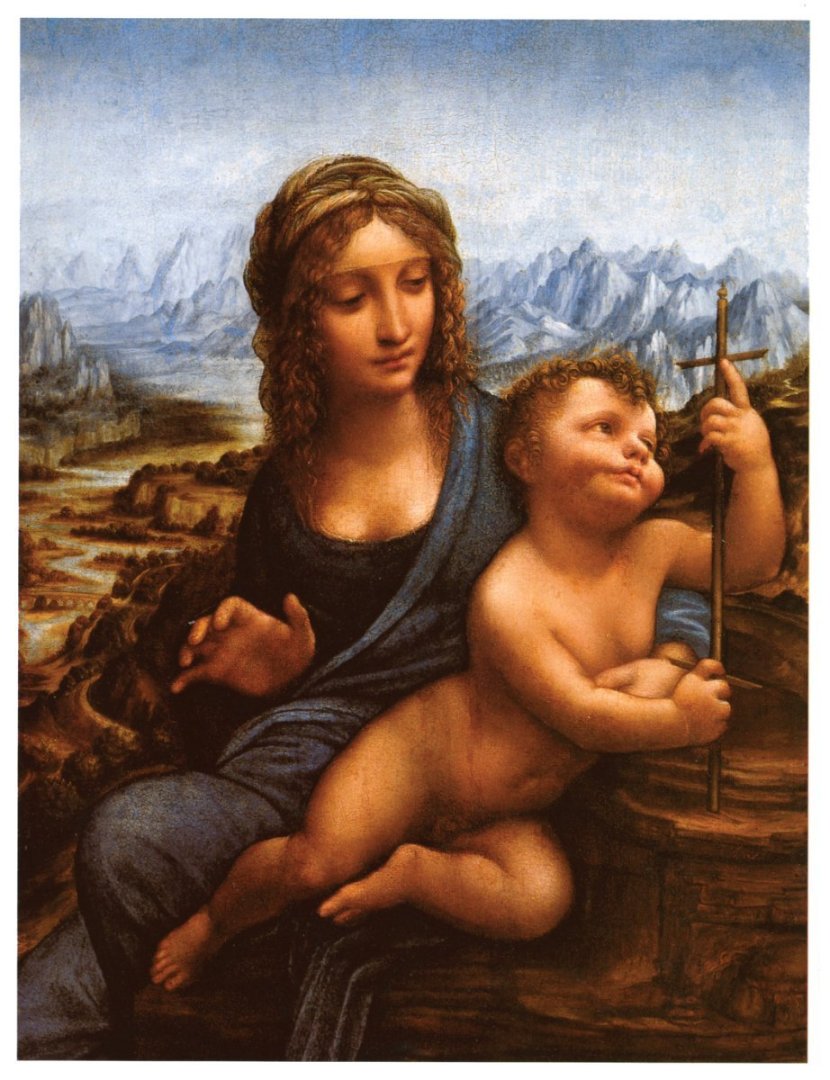

They are ancient.... A painting by DaVinci... The title is Madonna of the Yarnwinder one of two versions painted by DaVinci circa 1501 to 1507 and presented to Florimond Robertet, a secretary to King Louis XII of France. From Wiki... It's an ancient tool with many useful purposes still in use today by yarn makers... -

Yep there were quite a few engines like that in that time period... Would have been very interesting to see the design line mature in development... There was a lot of promise in multi cylinder, multi crankshaft sleeve valve engines... Mainly cause the valve arrangements were simpler and more mechanically efficient... There was the Wright R-2160 Tornado, Pratt & Whitney X-1800, Pratt & Whitney XH-3130, and several others on this side of the pond.... The design limits of piston ICE's is the valve configuration... Flow through the combustion chamber is the limiting factor and adding mechanical complexity, (push rod valve trains) reduces efficiency... Believe it or not, sleeve valves were well known in the steam engine community back in the 1880's... Finally getting around to them in the ICE community in the late 30's isn't brilliant engineering, it illustrates how slow development of technology can happen in an environment of "this is working and people are paying for it so why change"... By the time they realized the greater efficiency of sleeve valves coupled with lower reciprocating mass, the axial flow turbojet was running... no valves and no reciprocating masses to deal with... RR continued to explore the concept into the late 50's but none of them ever took flight... The commonly held engineering belief today is that ICE's are never going to reach the efficiency of a turbine engine.... Similar to a pure turbo jet is never going to match the thrust ratio of a rotating propeller or fan (fan jet)... Engine efficiency is all about flow.... And for piston engines the amazing RR and Napier developments still represent the pinnacle of high power piston engine development...

-

Yep, the production front.... (chuckle) The combat over money and contracts was even more intense than the combat against the enemy.... Wartime pressures be damned.... It was worse in Britain than it was here, but it was just as intense... For example, the entire production of P&W R2800 engines was allocated to the production lines at Vought for the corsair, the production of R2600 engines were allocated to Grumman for the Hellcat... The Hellcat was a dog with the Wright R2600 and was close to being canceled by the navy, it was barely more capable than the Wildcat it was replacing... The naval engineers working with Grumman on the Hellcat were well aware of the P&W R2800 and it's potential, but also of the orders that they were reserved for Vought and the Corsair... So, one of the engineers and one of the project directors arranged for two P&W R2800's to disappear from the deliveries to Vought and show up at Grumman... Once the Hellcat had the R2800 installed, it surpassed anyone's conception of what a fighter plane could do up to that time... (equaling the corsair's performance) The commercial powers that be, (in any nation) could care less about the war effort despite all their public pronouncements to the opposite... they only care about how many bucks are being deposited into their bank accounts or how many zeros are tacked onto the figure in the latest contract... And if they can lock down a government agency as their single source supplier, that's commercial heaven for them, equivalent to winning WWII all by themselves... Vought thought they had it in the bag over Grumman, and if the R2800 didn't mate with the F6F well, Grumman would have suffered the consequences.... Thankfully they did and a superlative fighter plane resulted and Grumman got all the accolades... Vought, and their commissioned investor allies in the navy, weren't very happy that the P&W R2800 supply was being split with Grumman.... (eventually split with Republic for the P-47 as well) But that one little violation of the contract and procurement rules saved naval aviation.... When the Corsair was going thru it's well known teething problems '43-'44, the Hellcat became the preeminent navy fighter plane, and a good thing it did.... Industrial warfare knows no battlefield or national preference and the only results that count are the sheckles in the treasure box.... Yes RR definitely wanted to bury the Napier Sabre...

-

It wasn't the pressure of war Andy, it was pure technological advancement... the engineering of thrust had far surpassed the relatively simple propeller... At it's highest development the Sabre design was capable of 4500 hp out of a 2500 lb engine... the Typhoon/Tempest could do 475 kts at sea level (full military power) 450 kts at 14k feet... Nothing could touch it at low level not even the fastest spit, mustang, FW, corsair, even the skeeter had to take a back seat to it in pure raw speed... When the Luftwaffe developed low level harassing attacks in '44 using the fastest FW-190 models, the Typhoons and Tempests were vectored to meet the attacks cause they were the only plane capable of catching them... They were coming in at just above sealevel, Below radar, dropping their bombs and running back across the channel.... Couldn't be intercepted cause you didn't know they were coming till you heard the engine roar.... Typhoons would catch them going back across the channel, throttle to the firewall, just above sealevel.... The typhoons would drop onto their tail from 1-2,000 ft and then walk them like they were standing still... No escape for the FW's, can't run, can't manuever, can't hide..... Even the Whittle powered jets of the time couldn't do that.... When the Luftwaffe realized that the bomber missions they were sending out were not returning, the pilots started refusing to fly them... But then it was like most prop planes of the day were average below 20k, (basically the same performance envelope) For example the P-51 is considered to be the best fighter design to come out of the war, but under 20,000ft it wasn't any better than anyone else's best fighter... (and markedly lower performance than the typhoon) It was above 20,000ft where it showed it's true abilities... The Typhoons and Tempests were the exact opposite, they showed their true capabilities below 20,000ft.... (they were actually fastest at sea level the higher they climbed the slower they got) It was an amazing airplane, but raw power in an airplane means speed, and turbines were a huge step forward in that department... Piston engines held on for a long time, but were for the most part replaced by turbines in military applications.... Even in turning the propeller....

-

70 years ago... The last inservice flight of a Sabre engined fighter was a Tempest of the Indian AF in '53... (the RAF had disposed of them by '49) The Napier Sabre had many different experimental models and was installed in a great many experimental aircraft, but the Typhoon & Tempest were the only planes that used them in production... When the last Tempest was put out to the boneyards, the Napier Sabre passed into history... There are currently 6 of them under restoration to flying status and four more in storage capable of being restored.... A sad fate for the most powerful single engined fighter plane ever produced... (Under 10,000 ft that is)

-

Renault RE20 Turbo by DocRob - FINISHED - Tamiya - 1/12

Egilman replied to DocRob's topic in Non-ship/categorised builds

You used the wrong word brother... "teach" is the correct word... I'm sure you meant to say teach a lot again with this build... -

Except in your case you want the cutter ground at 40 deg. thread profile set to cut from the left towards the right for left hand threads and the top slide set at 20 degrees... Ah, there is no engineering reason for the thread profile to be flat pointed, a round nose will work equally well, in fact engineering wise, probably better... That will slightly increase the depth of cut needed to execute the profile though...

-

Mild steel tearing is usually from too large of a cut with a not quite sharp enough cutter... Large cut does not necessarily mean a large amount of material being removed, sometimes it's too fast of a feed, other times it can simply be wrong type of material.... As you discovered it is not a heat issue... Without having it in hand I'm not so sure how I would approach it... If I had to do it in the tool room I would have started with a single point cutter to the base depth of the thread then gradually ground the flat face on the point of the cutter for successive passes... Not the most efficient way to do it agreed, but sometimes a stepped approach works best... If in a production environment we would have an expanding die made for this job... Reminds me of cutting square threads for lead screws, we only rough cut them, then ground the finish threads... I think the flat thread cutter tip is the issue here, it doesn't matter how deep the cut is, it acts like a chisel (think bulldozer blade) right at the point of the cutter and the deeper you go the force applied to the cutter tip rises geometrically due to the 40 degree taper increasing the shoulder width of the cut... With the size of the part, even mild steel can overwhelm a tool steel cutter.... (especially with such a tiny tip profile) I think if I had to do it on my bench lathe I would have done it by hand using a pointed cutter for the initial cut and a half round micro file to finish it off... (turning the lathe by hand as well rather than power) That is some exacting work my friend, pushing the skill level up.... (once you figure out how to do it you'll never forget it)

-

Timber-framed outdoor kitchen - Cathead - 1:1 scale

Egilman replied to Cathead's topic in Non-ship/categorised builds

Sad and humorous in a way, but very true... I never owned one, but I saw a lot of them... -

Wow! Sorry for being late here... I just got back from the emergency room where the doc put my eyeballs back in my head!!! Doc asked me what happened to have both my eyeballs pop out like that, so I showed him an image I printed out of this.... He joined me in the next bed over..... just WOW!!! Above and beyond Grant, above and beyond....

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.